Optimum part orientation and support configuration in a 3D printer

One of the main advantages of additive manufacturing is the possibility of real customization of parts. This technology is well suited for the production of individual implants for patients in areas of medicine such as cranio-maxillofacial surgery (HFLC) where optimal size, shape and mechanical properties are required.

- Objective: To demonstrate that modeling can help in choosing the right orientation and configuration of the supporting structure.

- Solution: the creation of three different configurations of support parts and their comparison

- Software Used: Materialize Magics

- Method: modeling and comparison of deformations of final configurations of support for details

- Industry: Healthcare

Problems of 3D printing of cranio-maxillofacial implants

')

Individual Maxillofacial Implant

Springing effect

The process of producing implants for CHFL causes many difficulties. If implants are not thermally processed, they are usually subjected to the so-called “springing” effect in some configurations of construction due to residual stresses. This effect causes significant deformations of the final design, as a result of which the implant may not be suitable for the patient. How serious the springing effect will be depends on the orientation of the part and the configuration of the support . However, the selection of the correct configuration is a complex and time consuming process.

In this example, we explore various configurations of support for the details of an individual implant for cranial-maxillofacial surgery and determine which configuration is least susceptible to springing and, accordingly, is most suitable for additive manufacturing . We do this by simulating the deformation using a well-calibrated natural stress method * and comparing the final deformations of the products after removing the support. To confirm the simulation results, we carried out an additional comparison with the manufactured configurations of the structure.

