Implementing ERP in industrial enterprises: Alevtina Svetozarovna and Excel against severe architects and an English factory

Implementing an ERP system is painful. This is mate, tears, screams, sometimes threats of physical violence (there were, unfortunately, such in our practice). But this is normal - serious changes cause a lot of emotion and influence people's careers, and implementing ERP in Russian enterprises for small changes is a waste of money.

Difficulties can be different, and they arise at various stages of the project. I would like to share our experience in solving problems during trial operation, when all the business processes in the new system are already described, the roles are set up, modifications are made, instructions are issued and you just have to start working. For each problem, I will describe its causes and give 1 or 2 cases - examples of solving such problems from our experience.

At the stage of trial operation, it is extremely important to form an feasible work plan for each of the business processes, indicate the terms and performers, select a relatively small list of objects that are being tested and make adjustments to the system, set up a control procedure. The key here is feasibility. Even without this, many difficulties await you, there is no need to additionally aggravate the situation with impracticable plans.

We do all this on our projects.

Problem number 1. Work plans are not fully implemented.

By experience, most often even these previously agreed and feasible plans remain unfulfilled. The main reason sounded by the performers is lack of time. Although the full list of reasons for a little more:

- Principle: "The main thing - to produce, and everything else will wait."

- Psychological moment: it is much easier for performers to do their usual routine than something new.

- Rejection of the ideology of the system by the performers: “Your system will not work. We have Alevtina Svetozarovna - the smartest woman, 60 years old at the plant, she keeps everything in her head, no system will take into account everything that she remembers. ”

- Objective reasons:

- low level of computer literacy of customer’s employees.

- As a rule, the complexity of data entry increases with automation - accounting becomes more detailed, more information is required to be entered into the system, and this takes more time.

I deliberately excluded from the list such items as sabotage and the real shortage of workers — this is not as often encountered as one might think.

What to do in such cases?

A set of measures to solve the problem №1:

- Increase the priority of the system . Contractors need to constantly articulate how the implementation of ERP-system is important for the enterprise. And not just constantly “dripping on the brain” on this issue (which, by the way, must be done without fail), but also explain logically why this is necessary: that Alevtina Svetozarovna is already 85 years old, she wants a well-deserved retirement, that without ERP-system to establish a normal accounting and planning does not work, and this will eventually lead to bankruptcy and layoffs, etc. There can be many arguments, but the main expected result of these actions is that the implementation of the system should receive at least the same priority as the current work.

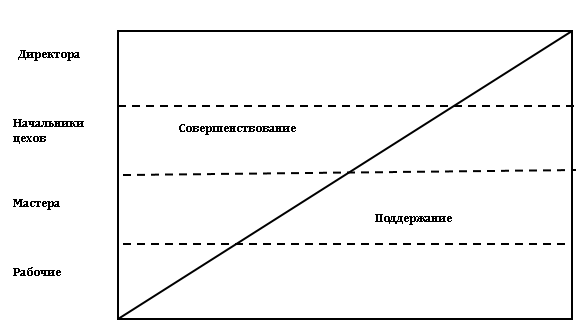

- Changing corporate culture . There are 2 management functions - maintenance and improvement. The first is needed to ensure the implementation of current technological, managerial and organizational standards. And improvement - these are steps aimed at improving the existing standards of work. According to kaizen, the worst companies are those that focus only on the first function. They are waiting for the collapse as a result of competition or changes in market conditions. In the application to industrial enterprises, this means that from the level of department heads already, management should pay more attention to improvement rather than “routine”. That is, it is necessary to convey to the management of the enterprise the need to move from such a picture:

to this:

- Permanent control and pressure on the performers from above . Everything is simple: no control - no work. It is important to regulate this procedure, to describe what exactly and with what frequency will be measured. Control is not a dialogue like this:

“Well, Ivanovich, do you work in a new system?” - “We work slowly” - “Well, well, well done. You already try there, the general asks me ",

it should be like this:

“Ivan Ivanovich, yesterday the commission checked your workshop, only with 5 batches of parts from 300 batches that are in your workshop, the accompanying documentation printed from the ERP system lay nearby. This is only 1.7% instead of 95%, which you must provide. Next week there will be a re-check if the results are the same, you will not see the quarterly premium. ”

- Do not theorize, and go to understand the specific jobs . You can not implement the ERP-system, sitting in the office. If an employee says that he does not have time to work in the system, you must go to his workplace and watch how he works. Perhaps he is simply using the wrong instruction or his monitor is too small.

- Teach, train and train again . You must be sure that all performers are trained to work with a computer and work with the system, that everyone has instructions and corresponding rights.

