As the 3D printing market grew in 2018 and what does this mean for business

The French company Sculpteo has published a regular annual report on the state of the 3D printing industry. The purpose of the study is to provide a comprehensive overview of the market of additive technologies, analyze trends and help companies build their business strategies. The report is based on a survey of more than 1,000 managers and technical specialists of production companies, which was conducted throughout the year throughout the world.

3D printing is an obvious competitive advantage.

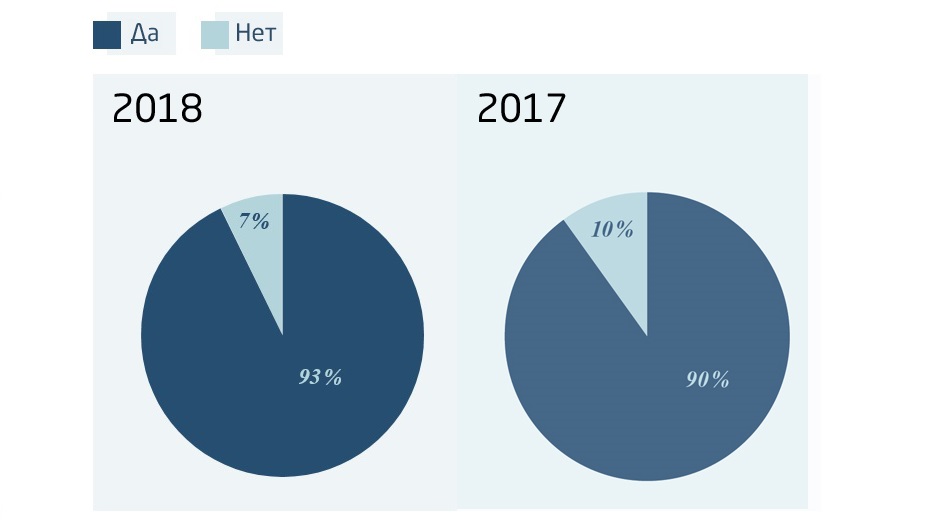

Regardless of the industry in which you work, 3D printing is a real competitive advantage. Thus, 93% of respondents view 3D printing as a competitive advantage, and this figure continues to grow from year to year.

Do you think 3D printing is a competitive advantage?

')

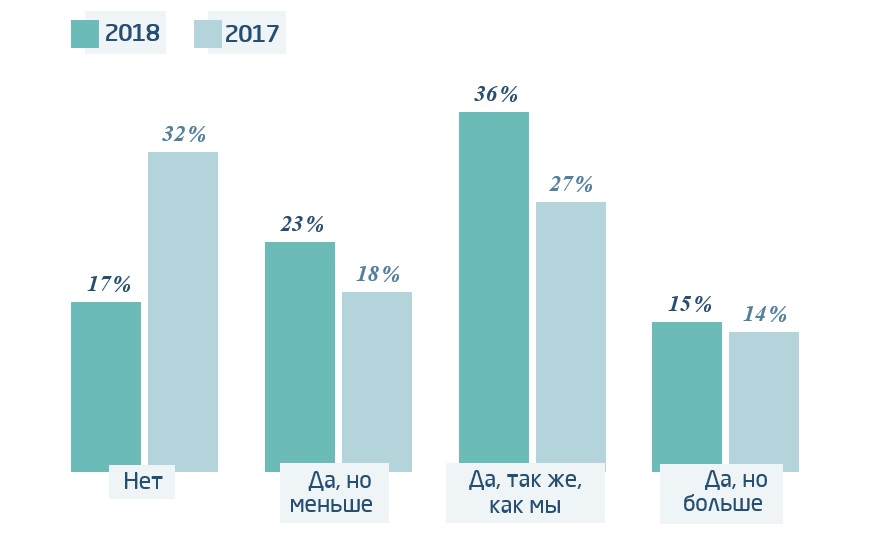

It can also be noted that since 3D printing is now beginning to be applied in a wide variety of industries, it is becoming an increasingly important condition for maintaining competitiveness . Thus, the majority of respondents noted that their competitors also use 3D printing - in 2018 the number of such answers was 74% versus 59% in 2017.

This once again confirms that more and more companies include additive manufacturing in their strategy; In many areas of activity, this is already a reliable and widespread process of production or prototyping.

Are your competitors using 3D printing?

