Metal processing on CNC machines: how to start producing world-class products?

I present to your attention an article on the topic of digitization of production and production of a new generation. The material will discuss CAD-CAM-system as an important component of competitive production. As an example, I will talk about one of these systems - Solid Edge + Solid Edge CAM Pro.

Is it important for you to significantly increase efficiency, reduce the time for design + production? Is the article sufficiently elaborated or is it better to dwell on something? I would be grateful for the feedback.

According to the analytical report , Russian engineering products are characterized by a low level of competitiveness in the global market. The explanation is in the problems experienced by the industry. We list the main ones:

At the same time, technology initiatives of industrialized countries, as indicated in the same report , are aimed primarily at accelerating the transition to new generation products, which are based on the Internet of Things technology (IoT), the introduction of automation systems and big data analysis. .

')

Leading companies in the industry are investing in technology — advanced equipment and processing technology — and production process control systems (MES systems).

Over the past three years, the most effective investments in the industrial sector have become investments in:

The digitalization of engineering and the transition to life cycle contracts will allow enterprises to advance in solving the problem of increasing the share of competitive products. It is estimated that with the new approach, the output of such products will increase from the current 16% to 30% by 2025 and to at least 50% by 2030.

The global industrial concern Siemens AG implements its digitalization strategy using software from Siemens PLM Software. According to experts of the latter, an engineering company, in order to increase competitiveness, should solve the following tasks:

As the practice of the leading companies in the industry has shown, consistently solving these problems is an inefficient and long process. An integrated approach and implementation of a CAD-CAM system is required, which manages all stages of the product manufacturing - from design to finished part.

A key feature of the digitalization of the production process is the ability to design not only the technical and functional characteristics of the product, but also the production and operation processes to meet market requirements. For this purpose, a physical product, its mathematical (software) model (the so-called digital twin, digital twin) are being developed to control product production and automatic monitoring.

As a result of the implementation of the system, the development process becomes more flexible: design engineers improve products, specialists optimize control processes, software technologists check strategies and choose the best way to manufacture products.

Consider the main drivers that reduce the complexity of programming, reduce processing time and the wear of CNC machines and, as a result, lead to an increase in output.

Value drivers along the entire process chain:

The main results of applying an effective CAD-CAM system:

See how to create control programs for turning and milling in Solid Edge CAM Pro will be at the next webinars.

Further, I will talk in general about the features and advantages of the CAM system.

Solid Edge CAM Pro, based on NX CAM, is part of the Siemens PLM Software solution line with Solid Edge . The software solution provides a wide range of functional capabilities, from biaxial milling and high-speed machining to programming of multifunctional machines and 5-axis milling.

CNC machine programmers can use Solid Edge CAM Pro to solve problems with different machining requirements — milling, drilling, turning and EDM.

Using synchronous technology, you can directly edit part models and prepare them for creating programs for CNC machines, including machining of blind holes and gaps, offset surfaces, as well as changing the dimensions of the part elements.

Solid Edge CAM Pro uses the concept of a master model to provide end-to-end design and development of programs for an NC by binding all CAM functions to a single model defining the geometry of the part. As a result, the programmer can start developing a program for a CNC machine without waiting for the designer to finish working. Full associativity provides a subsequent update of the control program operations for the CNC machine when the model geometry changes.

Solid Edge CAM Pro is a tool for manufacturers who “build” a digital workshop or plan to upgrade equipment. Using this system, the user can create optimal processing programs on CNC machines for models created in Solid Edge and models created in third-party CAD-formats, reduce production costs, improve the quality of manufactured products.

The introduction of Solid Edge + Solid Edge CAM Pro is a significant step towards the digitization of business processes and the growth of product competitiveness.

At the webinar on March 19, you can learn how to quickly start working in Solid Edge CAM Pro (after the end of the recording will be available for download).

Is it important for you to significantly increase efficiency, reduce the time for design + production? Is the article sufficiently elaborated or is it better to dwell on something? I would be grateful for the feedback.

Metalworking in the 21st century - challenges and opportunities

According to the analytical report , Russian engineering products are characterized by a low level of competitiveness in the global market. The explanation is in the problems experienced by the industry. We list the main ones:

- the decline in consumption in the domestic market, which began in 2014;

- increase the proportion of worn-out machines;

- lagging behind developed countries in the proportion of CNC machines;

- low level of optimization and automation of production and business processes of enterprises.

