Carbon M2 3D printers and robots: high-speed 3D printing

At the international exhibition of industrial technologies IMTS 2018 in Chicago, the American company Carbon showed in action an automated system SpeedCel l, consisting of several ultrafast 3D printing devices Carbon M2, printing using CLIP technology, a washing station and a robotic arm to service the entire system. The system is designed for high-speed printing of finished parts in production, but it can also print prototypes. We tell and show.

Video

Carbon Speedcell

- Printing technology: CLIP DLS (patented type of photopolymer stereolithography)

- Construction area, mm: 189 x 118 x 326

- Accuracy (pixel size), micron: 75

- Purpose: production

- Interface: Wi-Fi, USB, Ethernet

- Print speed: depends on the material / settings; up to 25-100 times higher than when printed by other technologies

Application

The SpeedCell system is easily scalable and can be used for both prototyping and serial production of parts.

')

Device

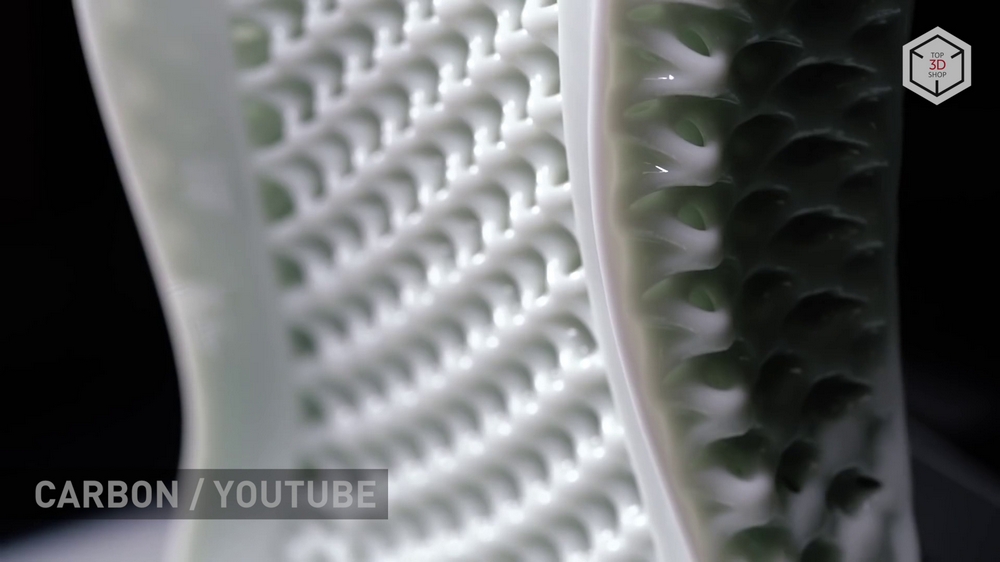

At the heart of the SpeedCell system are Carbon M2 3D printers using Continuous Liquid Interface Production technology or CLIP for short. The method of continuous printing in liquid medium was patented in 2014 and today it is the fastest method of photopolymer printing, surpassing the speed of SLA and DLP dozens of times

Carbon M2, the company's second generation of printers, was introduced last year. Its working volume is twice the parameters of the debut model M1 , while retaining all the other key characteristics.

Robots

To speed up the work of such an “additive cell,” Carbon suggests using a manipulator. When printing is finished on one of the 3D printers, Roboruk takes the platform with the finished object, moves it to the washing station, and then installs a clean platform on the 3D printer.

Installations of ultra-fast printing and systems based on them are becoming increasingly available for manufacturing companies that want to move away from traditional methods of manufacturing parts or supplement them with additive technologies.

Materials

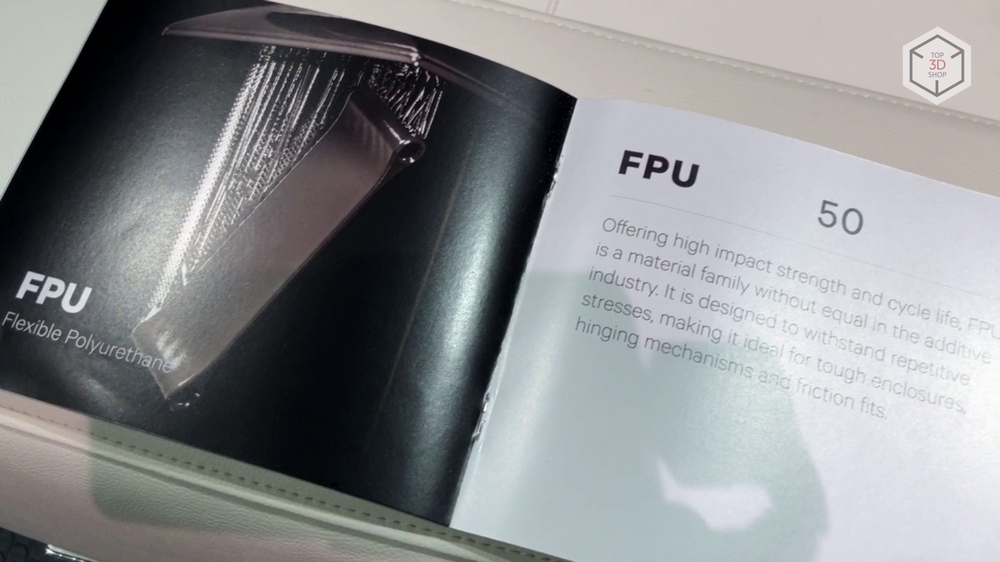

In addition to SpeedCell, Carbon presented at the IMTS exhibition also an updated range of consumables for its line of printers, which included both standard photopolymers and specialized resins.

The full list of materials now includes several rigid, flexible and elastic polyurethanes, the latest cyan ester resins, epoxy components and urethane methacrylate.

The Carbon range also includes material for dentists, silicone photopolymer and biocompatible polyurethane for medical purposes, which has already been approved by the US Food and Drug Administration.

Working with CLIP technology, Carbon 3D printers are champions in high-speed 3D printing with photopolymers and the only supplier of such equipment in the industrial segment.

The desktop analogue of reduced size, working on its own similar technology, is produced by XYZprinting: these are xPF series printers, in particular - MfgPro 180 xPF and MfgPro 220 xPF . Read more about them here .

To select and purchase production 3D printers, contact Top 3D Shop .

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/431424/

All Articles