Reverse engineering of the tractor: how to speed up the measurement process twice

Creaform Technologies in Action: Scanning a Tractor to Develop Attachments

MX (formerly known as MAILLEUX) is a family-owned business founded in France in 1951 that specializes in the design, manufacture and sale of loading equipment for agricultural tractors. MX is able to equip more than 600 tractor models with such equipment, which allows it to be among the world leaders in this market segment.

Among other things, the company has experience in developing brackets (for hanging loading manipulators) for all agricultural tractors on the market, as well as developing control systems for its loaders.

')

Problem: too slow

Tractor manufacturers rarely share information about their new products, and getting 3D models of these tractors is even more difficult, if not impossible. However, for the development and production of attachments such as MX loading arms, it is absolutely necessary to have 3D models. Therefore, the company has to perform 3D measurements of all the tractors for which it wants to design and produce attachments. These measurements are performed at the factory in order to obtain a 3D model of each tractor.

Creaform 3D solutions allowed us to reduce the measurement time by more than half, and consequently, reduce the time to marketUntil recently, MX measured, scanned and reconstructed a complete 3D model of the tractor using 3D manipulators (such as Romer and Faro). Such a process provided a viable solution, but labor costs were extremely high — it took a week to complete this task. In addition, during the measurement process, the measuring manipulators had to be moved several times, and each time the device needed to be recalibrated in a stable environment and re-installed.

Emmanuel Renu, Director of R & D, MX

Wanting to reduce the time spent on measurements and reduce associated costs, the company's technical service began to look for an alternative solution that would be both faster and more flexible, and would ensure high accuracy and reliability of measurements regardless of external conditions.

Eureka: Creaform 3D Scanner!

Optical Scanner for CMM MetraSCAN 3D

This happened at the MesurExpoVision industrial exhibition - representatives of the MX company discovered Creaform’s portable 3D technologies and appreciated the benefits that the company can receive in terms of optimizing the production process. Indeed, TRUaccuracy technology and dynamic measurement functions, which are an exclusive feature of the HandyPROBE coordinate measuring machines (CMM) and Creaform 3D scanners, guarantee fast, high-precision measurements.

Creaform metrological systems are not only completely insensitive to vibrations and movements in the surrounding space, but also allow you to dynamically increase the volume of measurements without any difficulty, eliminating the need to align an object or scan it in parts. This was an undeniable advantage for the MX, because it made it possible to completely eliminate such steps as moving the manipulator (when carrying out a full measurement of the tractor), calibration and planning.

Flexible measuring system

In the fall of 2012, the company acquired a scanning and sensing system, including the HandyPROBE portable CMM, the MetraSCAN 3D optical CMM scanner, the C-Track 780 dual camera tracker, and the Geomagic Solutions post-processing software from 3D Systems.

Today, MX uses Creaform technology to digitize its tractors — scanning all areas needed to design adaptable structures, including bracket attachment points and their surroundings (tractor cab, exhaust pipe, fuel tank, battery compartment, filters, pipes, radiator, engine, and belt drive pulley). The surfaces are then machined, cut and cleaned using Geomagic Solutions, and then exported to CAD in the .stl format.

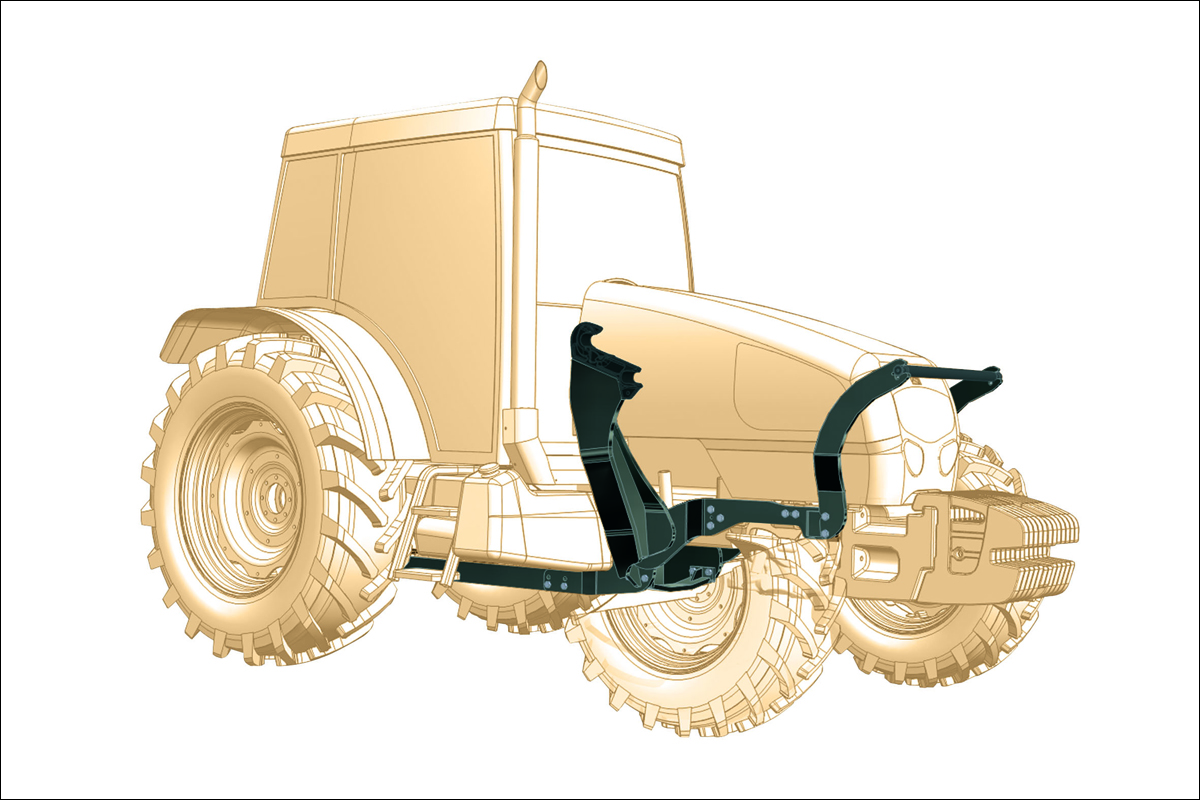

3D-model of the tractor, created in the Geomagic software based on the scan results

Moreover, the integration of these portable 3D-measurements from Creaform has enabled MX to create a flexible measurement system that can be used by 6 different resources of the project unit.

Fast measurements = workflow acceleration

Emmanuel Renu, director of MX's R & D department, explains how Creaform technologies were able to help the company: “This system allowed us to reduce the measurement time by more than half. By saving time, we can measure a greater number of tractors and, therefore, offer our customers more choice and reduce the time to market. Our goal is to bring the indicator of completed projects from 50 to about 100 per year, then we will, so to speak, “reach full speed”. This new equipment also speeds up and simplifies our work when measurements are required outside the company, whether in France or abroad. ”

“Without investing in this equipment, we could not keep up with the accelerating pace, because the speed of new tractors entering the market continues to grow as manufacturers offer more and more different options in order to better meet the needs of their consumers (farmers). Since we are now better equipped to perform measurements, we even strengthened our design units in order to optimize all this data, ”adds Renu.

Source: https://habr.com/ru/post/444796/

All Articles