Why low-cost 3D scanners are not suitable for professional tasks

How to correctly select and buy a 3D-scanner for solving professional problems? Why the use of budget devices can be a costly mistake?

Sites such as Pinshape and 3Dprint.com annually publish guidelines for choosing the best budget 3D scanner on the market, many of which are intended for amateur use. But what about high-quality 3D scanners for solving industrial and professional tasks?

')

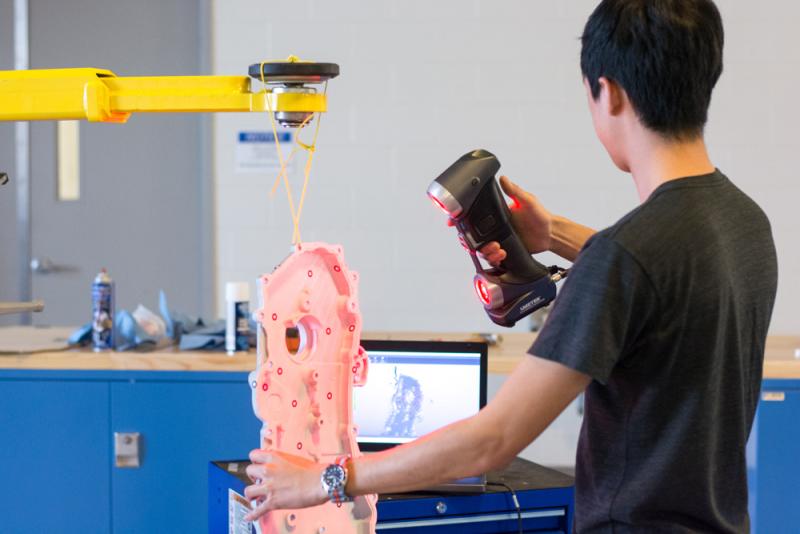

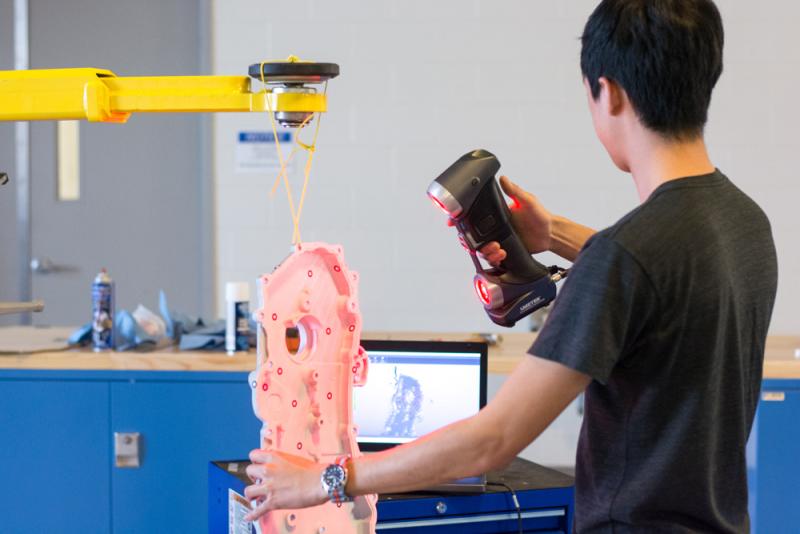

Creaform HandySCAN 3D - one of the most advanced solutions on the market of professional hand-held 3D scanners

Can the lack of coverage in these manuals of 3D metrological scanners lead to the fact that engineers and designers will use low-cost 3D scanners to solve their professional problems? This article is intended to supplement such guidelines and explain why the use of low-cost 3D scanners in professional activities can lead to costly consequences in the further technological chain.

Engineers and designers who need professional 3D scanning features, but who believe they can get the same results using a cheap scanner, will be disappointed.

Using 3D scanners that do not have these characteristics, engineers and designers risk getting poor-quality scan results and inaccurate data, which in turn could jeopardize the projects they are working on and their own career.

