Construction of the Sakhalin - Kuril communication line. Excursion on the Segero - ship-laying layer

Rejoice, comrades!

10 years ago we were glad that the optical communication lines crossed the Tatar Strait, three years ago we admired the fact that we finished laying optics on Magadan, and a couple of years ago on Kamchatka.

And then came the turn of the South Kuriles.

')

This fall, optics came to three Kuril Islands. Iturup, Kunashir and Shikotan.

As usual, I tried, as far as it was in my power to follow this matter, and I will tell you that everything has already been laid , tested and officially put into operation a couple of weeks ago .

I was able at the invitation of Rostelecom to visit the ship, which led the work on the laying of the cable.

The customer was the state in the person of Rostelecom, the same as last time, the Huawei company became the performer.

But the cable laying vessel was already different.

Naturally, in the process of laying cable, there were some political problems with neighbors . But it seems nothing further protest notes went. Although the devil knows what the situation will reach there. But this is a matter of politics, we will probably keep silent about it.

Korean Segero 1998 release.

Specification of the vessel on the site .

Anyone interested in other cable laying machines is an excellent selection for you to admire .

In 2017, the same team that built the line to Magadan and Kamchatka, conducted reconnaissance work in the Sea of Okhotsk on our hydrographic vessels, and in 2018 in May, the ship arrived in Vladivostok, took the team and technical specialists and went to the area of work for direct laying.

You had a unique opportunity to walk along the ship with a cable layer and see what and how.

Alas, no one else will tell you this, as last time, in the story about another Cable-laying machine .

+++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++++++++++++++++++++++++

If you do not know or have forgotten how the laying of underwater communication lines is conducted, then I will remind you, the stages of work on laying underwater communication lines:

At this stage, the bottom of the sea is investigated, or ready-made materials from previous studies are taken. Depending on the relief of the bottom, the route is built. Naturally, current communications at the bottom are taken into account. But the benefit is that the Sea of Okhotsk is not rich in underwater pipelines and underwater optical highways, well, except that the secret communication cables of the Pacific Fleet to which enemy submarines listen .

A hydrographic vessel is brought to the site of work and a study of the day, the relief and the determination of cable exit points on the shore ashore are carried out.

The cable is made immediately solid coil, so that under ideal conditions, it can be laid from beginning to end, and loaded onto the ship. At the production stage, erbium amplifiers EDFA (Erbium Doped Fiber Amplifier), a fiber-optic amplifier on an erbium-doped optical fiber, are immediately incorporated into the cable.

Due to the fact that Russia does not have such civilian ships, the manufacture of the cable and its installation were entrusted to Huawei.

Huawei does not have its own fleet and for this reason hired a subcontractor kt submarine, a Korean company that specializes in underwater work.

It's simple. At the bottom, from the ship, they lower the plow and turn the small one forward. He digs a trench, a cable is buried in it.

The only difference with the picture is that there is a couple of kilometers under the ship.

Here is another informative video:

If everything went well and the cable reached from shore to shore, then it was connected to the coast station. To do this, at the connection point, the cable is thoroughly buried in the bottom so that it is not washed by the sea, they are flooded with stones. Connect the earth's end with the sea.

This is how it looks close:

After the work is finished, they stick the wires, measure the losses, start the connection. If everything works, connect consumers. Usually they run at minimum speed, but in the cable there are usually additional conductors, which later on, when replacing equipment, large volumes of traffic transmission can be launched. Well, again, the reserve, which suddenly breaks.

In the description of the process, any coordination of money and work is omitted, but in our case it is no longer very important.

+++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++++++++++++++++++++++++++++

1 And now, you and I will step on board the ship Seghero and walk a little.

2 The first thing we have to do is ... yes, that's right, we will put on the means of protection in order not to hit our head where it is not necessary.

3 I last time did not think about how to immerse the cable on the ship. It turns out there is a special "filling neck". I honestly thought just through the open door in the board.

The main distinctive modules of the cable handler are

The rest is the same as other ships, engine, cabins, galley, dining room. The only thing is, for convenience, on such vessels there are a lot of different thrusters and automations for millimeter accuracy in keeping the vessel in place.

Let's go in order.

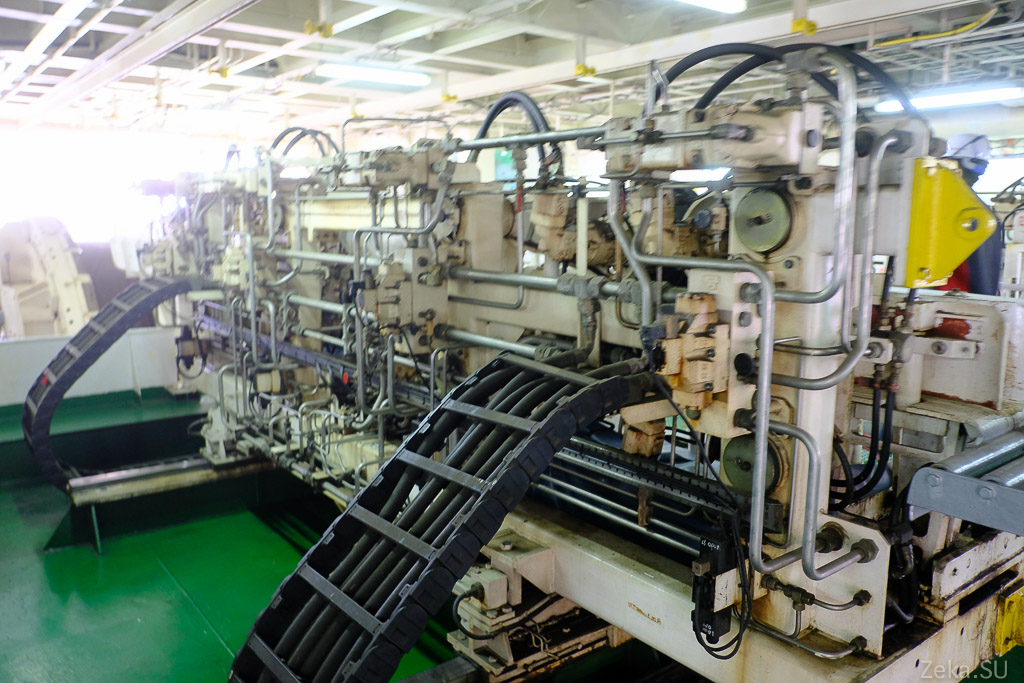

4. These mechanisms are conveyors for the transfer of cable from tanks to the stern.

5. Rollers for cable pulling

6

7. At the same time, you can simultaneously feed two cables from 2 tanks

eight.

9. I do not know what to call it, but the type of cable channels. Cables are traveling along them.

10. On the deck itself store signal amplifiers.

11. Alas, there is apparently no wet chamber on board. The storage scheme is implemented by the method of "Wet rag"

12.

This is a direct disappointment compared to the other cable layer I was able to visit. You can go and compare yourself http://zeka.su/2016/07/11/3406/

How do signal amplifiers work

Amplifiers are most often made on the basis of doping fiber with a rare-earth element erbium.

An additional high power laser beam, but different from the frequency of the laser transmitting information, is inserted into the fiber and causes the erbium atoms in the amplifier to go into an excited unstable state. When a photon of laser radiation weakened by a long fiber road with useful information collides with this atom, it receives energy from this excited atom and is re-emitted with a new force and flies farther, rather, it is re-emitted in the form of 2 quanta and useful photons become larger.

This is all if explained on the fingers, will be so.

Tennis balls are thrown into the pipe on which information is recorded and they fly through the pipe from point A to point B. The pipe is long, and when experiencing air resistance they slow down and may not reach the end of the pipe.

But close along a parallel pipe, air is pumped at high speed, and it causes the wheel blades to turn quickly like a water-mill, or a paddle steamer, located somewhere in the middle of the pipe.

Having flown to this wheel, tennis balls get this wheel on the ass, like a tennis racket and with new forces fly further ... another 80km =)

Who is interested in reading a normal and useful article on this topic , well, or Wikipedia .

Sorry for the confusion, but I'm not very strong in these matters.

But in more detail it is possible to esteem on Habré in kammentah

13. Also on this deck is the storage of additional equipment for laying. Couplings, adapters and so on. In short a lot of raskhodki