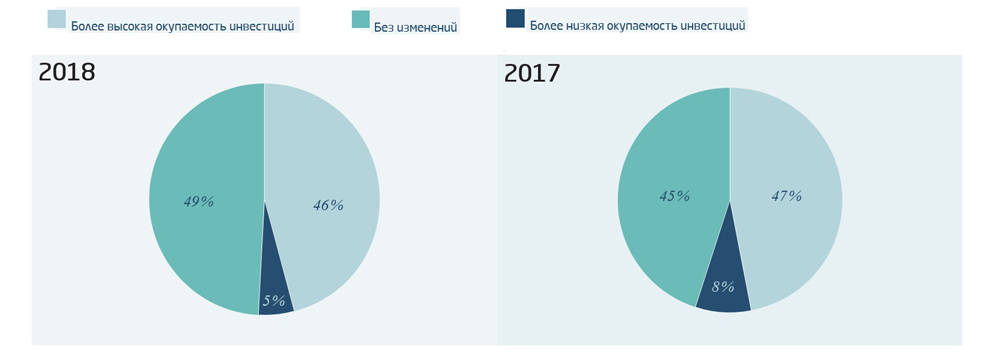

As for the return on investment of companies in 3D printing, 46% of respondents noted that in 2018 the return on investment increased, while for 49% of respondents it remained almost the same as in the previous year. This is a stable result, professional consumers of additive manufacturing are satisfied with their investment in 3D printing.

What is the return on investment in 3D printing in your company?

Using the full potential of 3D printing for various purposes

In 2018, companies were more likely to invest in 3D printing. Professionals, in fact, are beginning to apply this technology to solve a wider range of tasks, expanding the number of areas in which additive manufacturing is being introduced.

3D printing applications

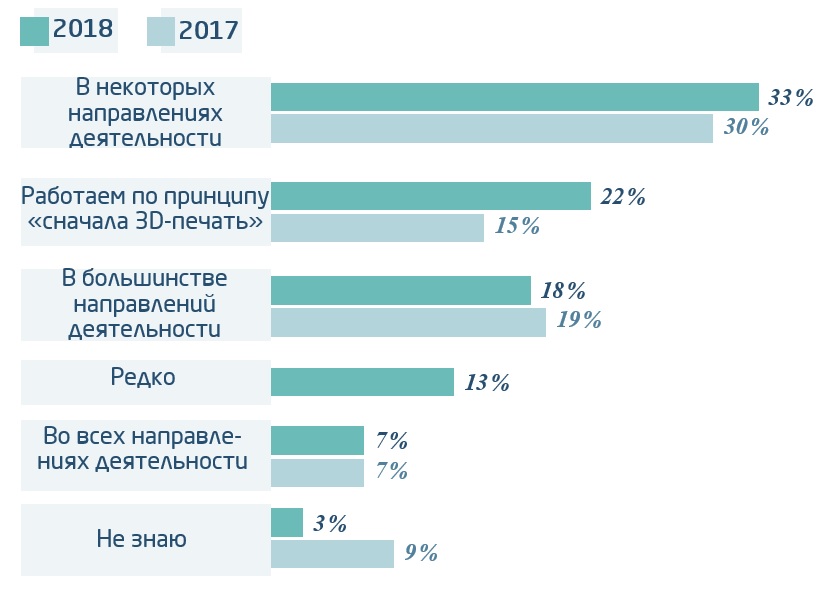

As in 2017, 3D printing is mainly used for prototyping, production and production of prototypes. There are no big changes, but at the same time, companies around the world are more inclined to use 3D printing for several purposes at once. It may be noted a higher degree of integration of 3D printing in various fields of activity of companies. Thus, the share of enterprises operating according to the principle “first - 3D printing” has grown from 15% to 22%!

Integration

Enterprises are adopting all the advantages of this advanced technology and use it without hesitation in various fields.

Which units derive the maximum benefit from the use of additive technologies?

As in 2017, 3D printing is mainly used for R & D, design and production. The share of use of 3D printing by R & D units is 46%, by design units - 43%, and the share of application of additive technologies directly in production is 41%.

