Why do we need advanced analytics in SIBUR

When you have a problem, you begin to look for ways to solve it, at the same time thinking about how you would not go through the same rake again the next time. Whatever you do, from small mobile applications to bulky information systems, an error always has a price, and the more critical the industry in which your product is used, the higher the price of this error. Therefore, the ideal situation seems to be when you are working in advance, namely, trying to predict the occurrence of a problem before its actual occurrence.

Extruder on the production of polypropylene

We in SIBUR have the Digital Technologies function, one of the directions of which is engaged in advanced analytics. We are involved in all the processes one way or another connected with the analysis of the data that the company has: from the readings of a multitude of sensors from production to stock reports and forecasts. Using this data, we create digital products that significantly help improve the company's operational efficiency.

')

My name is Alexander Mole, I represent the direction of advanced analytics, and under the cat I will tell you about this:

Operating efficiency can be improved in two ways. The first is an increase in the production of products through a more stable mode of production. The second is a reduction in losses due to unplanned shutdowns, each of which costs us millions in loss.

Very often, the working model that will be used for predictive analytics is simply a program. Like, here's a code for you, it will help predict possible problems, use. We decided to go another way and create a ready-made model as a complete turnkey product, the output is a working self-learning model that can be adjusted, convenient interfaces and monitoring terminals, as well as support that responds to requests from users of new functions. Our users are operators who monitor the production process, so they know exactly what should be changed in the product so that it is more convenient for them to use. After all, operators will monitor the terminal, respond to changes in indicators and make adjustments.

Therefore, we build such models according to the classical product scheme, for each product a team is created with the product owner, developer, designer, data engineer. Even in the team there is always a production technologist - an employee who understands exactly how the production process works, which we intend to improve.

Each of these projects we have lasts from 3 to 6 months, depending on its complexity. To begin with, we conduct reconnaissance by sending a team to the fields (to enterprises), we have such a research procedure called “framing” to determine exactly what the customer wants and whether it is possible to solve the problem with data. If it is possible, then we begin to evaluate further: is there enough data available to solve the problem, from where they can be unloaded, whether organizational changes will be required. Of course, we separately consider the economic effect in order to subsequently rank projects and undertake only those that give the maximum effect. It is clear that if we spend a lot of time and effort on a project that ultimately saves 5,000 rubles per month or a couple of light bulbs, then such a project is not really needed.

If we understand that the product will bring real benefits to the company (both in terms of optimizing the work itself and improving conditions for the staff, and in terms of direct financial benefits), then we start working. Now we have implemented almost a dozen different projects at such a pace, in this article I want to highlight a couple of the most significant of them.

One of the goods that SIBUR sells is polypropylene, we sell it in the form of pellets packaged in bags (we wrote about our products here ). The production of polypropylene from gas takes several stages, we will stop here on the last - cutting granules. There are peroxide grades of polypropylene, peroxide is added to the homogenized mass of polypropylene in the process to create them. That is, the melt flows with such polypropylene, peroxide is added to it on the fly, the whole mass is mixed and fed into the extruder.

Extruder is like a big meat grinder at its core. Only the size of an average two-room apartment. The parts of the extruder that are of interest to us in this business are screws (like a meat-screw screw, here it mixes the melt with peroxide), a die (this is an analog of the mesh in the meat grinder, to which this mixture is pressurized) and a blade cartridge that reverse sides of the spinneret are actively cutting polypropylene macaroni on the granules. Then the sliced granulate air flow rises on a special vibrating screen, the granules are packed in bags and in general are ready for transportation.

For various reasons, unplanned stops of the extruder occur.

For example, peroxide mixed badly, because the temperature was slightly disturbed, or insufficient pressure was applied, or something else. It ends with the fact that between this filler and the knife cassette the whole mass begins to stick. Because of this, instead of normal granules, an agglomerate is formed, which rises with the air flow upwards and clogs the vibrating screen.

The point here is that if these agglomerates become visible, it means that everything in the extruder itself is already very strongly hammered. It is necessary to stop production, disconnect everything, disassemble, get parts, clean the spinneret and knives. It all stops usually longer than half an hour, and costs the company serious money.

But where does the data science actually come from?

In 2017 there were 19 such shutdowns. We collected data on them, looked at the parameters of the technological mode of production - telemetry extrusion and polymerization. Analyzed all this, found a number of patterns. The result was the creation of a model that begins to signal the operator that something may soon be clogged, about an hour before the onset of such an event.