14. Here you can go to sea =)

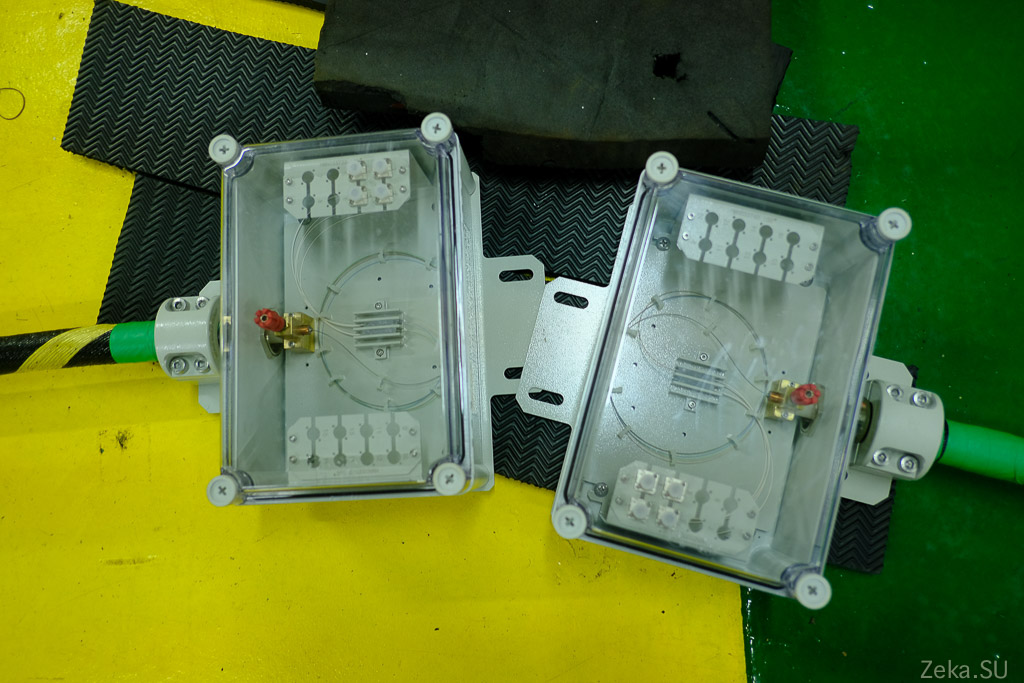

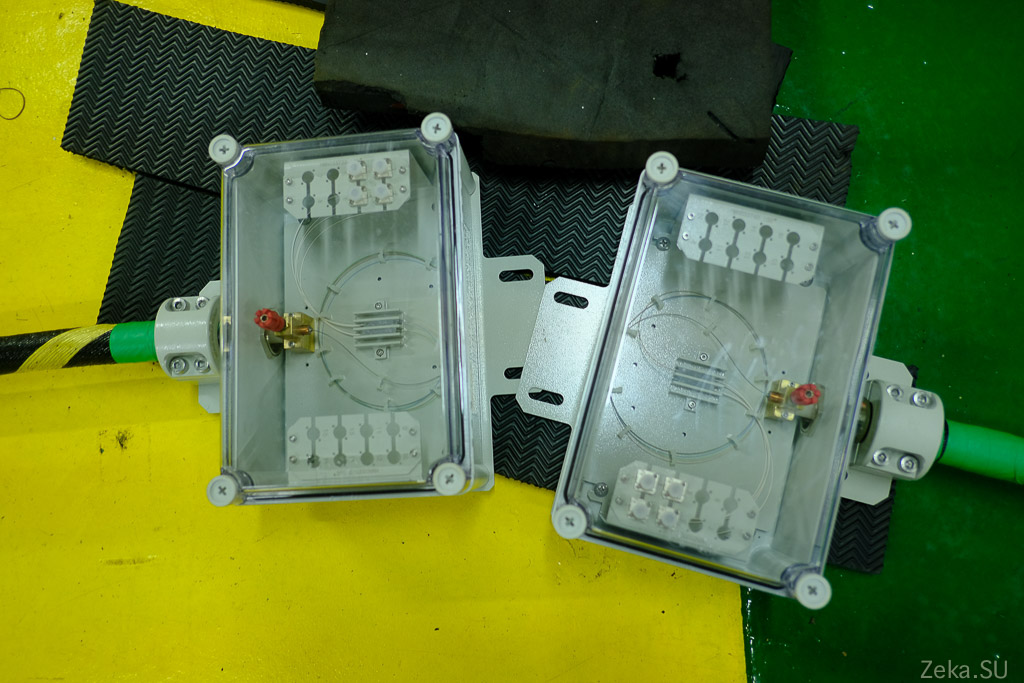

15. Here are the suspicious boxes that interested me.

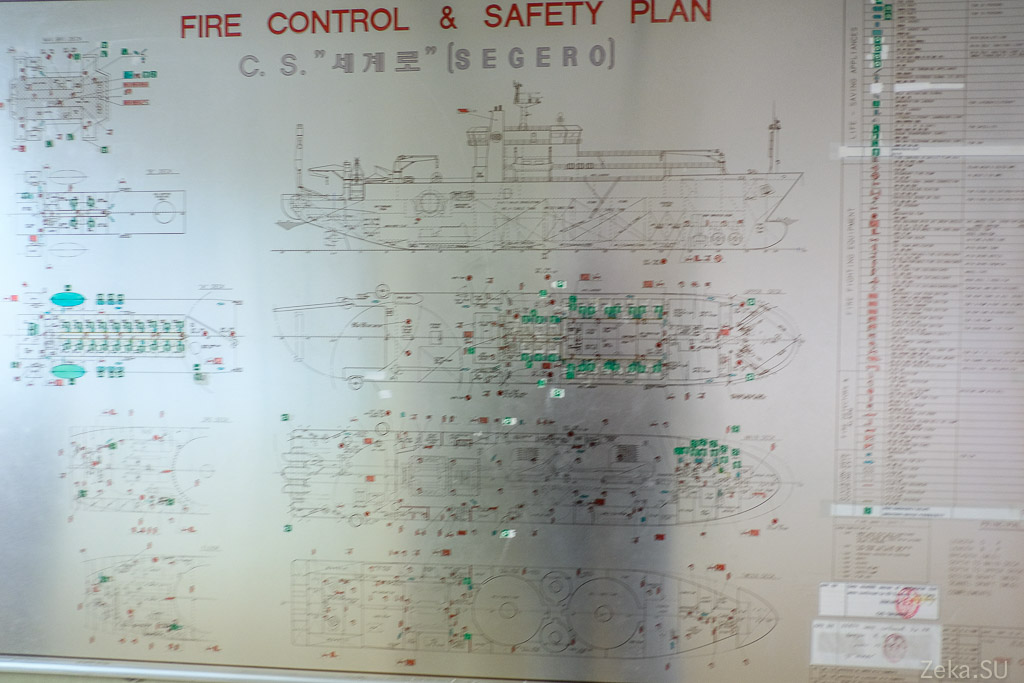

16. This is just an optical coupling for installation in a shoreline switching cabinet. This is the very end of the cable. The terminal equipment will already be connected to it. In the clutch it is just clear that 4 wires have been bred.

