Parsing PTZ cameras: what's inside and how it works

Today we prepare a PTZ camera and examine its iron components in detail in order to understand the principle of operation.

Before cutting, let's see a little

How to make video chatting comfortable enough for the participants to perceive it as living? This effect can be achieved if the camera captures not only the general plan of the room, but also a specific participant. Transitions between scenes should be fast and smooth so that communication does not cause discomfort and does not distract participants from the discussion of working issues.

How to achieve this? There are a couple of options:

- programmatically cut (and in our non-sprinkle) from the general plan, which is captured by the camera, the necessary part of the image;

- or install a PTZ camera. They come with mechanical or magnetic drives.

I could not find the camera with magnetic drives. But the cameras with the mechanics around - a dime a dozen. I also analyzed the modern and widely used model of PTZ FullHD cameras in the Russian Federation in order to understand how the logic and principle of work changed during 10 years of progress and development. So let's get started!

Tandberg - HD Precision Camera TTC8-01

So, we begin with a very common PTZ camera from the Norwegian company Tandberg. It was this camera that migrated to the Cisco Telepresence lineup without any significant changes and was sold until the early 2010s.

')

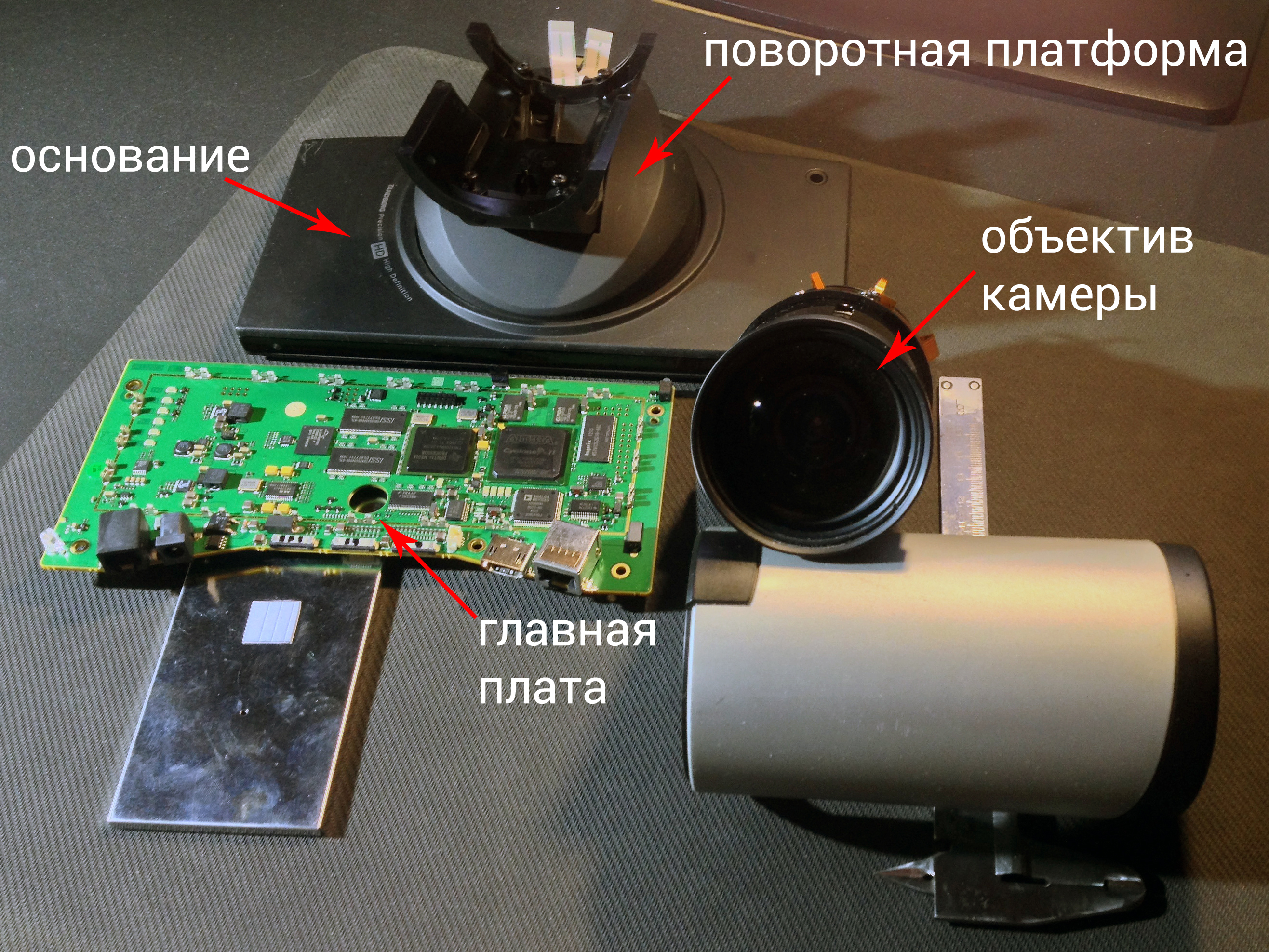

At one time, Tandberg made premium PTZ cameras, and this is told to us by a strict, concise design with a predominance of metal parts of the body.

Externally, Tandberg looks quite understandable - the optics and the matrix are placed in the silver tube, and the moving mechanisms are connected to the camera with the base.

Zoom: 7x optical

Matrix: 1/3 "CMOS

Minimum focal length: 0.3 m

Viewing angle: 42 0

Horizontal rotation angle: 180 0 (+90 0 ..- 90 0 )

Vertical inclination angle: 30 0 (+10 0 ..- 20 0 )

The massive metal base adds stability to the chamber and reliably protects the main board with electronics from external influences. It is on this basis that the turntable is located.

