We study nitrogen lasers - part 1. Transverse discharge lasers

Probably everyone interested in homemade electronic products wondered if it was possible to make a laser on their own at home. And surely, very often he stumbled upon a rather predictable answer from his elders, that it is very difficult or almost impossible, they say, laser radiation can only be obtained from special expensive crystals and glasses, or some other unknown materials that can be obtained only in Dark Swamps or in the Western West. In fact, it is not. The number of substances in which the laser process is possible is estimated in thousands, and some of them are literally under our feet, and literally around us, everywhere. So, for example, you can be surprised to learn that it is possible to obtain lasing in water vapor, in dyes extracted from felt-tip pens, and finally, in carbon dioxide exhaled by many living creatures, lasing with a power of hundreds of kilowatts was obtained. But, there is another laser working environment, which is much more common than all the others combined. This is nitrogen, which is 78% in atmospheric air.

If you make a request in Google "homemade laser", then it is the nitrogen that pops up first, with many examples of structures:

')

Consider the principle of its work and construction in more detail.

Nitrogen laser - a typical representative of molecular gas lasers, which works on electronic transitions in the nitrogen molecule. Its main property is intense generation in the ultraviolet range, with a main wavelength of 337.1 nm. The properties of nitrogen as a working medium make generation possible only in a pulsed mode, since transitions are self-limited, i.e. the duration of the population inversion at such transitions is limited by the accumulation of particles at the lower level; it is not longer than the lifetime of the particles on the upper working level. The lifetime of the upper level of nitrogen in the order of 40 nanoseconds, therefore, the emitted laser pulse is also very short, of the order of units to tens of nanoseconds. This imposes specific requirements on the electrical impulse of excitation - it must also be short with a steep front in order to have time to translate a large number of molecules into an excited state during the lifetime of the upper level.

At the same time, nitrogen, as an active medium, has a very high gain factor, so high that no mirrors are needed - it may well work in superluminance mode, when radiation amplification occurs in one pass. And yet, it can work in a wide range of pressures up to atmospheric. And, as it turned out, the oxygen in the air does not interfere, although it reduces the maximum achievable generation power. Thus, a rather attractive picture emerges for the homemaker: the working environment is extremely accessible, no fussing with vacuum and gases is needed, and scarce materials are not needed. Even the mirrors of the optical resonator are not needed. You only need to tinker a bit with high voltage. Let us consider in more detail the device of a nitrogen laser, which is proposed for independent production.

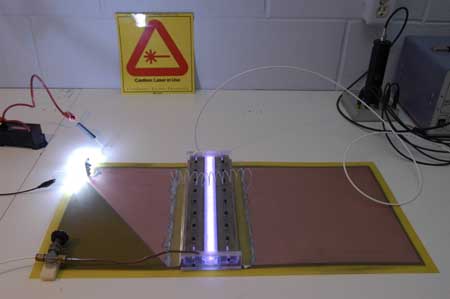

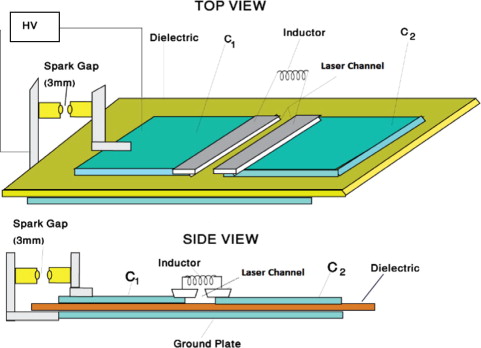

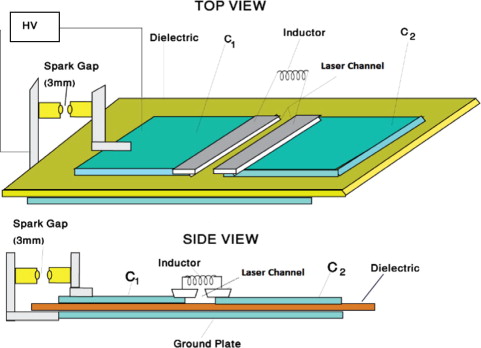

Based on the requirements for the excitation pulse, as a rule, a laser pumping circuit based on the Blumlein generator, which consists of two flat capacitors, which can be formed from several layers of aluminum or copper foil and a dielectric film, emerges. The switch in this device is the simplest spark gap of two screws with rounded heads. It would seem, where is the laser itself? And the process of generation of laser radiation is almost unnoticeable - in the gap between the two metal lines, in which a pulsed discharge is burning. Rulers are fixed on opposite edges of flat capacitors C1 and C2. The discharge burns across the axis of the lines, and the laser radiation goes along, respectively, a gas laser with a transverse discharge is obtained. So that the discharge does not light up at the moment of charging the capacitors - parallel to the laser gap a small choke is turned on, which short-circuits the DC gap. It is necessary to apply a high (of the order of 10-15 kV) voltage as shown in the diagram - and the laser will work. As a source of VN, any suitable means is suitable - a stun gun, a power supply unit from an air ionizer, an electrophore machine, a HV source from a CRT TV or monitor. Since it works without mirrors, the radiation comes from both ends of the lines. Since it emits in the ultraviolet - it allows you to become well acquainted with the luminescence of various objects and materials. And yet such a laser is quite convenient for pumping a dye laser - just addwater to the cuvette with the dye and place it under the beam.

For the same reason, as well, since the pulse energy is very small (tens of microjoules), its radiation is relatively safe for the eyes, since it is absorbed by the cornea and does not reach the retina. Although you shouldn’t look directly at the beam anyway - ultraviolet cornea burns are a rather unpleasant thing.

Thus, this scheme makes the “threshold of entry” into the world of laser technology very low; such a laser was built by countless people.