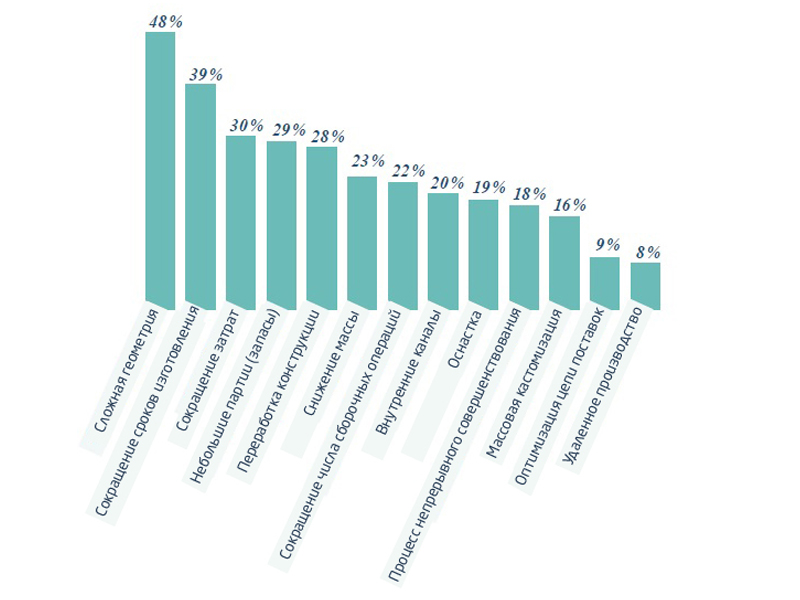

As for the advantages of 3D printing, (although the main reasons for using additive manufacturing, respondents called cost reduction and reduced production time) for 48% of them, the ability to create products of complex geometry also plays a significant role.

The benefits of 3D printing

Businesses are buying more 3D printers, but still using 3D printing services.

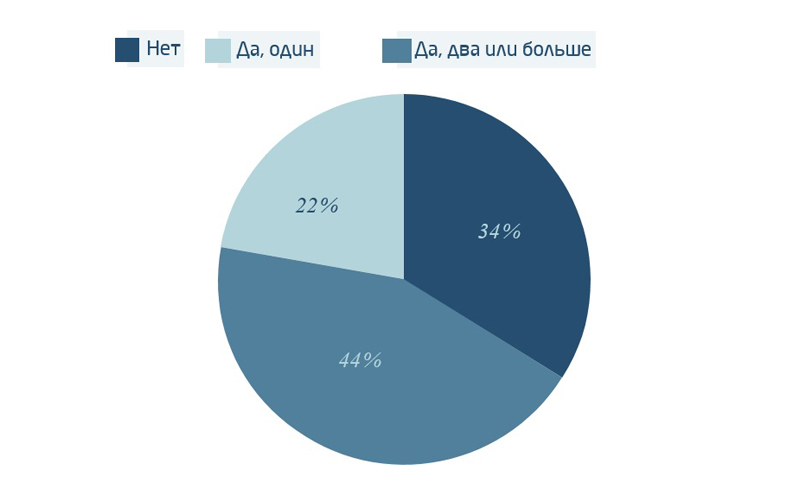

We clearly see that more and more companies are making the decision to purchase 3D printers . So, the majority of respondents have their own 3D printer (66%), and 44% have more than one. In 2017, 53% did not have any printers, and only 28% had two or more printers.

Does your company have its own 3D printer?

Most respondents have FDM printers (75% of those who own a 3D printer), which is fully justified, since it is the cheapest type of 3D printer. Additive installations of this type are also easier to use. SLA printers occupy the second place (29%), and only 15% of respondents have printers operating on SLS technology .

Thus, consumers are obviously less likely to acquire professional 3D printers , such as SLS printers, due to their higher price and complexity. Nevertheless, printers of this type have a much larger number of enterprises than in 2017 (8%), while the share of FDM printers has decreased (85% in 2017), which indicates an increase in the professional level of this market, even from a point view of acquired technologies.

As for 3D printing with metals , the most common are DMLS printers (16%). Only 4% of respondents have additive SLM-based installations. At the same time, the share of enterprises with metal 3D printers has increased significantly (2017 figures: 1% for DMLS printers and 2% for SLM printers).

What kind of 3D printer are you using?