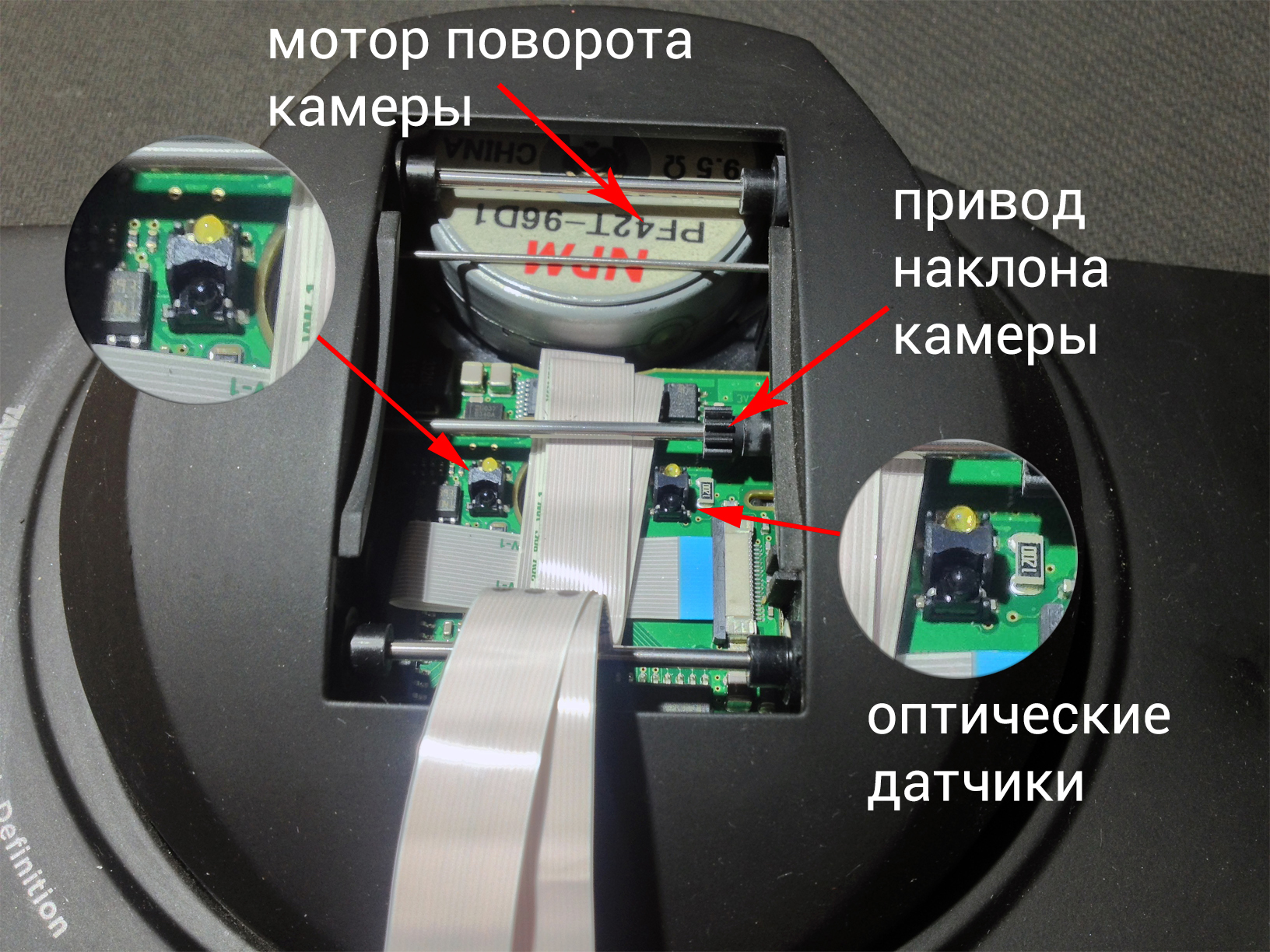

The bed of the camera rolls on special rollers located inside the moving platform. The operation of this mechanism resembles balancing a circus acrobat on metal cylinders.

In motion this node is driven by an ordinary electric motor with a gear wheel, along which the chamber bed rolls. To show the work of this mechanism, I had to uncover the good old Autodesk Fusion.

Optical sensors, which determine the angle of inclination of the reflected light from the marks, are called to monitor the collector motor at each moment of time. To do this, on the inner sides of the toothed racks, two special plates are installed, which form interruptions of reflected light, which determine the angle of inclination of the camera.

In order for the low-powered collector motor to cope with the heavy optics of the camera, the lens is balanced so that the center of gravity coincides with the axis of the motor. The massive load in the back of the camera provides the very balance.

In order for the low-powered collector motor to cope with the heavy optics of the camera, the lens is balanced so that the center of gravity coincides with the axis of the motor. The massive load in the back of the camera provides the very balance.

Under the dome is another drive motor that turns the camera left and right. However, it is structurally different from the collector in that the shaft turns in small steps (1 step = 3.750), that is, for one full revolution, 3600 / 3.750 = 96 steps are required. Also, an additional bonus is to keep the shaft in a predetermined position.

To stabilize the image of a PTZ camera, there are mechanisms to hold a given position, which means that if you direct the camera to the other side with your hands and perseverance, the plastic parts inside the camera will very quickly fail (if not immediately).

This rule holds true for the camera off. If you do not go into the subtleties of theoretical mechanics, then we can say that plastic gears can transmit rotation from the motor to the camera nodes, and not vice versa.

And the most important thing - about the camera. Structurally, it looks like a reflex camera, only without pentaprism and a mirror. The focal length is regulated by a collector motor and mechanical gears: these are, of course, not ultrasonic motors of modern “DSLRs”, but the small weight and dimensions for a stationary camera are not at all the key indicators.