Simulation of the entire platform in three minutes

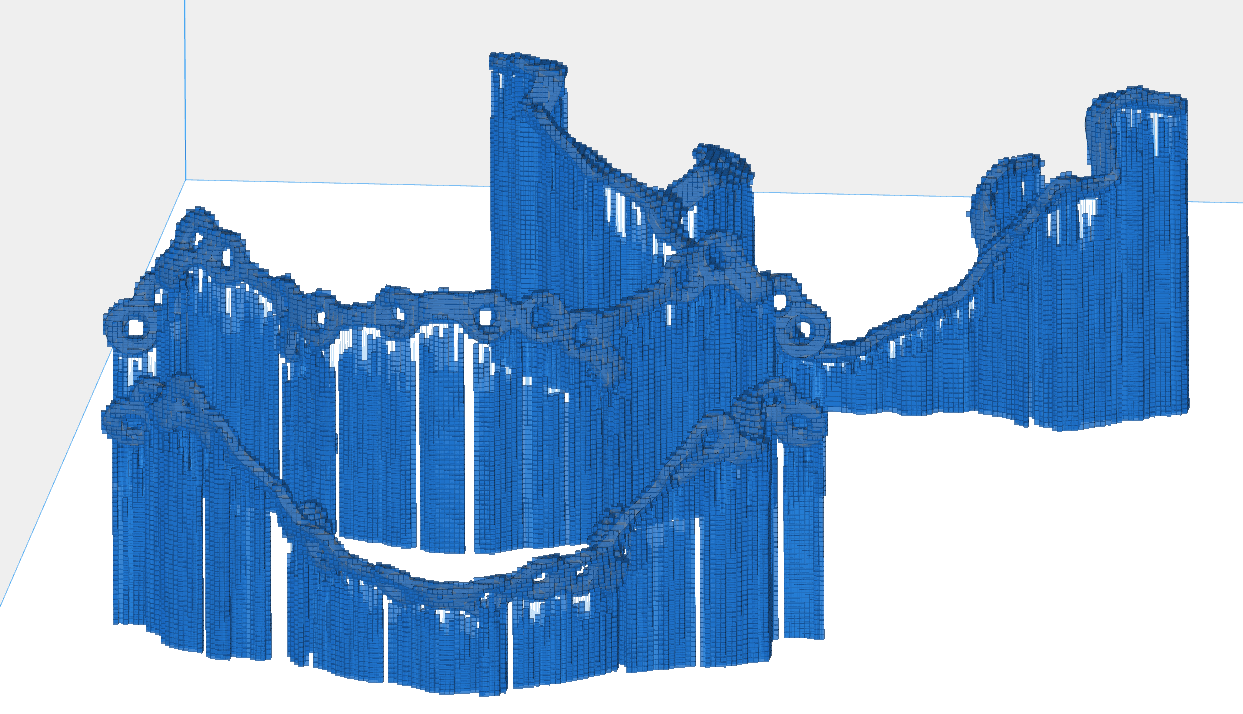

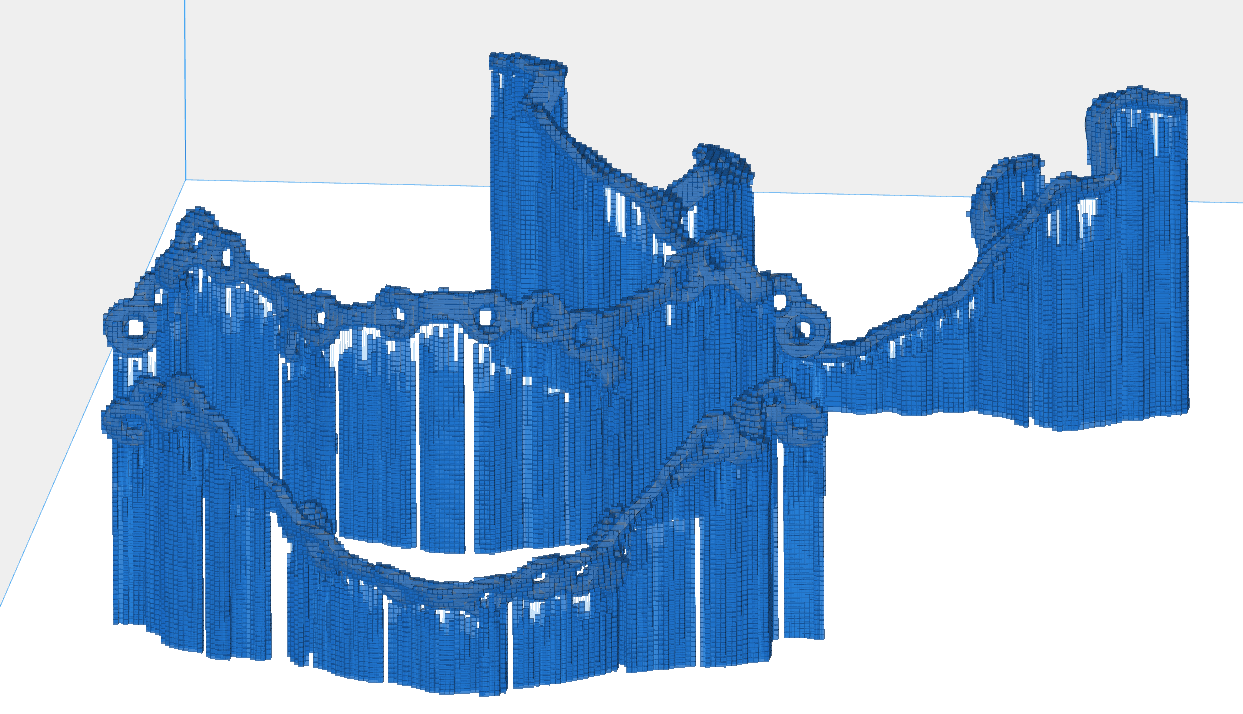

Visualization of step 2: voxelization of three different part orientations

Simulation is a powerful tool for minimizing unsuccessful printing sessions. It provides valuable information on how to post (or not to post) support or critical segments. Let's look at the modeling workflow.

- Obtaining CAD-geometry details and configurations supports.

- Voxelization of part geometry and verification of supporting structures in boundary conditions.

- Simulation of layer-by-layer construction by the method of own stresses.

- Interpolate voxel results to the original CAD geometry.

We decided to focus on the speed of modeling, so voxelization of parts has a rather large grain. Our goal was not to imitate the exact distortion of any configuration, but to determine which of the configurations is subject to the least qualitative distortion. In just three minutes, we modeled the entire voxelized platform.

Evaluation of results

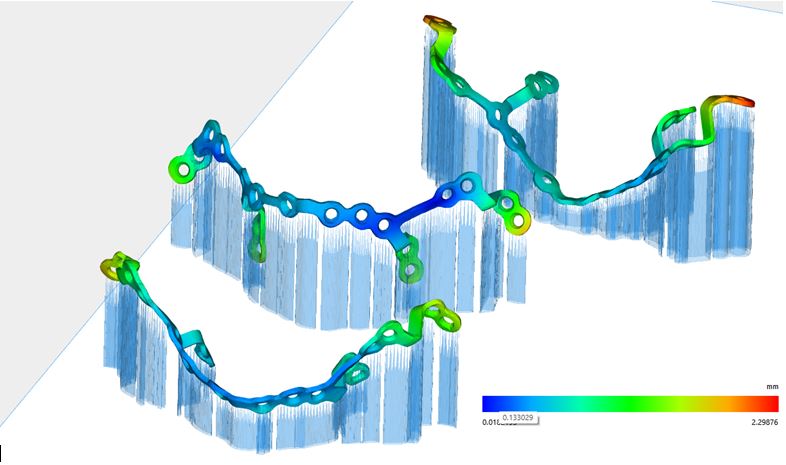

Modeling deformations after separation support

For modeling and viewing the results, the Magics Simulation software module was used. The selective loading function of the most relevant data for modeling in Magics has improved the process of selecting the optimal orientation. The figure below shows three different configurations of support details (transparent) and simulated deformations of implants after separation support. As you can see in the image, the configuration of supporting the part with the least deformation is in the middle. It does not contain red and yellow zones.

To confirm the simulation results, we compared the deviations in the design of deformed parts from the original CAD geometry of the simulated and printed parts. As can be seen below, the simulated and printed designs have the same character of deviations. The upper configuration contains the largest geometric deviation from the original CAD-geometry, and the average - the smallest deviation.

Comparison of simulated deformations and printed designs with the original geometry

In search of the least deformation

In this example, we used finite element modeling to quickly predict global deformations of three different configurations of the details of the cranio-maxillofacial implant. Rough voxelization made it possible to quickly model and obtain data on the qualitative tendencies of deformation. The actual test samples printed on the 3D printer confirmed that of the three configurations proposed in this study, the average underwent the least deformation after the removal of the supporting structure .

Thus, the second model also confirms that the predictive ability of modeling is a valuable tool for additive manufacturing engineers. Using the Magics simulation module, they can evaluate their projects before the manufacturing stage, which allows them to find the optimal orientation of parts and the configuration of support.

Please note that Materialize Magics is not a medical software. The user is responsible for approving the manufacturing process and the product for use as a medical device. Orthognathic implants of Materialise are protected by patents EP 2398411, US 8,784,456, US9,247,972, US 9,339,279. Other patents pending.

* The Internal Stress Method (ISM) is a simulation procedure adapted from welding modeling to predict residual stresses and strains in an additive manufacturing process. ISM simplifies the complex, time-consuming, thermomechanical process of additive production to a simple quasi-static analysis, allowing you to quickly and accurately simulate complex additive components.

Translation from English. Original article - by reference .

Source: https://habr.com/ru/post/445158/

All Articles