Recycling hard drives as e-garbage is a partial solution to iNEMI's problem.

The volume of "electronic garbage" is huge - since 2014, humanity annually generates about 42 million tons of this kind of waste. E-waste includes both simply discarded electronic and electrical devices and their components. Electronic waste is dangerous because they may contain harmful substances such as lead, mercury, polychlorinated biphenyls, polyvinyl chloride.

Some of the waste consists of hard disks, which are very difficult to recycle. But thanks to new technologies, drives with remanufactured magnets may soon appear (or rather, are already appearing).

So, in the second half of last year, Google received six HDDs for testing, manufactured by Seagate. The magnets in these disks were not new, they were removed from the reclaimed drives, which simply ended their life and failed. By the way, all these drives were written off from the Google data center.

')

As it turned out (in principle, there is no need to be surprised here), the disks work perfectly, not worse than devices made of new materials. HDD processing technology was developed by the Dutch company Teleplan. The process is very time consuming. First, the disks are placed in a room with a minimum level of dustiness, where they are disassembled, and manually. Magnets are removed from the discs and sent to Seagate. Next, the company installs them in new drives, however, only if the magnets can still be used (that is, they are removed from not too outdated moral devices).

Unfortunately, due to the laboriousness of the process, it is difficult to scale up disk utilization, considering how much time, effort, and finances are used for this, it is quite likely that just new disks are cheaper to produce. And the problem with HDD is more than relevant - only in the USA more than 20 million hard drives are written off each year . This is a huge pile of electronic waste.

One of the pilot projects of iNEMI involves removing the entire stack assembly of the heads, as well as the upper and lower magnets. Source: iNEMI

True, there is an alternative to the method proposed by Teleplan. A group of researchers from the Oak Ridge National Laboratory for Atomic Energy has proposed a new method for extracting rare earth magnets from disks for the reuse of these materials. And this, by the way, is fully consistent with the strategy developed by the US Department of Energy. The agency claims that the reuse of rare earth elements is the first line of defense in protecting national security.

The labs were able to find out that in most models of disks the magnets are located in the lower left corner of the drive. So in order to quickly get the magnets, you just need to chop off the angle from the HDD, so that there is still a certain margin in length (so as not to damage the magnets themselves).

After that, the chopped off elements are heated to a certain temperature in a special furnace. This is done so that the magnets lose their magnetic properties and are easily separated. The proposed method allows processing up to 7200 disks per day. Extracted magnets can be reused after the restoration of magnetic properties. But they can also be easily recycled - and not only for the manufacture of new magnets, but also for the production of rare earth elements necessary for many areas of science and technology.

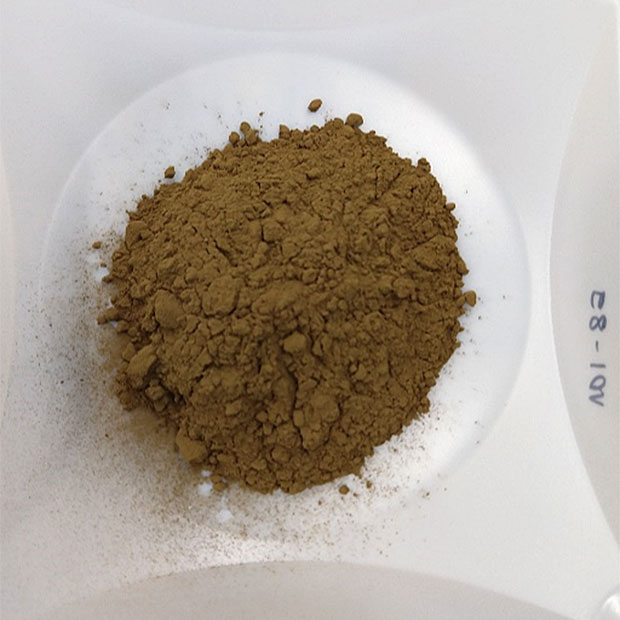

Rare earth oxides are extracted from magnets extracted from reclaimed hard drives, and then molded into metal ingots, which are subsequently converted into permanent magnets.

The extracted raw material is processed by grinding (literally to dust). Next, from the resulting substrate is extracted magnetic fraction. All this turns into an oxide powder, which serves as the raw material for the creation of new magnets. Urban Mining Company also produces magnets, which are used not only in IT, but also in other areas, including mechanical engineering. The strategy for using recycled materials, as mentioned above, is implemented by the US Department of Energy.

Source: https://habr.com/ru/post/444896/

All Articles