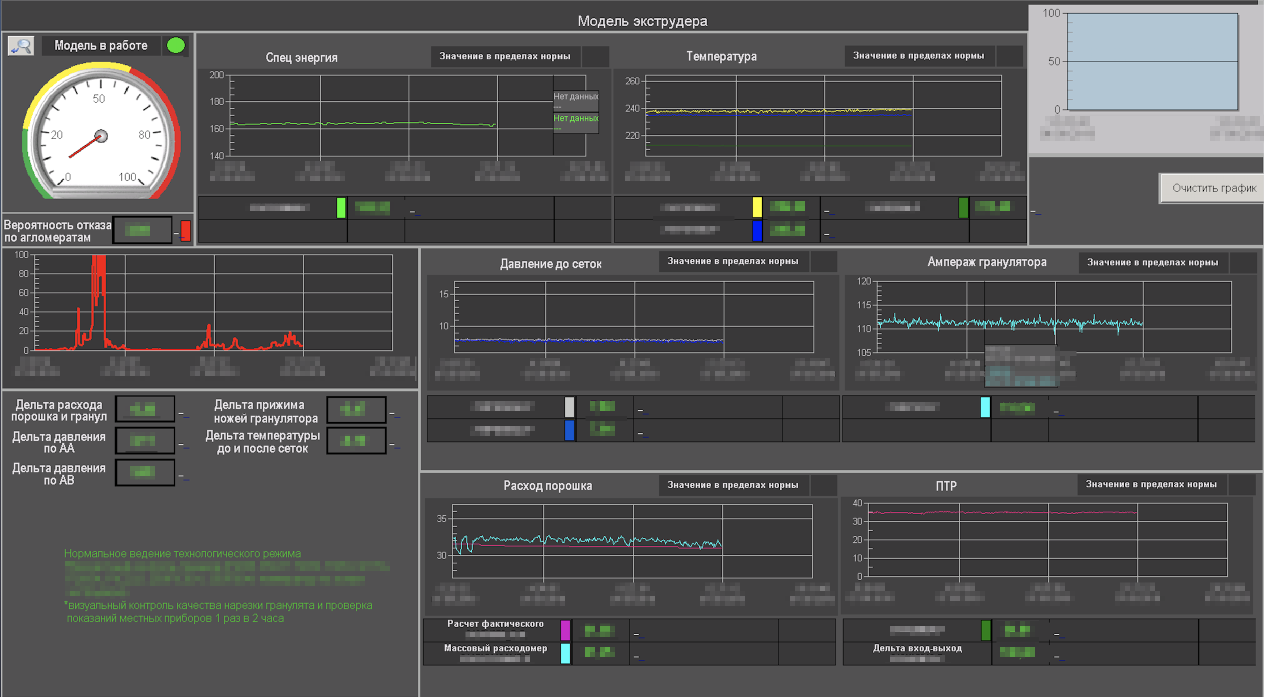

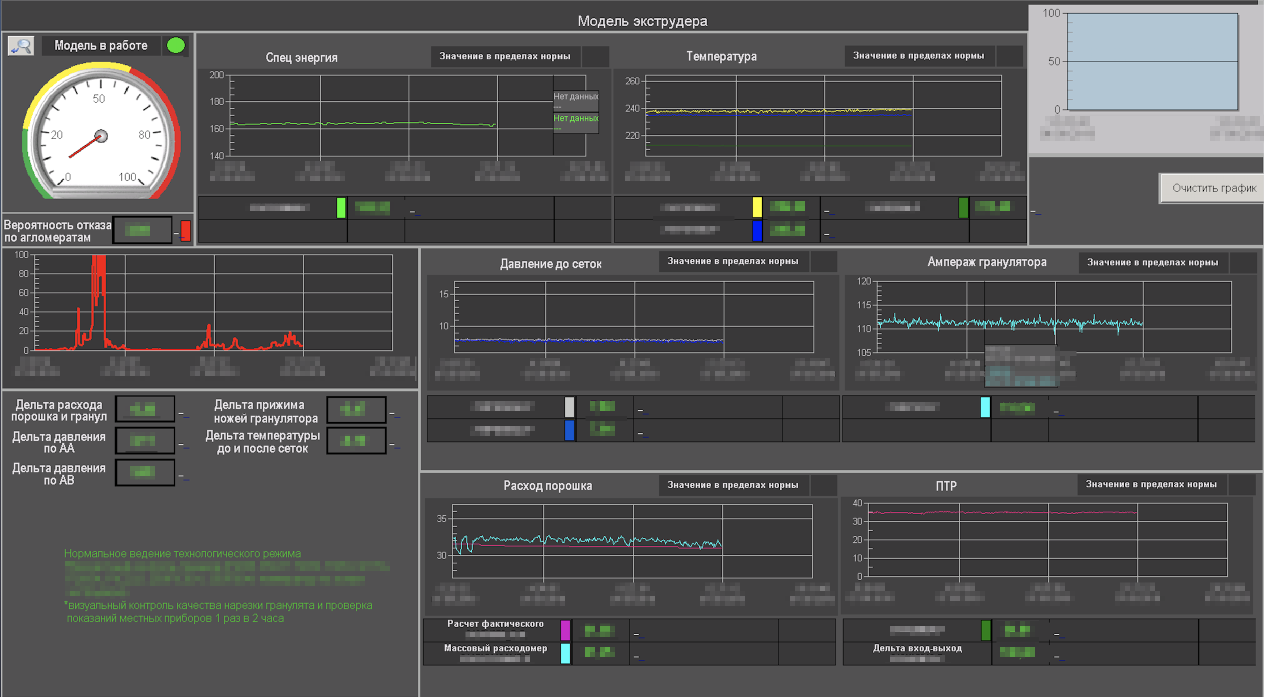

We have set the operators a complete system. Now they have an interface, several screens, to which we in real time display all the telemetry connected with the technical process. For simplicity, we highlight the desired indicators in different colors (green-yellow-red), as on the speedometer. And visually, when looking at an extruder, nothing can be assumed yet, and the system, having checked the telemetry and readings, will start to warn in advance that after 2 hours (the forecast horizon of our model) it may be blocked. And what if right now just strengthen the clamping of knives, for example, then an unscheduled stop can be avoided.

One of our main tasks at the same time is to ensure the survival of our tools. Operators must trust the system. If she will often act falsely, and he will be distracted and recheck everything, then sooner or later he will react to her alarms as a habitual stimulus. And even in general it will start to think that they have installed some kind of not very clear system, which sometimes works falsely and distracts from work. Therefore, we are on the move to teach the model to minimize this. We installed a video camera over the vibrating screen so that the operator can see how things are going, if suddenly the system blinks, in this case he will visually notice the agglomerates in advance, and not when the vibrating screen is already clogged. If production employees change knives or extruder settings, they immediately write to our support team and ask to take this into account in order for the model to work more accurately.

What is the result. The model was launched in 2018. And from this point on, we no longer had any unscheduled stops.

This project is from the scope of predictive maintenance. It helps a lot in work, for example, we predict by what time something may go wrong with one installation or another, it will be necessary to change the oil or bearing, and we need to pre-order the necessary parts to the warehouse so that by the time the event occurs it only remains to take and install them, and not solve issues with the order, delivery and other things.

We now turn to optimize the production of products by maintaining the optimal mode.

Butadiene is our intermediate product, from which, for example, subsequently, the well-known synthetic rubber is made. Butadiene production has one peculiarity; a catalyst is necessary for this, the element is quite valuable. It is usually purchased 2-3 years ahead and costs several billion rubles, as it contains precious metals.