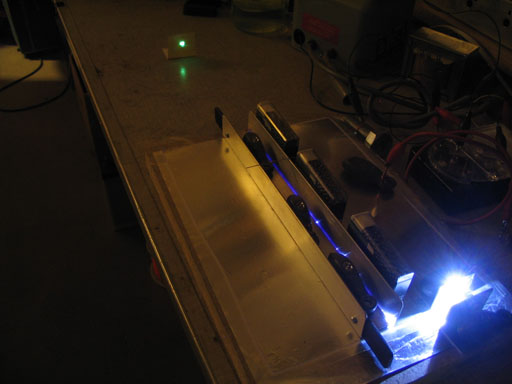

There are designs terrible. The green spot in the first photo is the luminescence of the “target” for radiation.

There are more detailed and accurate, such as this.

Yes, such a laser can be assembled in less than 2 minutes! Unless of course all the source materials are prepared, and the design is worked out, i.e. the hand is already full.

The availability and simplicity of the design of such a laser allows you to save a lot of money in Western university laboratories, if it does not impose special requirements on output parameters.

However, to guarantee the success of such a laser, there are several nuances that must be observed. The most important of them is that the edges of the ruler electrodes should be as smooth as possible and have rounded edges so that the discharge would not be able to assemble into one spark ignited from some kind of edge. The second is the correct choice of an insulating film for flat capacitors in order to obtain the maximum possible capacity with the highest possible electric strength. The third is the correct choice of the gap between the electrodes, which must be maintained exactly along the entire length and not be larger than 2-3 mm. It is then that the shortest current front will be obtained through the laser discharge. Tolerances on the last two nuances can be facilitated if the pressure of the working gas is reduced to 100-200 mmHg. Art., and if you apply pure nitrogen instead of air, but this automatically means the appearance of even a primitive, but a vacuum system, and the conclusion of the electrodes in a slightly tight volume. In this configuration, the distance between the electrodes can be increased, and the requirements for the steepness of the current front are somewhat reduced - flat capacitors can be replaced by compact ceramic. But such a design also has the right to exist.

For example, homemade lasers with nitrogen purging from Jarrod Kinsey.

Here, due to the abundance of various items on his desk, the laser itself is rather difficult to see.

