How to reduce the weight of an element of aircraft design by a third

S-shaped bracket - an element of the actuator of the increase of the aircraft lifting force

The project of optimization and additive production of the power element of the aircraft structure, implemented by ASCO Industries and SLM Solutions, has once again proved the effectiveness of selective laser melting technology. The new solution made it possible to improve the design and reduce the weight of the part, as well as to reduce the overall assembly and machining time.

About ASCO Industries nv

ASCO is a Belgian aerospace company headquartered in Brussels. It is a recognized world leader in the development of mechanisms for the drive of the slats (on the leading edge of the wing) and flaps (on the rear edge of the wing), as well as the machining of high-strength steels, titanium and aluminum alloys . ASCO is also renowned for its wide production and assembly capabilities for creating highly accurate and cost-effective solutions for aircraft landing gear and design elements such as fuselage frames and engine mountings.

Structural element of the Kruger flap drive mechanism

The considered S-shaped bracket is a structural element of the Kruger shield drive mechanism developed by ASCO in the framework of the AFLoNext project. It is believed that the Kruger flaps can effectively replace the slats on the leading edge of the wings in future platforms with laminar flow around the wing.

')

The bracket serves as a swivel linking the Kruger shield with a fixed leading edge. Its elegant form is the result of strict requirements for the distribution of space and high loads on the seating surfaces. The original project involved the machining of the bracket by ASCO. The machined version is made of high-strength stainless steel and weighs 2005. Interest in this element is due to the fact that in its original form it requires complex machining and has a poor material utilization factor.

Solution found: selective laser melting

ASCO and SLM Solutions have implemented a joint optimization project to produce the best new S-bracket design. Engineers from SLM Solutions have participated in the evaluation of various design stages in order to improve manufacturability. The use of SLM technology (installation with two lasers) has reduced the production time from 82 to 48 hours. SLM Solutions was able to successfully tune the process to the operating stresses of the structure and the heat exchange properties of large titanium parts.

Bracket design optimization

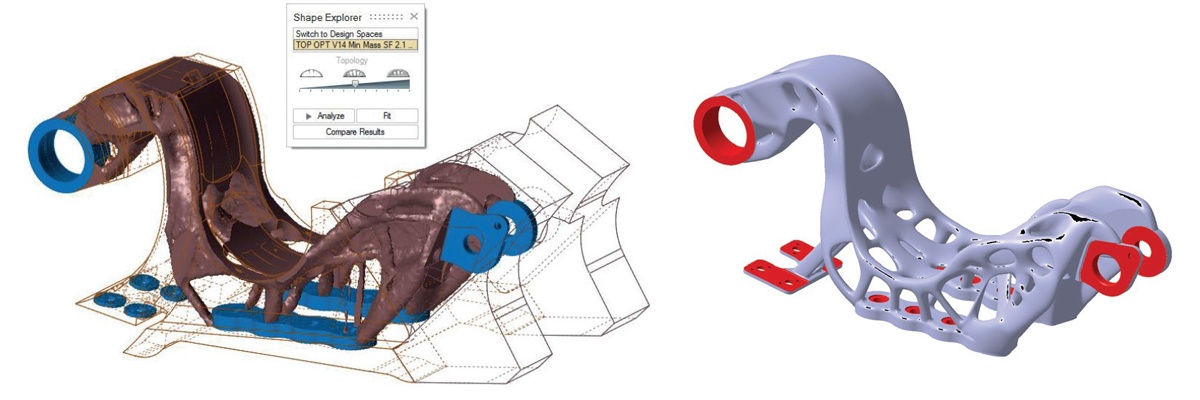

Since the printing of an element designed for machining provides few additional benefits, the design of the S-shaped bracket was redesigned for additive manufacturing by means of topological optimization . Its goal was to minimize the mass while maintaining the necessary strength, allowing it to withstand the aerodynamic loads specified in the AFLoNext project. In addition, two other elements were integrated into the bracket. After optimization, the weight of the bracket is 1416 g (the original unit weighed 2050 g), which means a 31% reduction in weight and a reduction in the total assembly time.

Increase material utilization

The material utilization rate of the mechanically processed version was approximately 17, while for a part printed on the SLM Solutions additive installation, this indicator dropped to 1.5 (taking into account the removable supports and a small amount of additional material removed during the post-processing of surfaces with high accuracy requirements ).

Reduced machining time

The previous machining time, starting from the initial blank, was about 4.5 hours. Applying the technology of selective laser melting, the processing needs to expose only a few surfaces that are highlighted in red in the figure at the top right.

The result of the project 3D-printing metals

- Reduce weight by 31% and reduce overall assembly time.

- Combining three parts into one.

- Reduction in material utilization from 17 to 1.5.

- Significant reduction in machining time.

- Reduction in production time by 42% to 24 hours / part due to the use of a SLM 280 Twin printer (as compared to a single-laser printer).

Source: https://habr.com/ru/post/444480/

All Articles