- Continuing work on optimizing artists' workplaces . The more people work with the system, the more valuable feedback they give. As this meaningful feedback is received, jobs can be optimized to reduce the time for entering information. But this should be done only after people have actively worked with the system for at least a month.

Case 1. Do not theorize, but go to jobs

Problem : One of our customers. At the stage of launching the system there were difficulties with the storekeeper, who complained that she did not have time to register the movement of inventory items in the system. The workstation of the storekeeper was additionally optimized, we made it so that it was necessary to enter the minimum information. Nothing helped.

How the problem was solved : the chief accountant of the enterprise came to the storekeeper at the warehouse and, with a stopwatch, measured how much time she spent on work. It turned out that 80% of the time is spent filling out paper cards for goods and materials. The chief accountant had enough authority to optimize the process, the storekeepers stopped demanding paper cards, and the problem of time constraints disappeared.

Problem number 2. The desire to do everything at once

This item has something in common with problem number 1. If a feasible plan was formed, it was agreed and approved, then there is only one way to go - you need to implement it . But often, instead, people make changes to it, adding new works, and then fail to cope with what happened. Here are some examples from our experience:

- The plan of trial operation laid the launch of only one type of product in the ERP system, and then decided that it was somehow not serious, and added several other finished products. As a result, no one product was made until the end of the work.

- in terms of trial operation, work was put on only one workshop, but “this is not our scale, let's start a couple of workshops to work in the system”. As a result, the management did not manage to devote sufficient time to monitoring all the workshops, and none of them could earn money normally.

- planned to run in the ERP-system accounting for one warehouse, and then the number of warehouses increased. As a result, the process was not fully launched in any of the warehouses.

Causes of this problem:

- Love for challenges. Our people are not interested in doing what seems simple, I want to challenge and test.

- Underestimating the complexity of the problem / reassessment of own forces. Managers do not always represent how much work their employees can perform. Sometimes people have the habit of promising at meetings more than they can do, in the hope that at the next meeting they will forget to ask about the results.

- Incorrectly prioritized. For example, it is necessary to deal with the elimination of errors in regulatory data, without which it is impossible in principle to start, and the customer stubbornly does not want to deal with this real problem and falls asleep us with reporting questions for economic services - reporting that is needed much later and only if correct regulations.

- Fear of leadership. This happens when the project manager on the part of the customer is the CEO or owner, who not only does not participate, but does not particularly delve into the implementation process. At the same time, he appears at certain control points and gives his weighty farewell: “No need to arrange a kindergarten here! How is it - to run only one shop? Why do you need 2 months for trial operation? I give you 3 weeks to launch in full, you need to meet this deadline or you know what I'll do with you. ” And if the project manager doesn’t have enough courage to answer: “There are no miracles, 9 women don’t give birth to one child in a month,” then he transmits these “valuable instructions” and “feasible deadlines” to the performers. Everyone understands that the plan is not feasible, but they are going to create the appearance of work so that there is no formal reason to find fault with them - while at the same time precious time is wasted that could be used for business.

What can be done with this?

A set of measures to solve the problem number 2:

- To go from simple to complex : we agreed on a workable plan, fulfilled, moved to a more serious plan. With each step, it will be clear how much work to actually perform with current resources, this will allow you to plan more precisely. Moreover, this is the only way to assess the real extent of the problem, which will allow you to make meaningful management decisions, rather than hiding your head in the sand.

- The ability to simplify . It is very important to be able, if necessary, to give up some requirements temporarily in order to accomplish the task as a whole: often it is better to do it at C grade than not at all.

In addition, we are not talking about doing at C grade and calm down. Usually, everything happens like this: they did it for C grade, slowly after a while they went to a foursome, and then 3-4 years later, when the system became native, they either went to a solid top five, or they understand that the four is already optimal in terms of the ratio of effort and the result is an option.

- Concentration on important tasks . First of all, you need to do the tasks that are needed now to start the system, and not the one that causes more noise.

The most important are the tasks that allow the release of managers from routine actions.

Case 2. The ability to simplify

Problem : One of our customers. The launch of the ERP system was hampered by the fact that the customer believed that the normal operation of the system required the formation of full operational routes. Technologists said that they would need 5 years of work to create the necessary operating routes.

How the problem was solved : the customer acknowledged that with this approach he would never start. After that, the data from the enclosures were taken as the basis for automation and implemented an account of inter-shop movements of parts and assembly units. This was enough for a full planning and accounting. Now there is a gradual transition from enclosures to operational routes with an already operating ERP system.

Case 3. Concentrate on the important.