At the same time, technology initiatives of industrialized countries, as indicated in the same report , are aimed primarily at accelerating the transition to new generation products, which are based on the Internet of Things technology (IoT), the introduction of automation systems and big data analysis. .

')

Leading companies in the industry are investing in technology — advanced equipment and processing technology — and production process control systems (MES systems).

Over the past three years, the most effective investments in the industrial sector have become investments in:

- multifunctional machining centers;

- Five-axis / universal processing used in the high-precision machining market;

- quick change tool / mount;

- high speed machining (HSM);

- software (software) for creating, simulating and checking control programs for CNC machines (hereinafter - UE).

The digitalization of engineering and the transition to life cycle contracts will allow enterprises to advance in solving the problem of increasing the share of competitive products. It is estimated that with the new approach, the output of such products will increase from the current 16% to 30% by 2025 and to at least 50% by 2030.

Highly automated CAD-CAM-system for solving engineering problems

The global industrial concern Siemens AG implements its digitalization strategy using software from Siemens PLM Software. According to experts of the latter, an engineering company, in order to increase competitiveness, should solve the following tasks:

- ensure maximum equipment load and reduce setup time;

- implement the collection of information on products and processes for the control and management of tooling and devices together with the details of the product based on templates;

- implement a simulation of the 3D model processing trajectory to simulate the kinematics of the machine and simulate the tool path;

- reduce programming time, implement automation of the creation of UE for processing standard elements (such as holes, for example);

- reduce processing time; introduce new processing strategies.

As the practice of the leading companies in the industry has shown, consistently solving these problems is an inefficient and long process. An integrated approach and implementation of a CAD-CAM system is required, which manages all stages of the product manufacturing - from design to finished part.

A key feature of the digitalization of the production process is the ability to design not only the technical and functional characteristics of the product, but also the production and operation processes to meet market requirements. For this purpose, a physical product, its mathematical (software) model (the so-called digital twin, digital twin) are being developed to control product production and automatic monitoring.

As a result of the implementation of the system, the development process becomes more flexible: design engineers improve products, specialists optimize control processes, software technologists check strategies and choose the best way to manufacture products.

Advantages of using CAD-CAM-system

Consider the main drivers that reduce the complexity of programming, reduce processing time and the wear of CNC machines and, as a result, lead to an increase in output.

Value drivers along the entire process chain:

The main results of applying an effective CAD-CAM system:

- Increased productivity and work efficiency due to:

- process templates and automation;

- reuse of processing tools and technologies;

- traceability "detail> process> manufacturing".

- Increase asset utilization by:

- reduce set-up time;

- the use of multifunctional machining centers, simulation in G-codes, interaction with the CNC rack.

- Optimization of operating expenses due to:

- reduce inventory through tool management;

- reduce tool costs;

- use of the tool in the CAM-system, tracking the lifetime of the tool.

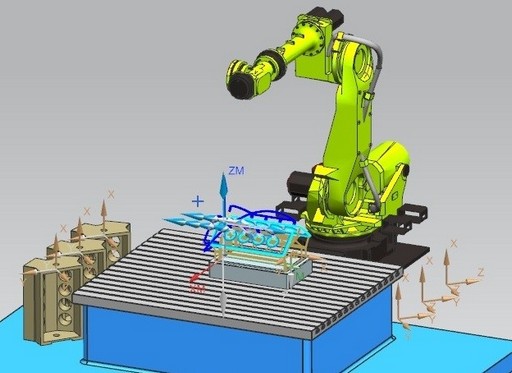

- Automation and production flexibility due to:

- support for deserted industries;

- use of production data analysis systems.

Solid Edge + Solid Edge CAM Pro: Siemens PLM Software's CAD-CAM system

See how to create control programs for turning and milling in Solid Edge CAM Pro will be at the next webinars.

Further, I will talk in general about the features and advantages of the CAM system.

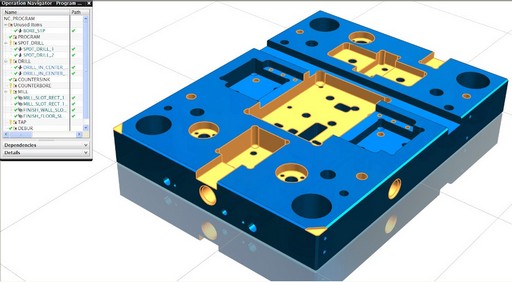

Solid Edge CAM Pro, based on NX CAM, is part of the Siemens PLM Software solution line with Solid Edge . The software solution provides a wide range of functional capabilities, from biaxial milling and high-speed machining to programming of multifunctional machines and 5-axis milling.