17. Alas, I do not know what it is, but also probably spare parts and other parts.

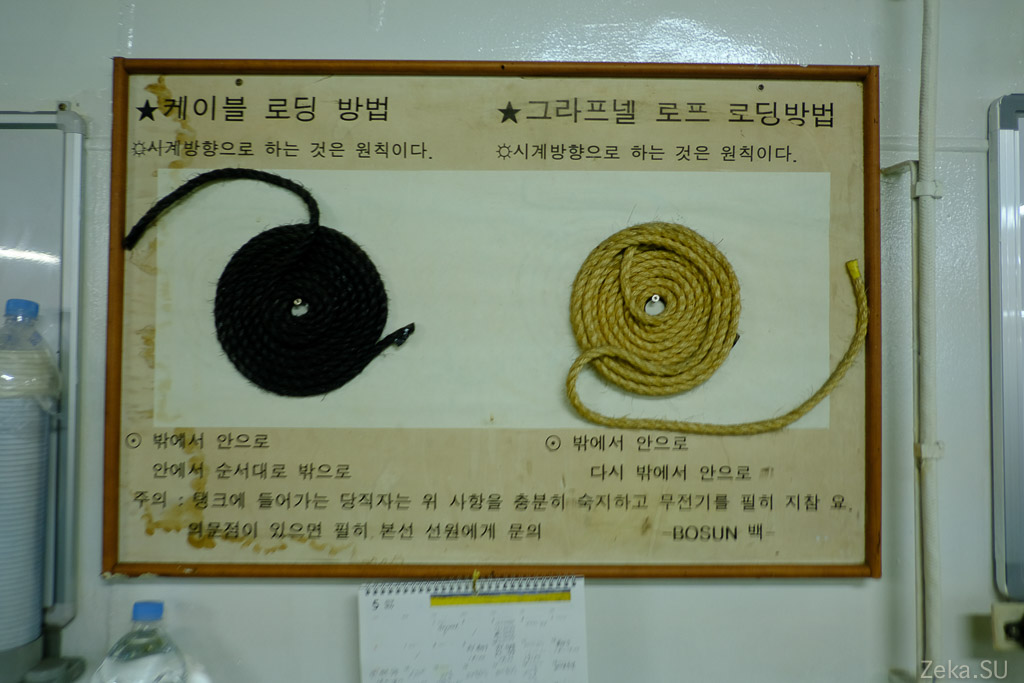

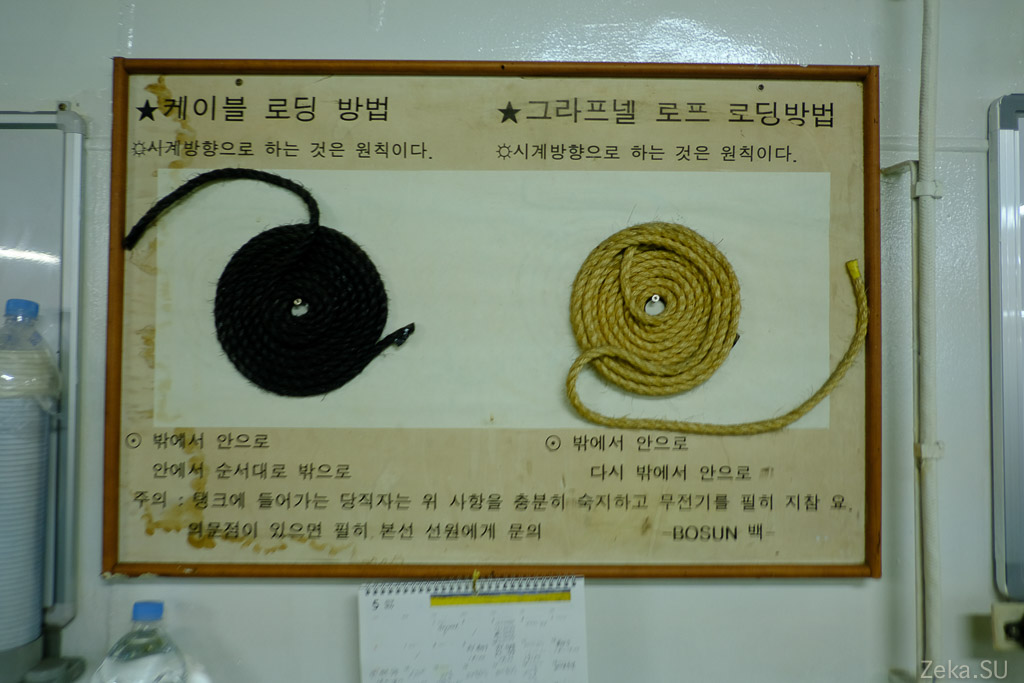

18. Visual aids on piling

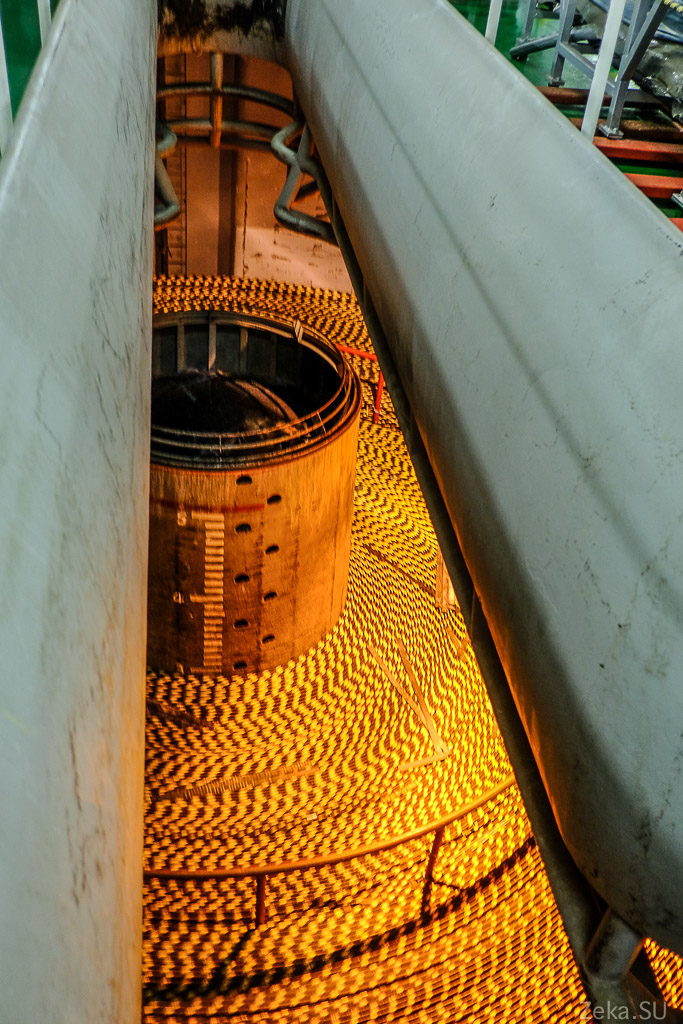

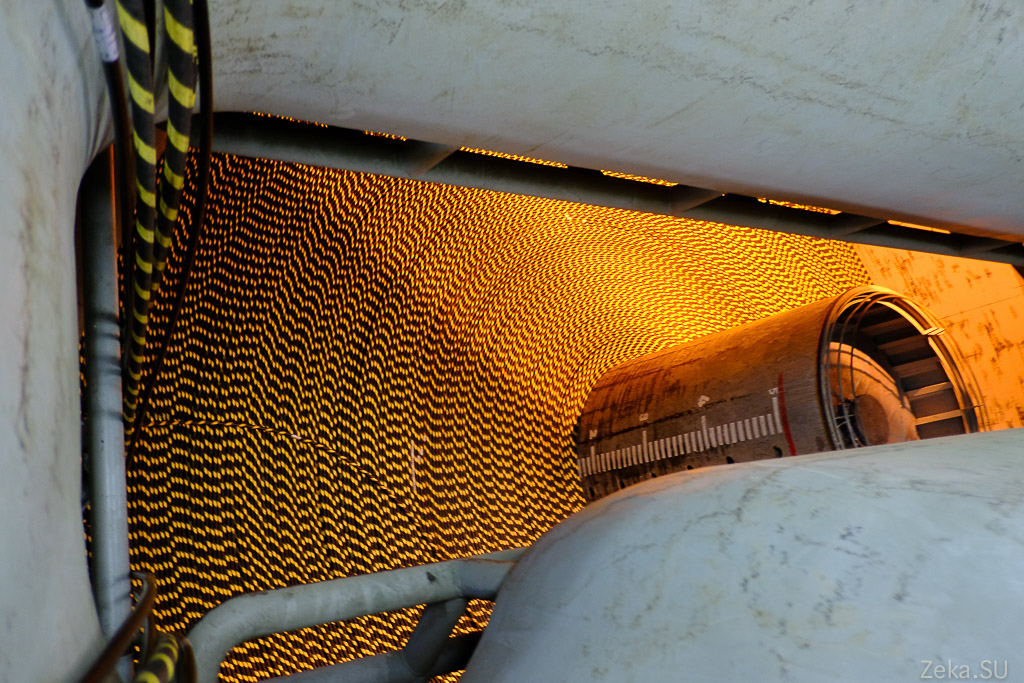

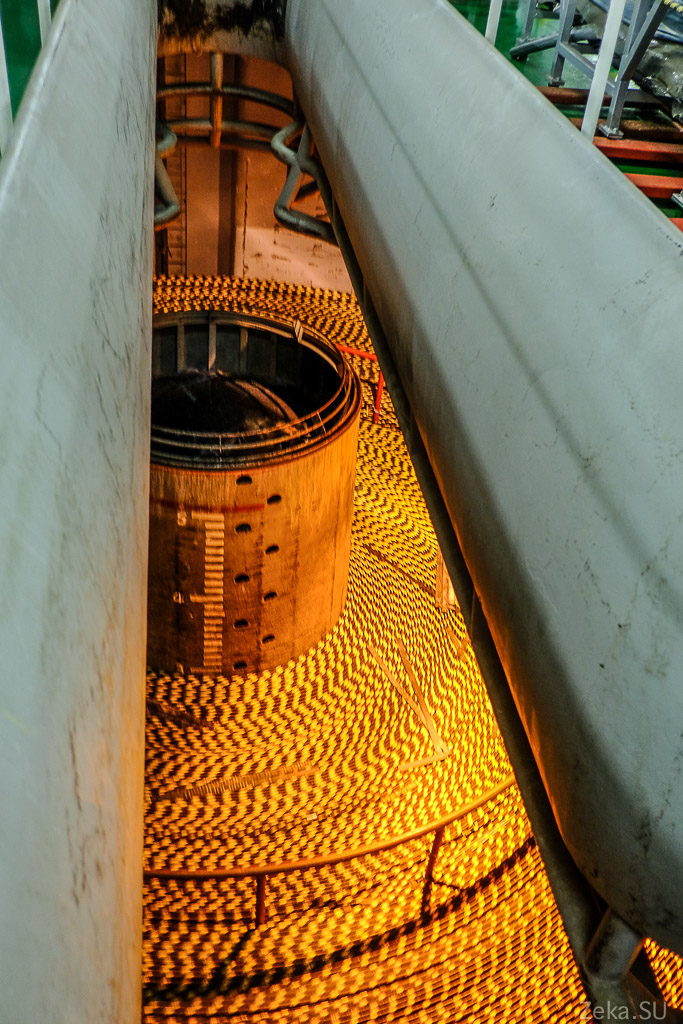

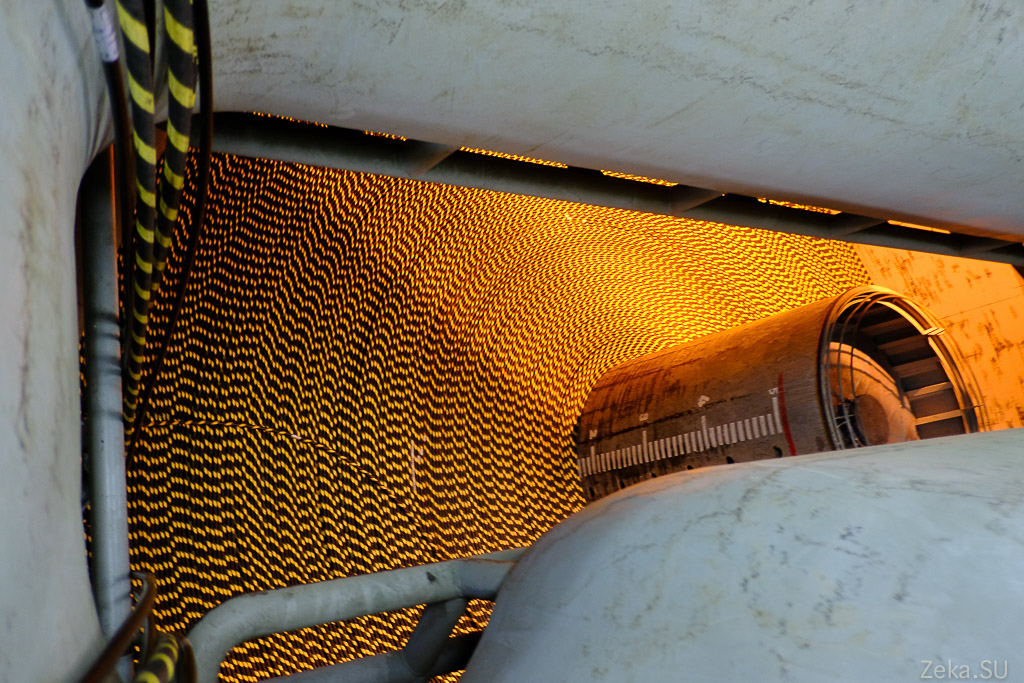

There are of course two cable tanks on the cable deck.

