Chinese polysilicon giant increases power

Chinese polysilicon manufacturer Daqo New Energy in December 2018 reported that it had increased its production capacity to 30,000 tons / year (relative to 20,000 tons per year compared with 2017 - approx. Translation.) , Followed by an increase of 5,000 tons / year for 6 months and another 35,000 tons / year by the end of March 2020.

Another turning point in the plans of the Chinese polysilicon giant, Daqo New Energy, has been passed through a systematic reduction in the price of raw materials for the production of solar panels. The last stage in increasing the production capacity has already been passed, and the process goes even ahead of schedule.

The end of phase 3B of the company's strategy from Chongqing (Chongqing) resulted in an increase in productivity of up to 30,000 tons per year and an agreement with local electricity providers to reduce the cost of electricity for the Xinjiang plant. This led to the fact that on December 18, 2018, Daqo in its press release reported that the company will produce polysilicon for only $ 7.5 per kilogram in the first three months of the new 2019 (the original wording is “Western New Year” - comment translation.) .

')

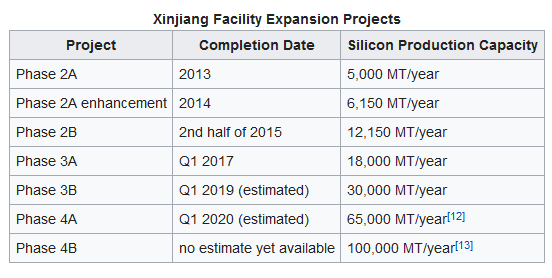

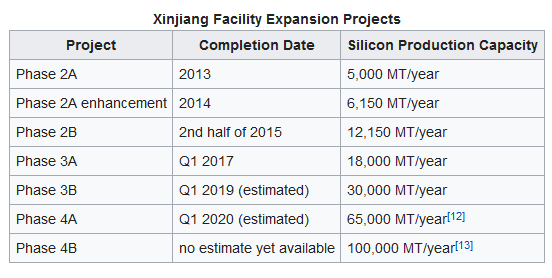

About the company's market conquest phases

The initial phases of Dago’s strategy to conquer the world, the conquest of the market, and a general overview of the company can be viewed on the Wikipedia page, since, by tradition, Chinese websites are not very informative.

In a cautionary appeal to European competitors such as Germany's Wacker Chemie, Daqo CEO Lungyen Zhang, said:

“Our team continues to optimize phase 3B to improve economic performance. This will give us even greater competitive advantage. ”

Plans to double production

Mr. Longen noted that further price cuts are not just boasting, noting that the elimination of narrow (economic and industrial) sites of phase 3B will increase productivity to 35,000 tons of polysilicon per year by the end of June 2019. And after 4-6 months the company plans to implement phase 4A of its plan and double the amount of polysilicon production, bringing it to 70,000 tons per year.

Daqo implements a widespread Chinese corporate strategy to oust competitors from the market, based on the infusion of large amounts of money and biting off a large chunk of the sales market with low margins. The management considers this method quite feasible, considering the restoration of global demand for photovoltaics.

“We are still confident in our strategy and believe that our leadership in the polysilicon industry will be strengthened as the market recovers”- added Mr. Lungyen in his statement.

___________________________

"Since you have read to the end ..."

After a fair remark Mavka-pony , I finish the production schedule by year. In 2017, about 20,000 tons of polysilicon were produced.

Source: https://habr.com/ru/post/433920/

All Articles