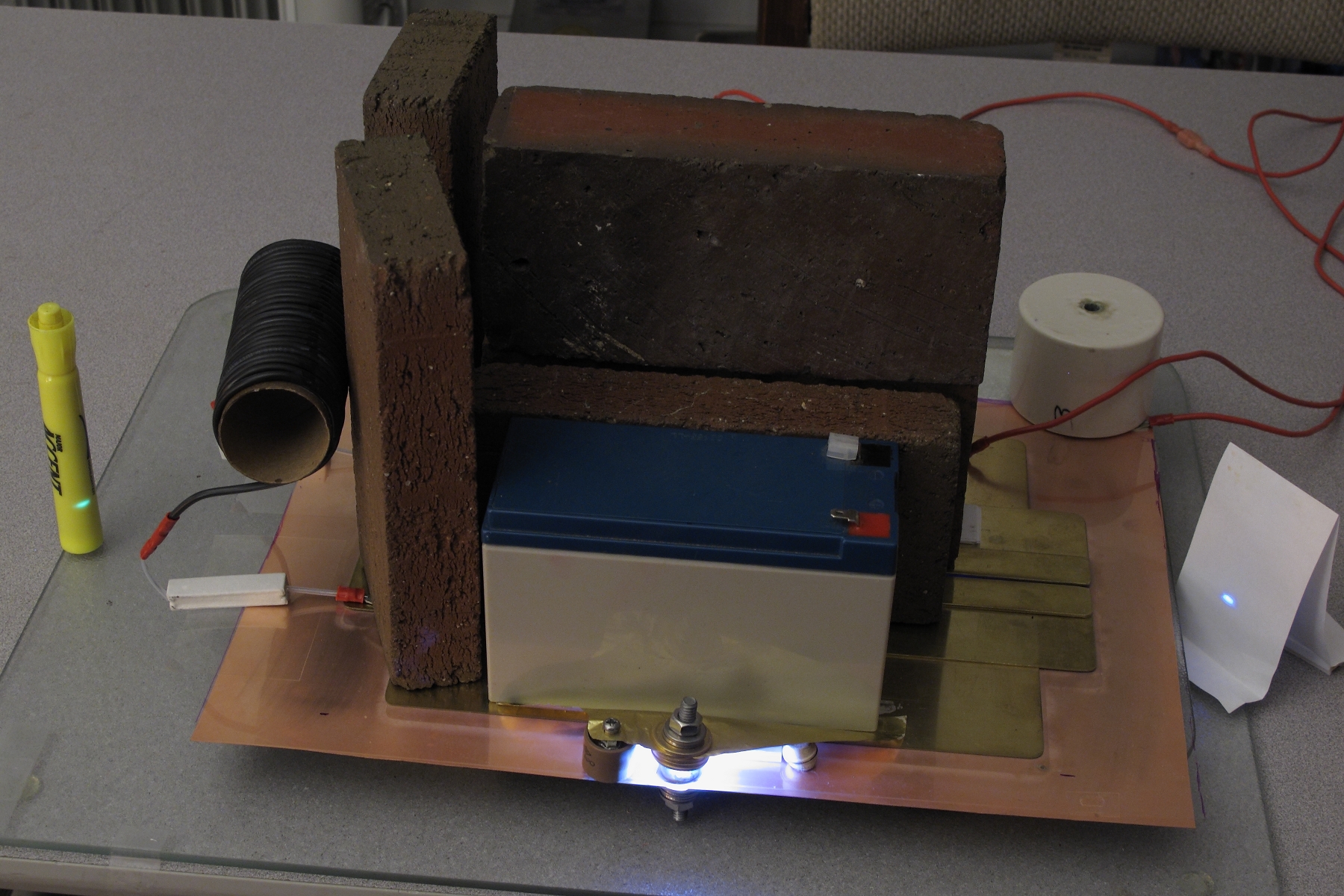

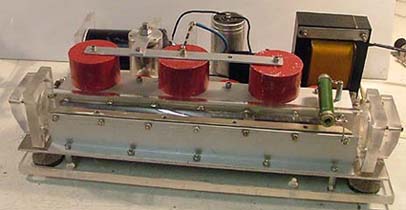

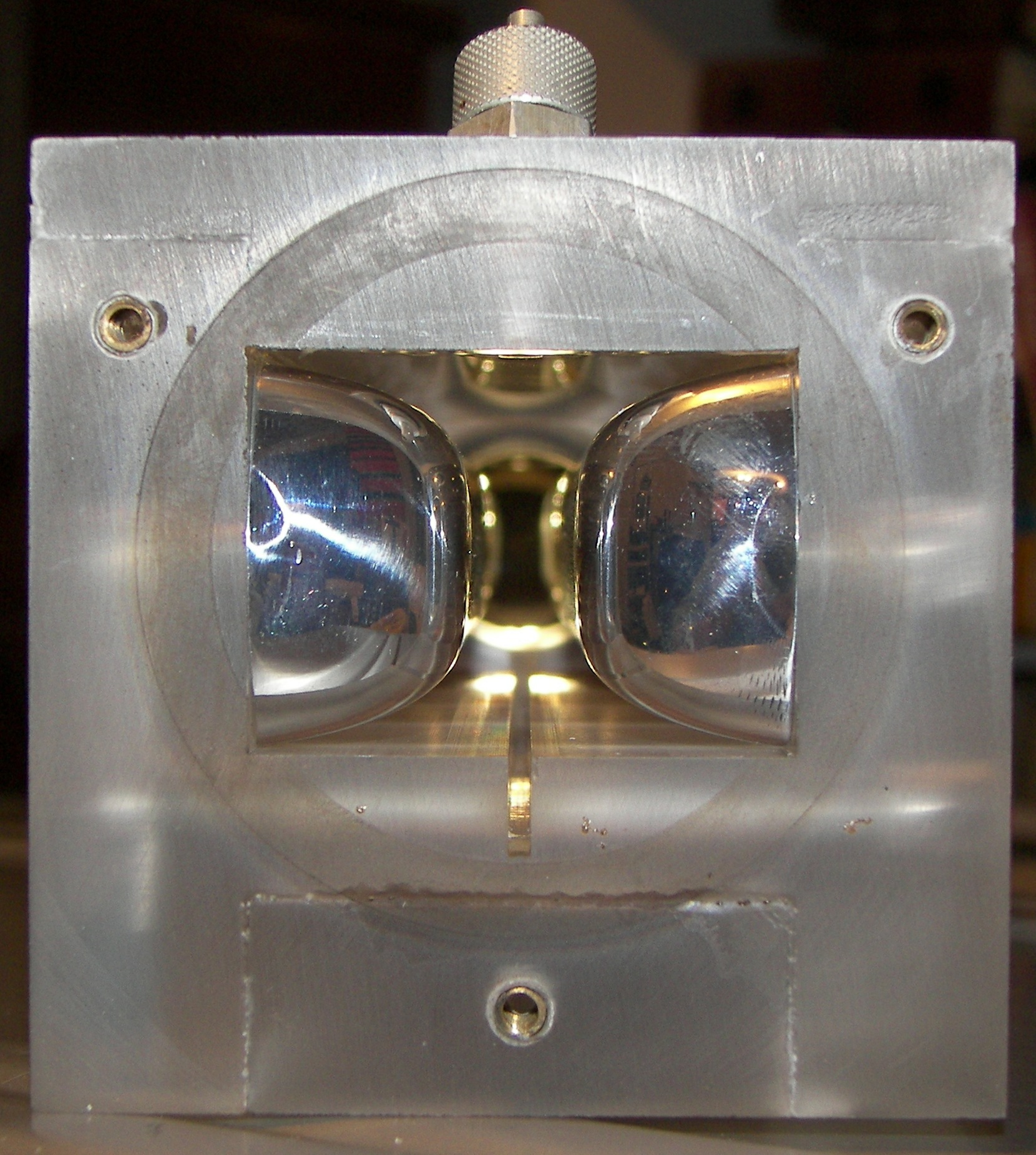

Nitrogen laser transverse discharge with reduced pressure, where flat capacitors are replaced by ceramic. The design of Thomas Rapp.

If anyone is interested in a very thorough and detailed guide to building such a laser with a description of all the unobvious nuances, then you should look again at the Yun Sothory website .