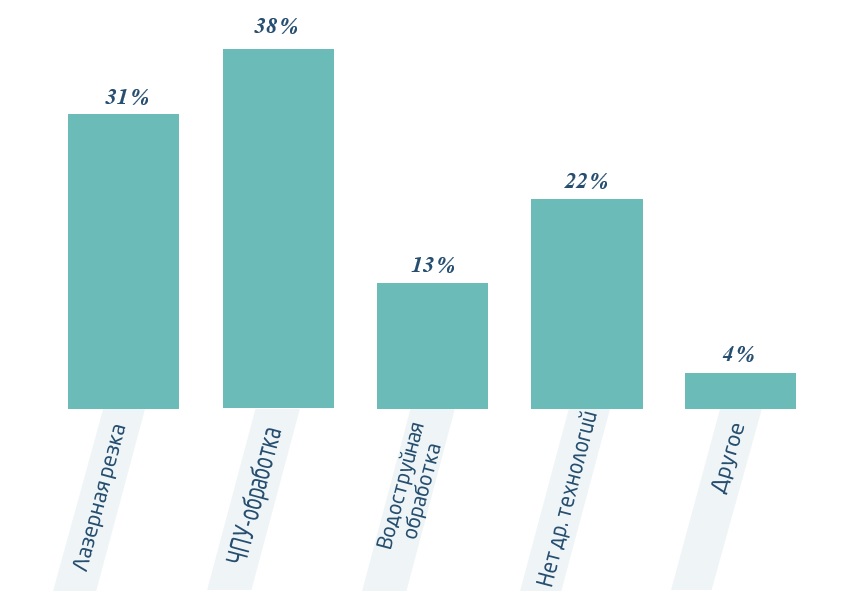

Do you use other digital production technologies?

What can you say about 3D printing services?

For example, the SLS technology is used by 38% of respondents, but only 15% of them have their own SLS printer. This suggests that companies make extensive use of professional 3D printing services , ensuring that they have access to those additive manufacturing technologies that they do not have.

8 major changes that companies consider necessary to make to maximize the benefits of 3D printing

- Improving the level of skills and training of employees

- Marketing and communication.

- Investing in 3D printers.

- Reducing the cost of 3D printing.

- Increase in sales.

- Improving the integration of 3D printing in the company’s business.

- Attraction of financing.

- Improving corporate culture and organization.

According to survey participants, in order to extract the maximum benefit from 3D printing, they, first of all, need to increase the level of qualification and training of their employees. Indeed, it is often the inadequate level of training in the field of technologies for additive manufacturing that is the factor that prevents enterprises from fully using 3D printing. Many point to the need to change corporate culture and organization.

You also need to make a lot of changes in marketing, sales and profits. According to respondents, to maximize the benefits from the use of additive technologies, it is important to invest more in marketing activities in areas related to 3D printing, and also to look for new ways to make a profit, either by increasing sales or by attracting funding.

7 major trends that will have a significant impact on 3D printing

- Cost reduction.

- Innovation in the field of materials .

- 3D printing with metals.

- Speed.

- 3D printing in medicine and bioprinting.

- Quality and accuracy.

- 3D printing for mass production.

The trend, which is called much more often than others, is the reduction of costs from year to year. This is understandable, since reducing the cost of 3D printing means simplifying the use of this technology. Also among the most influential trends still carry 3D-printing with metals.

Compared to 2017, respondents more often emphasized the need for innovation in the field of materials, which is associated with the growing importance of the supply of materials and their cost.

Also mentioned more often is the trend of using 3D printing for mass production , since it is increasingly becoming a full-fledged production process used for the manufacture of final products. This also leads to the fact that speed and quality are beginning to play an increasingly important role.

The significant reduction in the role of personal 3D printing is also understandable, since this confirms the trend towards an increase in the professional level of this market.

Industry statistics: aviation industry

Among the enterprises of the aviation industry there are practically no newcomers in the field of 3D printing (unlike other industries). Thus, 59% of respondents working in the aviation industry have a qualification at the specialist level and 38% have an average level of knowledge of 3D printing. Obviously, these companies have mastered additive technologies well enough and are more able to implement technical projects in their industry.

How do you assess your level of qualification in the field of 3D printing?

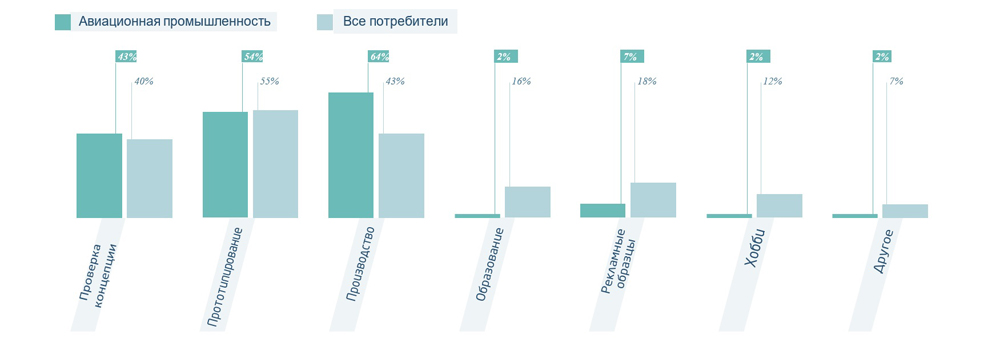

While in other industries, additive manufacturing is more often used to create prototypes and prototypes, in the aviation industry 3D printing is used mainly for production: for this purpose, 3D printing is used by 64% of respondents, which is much more than in other industries.