We have 2 reactor units of 8 reactors each. Without going into detail in the technological mode of production, to describe the work of the operator in simple words, you can: you have a given temperature (we call it “setpoint”), and it must be kept during the shift. It is regulated by means of dampers by supplying air. The task of the operator is to maintain the temperature at the upper permissible limit so that, on the one hand, the catalyst does not burn, and on the other, in order to obtain the maximum yield of the final product. Overall, it all comes down to maintaining the maximum stationary mode.

Therefore, it is necessary to keep the temperature close to the upper limit when the product is produced enough, but there is no harm for the catalyst yet. And everything would be fine (it would seem - fix the temperature and everything), but this is influenced by many different factors.

It should be said that from the operator there is also not so simple. Any action on temperature by opening the dampers has an inertia of several hours. This is just at home in the shower, I opened the hot water, I realized that I had gone too far, I added cold water, and then everything was OK. So far, the washing machine did not draw water, or one of the neighbors did not think about hygiene.

And here it is. You open the flap by 1 degree, and you can not estimate the effect of this on the overall temperature change much at once. Total for the shift, the average operator turns these flaps back and forth on average three times.

Here we collected historical data, looked at them, how much the temperature changes when the damper opens by 1 degree. On 2. On 3. As a result, they built a whole complex of models that became a de facto recommendation system for operators. If suddenly somewhere the temperature is different from the setpoint, the system will immediately alarm, which valve and how many degrees it is necessary to open slightly in order to reach the optimum temperature. The operator immediately sees and reacts.

The effect for production is on average about 1000 additional tons of butadiene per year.

Here was another additional effect from the use of our model; we have changed the collective image of the operator himself. They became more diligent and attentive, the operators put in KPI absenteeism outside the desired temperature. Now they are discussing which shift coped better with the task, quickly learn new model functions. In general, we gave them a good tool for them to do their work, and they give us quality feedback that allows us to improve this system.

The system automatically generates each operator at the end of the shift report with its effectiveness, so that it is clear who can boast today. And similar elements in production change the very culture of work. The very image of the operator has also changed - it has become more digital, now operators understand and use digital tools, possessing all the necessary skills, and are actively involved in the development and improvement of these tools.