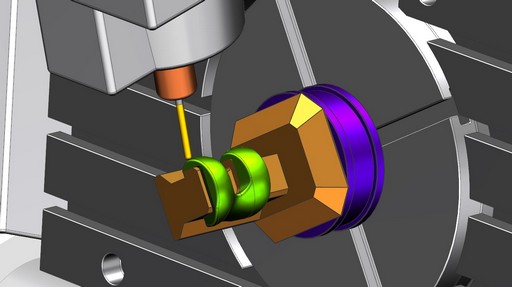

CNC machine programmers can use Solid Edge CAM Pro to solve problems with different machining requirements — milling, drilling, turning and EDM.

Using synchronous technology, you can directly edit part models and prepare them for creating programs for CNC machines, including machining of blind holes and gaps, offset surfaces, as well as changing the dimensions of the part elements.

Solid Edge CAM Pro uses the concept of a master model to provide end-to-end design and development of programs for an NC by binding all CAM functions to a single model defining the geometry of the part. As a result, the programmer can start developing a program for a CNC machine without waiting for the designer to finish working. Full associativity provides a subsequent update of the control program operations for the CNC machine when the model geometry changes.

Main features of Solid Edge CAM Pro

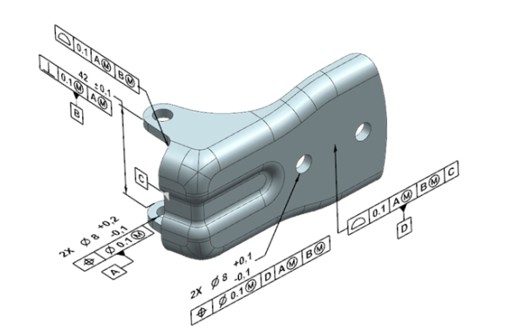

- Work with PMI - design and technological information of the 3D-model.

Product Manufacturing Information, PMI - production data associated with a three-dimensional model of a product in CAD. PMI data includes geometric dimensions and tolerances (GD & T), three-dimensional annotations (text labels), surface quality requirements, and material specifications. PMI data is supported in many file formats used for exchanging and visualizing product data (for example, PDF and JT). This data, if it is embedded into the model by a design engineer, is translated along with the geometry data from Solid Edge to Solid Edge CAM Pro. Thus, the CNC programmer gets all the necessary information from the design engineer. This allows you to avoid errors and delays associated with the use of 2D-drawings, to optimize production processes using an end-to-end product description, as well as to automate the creation of a control program based on this data.

- Feature-based machining.

The processing module on the basis of elements provides recognition of holes, pockets, flat edges (including on models imported from other CAD systems) and creation of a strategy for their processing. Recognition is performed both by the parameters of the construction elements and by their topology. This module significantly speeds up the programming of prismatic parts, provides optimization of processing, and requires less operator skill. The module automatically recognizes the product design and technological information (PMI) - tolerances, 3D annotations, surface cleanliness parameters when assigning the processing technology. For example, for precise holes, boring or deployment operations will be automatically added in addition to drilling (and you can customize your preferred type of operation).

Processing on the basis of elements is a vivid example of programming automation, which can lead to a significant reduction in the time to create a control program.

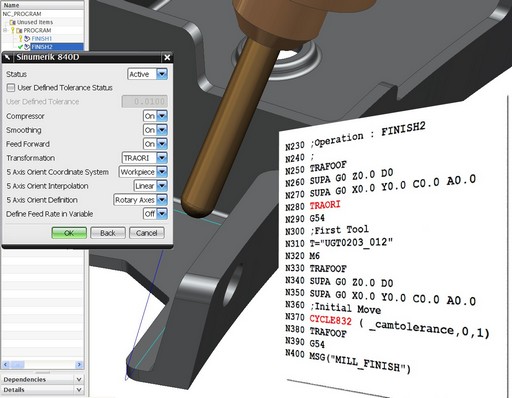

- Postprocessing and simulation.

Solid Edge CAM Pro includes its own post-processing system, which closely interacts with the core of the CAM system. This makes it easy to generate the required control program code for most types of machine and controller configurations.