19. They are 850 km of cable + stock.

20. The second repository

21. the tank walls are rounded so that the cable slides and does not fray

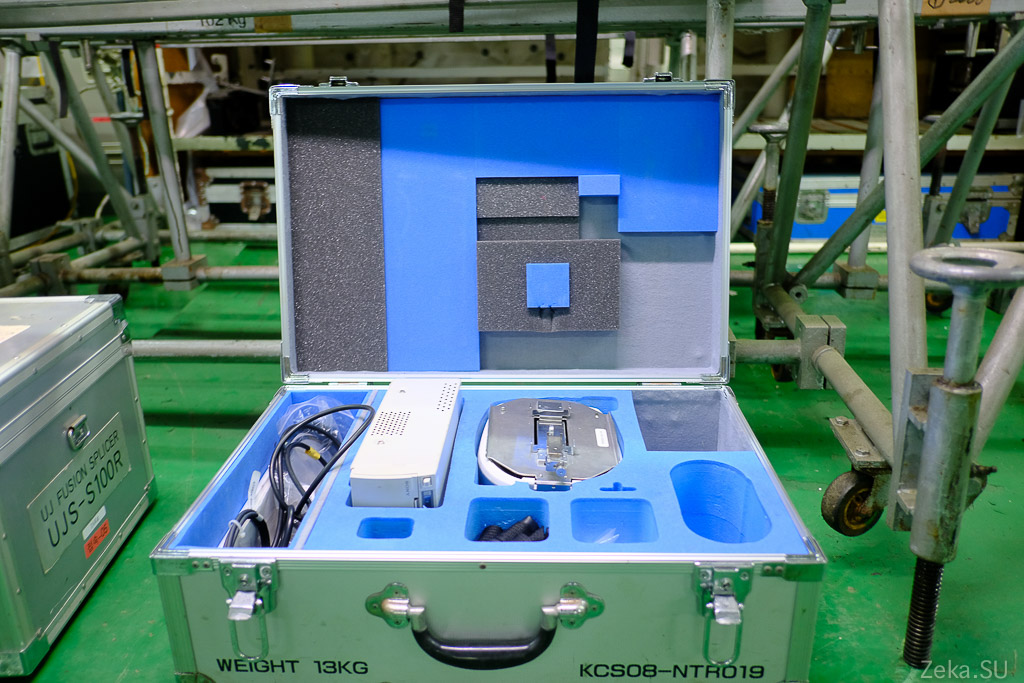

Now look at the "clean room". There are works on cutting the cable, welding optics and installing couplings, amplifiers and so on.

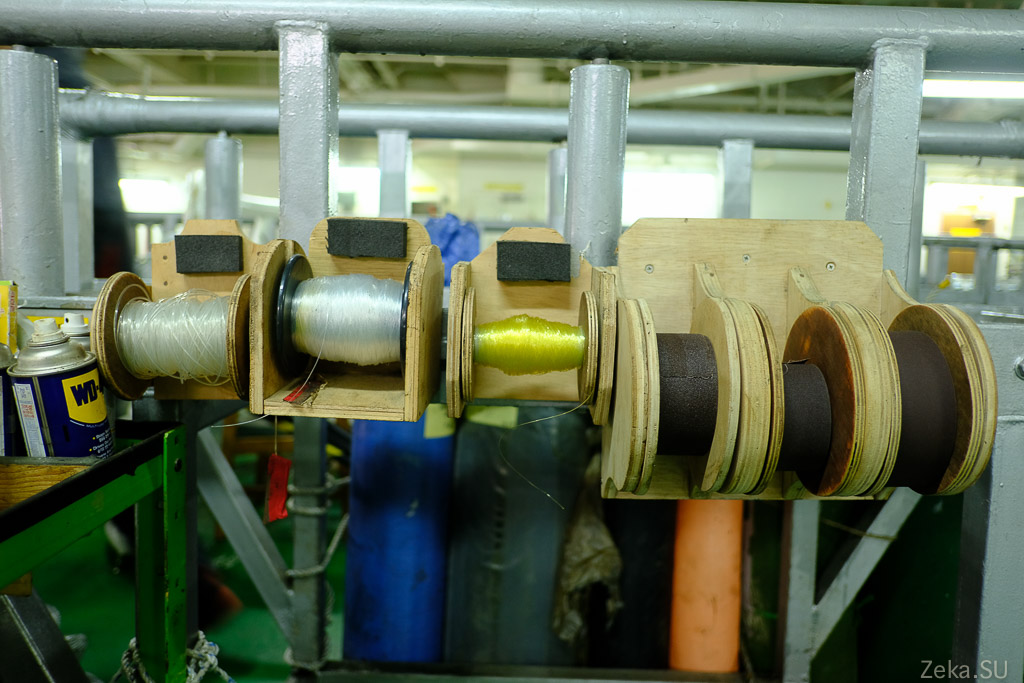

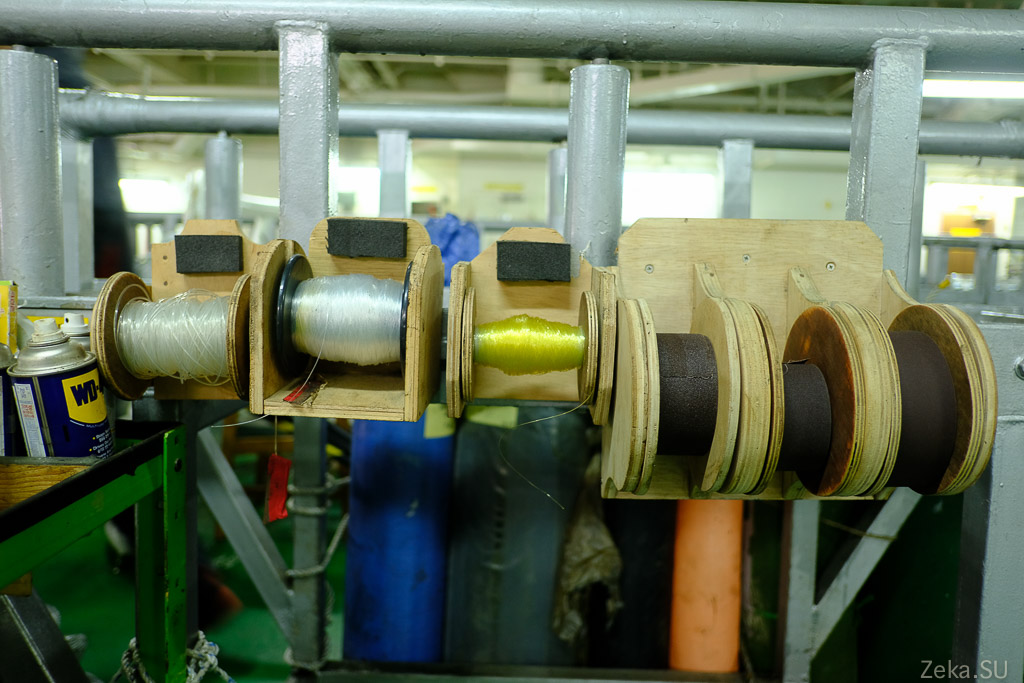

22. Workbench. Pay attention to homemade reels for materials

Tools and a bunch of all electrical tape.

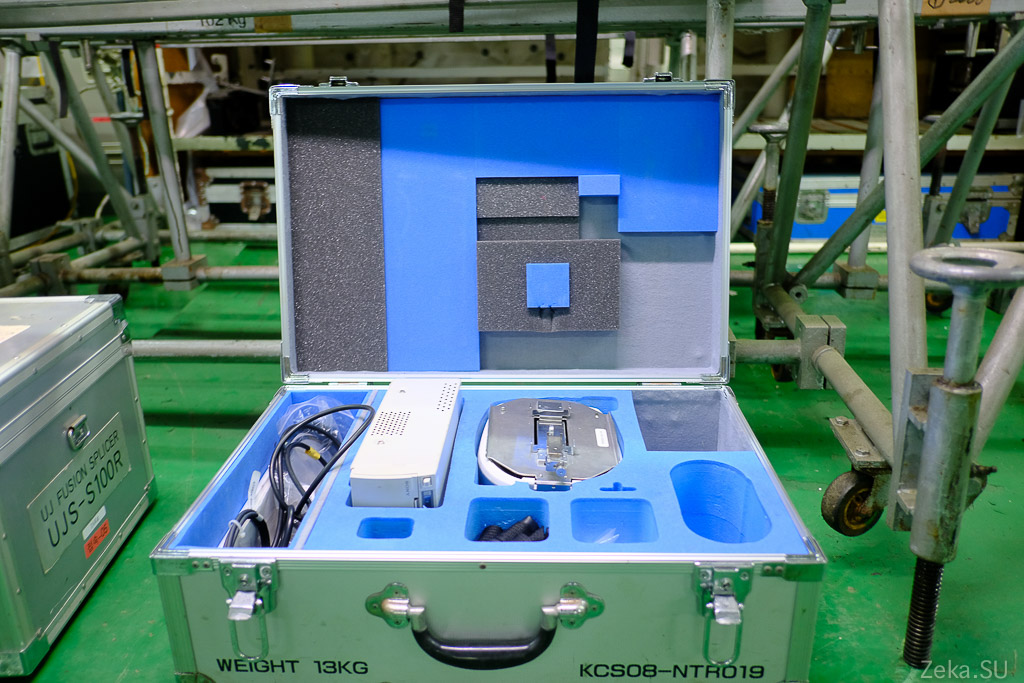

23. Welding machine

How it works you can see here or here .

24. The bed for mounting the coupling. This is a rather large and heavy construction.

25. Alas, I do not know what it is, but I assume that the terminal equipment for the ground station

26. X-ray equipment for testing manufactured underwater couplings. You understand that it is better to check 30 times, than to fiddle around with getting a cable and making a new clutch a month later

Now we will see how the pros work and how durable this submarine cable is.

Workers divide the end of the cable to install the coupling on it

27.

28. First, unstuck the plastic multilayer insulation.

29. Cable device. The top layer is plastic waterproofing. Further - the power bearing steel cables. Below them is a layer of polyethylene insulation. Inside the copper flexible tube. And in it already go optical fibers

30. I was not given rest here. There is a skin for stripping cable, and saws in the form of strings.

This string is convenient to cut plastic shells.

31. But to open the power steel frame it is necessary to use heavier artillery. Impeller and a few minutes of hard work

32. What is surprising about local workers is some disregard for TB. I hope nothing bad happened to them.

Well, and some technical details.

It seems to lay the wire - nothing complicated. Here I found a picture of how much any equipment you need to install on the cable before laying. Naturally, most of all you need to install on the longest cable - Sakhalin - Iturup (top line). Next, the cable goes to Kunashir, and then to Shikotan.

By the way, an additional project of this ship was the laying of a new communication line connecting Sakhalin with the mainland. The cable was laid through the Tatar Strait from Vanino to Uglegorsk. But there is a small communication line in comparison with the others.

With the cable deck we are done. Come on the stern and see the scuba equipment.