Metrological class 3D scanners are designed to enable engineers and designers to solve their professional tasks, while budget devices are more suitable for use in the non-industrial field, especially if accuracy is not critical.

Low-cost 3D scanners are ideal for home enthusiasts, while high-tech scanners are professional-oriented and allow them to get effective and accurate results.

Non-industrial use

Industrial application

Below are the results of comparative tests of two portable devices for scanning objects up to 50 cm - an inexpensive scanner based on white light technology and Creaform's Go! SCAN 3D scanner. Many of the parameters of these scanners at first glance seem comparable.

Moving parts

Viewing device

Recalibration

Tracking

Add additional data

The result obtained on a professional 3D-scanner

The result obtained on the budget 3D-scanner

Performance

Workflow comparison

Workflow Comparison for Sample Scan

Both devices were used for 3D scanning of the sculpture (800 mm) with a resolution of 2 mm. Go! SCAN 50 performed the setup, scanning and subsequent processing in 5 minutes 42 seconds, whereas for its “opponent” this process took 35 minutes and 20 seconds. Thus, it takes 30 minutes more to complete and export a scan using a non-professional scanner, and using Go! SCAN 50 takes about 7 times less time.

Accuracy

Scanning a ball tip 900 mm long with 38 mm spheres and a ball tip 1000 mm long with 50 mm spheres revealed that the Go! SCAN 50 accuracy is 2-3 times higher than that of an inexpensive scanner. The 3D Go! SCAN scanner showed clearly higher reliability of the results: the standard deviation is 4-5 times lower.

As expected, the Go! SCAN 50 3D scanner outperforms the non-professional device in all respects. It is faster, more accurate, easier to use and provides higher quality data.

Thus, professionals in the field of 3D scanning need higher quality solutions than amateurs and semi-professionals. The reason is simple: you have to pay for quality. One cannot expect a professional 3D scanner to cost as an amateur-level equipment and at the same time offer characteristics of a metrological class.

Sites such as Pinshape and 3Dprint.com annually publish guidelines for choosing the best budget 3D scanner on the market, many of which are intended for amateur use. But what about high-quality 3D scanners for solving industrial and professional tasks?

')

Creaform HandySCAN 3D - one of the most advanced solutions on the market of professional hand-held 3D scanners

Can the lack of coverage in these manuals of 3D metrological scanners lead to the fact that engineers and designers will use low-cost 3D scanners to solve their professional problems? This article is intended to supplement such guidelines and explain why the use of low-cost 3D scanners in professional activities can lead to costly consequences in the further technological chain.

Engineers and designers who need professional 3D scanning features, but who believe they can get the same results using a cheap scanner, will be disappointed.

Factors determining the price of an industrial 3D scanner

- Engineers and designers need a 3D scanner with high accuracy to ensure that the result is exactly the project. A deviation of only 0.01 mm may result in the product being rejected.

- They also need high resolution to ensure accurate positioning. If the data is incorrectly positioned, combined, or integrated, the result is similar to scanning in unstable conditions.

- In addition to accuracy and resolution, industrial 3D-scanners have other features: speed allows you to reduce the time of digitizing an object and increase the speed of data collection and transmission.

- Thanks to the versatility of the device, you can scan various products regardless of their material, shape, color or size.

- Finally, ease of use determines the quality of the work and the results obtained.

Using 3D scanners that do not have these characteristics, engineers and designers risk getting poor-quality scan results and inaccurate data, which in turn could jeopardize the projects they are working on and their own career.

The difference between industrial and budget 3D-scanners

Metrological class 3D scanners are designed to enable engineers and designers to solve their professional tasks, while budget devices are more suitable for use in the non-industrial field, especially if accuracy is not critical.

Low-cost 3D scanners are ideal for home enthusiasts, while high-tech scanners are professional-oriented and allow them to get effective and accurate results.

Non-industrial use

Industrial application

Creaform Go! SCAN 50 professional 3D scanner completed setup, scanning and subsequent processing in 5 minutes 42 seconds, while in an inexpensive device this process took 35 minutes and 20 seconds.