Problem : Also one of our customers. A large amount of regulatory information, which is transferred from the old samopisnaya system, the customer understands that there are many mistakes. The bulk of the questions concerned the correctness of the routes. In an amicable way, it is necessary to check and correct everything, but this is a huge amount of information, and technologists and designers are already loaded. In addition, the question arose: how to check that everything is corrected correctly if nobody works in the system?

How the problem was solved : the customer acknowledged that he did not need the “standardization” in full. It was decided that only the positions currently being produced will be adjusted: every time a part enters the Quality Control Department, the controller compares the routing card and the routeing card from the system. If there are discrepancies, then the part is not transferred further, the technologist arrives within 15 minutes and makes adjustments to the system. Here were 2 key points that made it possible to succeed:

- focus only on the products currently being produced;

- make work on the correction of routes in the system priority.

Problem number 3. The performers do not have an understanding that the work of the remaining divisions depends on their work.

During the development of functional designs, an in-depth analysis of business processes is done, all roles and functions, inputs and outputs, and interconnections between departments are clearly stated.

But often the performers do not understand how the results of their work will affect the rest. Examples:

- design and technological documentation specifies the materials and purchases without considering whether they can, in principle, be found on the market now.

There may be objections from the series: “Why should a designer or a technologist think about what is on the market? For the same there is a supply. ” I think it would be fair if the management initially told the designers and technologists: “You are the creators, so create, do not limit yourself in choosing colors for your beautiful paintings”, but the supply department suggested: “Everything that these guys ask should be brought on time. Do not spare money, take at least from the North Pole, but creativity should not stop ". Unfortunately, even having voiced the first part, they forget about the second part - the supply should always be purchased as cheaply as possible and not exceeding the budget.

- during the purchase, due to insignificant differences in the names of nomenclatures, they are entered under different codes. The supply is all good - the nomenclature is entered into, even if the same position sits under different part numbers. But planners "are buried" in replacements, all planning breaks down.

Causes of this problem:

- The performers do not know the whole process, they are not aware of the interconnections between the departments.

- The performers understand how the process works, but they are so loaded that they cannot afford such luxury as thinking of the rest.

- The process requires improvement: for example, an employee may turn out to be an “extra link” in a chain — information is taken from one department, enters into the system, and then another department uses it. It is difficult to expect that a person in such conditions will somehow check the information and take care of its correctness.

In the absence of automation or local automation within a single department, problems with the interaction of departments do not seem to arise, they are invisible. And ERP is an integrated product that does not allow to ignore the inconsistencies and imperfections of the process.

A set of measures to solve problem number 3:

- Permanent user training . It is desirable to complete the training with the signing of any document that he now bears full responsibility for everything he does in the system. This document may not have legal force, but it will have a psychological effect.

- Meetings . Hold periodic meetings with several departments to discuss situations in which one department suffers from the actions of another.

- Educational activities . In certain situations, offer the perpetrators to correct the results of their mistakes.

- Process optimization . Do not allow "extra links", as much as possible to close the possibility for errors.

There is no fundamentally added clause on reducing the burden on performers, so that they have time to think about how their work affects other departments. While the employee believes that a large amount of work is an excuse for poor quality work and sabotage the activities of his colleagues, he will be loaded with a correction of his own jambs.

Case 4. English factory

The plant is English, so there are no “Problem” and “How the problem was solved” sections in this case, it was included in this article as an example.

At one time, my colleagues traveled to get acquainted with one ERP-system at an English factory, where they manufactured equipment for aviation. They were amazed that each employee, to whom they approached and asked about what his work consisted of, tried to tell about how the process works in general, and not just about its part. That is, each of the performers understood the whole process and its influence on the overall work.

I can not unequivocally assert that this fact correlates with the first, but at that plant there were fewer employees than in similar Russian ones, but they produced the same amount.

Problem number 4. “Why didn't you tell us about that?”

At the design stage, each process is demonstrated. This describes the various modes of operation of the system and important chips that can be used in the future.

But this is not enough. On many projects, when launching into trial operation, questions arose:

- “Why didn't you tell us about this before?”

- “Why is this mode of operation not described in the instructions?”

Causes of this problem:

- It is necessary to grow up to understanding some peculiarities, it makes sense to discuss them only after they are stuck in practice. From my own experience, I can say that even when I told the client to the maximum about all the functionality that at least theoretically might be needed on the project, in the future, similar questions arose anyway - people listened, but filtered what they thought at that time not much necessary.

- Even if the TK is good, sometimes additional requirements arise. Some modes of operation initially simply are not supposed to be used, so they are not told about them.

- Modern ERP-systems are very redundant in functionality (at least, so that you can automate the activities of any enterprises), so there will always be those functions that the integrator did not tell the client.