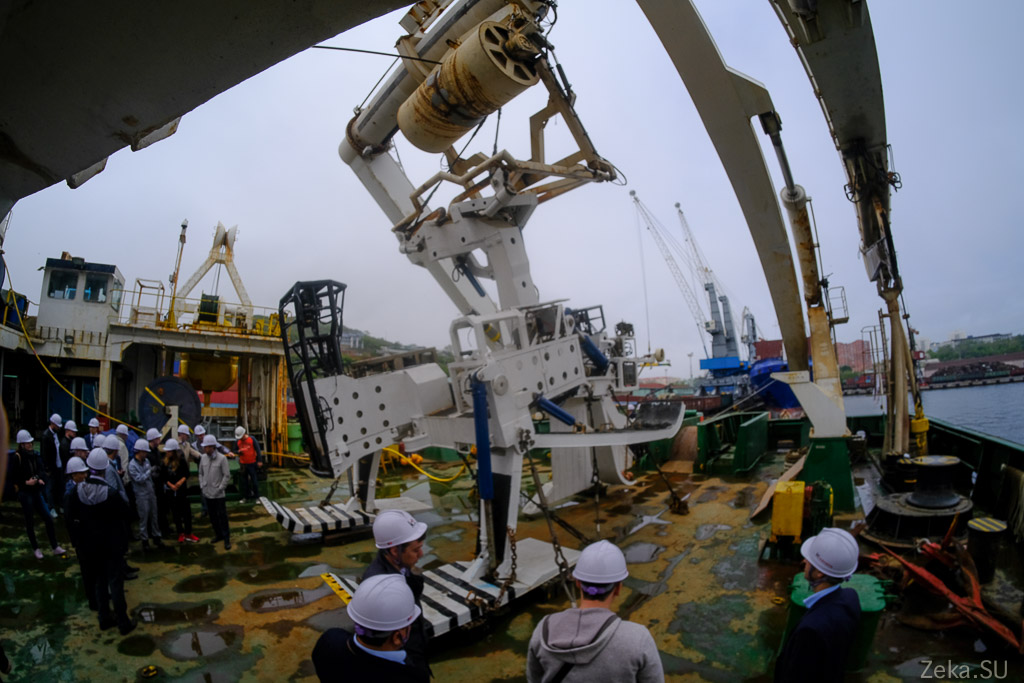

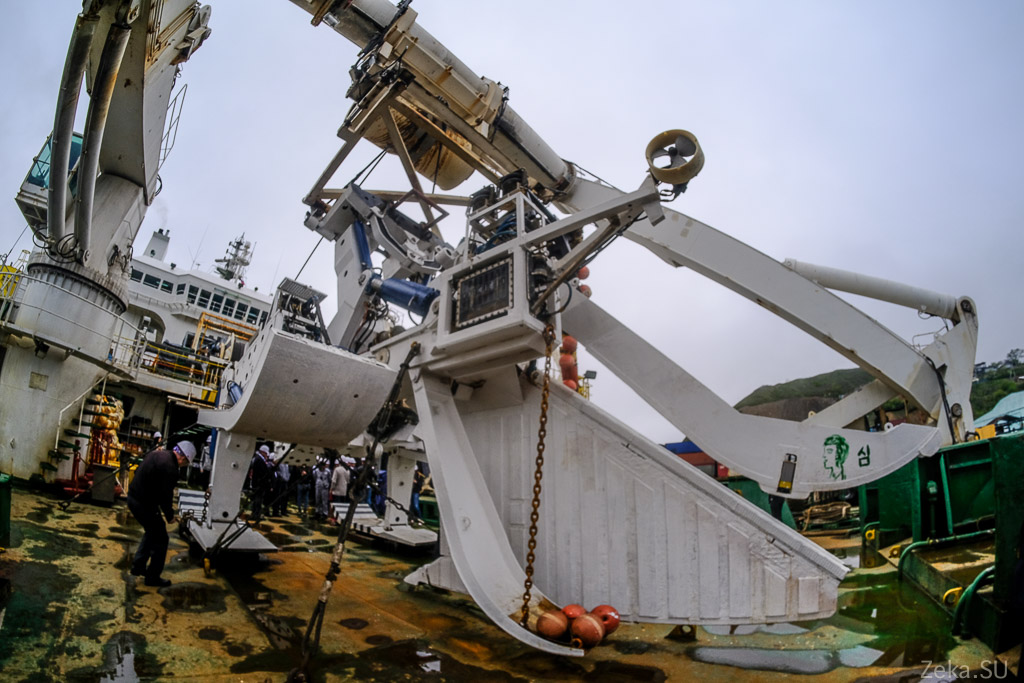

The only deep-water unit on this vessel is a plow.

The plow is lowered on the cable to the bottom and stretches behind the moving ship like an ordinary plow across the field after a horse. In the process of moving from the top to the team, the plow deepens its working canine into the bottom and digs a trench there to a depth of one meter. A channel passes through the canine cable and our cable is immediately in the trench. Which can be immediately filled up with soil.

Of course, this scheme may not work on rocky massifs in the coastal strip, but in the ocean itself at the bottom is usually quiet and the bottom is the deposition of soft sedimentary rocks or even silt. In such soils plow can dig at the maximum depth of the knife. If the cable is left lying on top, it can be damaged. For example, if someone from the fishermen or scientists will trail the animals from the bottom or the shark will get too nervous. There are many examples. In shallow water where there is active shipping, the cable has to be additionally filled up with a rocker for safety. Suddenly, a careless captain will throw an anchor near him and then pull all 850 km of cable with his anchor.

Excellent video showing the work of the plow

And another video that scare all owners of underwater cables.

The plow weighs almost 30 tons and can work at depths up to 1500 meters.

More detailed specifications can be seen on the website of the owner http://www.ktsubmarine.co.kr/eng/equipment/plough.asp

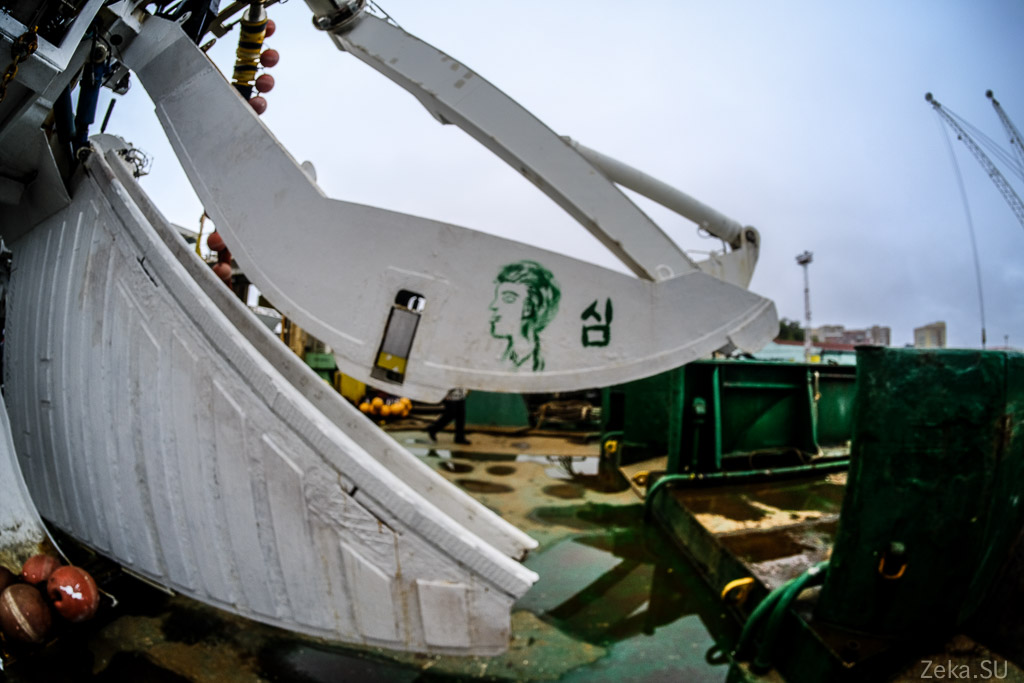

33. The plow in the front has two skis. They get up on the ground and he rides on a ski on a tether on these skis.

34. In its back is the canine. Fang digs into the ground and plows out a trench of a given depth. On the rear edge of the canine under the water in the trench cable is put through a special "tongue"

Above the canine is installed cameras, lighting and sensors to monitor the work process.

The picture is transferred to the operators on the deck.

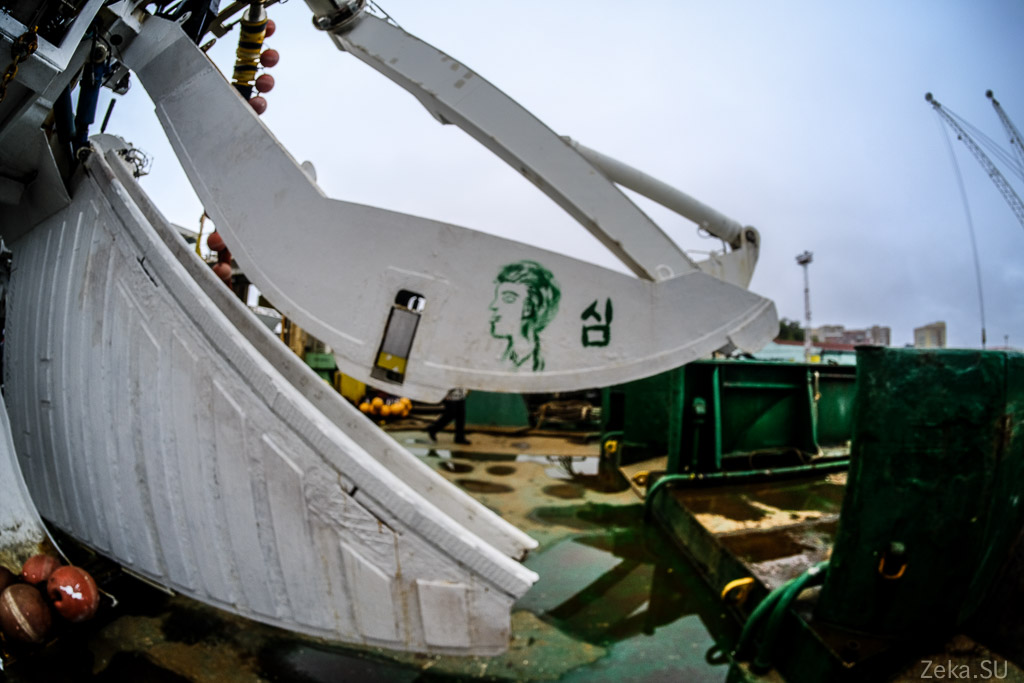

35. What a little green man is meant for is incomprehensible. But suppose that the plow has its own name in the ship’s role and everyone calls on it

