How we did a book scanner for ships

It all started with the fact that once we saw a giant crap (otherwise you can not say), which looked one on one, like a hydraulic press of some factory. She creaked, hissed and crushed the book. Specially trained operators ran around and shied away from her every movement.

It turned out that different archives, libraries, courts and other structures purchase scanners, or, let's say, classical solutions, which in terms of the content are very similar to the 90s. Because then the first scanners for libraries were developed, and they have not been modified since then.

')

The task of the scanner was to mechanically align the scanned material on a plane, and then scan it.

Since then, two things have changed:

- Approaches to the design of electronics.

- Approaches to machine vision.

First experience: pressure sensors

Hypothesis: it is necessary to press the book to the glass not with all the dope, how much is, but to safe pressure for the hand. Put the sensors and just take readings from them for the lifting table. This will reduce operator fears and injuries.

Second experience: image alignment

With this result, we came to one of the customers from the judicial sphere. The stitched documents in the courts (most often court cases) are very thick. The same pile of documents are in civil engineers and in different archives.

Hypothesis: you can align very much not by hand, but by using machine vision. In the end, even with a regular tablet, you can take a picture of a document today and immediately receive it in the form of almost photocopies. What makes the scanner worse?

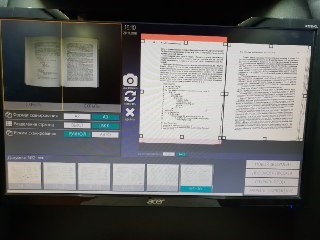

We added the software, and there appeared all sorts of turns and tilts automatically and with the help of the operator.

This is what happened:

Then they were also played with setting the limit value of the clamping force:

The third experience: do not press

We have at the entrance to the office is a 3D-scanner of the face, which is able to build a 3D-model of the face on one photo. He does this with the help of a grid projector: comparing the imposition of a grid on a face, he calculates the geometry of this face. The following hypothesis was logical: why press a document if it is enough to project laser marks on it?

It turned out enough laser stripes - these are:

On top there is a camera that shoots.

TK: black-and-white scanners, so you can simply cut off the laser wavelength and get a separate channel with geometry and a channel with information from the scanned document.

Then you can “restore” the geometry to the point where the laser lines will be straight again as a result. This is what happens:

That's the end of the story.

The task, by the way, turned out to be very relevant for cases when it is necessary to scan very dilapidated and multi-format stitched documents, drawings, books. When the page is strewed into the dust of a careless touch with your fingers, pressing it against a flat surface is the same as immediately destroying.

Result

We managed to make the right decision and put it into the series simply because, apparently, other market players were not interested or not very profitable, so that the scanners were cheap and worked quickly. Our price-effect and price-quality scanners came out very, very good.

Where do legs grow from? We received experience with similar images when we recognized agricultural census data in the country. Then it was necessary to disassemble the handwritten font: tablets were given to the inspectors only at the next census. Plus, we have a robotics lab, where you can quickly assemble a prototype of any device that just arises in our inflamed brains. Actually, that's what happened. We ruined a certain amount of materials, until we picked up the correct model of raising the table, long poked around with lasers, but found what you need.

Well, we are a large-sized integrator, so when we came to one of the customers and showed our results, they listened to us. And saved.

Here are three generations of our scanners and principles of operation:

Top Clip Scanner:

Scanner with clip on the bottom:

Scanner without clamping:

Links

- Agricultural Census

- Industrial vision and addicts

- My mail is bookscan@croc.ru

Source: https://habr.com/ru/post/431462/

All Articles