Predictive model of coke formation butylene fraction

Lattices with thermocouples (thermal sensors) are installed in the reactors. Often, during the operation of the reactor, coke adheres to these grids, which leads to the destruction of the grids and an increase in the repair time at shutdown. And when this happens, the reactor is stopped, it is all cleaned, and the damaged elements are replaced. A simple time of about 7 days. The idea was to predict the formation of coke, to burn it with a stop for a short period and in this case without opening the reactor itself, thereby increasing the turnaround time.

How can you understand that coke begins to accumulate in the reactor? Make him x-ray. But it entails large financial costs. Therefore, it was decided to optimize them and resort to analytics.

When coke begins to stick to temperature sensors, as a rule, they show a slightly lower temperature, as well as a lower dispersion of this temperature. We watched this, built a model that predicted coking without gamma scanning. This model is still at the pilot stage, now its use allows:

There may be an opinion that analytics in production is connected only with production itself. In fact, this is not the case, we also have marketing cases. For example, we can predict market prices for certain types of products.

It is important to note once again, we do not build models for the sake of models, we create finished products based on them. Therefore, we also created an ML framework, which has actually become the unified standard of model requirements. Regardless of which team made the product, or even third-party contractors through the API, creating their own models, it is important for us that all these models be in a single interface. This allows us to understand which model works fine, which starts to degrade, which one did not start at all due to lack of data and so on.

When there were only 5 models, everything was simple, and with monitoring, and with support. And when there are more of them (including contractors), an ML framework comes to the rescue, allowing you to save each digital product in a unified manner into a container and automatically deploy an API. We can put all the models in there and monitor them simultaneously.

Therefore, we use our own framework.

We have a lot of tasks, obvious and not so much, and we will be very happy for the data-Cyntists who decided to try themselves in a large enterprise, now we are looking for:

Product Owner (Moscow);

Data Scientist ( Moscow , Nizhny Novgorod , Tomsk ).

And here is a short video about how we work

Extruder on the production of polypropylene

We in SIBUR have the Digital Technologies function, one of the directions of which is engaged in advanced analytics. We are involved in all the processes one way or another connected with the analysis of the data that the company has: from the readings of a multitude of sensors from production to stock reports and forecasts. Using this data, we create digital products that significantly help improve the company's operational efficiency.

')

My name is Alexander Mole, I represent the direction of advanced analytics, and under the cat I will tell you about this:

- how to reduce the number of unplanned stops of an extruder that cuts polypropylene into pellets and tends to get clogged;

- as with data analysis and a customized model, butadiene production can be increased by more than 100 tons per month;

- why reactor problems are easier to predict than to investigate it using x-rays.

Operating efficiency can be improved in two ways. The first is an increase in the production of products through a more stable mode of production. The second is a reduction in losses due to unplanned shutdowns, each of which costs us millions in loss.

Very often, the working model that will be used for predictive analytics is simply a program. Like, here's a code for you, it will help predict possible problems, use. We decided to go another way and create a ready-made model as a complete turnkey product, the output is a working self-learning model that can be adjusted, convenient interfaces and monitoring terminals, as well as support that responds to requests from users of new functions. Our users are operators who monitor the production process, so they know exactly what should be changed in the product so that it is more convenient for them to use. After all, operators will monitor the terminal, respond to changes in indicators and make adjustments.

Therefore, we build such models according to the classical product scheme, for each product a team is created with the product owner, developer, designer, data engineer. Even in the team there is always a production technologist - an employee who understands exactly how the production process works, which we intend to improve.

Each of these projects we have lasts from 3 to 6 months, depending on its complexity. To begin with, we conduct reconnaissance by sending a team to the fields (to enterprises), we have such a research procedure called “framing” to determine exactly what the customer wants and whether it is possible to solve the problem with data. If it is possible, then we begin to evaluate further: is there enough data available to solve the problem, from where they can be unloaded, whether organizational changes will be required. Of course, we separately consider the economic effect in order to subsequently rank projects and undertake only those that give the maximum effect. It is clear that if we spend a lot of time and effort on a project that ultimately saves 5,000 rubles per month or a couple of light bulbs, then such a project is not really needed.

If we understand that the product will bring real benefits to the company (both in terms of optimizing the work itself and improving conditions for the staff, and in terms of direct financial benefits), then we start working. Now we have implemented almost a dozen different projects at such a pace, in this article I want to highlight a couple of the most significant of them.

Predictive maintenance of the extruder in the production of polypropylene

One of the goods that SIBUR sells is polypropylene, we sell it in the form of pellets packaged in bags (we wrote about our products here ). The production of polypropylene from gas takes several stages, we will stop here on the last - cutting granules. There are peroxide grades of polypropylene, peroxide is added to the homogenized mass of polypropylene in the process to create them. That is, the melt flows with such polypropylene, peroxide is added to it on the fly, the whole mass is mixed and fed into the extruder.