A set of measures to solve problem number 4:

- Acceptance You just have to accept this feature and deal with problems as they arise.

Case 5. "I understand your trick"

After the successful implementation of the ERP system, a key employee of the customer, over a cup of tea, told us:

“I understood your cunning. You gave us information in doses so that we are not afraid. If we from the very beginning represented the whole scope of work, we would have abandoned the project. And so - without raising our heads, constantly solving the problems that arise, they slipped through and got a working system. ”

Problem number 5. “Two write, three in mind”

During the development of functional designs, an in-depth analysis of business processes is done, all roles and functions, inputs and outputs, and interconnections between departments are clearly stated.

And then at the stage of trial operation there are “details” when, according to all regulations, the work is done in one way, but in fact - in another. Everyone knows about it, but for the time being they don’t say:

- According to technology, the part is processed in workshop number 1, but everyone knows that the specified machine has long been moved to workshop number 21 and the lot is being transported there. There is no time to change technology, and why, if everyone already knows everything?

“Now think of how to reflect this in the ERP system so that you do not create a new route, do not make changes to the current one, and learn everything correctly! You can not? So your system does not understand our features and does not suit us! ”

- Parts that go into finished products are painted as part of the product after assembly, and if the part goes as a spare part for sale, it is painted separately. “And why in your documents nowhere is the paint consumption and the corresponding operations specified?” - “I don’t know. Still, and so aware that the parts for sale are painted. "

The reasons for this:

- Laziness of performers.

- Lack of labor discipline.

A set of measures to solve the problem number 5:

- Fight it . Mercilessly Fiercely. Everywhere. Is always.

We do not have cases for this problem, because we are struggling with this. Mercilessly Fiercely. Everywhere. Is always.

Problem number 6. "We are very, very special and unique"

When developing functional designs, a deep analysis and unification of business processes is done. As a rule, at this stage, the customer’s staff will remember the installation of the manual: “It is necessary to introduce the most standard functionality, fewer improvements — cheaper implementation”.

And then the trial operation begins and the individual employees of the customer begin to “slowly cook the frog”:

- “We even had this functionality in the old samopinny system, is it really that such an expensive ERP cannot do little things? Modify! ”

- “This is an obvious mistake; planning cannot work like this. Yes, you showed us how it will work, yes, we agreed on the design. Probably, we were not in ourselves. Let's redo the planning so that it works like this Excel file, tested by years and Alevtina Svetozarovna, the smartest woman, is 60 years old at the plant. ”

Causes of this problem:

- Fear of new and desire to work with familiar things.

- A program written for a specific user, a particular company will always be more convenient for him than ERP-systems on the market. Especially if this program works inside a small unit. And when we come with our unification, the staff of this unit rightly declare that their program was more convenient than “this Accapta of yours.” But the goal of the enterprise in the implementation of ERP-systems is not the convenience of specific employees, but transparent accounting and planning, which the self-written program will never give.

A set of measures to solve problem number 6:

- Unification forever . Save the installation to the maximum unification of the work of various departments for the entire project, and not only at the initial stages.

- Minimum system modifications . Consider improvements as an extreme measure, which can be resorted to at the very end.

- Do not take as utilization programmers as KPI . If the customer has its own staff of developers, it is very important to resist the temptation to download programmers 100% so that they do not stand idle.

- Severe architect, preferably bearded . If the client has a staff of programmers, then ideally one should hire an individual highly qualified specialist who would act as a system architect. This employee should check all the improvements for compliance with the ideology of the system, make recommendations and not let in the work that does not fit into the architecture of the existing solution.

Case 6. “Programmer lawlessness”

A client came to us with his problem: they introduced the system several years ago, after which his development department (3-4 programmers) worked day and night to close all the users' desires. During this time, they "killed" the system - it was impossible to work in it, because everything slowed down. The client had to re-introduce the system and the implementation was faced with a serious difficulty - spoiled by users, accustomed to, that all their wishes are fulfilled. And here the problem is not even in programmers (they are not to blame for anything, what they were told, they did), but in the absence of that architect.

These tips may seem simple and obvious to you, but this does not cease to be effective and efficient. Yes, and follow them a few. It's like with health - everyone knows that in order to stay healthy until old age, you should follow simple recommendations: control your diet, play sports, follow your tongue and thoughts, not change your spouse / wife, avoid dark alleys and scumbags. But there are not so many happy and healthy people.

That's all. Implement ERP, solve problems, be kinder. And fight with laziness and lack of production discipline. Mercilessly Fiercely. Everywhere. Is always…

')

Source: https://habr.com/ru/post/443398/

All Articles