36. "The tongue" which is responsible for feeding the cable into the trench. Can be lowered and raised adjusting the laying depth or cable tension

37. Close-up

38. Front view

39. Plow thing is complicated. Do you see a bunch of control hydraulics to lower the canine and the rear pair of skis?

40. Let's go upstairs. admire from a height. Prior to this, you are required to become familiar with TB.

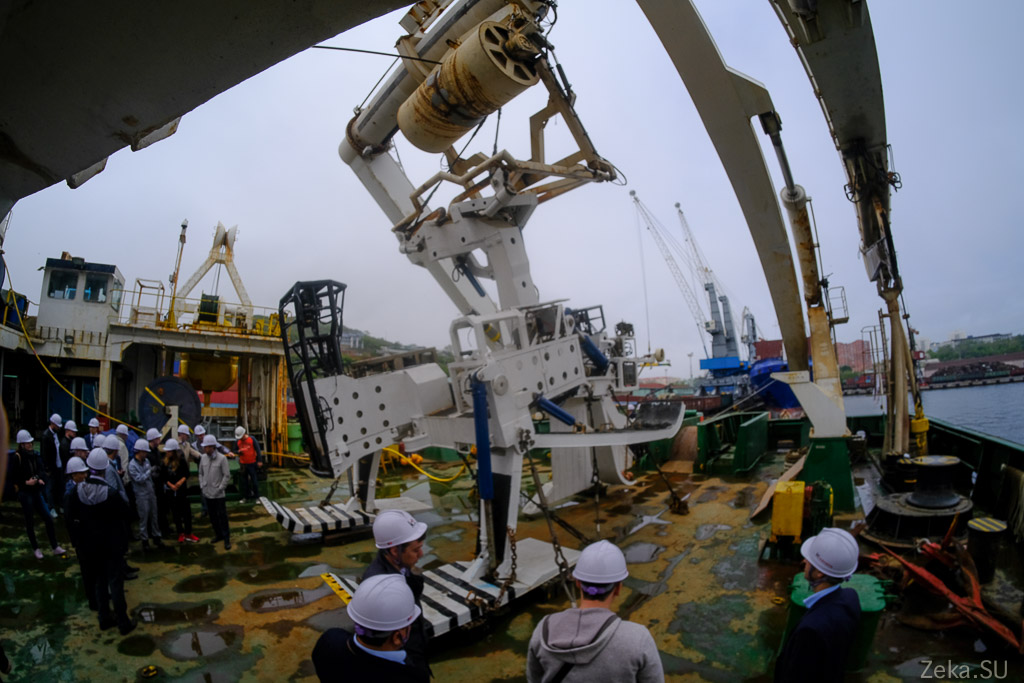

41. Plow top view. Those in white helmets are not with me.

42. Judging by the fresh color, the plow was recently cleaned up. I am sure that after work he is all dirty and rusty. There is some dirt left on the ski.

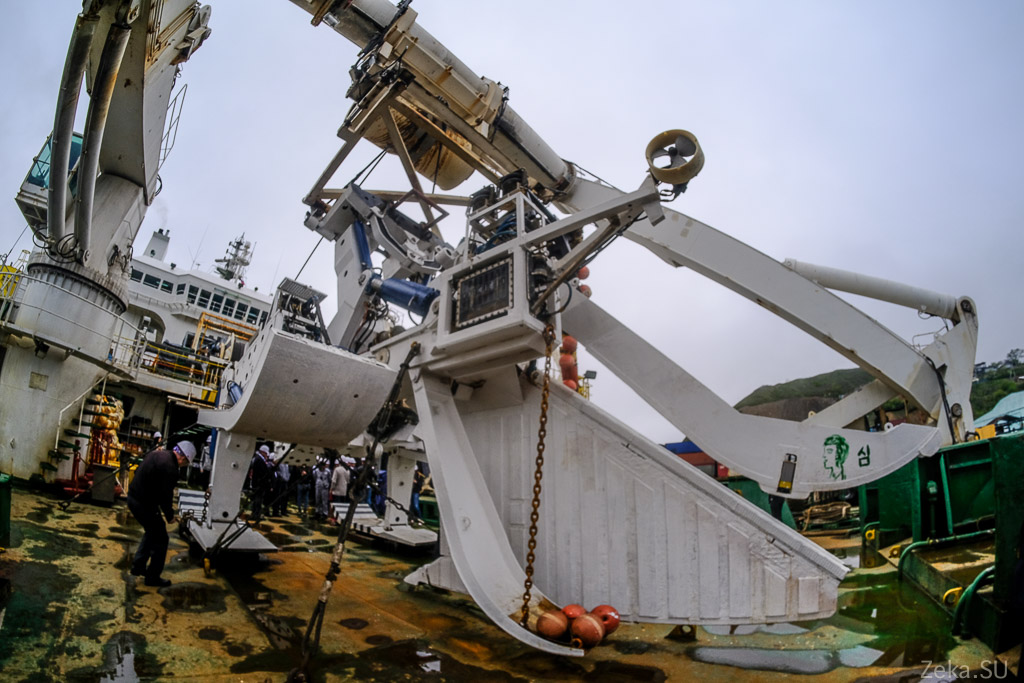

43. Above the plow there is a “portal” crane which throws the plow overboard. Alas, he did not fit into the frame

44. But this is clearer.

45. Additional crane

46.

An additional crane is required to work with other things besides the plow. Lifting the cable left on time from work.

Just imagine, you are laying the cable, and you face a storm. What to do? Winding 1000 km of cable?

No, everything is simple. Cut the cable on the place where they finished. We tie a float or 10 floats to it and leave it here. Themselves collect all the manat and swim away to a secure port. At the end of the storm, we float into place, winch the end of the cable on the floats and drag it onto the cable deck. There we cut, we attach our end and we continue laying. That's all.

48. And stocks of any floats we have in stock. Although these are more likely to put the cable on shore.

49. Stock anchors for securing floats in place

50. Okay, we digress. Here is the carrying cable for lowering the plow

51. On the upper deck there are containers for storing all sorts of small things.

52. The entrance to the cable deck is sealed in case of a storm

53. And this is the "drain" for the cable that goes to the depth

54. Perhaps we’ll finish the stern deck inspection and note that the local staff are very creative.

Here is a set of homemade and inexpensive anchors. I assume that they are disposable

Then we will go with the heart of the ship, in its control room ...

Actually from here all control is carried out

55. Starboard

56. Left side

57. Nose of the ship. Helipad. Under her dining room for the crew

58. Remote

59. There is a direct order. Everything is much better than on our courts of the Stone Age.

60. Place navigator

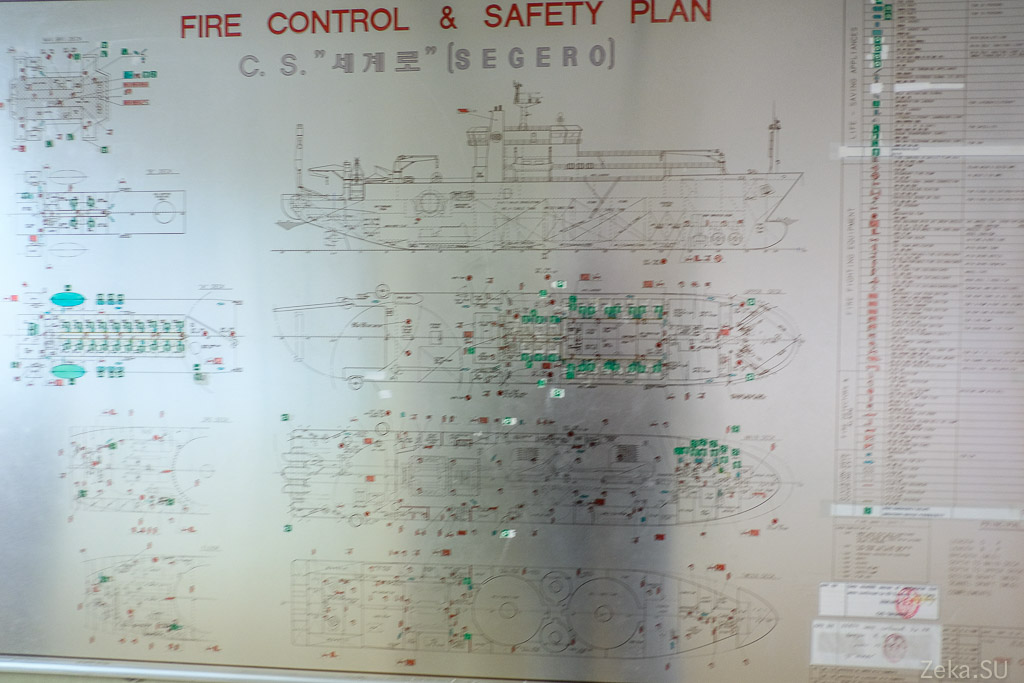

61. Scheme of the vessel. By the way, I lied to you. On the vessel there are not 2 cable tanks, but 4. On the lower scheme two additional smaller volumes are visible.

62. In the middle of the logging there is the most important place, without which problems could be aggravated. Great toilet. I went and checked. All clean

63

64. I was told in confidence that, in spite of a mess, toilets on Seghero are much cleaner than on KabelInnovator. Do you know this indicator

65. Separate control room for all deep-water operations. The heart of everything.

Here are the operators who manage all technological processes. plow work, cable feed

66. Radar positioning

67. Communication and all that is needed in one place.

68. Another secret card. Work Plans Where and where we are sailing. Where are we laying

69. The purpose of this equipment, alas, was not disclosed. Probably a commercial secret

70. Stern cabin control, outside view

71. Remote. So I understand a lot is duplicated from the front cabin

72. View of the aft deck

73. The plow crane and auxiliary cranes are visible.

Well, and for order, look into the cabin of the company-dining room for the crew. Alas, it is small and does not immediately accommodate all 60 crew members.