Extruder is like a big meat grinder at its core. Only the size of an average two-room apartment. The parts of the extruder that are of interest to us in this business are screws (like a meat-screw screw, here it mixes the melt with peroxide), a die (this is an analog of the mesh in the meat grinder, to which this mixture is pressurized) and a blade cartridge that reverse sides of the spinneret are actively cutting polypropylene macaroni on the granules. Then the sliced granulate air flow rises on a special vibrating screen, the granules are packed in bags and in general are ready for transportation.

For various reasons, unplanned stops of the extruder occur.

For example, peroxide mixed badly, because the temperature was slightly disturbed, or insufficient pressure was applied, or something else. It ends with the fact that between this filler and the knife cassette the whole mass begins to stick. Because of this, instead of normal granules, an agglomerate is formed, which rises with the air flow upwards and clogs the vibrating screen.

The point here is that if these agglomerates become visible, it means that everything in the extruder itself is already very strongly hammered. It is necessary to stop production, disconnect everything, disassemble, get parts, clean the spinneret and knives. It all stops usually longer than half an hour, and costs the company serious money.

But where does the data science actually come from?

In 2017 there were 19 such shutdowns. We collected data on them, looked at the parameters of the technological mode of production - telemetry extrusion and polymerization. Analyzed all this, found a number of patterns. The result was the creation of a model that begins to signal the operator that something may soon be clogged, about an hour before the onset of such an event.

We have set the operators a complete system. Now they have an interface, several screens, to which we in real time display all the telemetry connected with the technical process. For simplicity, we highlight the desired indicators in different colors (green-yellow-red), as on the speedometer. And visually, when looking at an extruder, nothing can be assumed yet, and the system, having checked the telemetry and readings, will start to warn in advance that after 2 hours (the forecast horizon of our model) it may be blocked. And what if right now just strengthen the clamping of knives, for example, then an unscheduled stop can be avoided.

One of our main tasks at the same time is to ensure the survival of our tools. Operators must trust the system. If she will often act falsely, and he will be distracted and recheck everything, then sooner or later he will react to her alarms as a habitual stimulus. And even in general it will start to think that they have installed some kind of not very clear system, which sometimes works falsely and distracts from work. Therefore, we are on the move to teach the model to minimize this. We installed a video camera over the vibrating screen so that the operator can see how things are going, if suddenly the system blinks, in this case he will visually notice the agglomerates in advance, and not when the vibrating screen is already clogged. If production employees change knives or extruder settings, they immediately write to our support team and ask to take this into account in order for the model to work more accurately.

What is the result. The model was launched in 2018. And from this point on, we no longer had any unscheduled stops.

This project is from the scope of predictive maintenance. It helps a lot in work, for example, we predict by what time something may go wrong with one installation or another, it will be necessary to change the oil or bearing, and we need to pre-order the necessary parts to the warehouse so that by the time the event occurs it only remains to take and install them, and not solve issues with the order, delivery and other things.

We now turn to optimize the production of products by maintaining the optimal mode.

Butadiene Advisor

Butadiene is our intermediate product, from which, for example, subsequently, the well-known synthetic rubber is made. Butadiene production has one peculiarity; a catalyst is necessary for this, the element is quite valuable. It is usually purchased 2-3 years ahead and costs several billion rubles, as it contains precious metals.