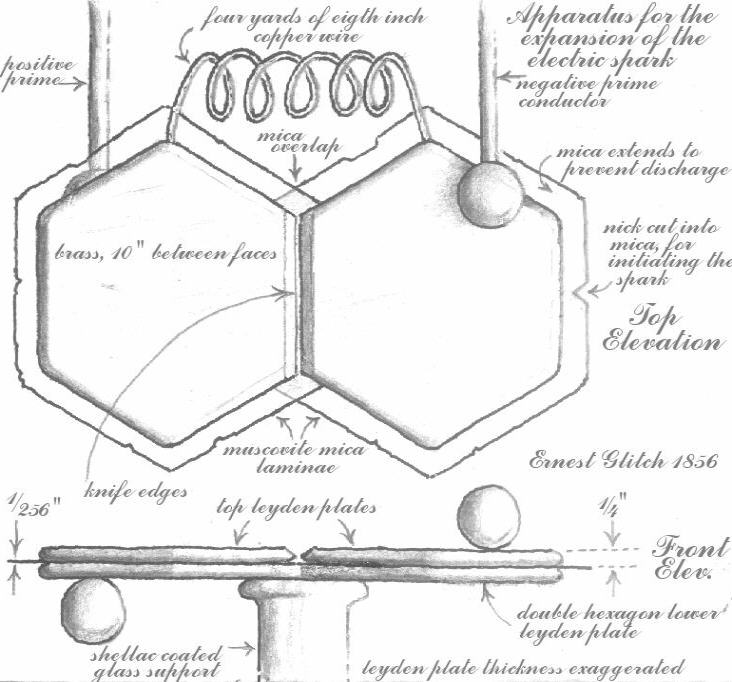

And there is also a fairly popular legend that the laser effect with a spark discharge in long air gaps could be detected long before the discovery of the principles of operation of the laser itself, in those times when they were just beginning to learn electricity. But this is a beautiful fake, like this one. That does not negate the veracity of its content.

An article describing the "laser of Victorian times" is here .

Now let us consider what kind of mass-produced nitrogen lasers are in principle. In the West, absolutely all the nitrogen lasers I have encountered are transversely pumped from the Blumlein generator. Just like the self-made laser described, only convenient laser controls were added there, more advanced power sources, instead of the simplest spark gap, a pulsed hydrogen thyratron or a controlled high-pressure spark gap, instead of large flat film and foil capacitors, many small ceramic electrodes between which the discharge takes place are located in a closed volume in which you can adjust the pressure and generally fill up any other gas. But the principle remains the same. This scheme has the following advantages:

Along with this, there are some drawbacks:

All the advantages and disadvantages mentioned are fully applicable to the self-made nitrogen laser.

Let's see how nitrogen lasers from Western manufacturers look like and compare their design with the simplest self-made one.

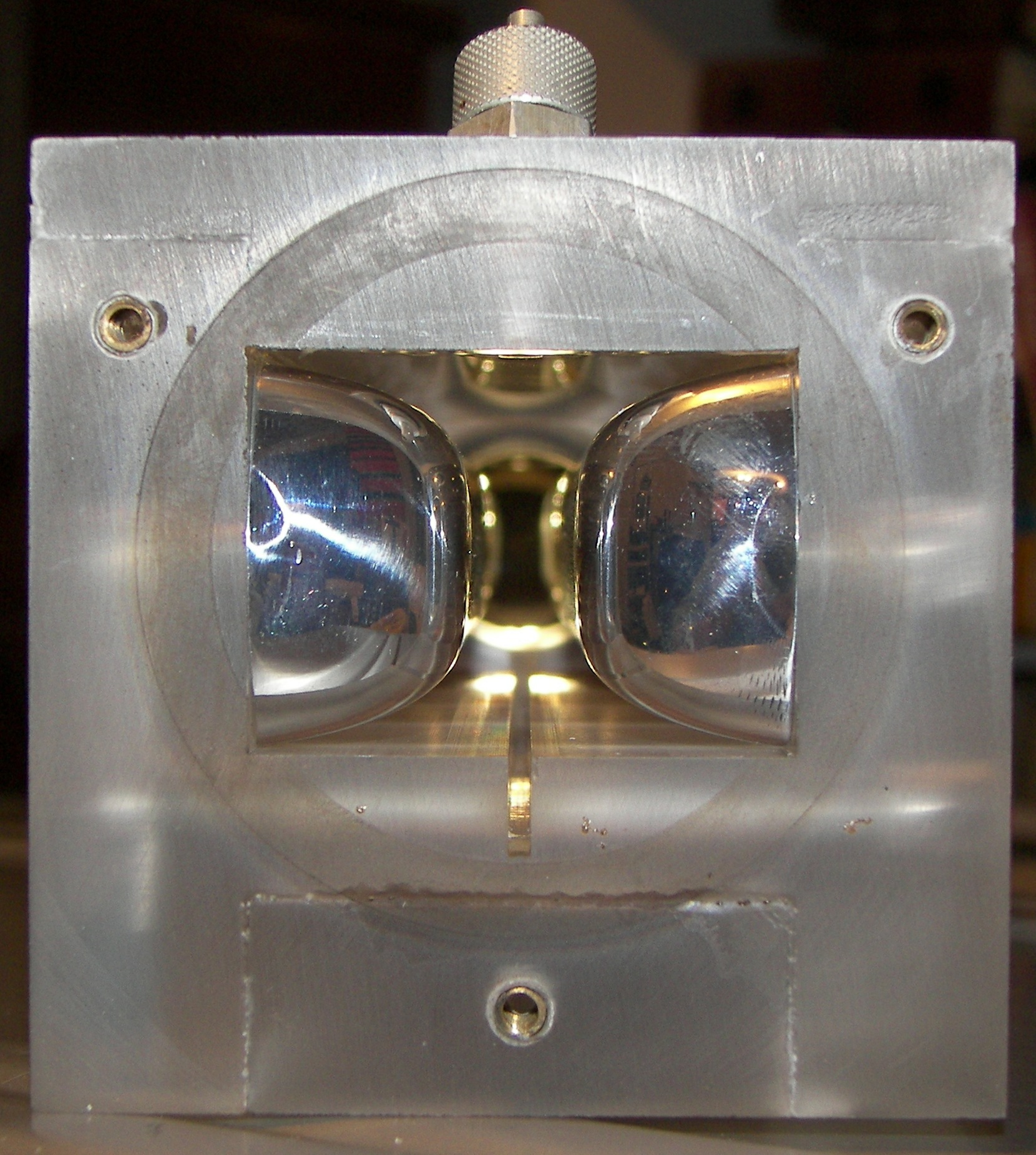

Small-sized nitrogen laser company Spectra-Physics and its laser camera with strapping. This transverse discharge laser with reduced pressure.