A practical comparison of two 3D scanners

Below are the results of comparative tests of two portable devices for scanning objects up to 50 cm - an inexpensive scanner based on white light technology and Creaform's Go! SCAN 3D scanner. Many of the parameters of these scanners at first glance seem comparable.

Moving parts

- The design of an inexpensive 3D scanner includes a flash lamp as a light source, the device must be cooled with a fan. In addition to making the scanner rather noisy, moving parts are an important source of potential malfunction and will have to be replaced later.

- Go! SCAN 3D scanners, just like other technologies manufactured by Creaform, are solid-state, which means that they do not use moving parts. This minimizes the risk of malfunction and guarantees the longest possible lifetime of use.

Viewing device

- The viewing device of the budget scanner quickly overflows, making it confusing and difficult to use. Also, only the last 50 frames read are displayed.

- Go! SCAN 50 offers excellent real-time visualization.

Recalibration

- The non-professional scanner manufacturer claims that re-calibrating their scanners does not require special equipment and recommends that users recalibrate the scanner by using the wall as a flat surface. However, the wall can not be considered as a reference plane.

- Go! SCAN 50 comes with an exceptionally stable and reliable instrument that guarantees maximum performance by performing a simple re-calibration procedure.

Tracking

- Low cost scanners are known for losing tracking during 3D scanning , which makes the process extremely complex and tedious. If you lose track of the user can only start a new session or start all over again.

- Creaform ’s VXelements software has very powerful tracking capabilities. This makes it almost impossible to lose tracking when scanning a part with Go! Scan.

Add additional data

- When a discontinuity occurs, the user of the budget scanner should briefly review the source data, identify the frame of failure, separate the sequence in this area, and then switch to manual alignment of the two sequences. This process should be performed every time when a discontinuity occurs.

- Go! SCAN 50 offers to continue the scanning function (instead of manual alignment), which makes it possible to continue scanning from the point selected by the user of the last mounted 3D frame, known texture features or any known mounted target applied to the part.

The result obtained on a professional 3D-scanner

The result obtained on the budget 3D-scanner

Performance

- The ability to use target positioning can be compensated for by the absence of part geometry. A cheap scanner will have to use a workaround and simulate geometry with external objects or mimic the texture with colored stickers.

- Go! SCAN 50 can more reliably use texture information for positioning (for example, virtual positioning of a target), which at the same time makes it more accurate and easier to use.

Workflow comparison

- The automatic workflow offered by Vxelements software saves a lot of user time and effort.

- Since a conventional scanner does not align data and generates combined results in real time, the user must go through several steps to create a mesh model. Calculations at some of these stages take a very long time (20-30 minutes or more), and the user will have to go through this process to find out if more data is needed for scanning.

Workflow Comparison for Sample Scan

Both devices were used for 3D scanning of the sculpture (800 mm) with a resolution of 2 mm. Go! SCAN 50 performed the setup, scanning and subsequent processing in 5 minutes 42 seconds, whereas for its “opponent” this process took 35 minutes and 20 seconds. Thus, it takes 30 minutes more to complete and export a scan using a non-professional scanner, and using Go! SCAN 50 takes about 7 times less time.

Accuracy

Scanning a ball tip 900 mm long with 38 mm spheres and a ball tip 1000 mm long with 50 mm spheres revealed that the Go! SCAN 50 accuracy is 2-3 times higher than that of an inexpensive scanner. The 3D Go! SCAN scanner showed clearly higher reliability of the results: the standard deviation is 4-5 times lower.

Conclusions: the right choice of 3D scanner for professionals

As expected, the Go! SCAN 50 3D scanner outperforms the non-professional device in all respects. It is faster, more accurate, easier to use and provides higher quality data.

Thus, professionals in the field of 3D scanning need higher quality solutions than amateurs and semi-professionals. The reason is simple: you have to pay for quality. One cannot expect a professional 3D scanner to cost as an amateur-level equipment and at the same time offer characteristics of a metrological class.

Source: https://habr.com/ru/post/445896/

All Articles