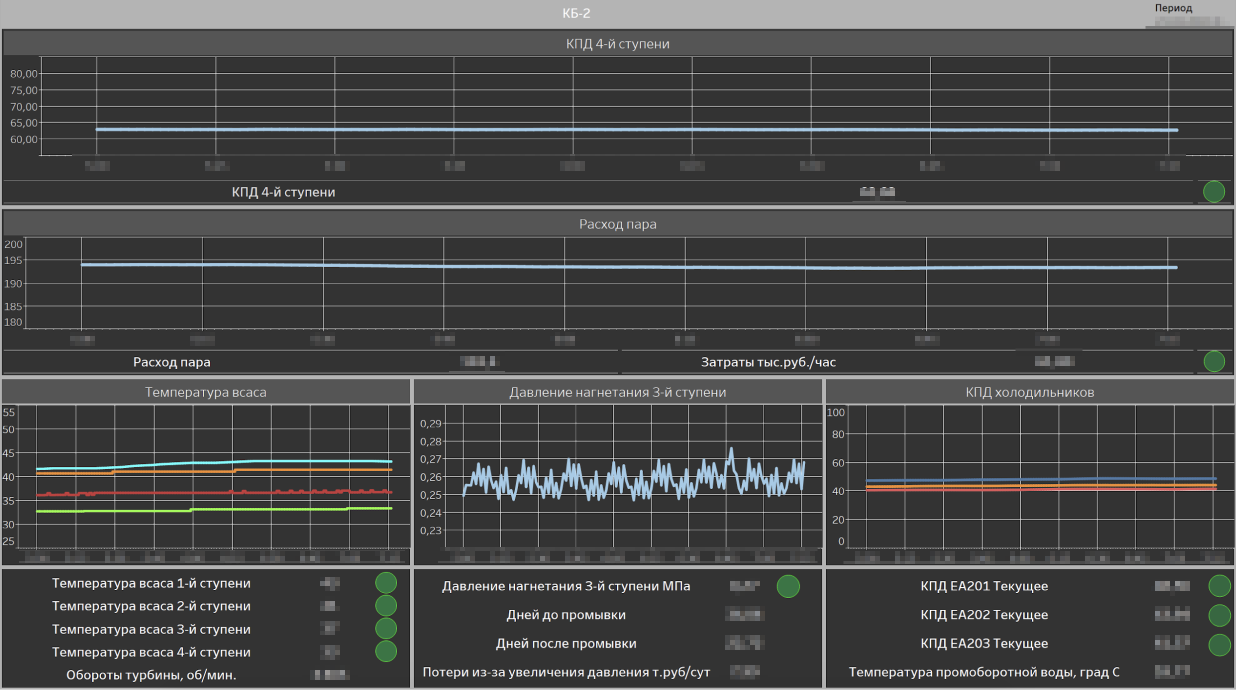

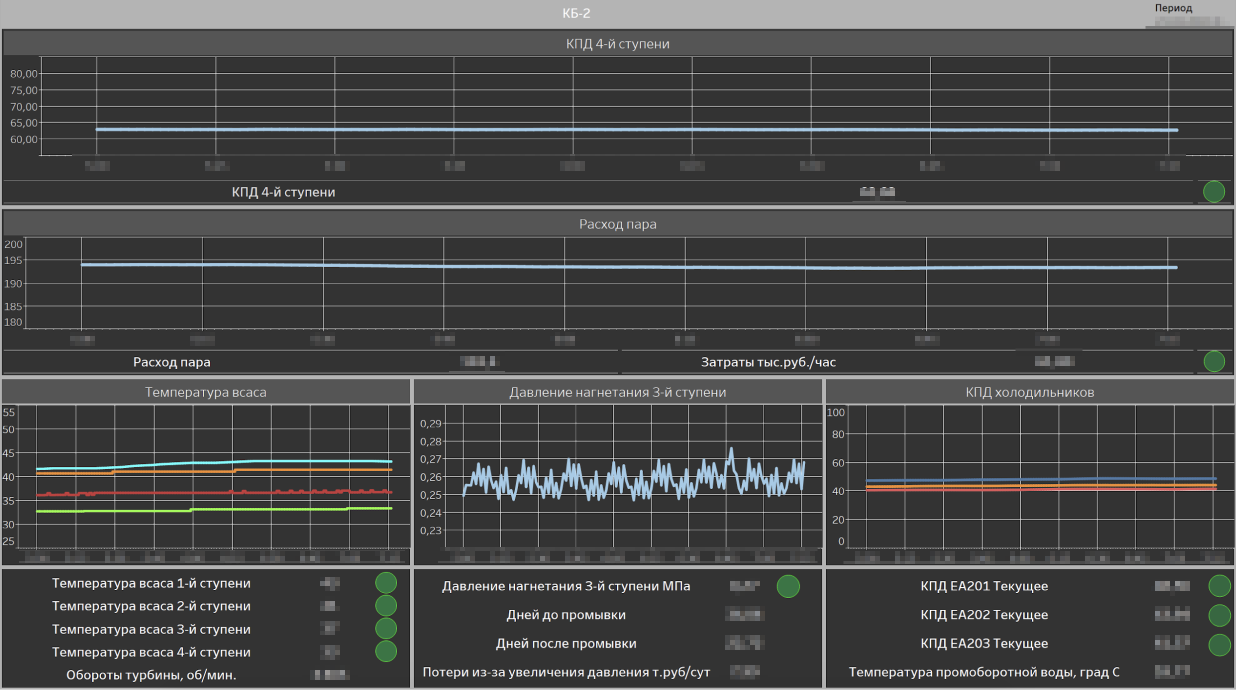

We have 2 reactor units of 8 reactors each. Without going into detail in the technological mode of production, to describe the work of the operator in simple words, you can: you have a given temperature (we call it “setpoint”), and it must be kept during the shift. It is regulated by means of dampers by supplying air. The task of the operator is to maintain the temperature at the upper permissible limit so that, on the one hand, the catalyst does not burn, and on the other, in order to obtain the maximum yield of the final product. Overall, it all comes down to maintaining the maximum stationary mode.

Therefore, it is necessary to keep the temperature close to the upper limit when the product is produced enough, but there is no harm for the catalyst yet. And everything would be fine (it would seem - fix the temperature and everything), but this is influenced by many different factors.