Instead of flat capacitors, they are ceramic, on top there is a controlled spark gap. The laser chamber is filled with nitrogen and sealed.

A powerful nitrogen laser operating on a non-fundamental transition in the blue region of the spectrum. You can see a lot of small ceramic capacitors and a blocking choke between the electrodes. To obtain lasing at wavelengths other than 337.1 nm, the addition of helium to nitrogen is required.

The very first laser camera with a transverse discharge, which was made in 1973.

Laser installation company Molectron.

The interiors of a high-power transverse-discharge laser, which, when changing the gas mixture and optics, can work as a CO2 laser or as an excimer laser.

The appearance of the electrodes of a commercially available transverse-discharge laser.

Laser camera for picosecond pulse durations.

Now, after all that has been said above, a quite reasonable question will arise to me whether I tried to repeat this construction. In fact, no, did not try. There were objective reasons for this. In short, I like a completely different type of nitrogen laser - not a transverse laser, but a longitudinal discharge! But about it in the following part .

Used sources:

1. www.jarrodkinsey.org

2. www.rapp-instruments.de

3. www.spakbangbuzz.com

4. www.jonsinger.org

5. www.swissrocketman.fr

6. www.mylaser.ucoz.ru

7. www.laserkids.sourceforge.net

8. www.technology.niagarac.on.ca

I hope I have not forgotten anyone.

If you make a request in Google "homemade laser", then it is the nitrogen that pops up first, with many examples of structures:

')

Consider the principle of its work and construction in more detail.

Nitrogen laser - a typical representative of molecular gas lasers, which works on electronic transitions in the nitrogen molecule. Its main property is intense generation in the ultraviolet range, with a main wavelength of 337.1 nm. The properties of nitrogen as a working medium make generation possible only in a pulsed mode, since transitions are self-limited, i.e. the duration of the population inversion at such transitions is limited by the accumulation of particles at the lower level; it is not longer than the lifetime of the particles on the upper working level. The lifetime of the upper level of nitrogen in the order of 40 nanoseconds, therefore, the emitted laser pulse is also very short, of the order of units to tens of nanoseconds. This imposes specific requirements on the electrical impulse of excitation - it must also be short with a steep front in order to have time to translate a large number of molecules into an excited state during the lifetime of the upper level.

At the same time, nitrogen, as an active medium, has a very high gain factor, so high that no mirrors are needed - it may well work in superluminance mode, when radiation amplification occurs in one pass. And yet, it can work in a wide range of pressures up to atmospheric. And, as it turned out, the oxygen in the air does not interfere, although it reduces the maximum achievable generation power. Thus, a rather attractive picture emerges for the homemaker: the working environment is extremely accessible, no fussing with vacuum and gases is needed, and scarce materials are not needed. Even the mirrors of the optical resonator are not needed. You only need to tinker a bit with high voltage. Let us consider in more detail the device of a nitrogen laser, which is proposed for independent production.

Based on the requirements for the excitation pulse, as a rule, a laser pumping circuit based on the Blumlein generator, which consists of two flat capacitors, which can be formed from several layers of aluminum or copper foil and a dielectric film, emerges. The switch in this device is the simplest spark gap of two screws with rounded heads. It would seem, where is the laser itself? And the process of generation of laser radiation is almost unnoticeable - in the gap between the two metal lines, in which a pulsed discharge is burning. Rulers are fixed on opposite edges of flat capacitors C1 and C2. The discharge burns across the axis of the lines, and the laser radiation goes along, respectively, a gas laser with a transverse discharge is obtained. So that the discharge does not light up at the moment of charging the capacitors - parallel to the laser gap a small choke is turned on, which short-circuits the DC gap. It is necessary to apply a high (of the order of 10-15 kV) voltage as shown in the diagram - and the laser will work. As a source of VN, any suitable means is suitable - a stun gun, a power supply unit from an air ionizer, an electrophore machine, a HV source from a CRT TV or monitor. Since it works without mirrors, the radiation comes from both ends of the lines. Since it emits in the ultraviolet - it allows you to become well acquainted with the luminescence of various objects and materials. And yet such a laser is quite convenient for pumping a dye laser - just add

For the same reason, as well, since the pulse energy is very small (tens of microjoules), its radiation is relatively safe for the eyes, since it is absorbed by the cornea and does not reach the retina. Although you shouldn’t look directly at the beam anyway - ultraviolet cornea burns are a rather unpleasant thing.

Thus, this scheme makes the “threshold of entry” into the world of laser technology very low; such a laser was built by countless people.