Electronics

The digital signal processor from Texas Instruments with advanced computing power at the beginning of the 2000s, capable of performing nearly 6 billion instructions per second, drives all tasks. At that time, it was an advanced solution in SoC format (System on the Chip), which implemented a multi-level L1 / L2 cache, 64-bit interface to external RAM, 10/100 Mbps Ethernet, 3 video ports with support for several permissions, as well as the management of other peripherals.

The digital signal processor from Texas Instruments with advanced computing power at the beginning of the 2000s, capable of performing nearly 6 billion instructions per second, drives all tasks. At that time, it was an advanced solution in SoC format (System on the Chip), which implemented a multi-level L1 / L2 cache, 64-bit interface to external RAM, 10/100 Mbps Ethernet, 3 video ports with support for several permissions, as well as the management of other peripherals.

The next advanced chip of its time - Altera Cyclone 2. In fact, this is an ordinary FPGA (programmable logic integrated circuit). Device manufacturers can program such schemes for any task, from servo control to transferring memory data.

The next advanced chip of its time - Altera Cyclone 2. In fact, this is an ordinary FPGA (programmable logic integrated circuit). Device manufacturers can program such schemes for any task, from servo control to transferring memory data.

The HDMI interface of version 1.3 is implemented by the AD9889B chip supporting FullHD (1080p) resolution with protection of the transfer of media content using HDCP v technology. 1.2.

The HDMI interface of version 1.3 is implemented by the AD9889B chip supporting FullHD (1080p) resolution with protection of the transfer of media content using HDCP v technology. 1.2.

The remaining components are memory modules and passive radio components designed to operate the main components.

Subject number 2: leverMic 1012w

Zoom: 12x optical

Matrix: 1 / 2.8 ″ CMOS HD sensor

Minimum focal length: 0.3 m

Viewing angle: 72.5 0

Angle of rotation across: 340 0 (+170 0 ..- 170 0 )

Vertical tilt angle: 120 0 (+90 0 ..- 30 0 )

The camera body is entirely made of plastic and has a wide and stable base. The front of the camera are IR receivers for the remote control, and the rear are the interface connectors. The weight of the camera is small: I suppose that you can hang it in the armstrong on the ceiling or fix it on a plasterboard partition.