For what purpose do you use 3D printing?

This shows that the technology is developing and already allows you to create technical details for such industries.

54% of respondents working in the aviation industry increased their income by 1-50%, while the total share of companies that increased their income was 71%. It looks promising enough and suggests that 3D printing provides real financial advantages to such companies using additive technologies for production.

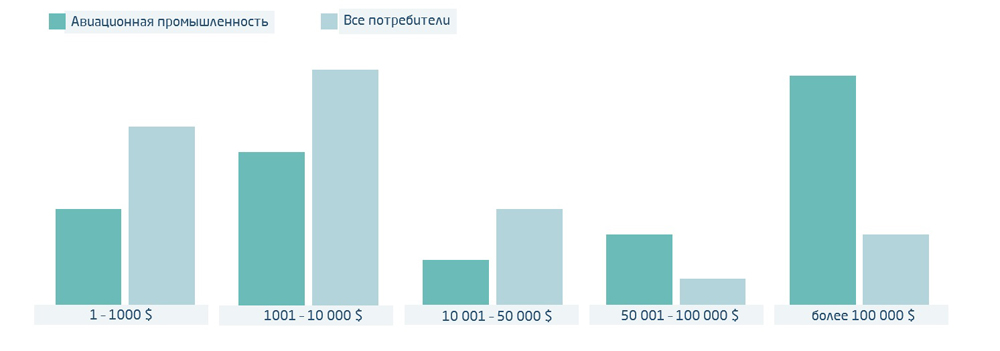

In 2018, 37% of representatives of aviation enterprises spent more than 100 thousand dollars on 3D printing.

How much do you spend on 3D printing?

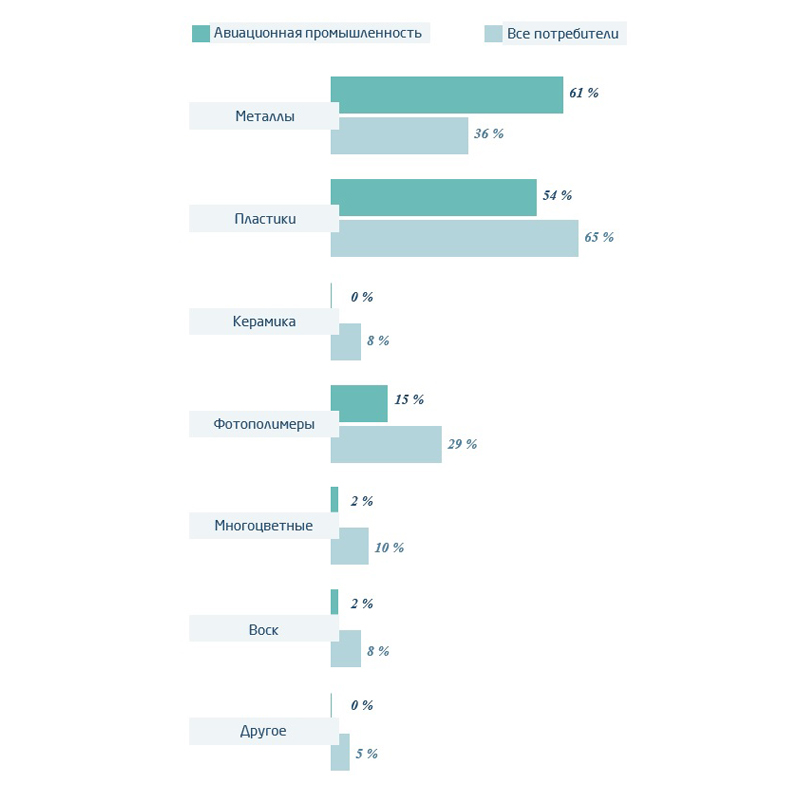

Since these companies use additive production for production, it can be assumed that such a high level of costs is explained by the fact that they have to use expensive materials and technologies . This assumption confirms the fact that 61% of respondents use 3D printing with metals versus 30% of the total sample. This level of costs also shows that companies are confident in this production technology and are not afraid to invest big money in it. And since, as we see, respondents are talking about increasing their income, we can conclude that they are satisfied with their investments.

What materials do you use for 3D printing?

To what extent is 3D printing integrated into your business?

Translation from English. The material Sculpteo State of 3D Printing 2018 is abbreviated.

Source: https://habr.com/ru/post/441172/

All Articles