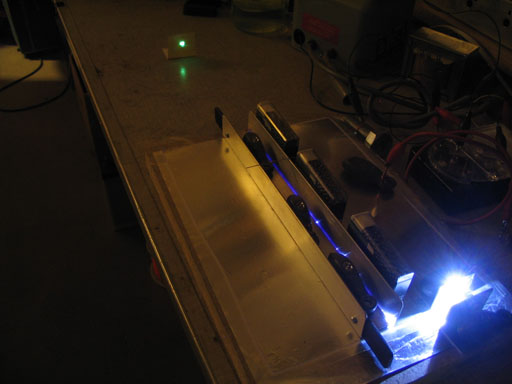

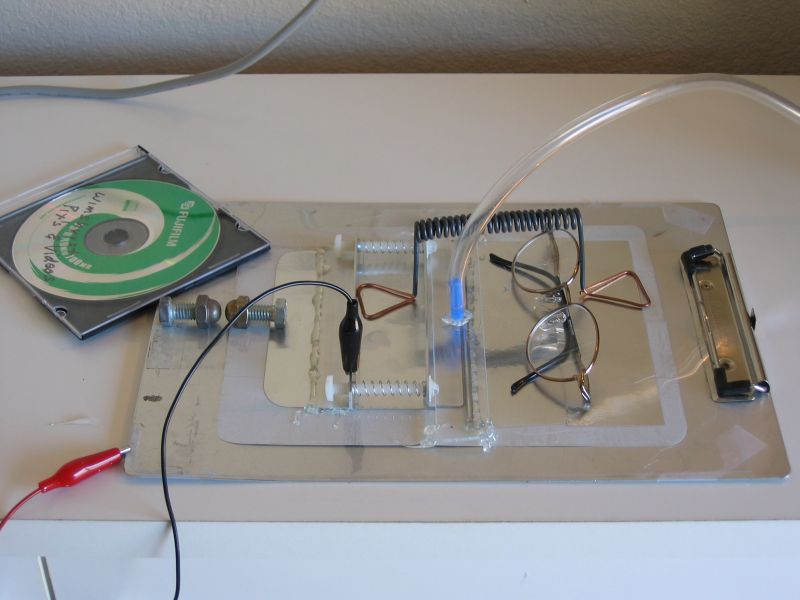

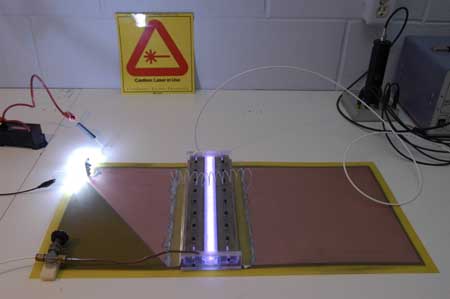

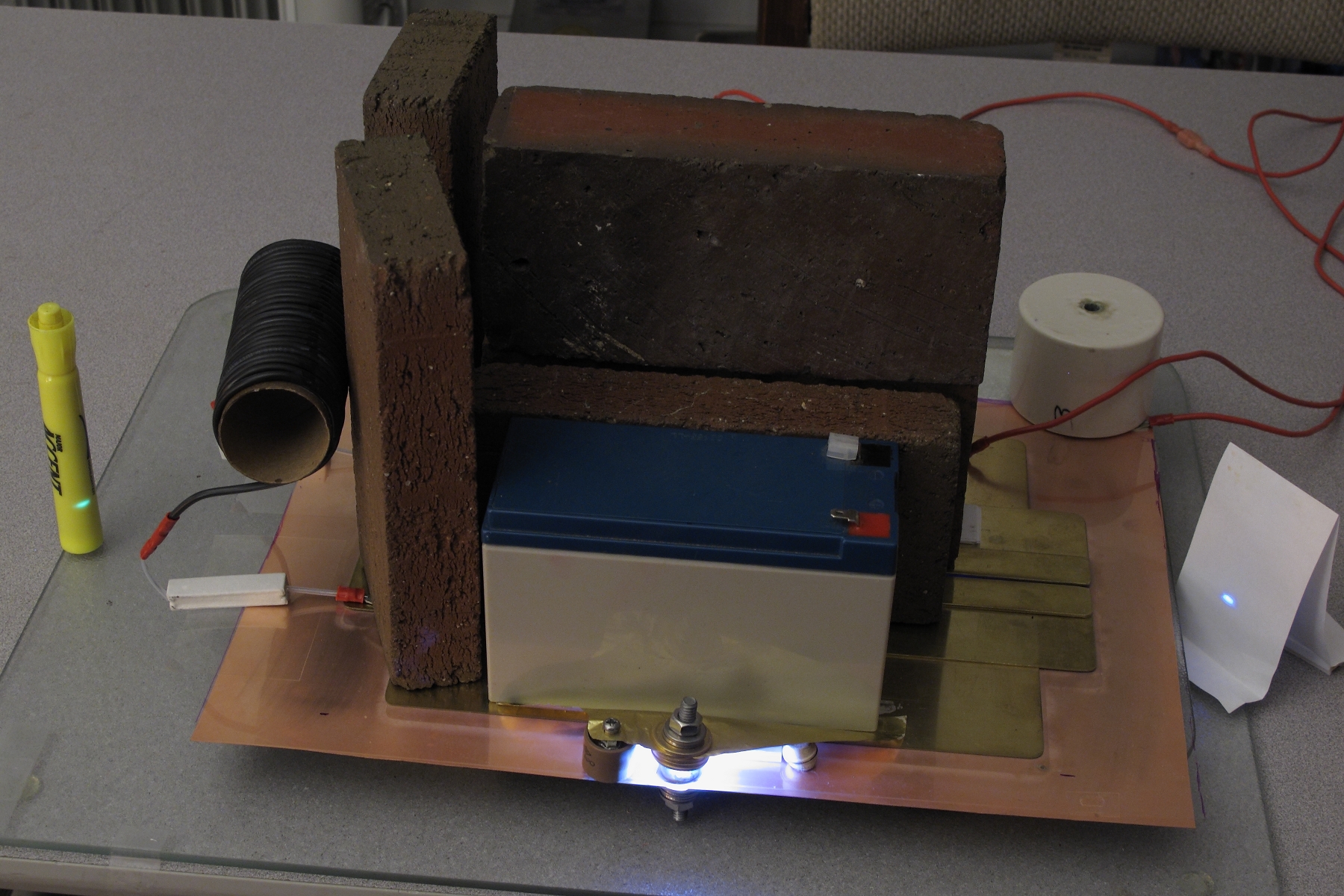

There are designs terrible. The green spot in the first photo is the luminescence of the “target” for radiation.