It should be said that from the operator there is also not so simple. Any action on temperature by opening the dampers has an inertia of several hours. This is just at home in the shower, I opened the hot water, I realized that I had gone too far, I added cold water, and then everything was OK. So far, the washing machine did not draw water, or one of the neighbors did not think about hygiene.

And here it is. You open the flap by 1 degree, and you can not estimate the effect of this on the overall temperature change much at once. Total for the shift, the average operator turns these flaps back and forth on average three times.

Here we collected historical data, looked at them, how much the temperature changes when the damper opens by 1 degree. On 2. On 3. As a result, they built a whole complex of models that became a de facto recommendation system for operators. If suddenly somewhere the temperature is different from the setpoint, the system will immediately alarm, which valve and how many degrees it is necessary to open slightly in order to reach the optimum temperature. The operator immediately sees and reacts.

The effect for production is on average about 1000 additional tons of butadiene per year.

Here was another additional effect from the use of our model; we have changed the collective image of the operator himself. They became more diligent and attentive, the operators put in KPI absenteeism outside the desired temperature. Now they are discussing which shift coped better with the task, quickly learn new model functions. In general, we gave them a good tool for them to do their work, and they give us quality feedback that allows us to improve this system.

The system automatically generates each operator at the end of the shift report with its effectiveness, so that it is clear who can boast today. And similar elements in production change the very culture of work. The very image of the operator has also changed - it has become more digital, now operators understand and use digital tools, possessing all the necessary skills, and are actively involved in the development and improvement of these tools.