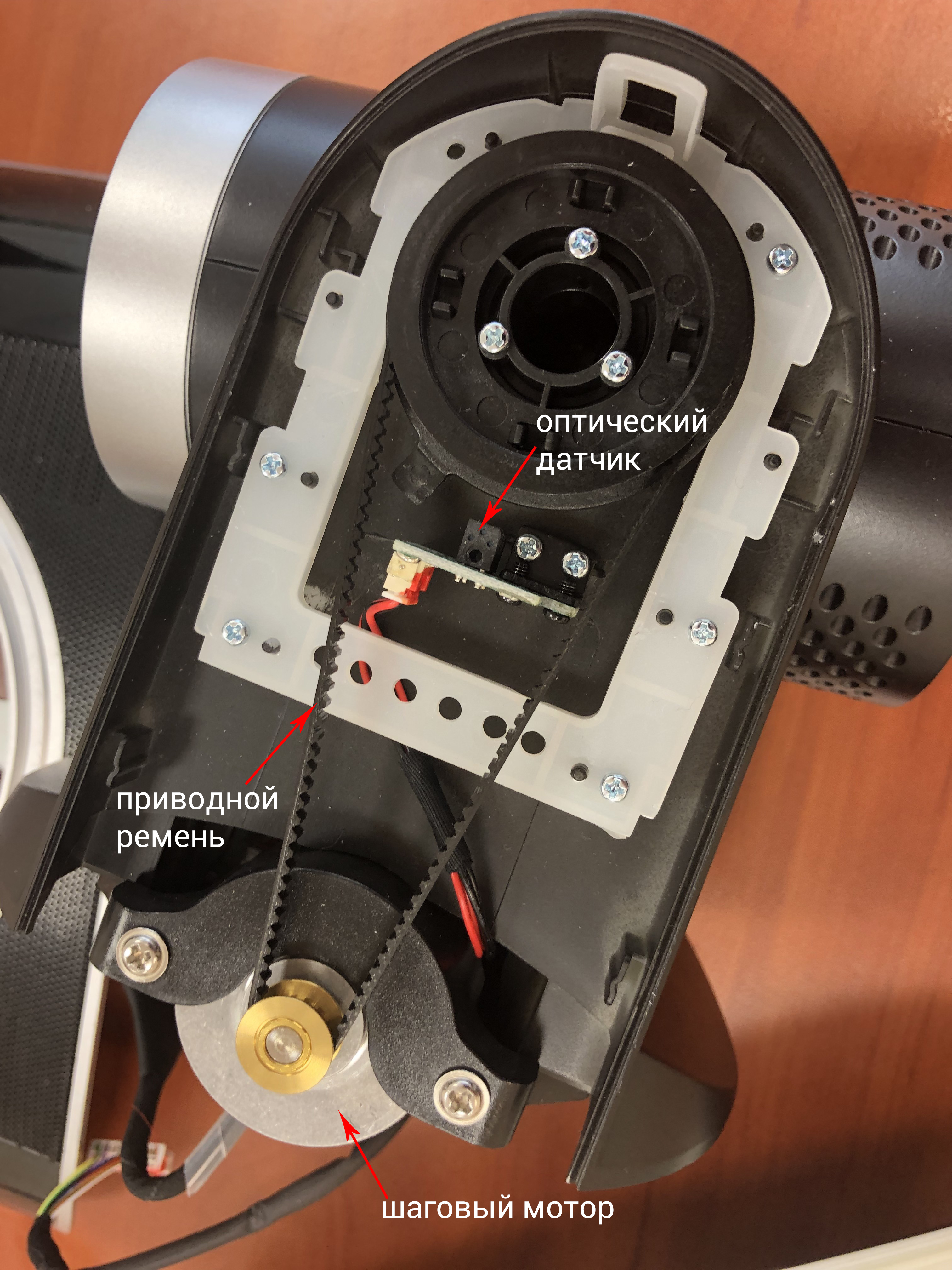

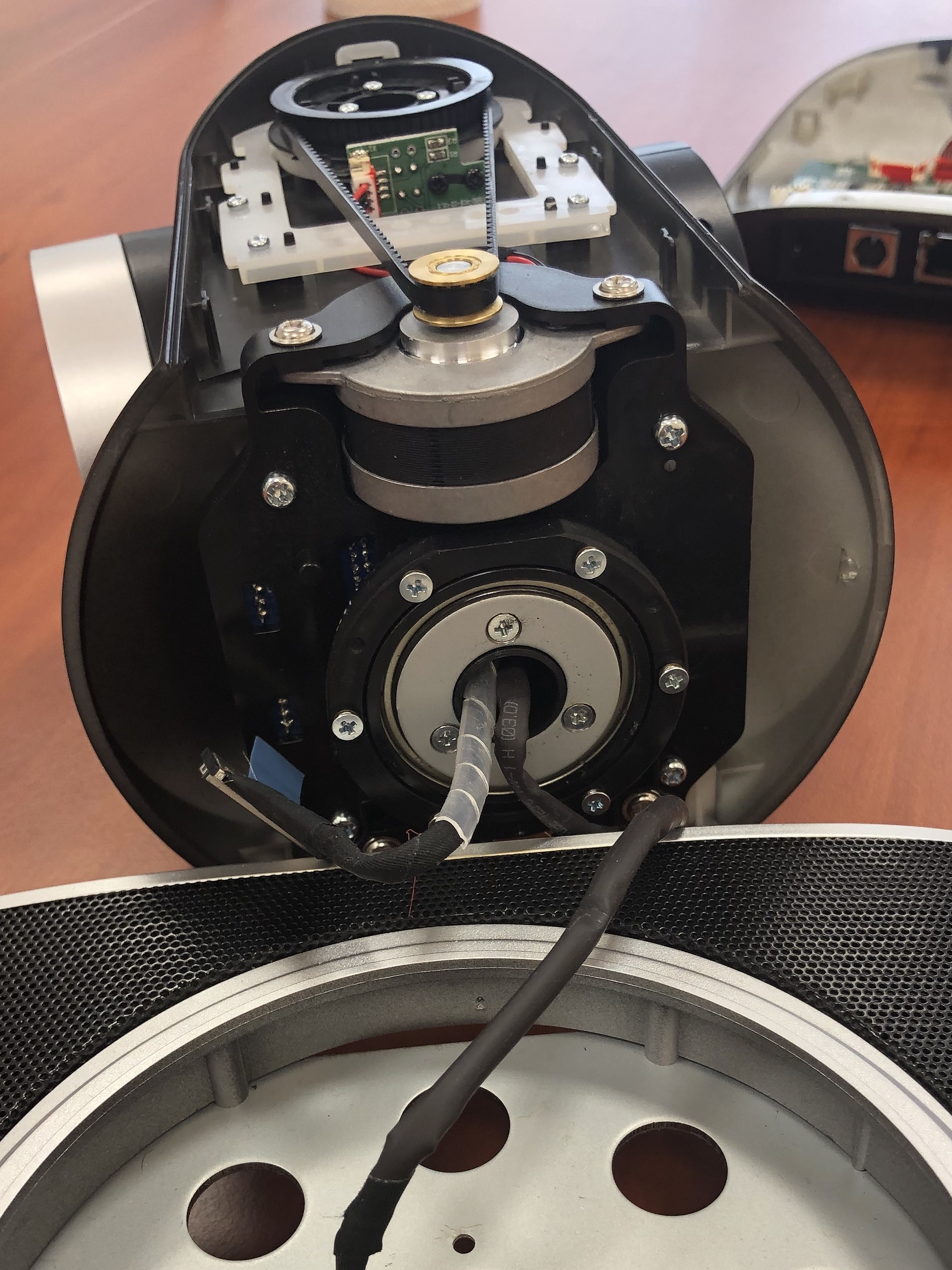

The axes of movement are organized much simpler and clearer than those of Tandberg; stepping motors work as the driving force, transmitting torque to the driving pulleys.

The movable platform has 2 hollow racks, between which the camera is fixed, in the cavity of one of the racks the drive mechanism is hidden, due to which the angle of inclination changes.

A little below the drive pulley is the optical sensor. This limit switch is needed to determine the position of the camera after switching on.

When starting the lens tilts down, and when a special spike interrupts the flow of light in the optical sensor, the system realizes that the lowest point has been reached. All further positioning is done by counting the steps.

The motor turning the camera left and right is hidden behind a mating flange with 6 screws, equipped with the same limit switch to determine the horizontal position of the camera.

Since the mating flange is fixed, there are 2 cables in the center: for controlling the motors and a loop from the digital matrix.

As we can see, the mechanical gear system entirely consists of powerful stepping motors, which makes camera positioning more accurate and fast, and belt drives reduce the device's own noise level.

Camera electronics is very similar, so let's talk about obvious differences. Of the new products, USB3.0 and RS-232 appeared, with the help of which you can get video in compressed form, as well as collect a whole cascade of similar cameras and through UART (RS232) fully automate their guidance to conference participants.

IMHO

As you can see, a modern PTZ camera is more reliable in design, has a better sensor and is versatile in connection methods, but otherwise is not far from its predecessor. In addition to one - the price, which was 5 times lower. Therefore, today we see more and more PC-equipped meeting rooms where this PTZ beast has already ceased to be exotic.

Source: https://habr.com/ru/post/444286/

All Articles