The program includes a utility PostBuilder, which allows you to create and edit postprocessors. Using the graphical user interface of the utility, the user can set the parameters of the desired program code for the CNC machine.

The postprocessor library is an online resource that contains many processes that support a large number of different machines and tools. Also, Solid Edge CAM Pro includes an optimized post-processor Sinumerik, which automatically selects the main controller settings in accordance with the process operation data.

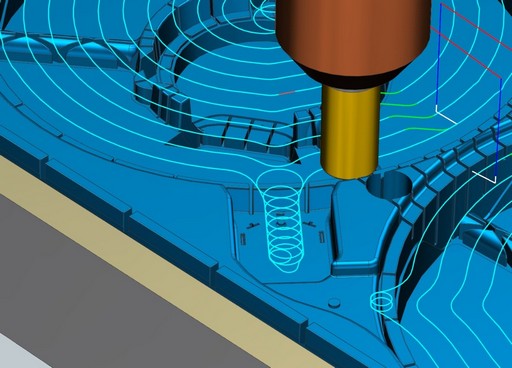

- Simulation processing on the machine.

One of the main advantages of the Solid Edge CAM Pro system is the integrated functions of simulation modeling and machining verification, which allow specialists to check the tool path during the programming process of CNC machines. In this case a multi-level verification process is available. For example, G-code based simulation simulations show motion controlled by the output of a CNC machine program code on an embedded NX postprocessor. The 3D model of the machine along with the part, tools and tool moves in accordance with the movements of the tool based on the G-code.

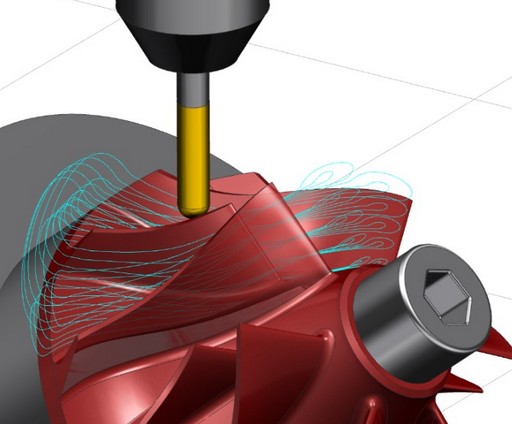

- Five axis treatment.

Key Benefits: Advanced machining strategies with flexible tool axis control options, variable axis profiling automatically processes complex walls based on bottom geometry, Z-profile processing with an inclined tool can reduce tool deflection for better surface cleanliness. For complex parts used in the aerospace and energy industries, Solid Edge CAM Pro offers a flexible approach and a range of axes control options for five-axis machining. For example, when programming a part with several pockets with engineered walls, it is necessary to select the bottom of the pocket once, and the system will create finishing paths for the walls.

- High speed machining (High speed machining-HSM).

High-speed roughing in Solid Edge CAM Pro supports high material removal rates while managing tool loads. Effective HSM strategies for milling at high speeds reduce machining time and improve the quality of machined surfaces on molds and dies, prismatic and complex parts. A wide selection of high-speed machining strategies is available to the user to effectively mill hardened parts while ensuring smooth tool movement and consistent cutting power.

- Application programming. Milling turbo components.

The Turbomachinery Milling module is designed for programming CNC machines that process multi-blade and multi-axis rotational parts. The possibility of processing blades with undercuts. In addition, processing of several dividers is supported, which allows to work more effectively with CAD data regardless of the system in which they were created. Blades may consist of one or more surfaces. Clearances between surfaces and surface overlays are corrected automatically. The system allows you to create smooth tool paths on adjacent surfaces with incompatible parametric lines. Defines the machining operations for one element of a monowheel or impeller, and then automatically applies them to the rest of the part.

Digital shop with Solid Edge CAM Pro

Solid Edge CAM Pro is a tool for manufacturers who “build” a digital workshop or plan to upgrade equipment. Using this system, the user can create optimal processing programs on CNC machines for models created in Solid Edge and models created in third-party CAD-formats, reduce production costs, improve the quality of manufactured products.

The introduction of Solid Edge + Solid Edge CAM Pro is a significant step towards the digitization of business processes and the growth of product competitiveness.

At the webinar on March 19, you can learn how to quickly start working in Solid Edge CAM Pro (after the end of the recording will be available for download).

Source: https://habr.com/ru/post/443856/

All Articles