Predictive model of coke formation butylene fraction

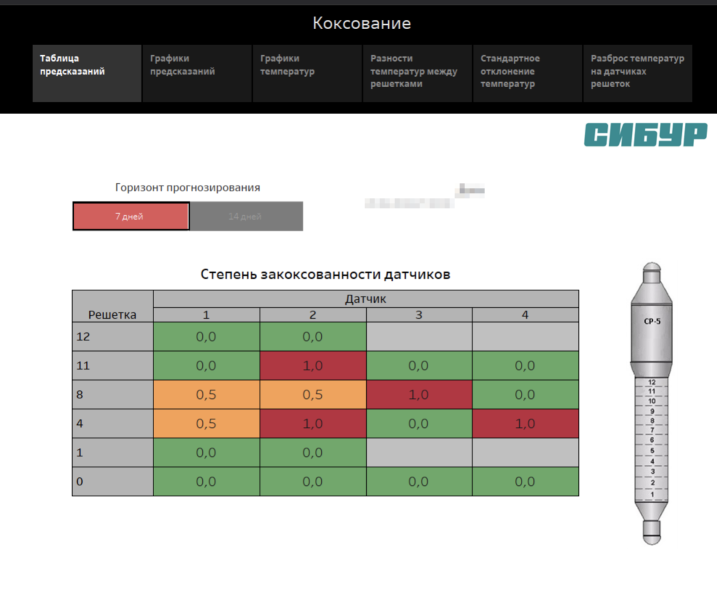

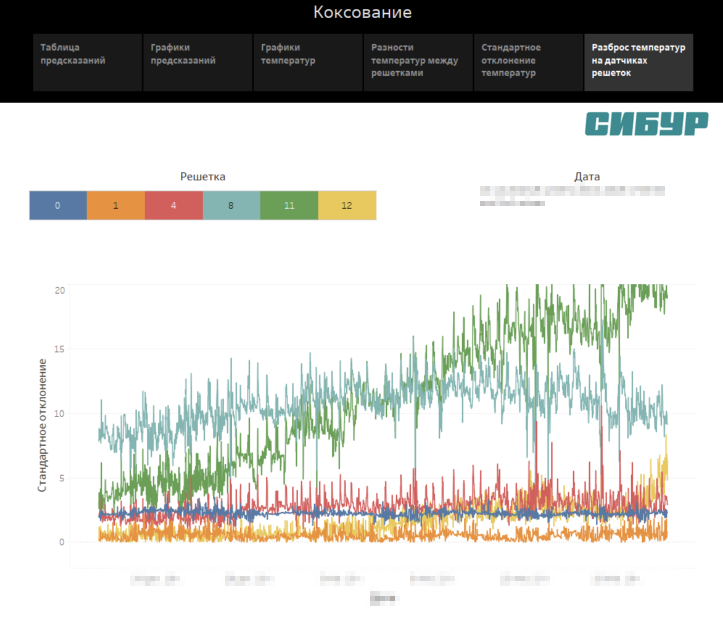

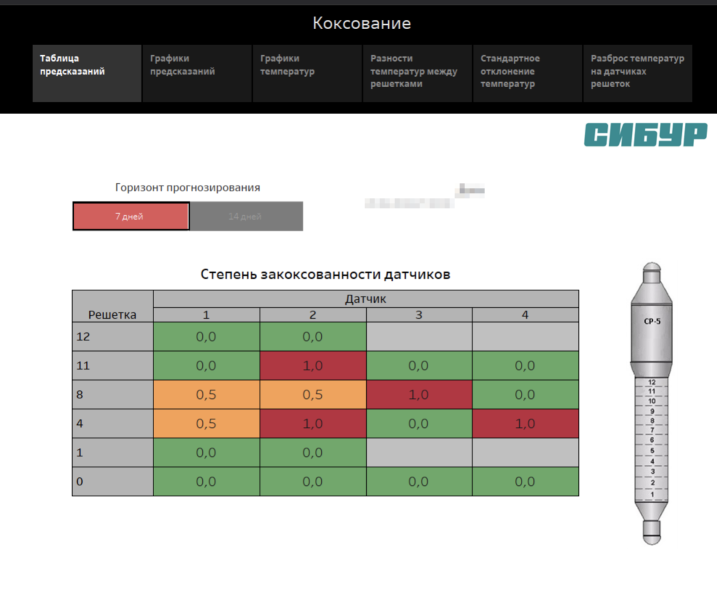

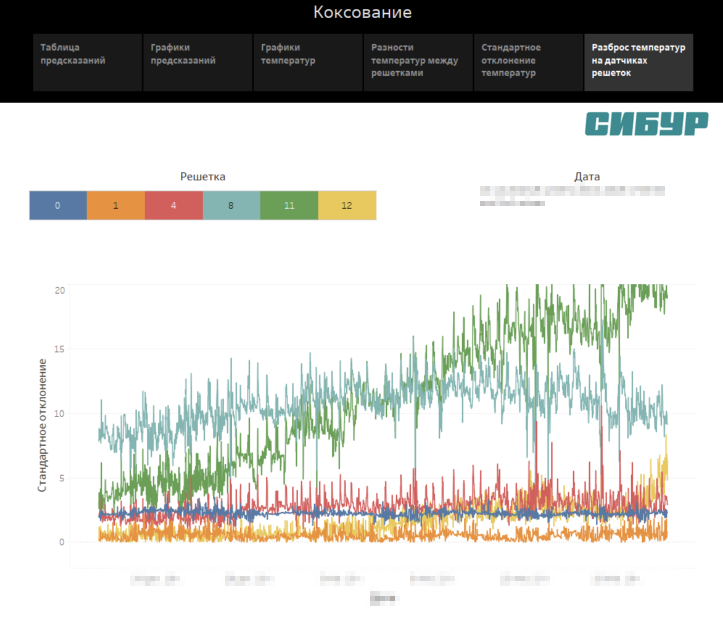

Lattices with thermocouples (thermal sensors) are installed in the reactors. Often, during the operation of the reactor, coke adheres to these grids, which leads to the destruction of the grids and an increase in the repair time at shutdown. And when this happens, the reactor is stopped, it is all cleaned, and the damaged elements are replaced. A simple time of about 7 days. The idea was to predict the formation of coke, to burn it with a stop for a short period and in this case without opening the reactor itself, thereby increasing the turnaround time.

How can you understand that coke begins to accumulate in the reactor? Make him x-ray. But it entails large financial costs. Therefore, it was decided to optimize them and resort to analytics.

When coke begins to stick to temperature sensors, as a rule, they show a slightly lower temperature, as well as a lower dispersion of this temperature. We watched this, built a model that predicted coking without gamma scanning. This model is still at the pilot stage, now its use allows:

- Give a single interface to monitor all sensors on all arrays.

- Understand and plan in advance the repair work and the load on the repair staff.

- Reduce the repair time and downtime due to repairs.

Not a single production

There may be an opinion that analytics in production is connected only with production itself. In fact, this is not the case, we also have marketing cases. For example, we can predict market prices for certain types of products.

It is important to note once again, we do not build models for the sake of models, we create finished products based on them. Therefore, we also created an ML framework, which has actually become the unified standard of model requirements. Regardless of which team made the product, or even third-party contractors through the API, creating their own models, it is important for us that all these models be in a single interface. This allows us to understand which model works fine, which starts to degrade, which one did not start at all due to lack of data and so on.

When there were only 5 models, everything was simple, and with monitoring, and with support. And when there are more of them (including contractors), an ML framework comes to the rescue, allowing you to save each digital product in a unified manner into a container and automatically deploy an API. We can put all the models in there and monitor them simultaneously.

Therefore, we use our own framework.

We have a lot of tasks, obvious and not so much, and we will be very happy for the data-Cyntists who decided to try themselves in a large enterprise, now we are looking for:

Product Owner (Moscow);

Data Scientist ( Moscow , Nizhny Novgorod , Tomsk ).

And here is a short video about how we work

Source: https://habr.com/ru/post/442910/

All Articles