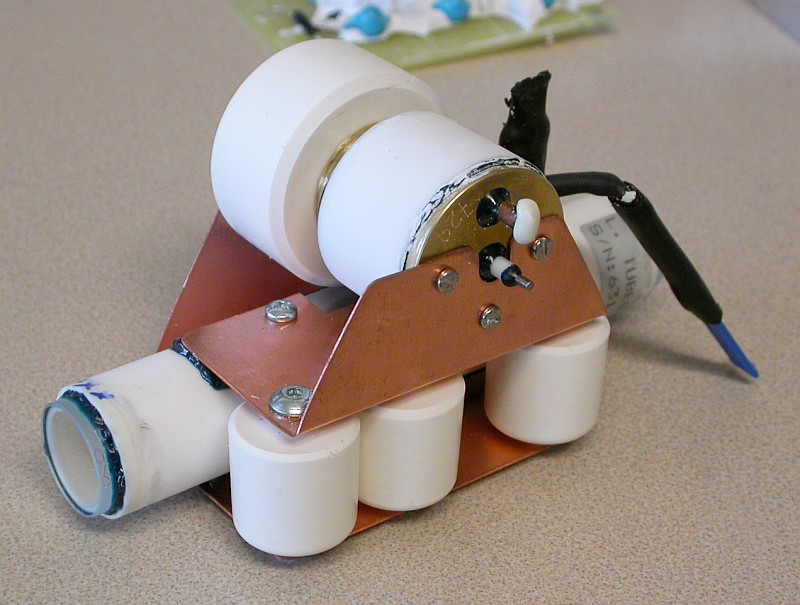

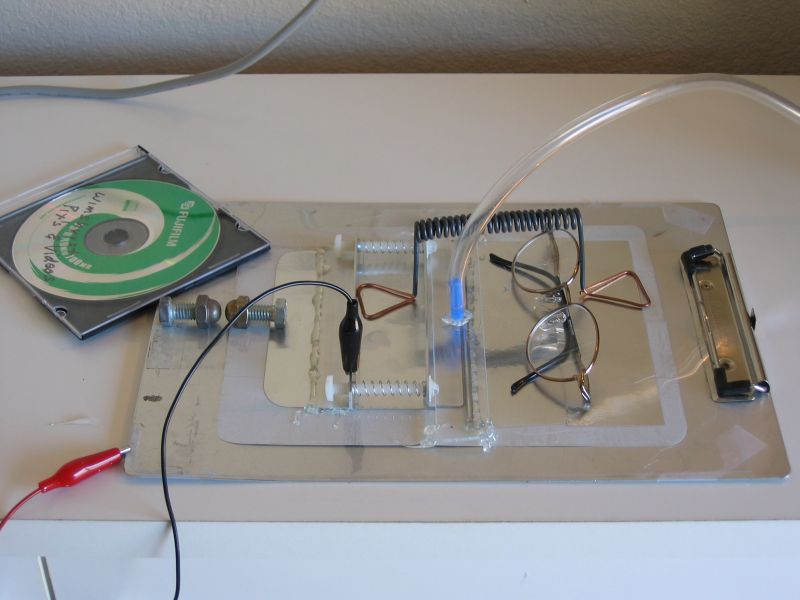

There are more detailed and accurate, such as this.

Yes, such a laser can be assembled in less than 2 minutes! Unless of course all the source materials are prepared, and the design is worked out, i.e. the hand is already full.

The availability and simplicity of the design of such a laser allows you to save a lot of money in Western university laboratories, if it does not impose special requirements on output parameters.

However, to guarantee the success of such a laser, there are several nuances that must be observed. The most important of them is that the edges of the ruler electrodes should be as smooth as possible and have rounded edges so that the discharge would not be able to assemble into one spark ignited from some kind of edge. The second is the correct choice of an insulating film for flat capacitors in order to obtain the maximum possible capacity with the highest possible electric strength. The third is the correct choice of the gap between the electrodes, which must be maintained exactly along the entire length and not be larger than 2-3 mm. It is then that the shortest current front will be obtained through the laser discharge. Tolerances on the last two nuances can be facilitated if the pressure of the working gas is reduced to 100-200 mmHg. Art., and if you apply pure nitrogen instead of air, but this automatically means the appearance of even a primitive, but a vacuum system, and the conclusion of the electrodes in a slightly tight volume. In this configuration, the distance between the electrodes can be increased, and the requirements for the steepness of the current front are somewhat reduced - flat capacitors can be replaced by compact ceramic. But such a design also has the right to exist.

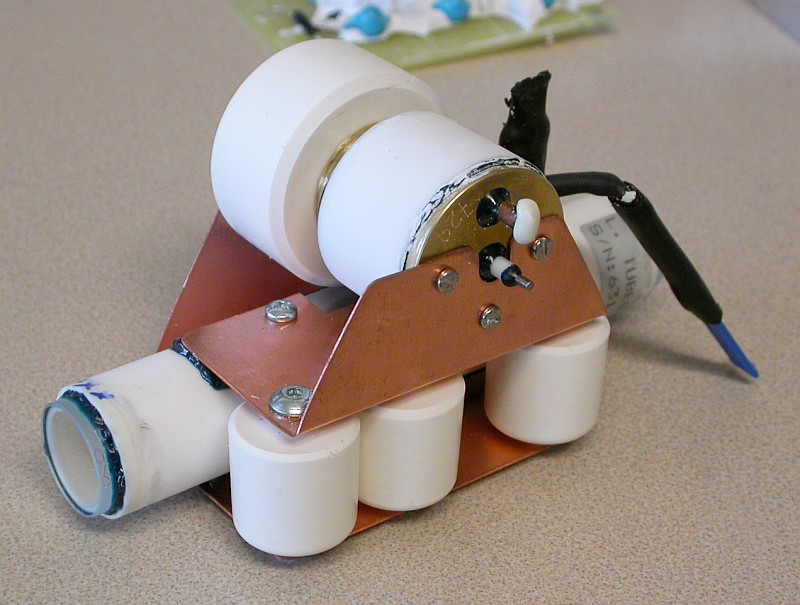

For example, homemade lasers with nitrogen purging from Jarrod Kinsey.