74. They were not allowed into the galley, but it is immediately obvious that here we have only Asians. Whole 3 rice cookers

75. Of the entertainment there is video and karaoke

Well, now leave the hospitable ship and look at it from afar.

Thanks for the hospitality of all.

76.

77. Parked in the commercial port

78. Feed equipment

79. Almost nothing on the nose

80

And a small video shot in Japan about the work of this vessel.

The work on laying the line with Vanino to Sakhalin was carried out in the summer of 2018, and then the ship went to Korsakov, refueled and went to the place of work in the Sea of Okhotsk.

By October, the laying work had already been completed and commissioning began.

Coast stations were connected to communication centers in Kurilsk, Yuzhno-Kurilsk, and Krabzavodsk. And the updated communication lines to the nearest settlements were laid: Hot Beach, Reidovo, Malokurilskoe. Alas, the remaining settlements are not yet connected due to their remoteness. But there is only a question of technology. It is necessary to lay ground optical cables and that's it. They promise that in 2019 Mendeleevo and Clear Airport will be connected to the fast Internet.

Alas, I do not have a roadmap.But since 2019, Rostelecom is launching a project to connect the last mile of fast Internet in villages up to 100 inhabitants. (there used to be up to 200) This is the Elimination of Digital Inequality project and it is possible that the project will include the rest.

In February, a group of high-ranking officials chose Shikotan and solemnly opened the Internet connection in state institutions. School, house of culture, rural administrations.

Alas, I did not find photos from the event on the Internet. Here is the only one. From the club of the village Krabzavodskoe - Shikotan.

Well, there is a report of the 1st channel. Show a little ship itself and even the rack in the communication node. The rest is any official.

https://www.1tv.ru/news/2019-02-26/361072-zhiteli_yuzhnyh_kuril_poluchili_dostup_k_vysokoskorostnomu_internetu

That's all. We would like to thank Rostelecom for the honor to visit such an interesting vessel.

10 years ago we were glad that the optical communication lines crossed the Tatar Strait, three years ago we admired the fact that we finished laying optics on Magadan, and a couple of years ago on Kamchatka.

And then came the turn of the South Kuriles.

')

This fall, optics came to three Kuril Islands. Iturup, Kunashir and Shikotan.

As usual, I tried, as far as it was in my power to follow this matter, and I will tell you that everything has already been laid , tested and officially put into operation a couple of weeks ago .

I was able at the invitation of Rostelecom to visit the ship, which led the work on the laying of the cable.

The customer was the state in the person of Rostelecom, the same as last time, the Huawei company became the performer.

But the cable laying vessel was already different.

Naturally, in the process of laying cable, there were some political problems with neighbors . But it seems nothing further protest notes went. Although the devil knows what the situation will reach there. But this is a matter of politics, we will probably keep silent about it.

Korean Segero 1998 release.

Specification of the vessel on the site .

Anyone interested in other cable laying machines is an excellent selection for you to admire .

In 2017, the same team that built the line to Magadan and Kamchatka, conducted reconnaissance work in the Sea of Okhotsk on our hydrographic vessels, and in 2018 in May, the ship arrived in Vladivostok, took the team and technical specialists and went to the area of work for direct laying.

You had a unique opportunity to walk along the ship with a cable layer and see what and how.

Alas, no one else will tell you this, as last time, in the story about another Cable-laying machine .

+++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++++++++++++++++++++++++

If you do not know or have forgotten how the laying of underwater communication lines is conducted, then I will remind you, the stages of work on laying underwater communication lines:

1 Research and design

At this stage, the bottom of the sea is investigated, or ready-made materials from previous studies are taken. Depending on the relief of the bottom, the route is built. Naturally, current communications at the bottom are taken into account. But the benefit is that the Sea of Okhotsk is not rich in underwater pipelines and underwater optical highways, well, except that the secret communication cables of the Pacific Fleet to which enemy submarines listen .

A hydrographic vessel is brought to the site of work and a study of the day, the relief and the determination of cable exit points on the shore ashore are carried out.

2 Cable manufacturing and loading

The cable is made immediately solid coil, so that under ideal conditions, it can be laid from beginning to end, and loaded onto the ship. At the production stage, erbium amplifiers EDFA (Erbium Doped Fiber Amplifier), a fiber-optic amplifier on an erbium-doped optical fiber, are immediately incorporated into the cable.

Due to the fact that Russia does not have such civilian ships, the manufacture of the cable and its installation were entrusted to Huawei.

Huawei does not have its own fleet and for this reason hired a subcontractor kt submarine, a Korean company that specializes in underwater work.

3 gasket

It's simple. At the bottom, from the ship, they lower the plow and turn the small one forward. He digs a trench, a cable is buried in it.

The only difference with the picture is that there is a couple of kilometers under the ship.

Here is another informative video:

4 Connect to shore

If everything went well and the cable reached from shore to shore, then it was connected to the coast station. To do this, at the connection point, the cable is thoroughly buried in the bottom so that it is not washed by the sea, they are flooded with stones. Connect the earth's end with the sea.

This is how it looks close:

5 Testing and commissioning

After the work is finished, they stick the wires, measure the losses, start the connection. If everything works, connect consumers. Usually they run at minimum speed, but in the cable there are usually additional conductors, which later on, when replacing equipment, large volumes of traffic transmission can be launched. Well, again, the reserve, which suddenly breaks.

In the description of the process, any coordination of money and work is omitted, but in our case it is no longer very important.

+++++++++++++++++++++++++++++++++++++++++++++++++ +++++++++++++++++++++++++++++++++++++++

Cable laying machine Segero

1 And now, you and I will step on board the ship Seghero and walk a little.

2 The first thing we have to do is ... yes, that's right, we will put on the means of protection in order not to hit our head where it is not necessary.

3 I last time did not think about how to immerse the cable on the ship. It turns out there is a special "filling neck". I honestly thought just through the open door in the board.

The main distinctive modules of the cable handler are

- Cable deck. It makes all the work with the cable. Cutting, fixing, cable transfer to the outside and so on. On the cable deck is to separately allocate wet storage amplifiers. (Underwater signal boosters must be stored in a humid environment). “Clean room” - required for cable welding work. X-ray cabinet - to check the quality of connections.

- Cable tanks. Tanks in the form of barrels where they store stocks of cable.

- Aft deck with cranes and laying tools. They usually place scuba equipment for gaskets and cranes to control this heavy equipment. Also control panels.

- Own underwater equipment plow and additional underwater robots.

- Additional stern cabin. Since it is often required to position a ship very precisely at sea during operations, it usually has a double cabin, front and rear. So that the helmsman could control the process from all sides.

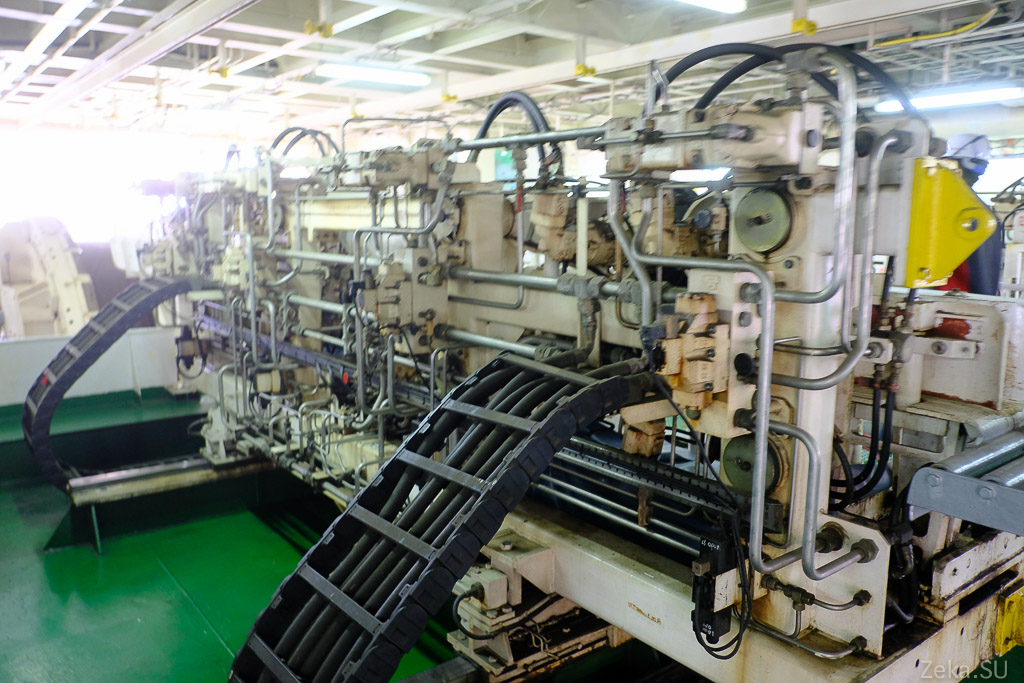

The rest is the same as other ships, engine, cabins, galley, dining room. The only thing is, for convenience, on such vessels there are a lot of different thrusters and automations for millimeter accuracy in keeping the vessel in place.

Let's go in order.

Cable Deck

4. These mechanisms are conveyors for the transfer of cable from tanks to the stern.

5. Rollers for cable pulling

6

7. At the same time, you can simultaneously feed two cables from 2 tanks

eight.

9. I do not know what to call it, but the type of cable channels. Cables are traveling along them.

10. On the deck itself store signal amplifiers.

11. Alas, there is apparently no wet chamber on board. The storage scheme is implemented by the method of "Wet rag"

12.

This is a direct disappointment compared to the other cable layer I was able to visit. You can go and compare yourself http://zeka.su/2016/07/11/3406/

How do signal amplifiers work

Amplifiers are most often made on the basis of doping fiber with a rare-earth element erbium.

