Digital archiving of works of art: 6 incredible features

The estate of Vaux-le-Vicomte - a masterpiece of classical French architecture and art

Built in the 17th century, the estate of Vaux-le-Viscount is the brainchild of three leading artists of the time: gardener-decorator Andre Lenotra, architect Louis Levo and artist-decorator Charles Lebrun. The genius of the three creators allowed to achieve the most exquisite harmony between architecture and landscape, which was an innovative achievement, not surpassed throughout the XVII century. And although these creations are now the object of the French heritage, artists could never have imagined that their works would once, even centuries later, be reproduced using a 3D scanner !

This monument of classical French architecture makes a strong impression by the elegant monumentality of the palace and surrounding areas. In the mirrors of the ponds are reflected extensive gardens, decorated with numerous sculptures. Vaux-le-Vicomte became a role model in Europe and inspired even the Palace of Versailles, which served as the residence of the kings Louis XIV, Louis XV and Louis XVI.

')

The statues of the estate are still unmatched, although they are from 110 to 360 years old. Unfortunately, they are constantly exposed to adverse weather conditions and vegetation. The state of the statues is influenced by lichens, mosses, processes of corrosion and destruction are taking place, which threaten the safety of 61 statues of the estate. The deterioration of their condition prompted the Chief Architect of Historic Monuments (CAHM), the Regional Administration for Cultural Affairs (RDCA) and the de Vogues family, which owns and manages the estate, to launch a heritage preservation campaign funded by individuals and companies. The most important role in the implementation of this project was played by 3D scanning .

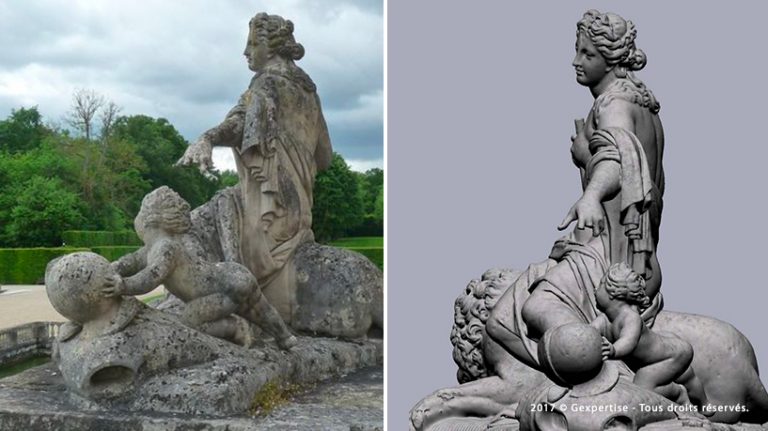

The statue "Tigers" by Georges Garde (XIX century) and the result of 3D scanning

The restoration project of the statues of the estate of Vaux-le-Vicomte appeared ten years ago, when it became necessary to restore three significantly damaged statues of the 17th century. They were created by Michel Angier, one of the favorite sculptors of Nicolas Fouquet, the first owner of the estate. Since the solution of this problem required large funds, a campaign was launched to finance the restoration work. According to Alexander de Voghe, the owner and manager of this unique French estate, “the success of this initiative, the enthusiasm of the sponsors and the joy of being able to restore these curiosities prompted us to continue, and we included all the statues - only 61 works of art.”

4 priority goals of restoration

Today, individuals and companies wishing to contribute to the preservation of masterpieces are connected to cooperation with the co-owners of the estate. The restoration program is estimated at 13 million euros, is designed for ten years and is based on four priority objectives:

- preserve the garden (planting trees to restore the main natural space);

- to restore the palace (namely, three through arcades to the north and south of the palace, so that visitors could see the outlines of the garden from the entrance gates, despite the massiveness of the building);

- restore or purchase works of art (24 statues in the garden);

- increase attendance and support cultural initiatives (to promote access to the estate of people with reduced mobility).

Saving masterpieces in 3D

3D digitization of the “Mercy” statue by Michel Angier (17th century)

Although the restoration was carried out primarily through the cleaning of works of art, it was strongly suggested to find a way to preserve 61 statues of the estate without damaging them and saving them for posterity. Gexpertise's modeling department, which specializes in technical study of buildings and creating 3D models , helped to carry out work on the preservation of the estate through 3D scanning: a digital archive of historical heritage was created using a hand-held 3D scanner.

“In addition to cleaning 61 statues on the restoration program, CAHM also recommended creating archives of works of art for tenders,” said Benoit Derio, project manager at Gexpertise. Indeed, the gradual or accidental loss of the fragile parts of these sculptures is an important reason to preserve, as far as possible, the memory of their original form and to be able to reproduce the copy in the future. This task is solved by a modern and inexpensive technology - digitization in 3D. It replaces plaster molding, which eliminates the need for physical storage and makes it possible to obtain secondary specimens for image reproduction.

Digital archiving features

Digital archiving allows you to:

- create a database of 3D-data;

- to measure and analyze objects ;

- perform a quantitative assessment of the restoration work;

- create an archive of artistic heritage;

- create 3D reproductions;

- create a virtual museum with renovations in case of damage.

Statues are digitized using the Creaform Go! SCAN 3D handheld 3D scanner.

Contactless technology and simple 3D scanning process

Under the direction of the team of curator and restorer of art objects Serge Gjordani, who is engaged in the restoration of works of stone and marble, project manager Benoit Derio and researcher Florian Lüye, were in the estate from March to May 2016 to perform an exceptional mission - 3D digitization of 30 statues according to plan first phase of the project. Then, thanks to a new charitable contribution, the second stage and the transfer of the remaining 31 statues to digital format were made from July 2016 to January 2017.

“The Go! SCAN 3D portable 3D scanner uses contactless technology that allows you to work together and create a polygonal mesh in real-time software. Thanks to the scanner, we completely digitized all the statues, and then processed the raw data obtained with the scanner, ”says Florian.

Post-processing of the generated file is performed by specialized software to modify the resulting original modeling. “For 3D printing, the grid of the statue must be“ clean ”and“ airtight, ”the expert explains. The office cleaned the grid, filled holes, reduced noise (anti-aliasing) and texturing before the final export of files. “One day of data collection in the field requires, on average, one day of processing, while the size of the object or the level of its detail can change these deadlines,” said Benoit, whose functions also included advising sponsors on 3D printing. “We do not just create archives in digital form, we supervise the whole process and help our clients use all the features of a 3D printer , for example, printing at different scales, or reverse engineering of any part of the statue.”

3D scanner Go! SCAN in the hands of specialists

This handheld 3D scanner records three-dimensional data in color to represent geometry and textures in all their richness, yielding exceptionally realistic results. This tool allows surveyors to model large objects with an accuracy of 0.100 mm. This scanner provides visual information from the entire site and the confidence that processing is completed, which allows you not to move back and forth around the site. It meets the needs for high accuracy and high resolution, which are necessary when working with such complex and demanding objects as Vaux-le-Vicont.

Source: https://habr.com/ru/post/445754/

All Articles