Here, due to the abundance of various items on his desk, the laser itself is rather difficult to see.

Nitrogen laser transverse discharge with reduced pressure, where flat capacitors are replaced by ceramic. The design of Thomas Rapp.

If anyone is interested in a very thorough and detailed guide to building such a laser with a description of all the unobvious nuances, then you should look again at the Yun Sothory website .

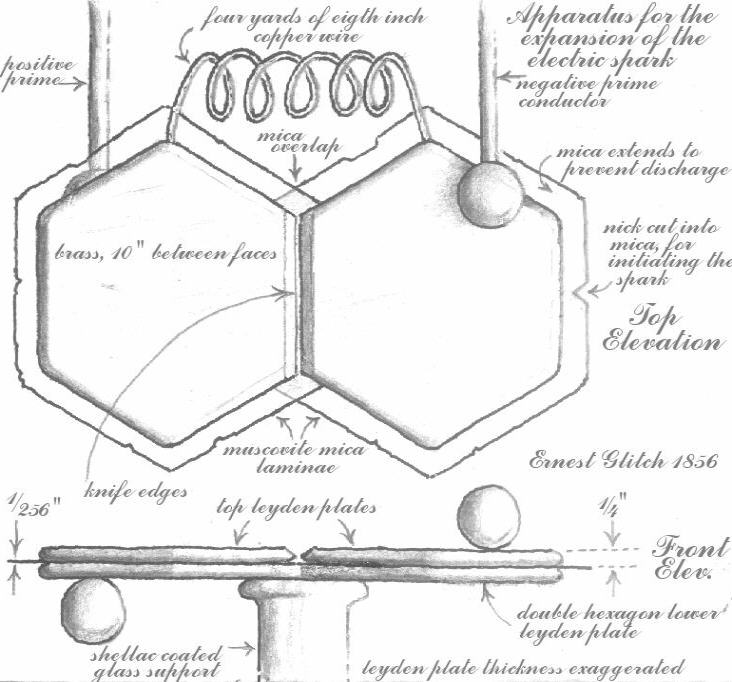

And there is also a fairly popular legend that the laser effect with a spark discharge in long air gaps could be detected long before the discovery of the principles of operation of the laser itself, in those times when they were just beginning to learn electricity. But this is a beautiful fake, like this one. That does not negate the veracity of its content.

An article describing the "laser of Victorian times" is here .

Now let us consider what kind of mass-produced nitrogen lasers are in principle. In the West, absolutely all the nitrogen lasers I have encountered are transversely pumped from the Blumlein generator. Just like the self-made laser described, only convenient laser controls were added there, more advanced power sources, instead of the simplest spark gap, a pulsed hydrogen thyratron or a controlled high-pressure spark gap, instead of large flat film and foil capacitors, many small ceramic electrodes between which the discharge takes place are located in a closed volume in which you can adjust the pressure and generally fill up any other gas. But the principle remains the same. This scheme has the following advantages:

- Simplicity. As mentioned above, in many cases even the design of an improvised simplest nitrogen laser operating in atmospheric air is quite applicable, even with quite serious scientific work in the laboratory.

- A rather serious output pulse energy is tens of millijoules at large installations.

- A very short pulse duration, in some cases a component of hundreds of picoseconds.

- The combination of the previous two factors makes it possible to achieve huge pulsed power - tens to hundreds of megawatts.

Along with this, there are some drawbacks:

- Disgusting beam quality. The beam is not round but oblong, with irregular intensity over the cross section. In some cases, this is not critical when, for example, you need to pump a dye laser.

- Limited pulse repetition rate, usually no more than a few tens of Hz.

- Energy instability from impulse to impulse.

- Some designs require periodic maintenance - changing the working gas, maintaining its pressure, periodic cleaning and polishing of the electrodes.

All the advantages and disadvantages mentioned are fully applicable to the self-made nitrogen laser.

Let's see how nitrogen lasers from Western manufacturers look like and compare their design with the simplest self-made one.

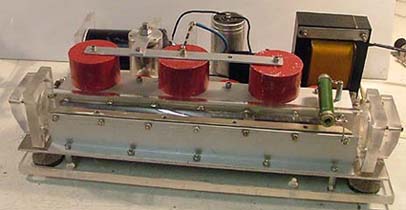

Small-sized nitrogen laser company Spectra-Physics and its laser camera with strapping. This transverse discharge laser with reduced pressure.

Instead of flat capacitors, they are ceramic, on top there is a controlled spark gap. The laser chamber is filled with nitrogen and sealed.

A powerful nitrogen laser operating on a non-fundamental transition in the blue region of the spectrum. You can see a lot of small ceramic capacitors and a blocking choke between the electrodes. To obtain lasing at wavelengths other than 337.1 nm, the addition of helium to nitrogen is required.

The very first laser camera with a transverse discharge, which was made in 1973.

Laser installation company Molectron.

The interiors of a high-power transverse-discharge laser, which, when changing the gas mixture and optics, can work as a CO2 laser or as an excimer laser.

The appearance of the electrodes of a commercially available transverse-discharge laser.

Laser camera for picosecond pulse durations.

Now, after all that has been said above, a quite reasonable question will arise to me whether I tried to repeat this construction. In fact, no, did not try. There were objective reasons for this. In short, I like a completely different type of nitrogen laser - not a transverse laser, but a longitudinal discharge! But about it in the following part .

Used sources:

1. www.jarrodkinsey.org

2. www.rapp-instruments.de

3. www.spakbangbuzz.com

4. www.jonsinger.org

5. www.swissrocketman.fr

6. www.mylaser.ucoz.ru

7. www.laserkids.sourceforge.net

8. www.technology.niagarac.on.ca

I hope I have not forgotten anyone.

Source: https://habr.com/ru/post/432464/

All Articles