An additional high power laser beam, but different from the frequency of the laser transmitting information, is inserted into the fiber and causes the erbium atoms in the amplifier to go into an excited unstable state. When a photon of laser radiation weakened by a long fiber road with useful information collides with this atom, it receives energy from this excited atom and is re-emitted with a new force and flies farther, rather, it is re-emitted in the form of 2 quanta and useful photons become larger.

This is all if explained on the fingers, will be so.

Tennis balls are thrown into the pipe on which information is recorded and they fly through the pipe from point A to point B. The pipe is long, and when experiencing air resistance they slow down and may not reach the end of the pipe.

But close along a parallel pipe, air is pumped at high speed, and it causes the wheel blades to turn quickly like a water-mill, or a paddle steamer, located somewhere in the middle of the pipe.

Having flown to this wheel, tennis balls get this wheel on the ass, like a tennis racket and with new forces fly further ... another 80km =)

Who is interested in reading a normal and useful article on this topic , well, or Wikipedia .

Sorry for the confusion, but I'm not very strong in these matters.

But in more detail it is possible to esteem on Habré in kammentah

13. Also on this deck is the storage of additional equipment for laying. Couplings, adapters and so on. In short a lot of raskhodki

14. Here you can go to sea =)

15. Here are the suspicious boxes that interested me.

16. This is just an optical coupling for installation in a shoreline switching cabinet. This is the very end of the cable. The terminal equipment will already be connected to it. In the clutch it is just clear that 4 wires have been bred.

17. Alas, I do not know what it is, but also probably spare parts and other parts.

18. Visual aids on piling

There are of course two cable tanks on the cable deck.

19. They are 850 km of cable + stock.

20. The second repository

21. the tank walls are rounded so that the cable slides and does not fray

Now look at the "clean room". There are works on cutting the cable, welding optics and installing couplings, amplifiers and so on.

22. Workbench. Pay attention to homemade reels for materials

Tools and a bunch of all electrical tape.

23. Welding machine

How it works you can see here or here .

24. The bed for mounting the coupling. This is a rather large and heavy construction.

25. Alas, I do not know what it is, but I assume that the terminal equipment for the ground station

26. X-ray equipment for testing manufactured underwater couplings. You understand that it is better to check 30 times, than to fiddle around with getting a cable and making a new clutch a month later

Now we will see how the pros work and how durable this submarine cable is.

Workers divide the end of the cable to install the coupling on it

27.

28. First, unstuck the plastic multilayer insulation.

29. Cable device. The top layer is plastic waterproofing. Further - the power bearing steel cables. Below them is a layer of polyethylene insulation. Inside the copper flexible tube. And in it already go optical fibers

30. I was not given rest here. There is a skin for stripping cable, and saws in the form of strings.

This string is convenient to cut plastic shells.

31. But to open the power steel frame it is necessary to use heavier artillery. Impeller and a few minutes of hard work

32. What is surprising about local workers is some disregard for TB. I hope nothing bad happened to them.

Well, and some technical details.

It seems to lay the wire - nothing complicated. Here I found a picture of how much any equipment you need to install on the cable before laying. Naturally, most of all you need to install on the longest cable - Sakhalin - Iturup (top line). Next, the cable goes to Kunashir, and then to Shikotan.

By the way, an additional project of this ship was the laying of a new communication line connecting Sakhalin with the mainland. The cable was laid through the Tatar Strait from Vanino to Uglegorsk. But there is a small communication line in comparison with the others.

With the cable deck we are done. Come on the stern and see the scuba equipment.

Aft deck

The only deep-water unit on this vessel is a plow.

The plow is lowered on the cable to the bottom and stretches behind the moving ship like an ordinary plow across the field after a horse. In the process of moving from the top to the team, the plow deepens its working canine into the bottom and digs a trench there to a depth of one meter. A channel passes through the canine cable and our cable is immediately in the trench. Which can be immediately filled up with soil.

Of course, this scheme may not work on rocky massifs in the coastal strip, but in the ocean itself at the bottom is usually quiet and the bottom is the deposition of soft sedimentary rocks or even silt. In such soils plow can dig at the maximum depth of the knife. If the cable is left lying on top, it can be damaged. For example, if someone from the fishermen or scientists will trail the animals from the bottom or the shark will get too nervous. There are many examples. In shallow water where there is active shipping, the cable has to be additionally filled up with a rocker for safety. Suddenly, a careless captain will throw an anchor near him and then pull all 850 km of cable with his anchor.

Excellent video showing the work of the plow

And another video that scare all owners of underwater cables.

Plow

The plow weighs almost 30 tons and can work at depths up to 1500 meters.

More detailed specifications can be seen on the website of the owner http://www.ktsubmarine.co.kr/eng/equipment/plough.asp

33. The plow in the front has two skis. They get up on the ground and he rides on a ski on a tether on these skis.

34. In its back is the canine. Fang digs into the ground and plows out a trench of a given depth. On the rear edge of the canine under the water in the trench cable is put through a special "tongue"

Above the canine is installed cameras, lighting and sensors to monitor the work process.

The picture is transferred to the operators on the deck.

35. What a little green man is meant for is incomprehensible. But suppose that the plow has its own name in the ship’s role and everyone calls on it

36. "The tongue" which is responsible for feeding the cable into the trench. Can be lowered and raised adjusting the laying depth or cable tension

37. Close-up

38. Front view

39. Plow thing is complicated. Do you see a bunch of control hydraulics to lower the canine and the rear pair of skis?

40. Let's go upstairs. admire from a height. Prior to this, you are required to become familiar with TB.

41. Plow top view. Those in white helmets are not with me.

42. Judging by the fresh color, the plow was recently cleaned up. I am sure that after work he is all dirty and rusty. There is some dirt left on the ski.

43. Above the plow there is a “portal” crane which throws the plow overboard. Alas, he did not fit into the frame

44. But this is clearer.

45. Additional crane

46.

An additional crane is required to work with other things besides the plow. Lifting the cable left on time from work.

Just imagine, you are laying the cable, and you face a storm. What to do? Winding 1000 km of cable?

No, everything is simple. Cut the cable on the place where they finished. We tie a float or 10 floats to it and leave it here. Themselves collect all the manat and swim away to a secure port. At the end of the storm, we float into place, winch the end of the cable on the floats and drag it onto the cable deck. There we cut, we attach our end and we continue laying. That's all.

48. And stocks of any floats we have in stock. Although these are more likely to put the cable on shore.

49. Stock anchors for securing floats in place

50. Okay, we digress. Here is the carrying cable for lowering the plow

51. On the upper deck there are containers for storing all sorts of small things.

52. The entrance to the cable deck is sealed in case of a storm

53. And this is the "drain" for the cable that goes to the depth

54. Perhaps we’ll finish the stern deck inspection and note that the local staff are very creative.

Here is a set of homemade and inexpensive anchors. I assume that they are disposable

Then we will go with the heart of the ship, in its control room ...

Cutting

Actually from here all control is carried out

55. Starboard

56. Left side

57. Nose of the ship. Helipad. Under her dining room for the crew

58. Remote

59. There is a direct order. Everything is much better than on our courts of the Stone Age.

60. Place navigator

61. Scheme of the vessel. By the way, I lied to you. On the vessel there are not 2 cable tanks, but 4. On the lower scheme two additional smaller volumes are visible.

62. In the middle of the logging there is the most important place, without which problems could be aggravated. Great toilet. I went and checked. All clean

63

64. I was told in confidence that, in spite of a mess, toilets on Seghero are much cleaner than on KabelInnovator. Do you know this indicator

65. Separate control room for all deep-water operations. The heart of everything.

Here are the operators who manage all technological processes. plow work, cable feed

66. Radar positioning

67. Communication and all that is needed in one place.

68. Another secret card. Work Plans Where and where we are sailing. Where are we laying

69. The purpose of this equipment, alas, was not disclosed. Probably a commercial secret

70. Stern cabin control, outside view

71. Remote. So I understand a lot is duplicated from the front cabin

72. View of the aft deck

73. The plow crane and auxiliary cranes are visible.

Well, and for order, look into the cabin of the company-dining room for the crew. Alas, it is small and does not immediately accommodate all 60 crew members.

74. They were not allowed into the galley, but it is immediately obvious that here we have only Asians. Whole 3 rice cookers

75. Of the entertainment there is video and karaoke

Well, now leave the hospitable ship and look at it from afar.

Thanks for the hospitality of all.

76.

Appearance

77. Parked in the commercial port

78. Feed equipment

79. Almost nothing on the nose

80

And a small video shot in Japan about the work of this vessel.

Progress

The work on laying the line with Vanino to Sakhalin was carried out in the summer of 2018, and then the ship went to Korsakov, refueled and went to the place of work in the Sea of Okhotsk.

By October, the laying work had already been completed and commissioning began.

Coast stations were connected to communication centers in Kurilsk, Yuzhno-Kurilsk, and Krabzavodsk. And the updated communication lines to the nearest settlements were laid: Hot Beach, Reidovo, Malokurilskoe. Alas, the remaining settlements are not yet connected due to their remoteness. But there is only a question of technology. It is necessary to lay ground optical cables and that's it. They promise that in 2019 Mendeleevo and Clear Airport will be connected to the fast Internet.

Alas, I do not have a roadmap.But since 2019, Rostelecom is launching a project to connect the last mile of fast Internet in villages up to 100 inhabitants. (there used to be up to 200) This is the Elimination of Digital Inequality project and it is possible that the project will include the rest.

In February, a group of high-ranking officials chose Shikotan and solemnly opened the Internet connection in state institutions. School, house of culture, rural administrations.

Alas, I did not find photos from the event on the Internet. Here is the only one. From the club of the village Krabzavodskoe - Shikotan.

Well, there is a report of the 1st channel. Show a little ship itself and even the rack in the communication node. The rest is any official.

https://www.1tv.ru/news/2019-02-26/361072-zhiteli_yuzhnyh_kuril_poluchili_dostup_k_vysokoskorostnomu_internetu

That's all. We would like to thank Rostelecom for the honor to visit such an interesting vessel.

Source: https://habr.com/ru/post/444474/

All Articles