Printing Factory: Why LANIT-Integration has launched its own “printing house”

Design and implementation of integrated engineering and IT solutions involves the creation of a large amount of technical documentation in accordance with the requirements of the legislation. Its preparation and release in " LANIT-Integration " is engaged in a special unit. In hot periods, on average, every four hours we print about 40 volumes of documentation consisting of 1000 sheets of drawings, spending about 750 meters of paper with an area of over 400 square meters. m. At peak loads, volumes increase by 2-2.5 times. Without the equipment to cope with such tasks, perhaps, it would be impossible. Today I will tell you how and why we switched to another class of equipment and what helped to significantly reduce the time at the last stage of the preparation of documentation - when printing and stitching.

A source

A source

Before releasing a high-quality set of technical documentation, you need to do a serious job: agree with the customer on the documentation and the number of copies, and add the necessary effort to all stages of the documentation preparation to the general project schedule.

Diverse tasks pass through our department, but now we are talking about printing documentation. Here are the basic operations that an electronic document usually goes through before becoming a physical volume.

')

1) Editing

How long this stage will last depends not only on the volume, but also on the quality of the material we received. Editing can not be transferred to anyone - only qualified staff can edit and execute documentation. They rely on construction, design standards for automated systems and software documents.

In addition to national standards for some projects, the requirements of the regulations of the contracting authority should be taken into account. For example, corporate standardization systems have been formed in leading oil and gas companies. These documents reflect the features of the technologies used. Some companies in this sector also use international (ISO) and European (CEN) standards along with Russian ones. Special requirements are placed on documentation in the financial sector and at the enterprises of the rocket and space industry. We have already had to take into account their internal standards.

2) Conversion

The PDF format is convenient for both previewing the finished document and writing to electronic media for delivery to the customer, and for sending to print, therefore, we usually combine all the files of editable formats into a single PDF file.

3) Listing

Print speed is more dependent on the parameters and the number of equipment.

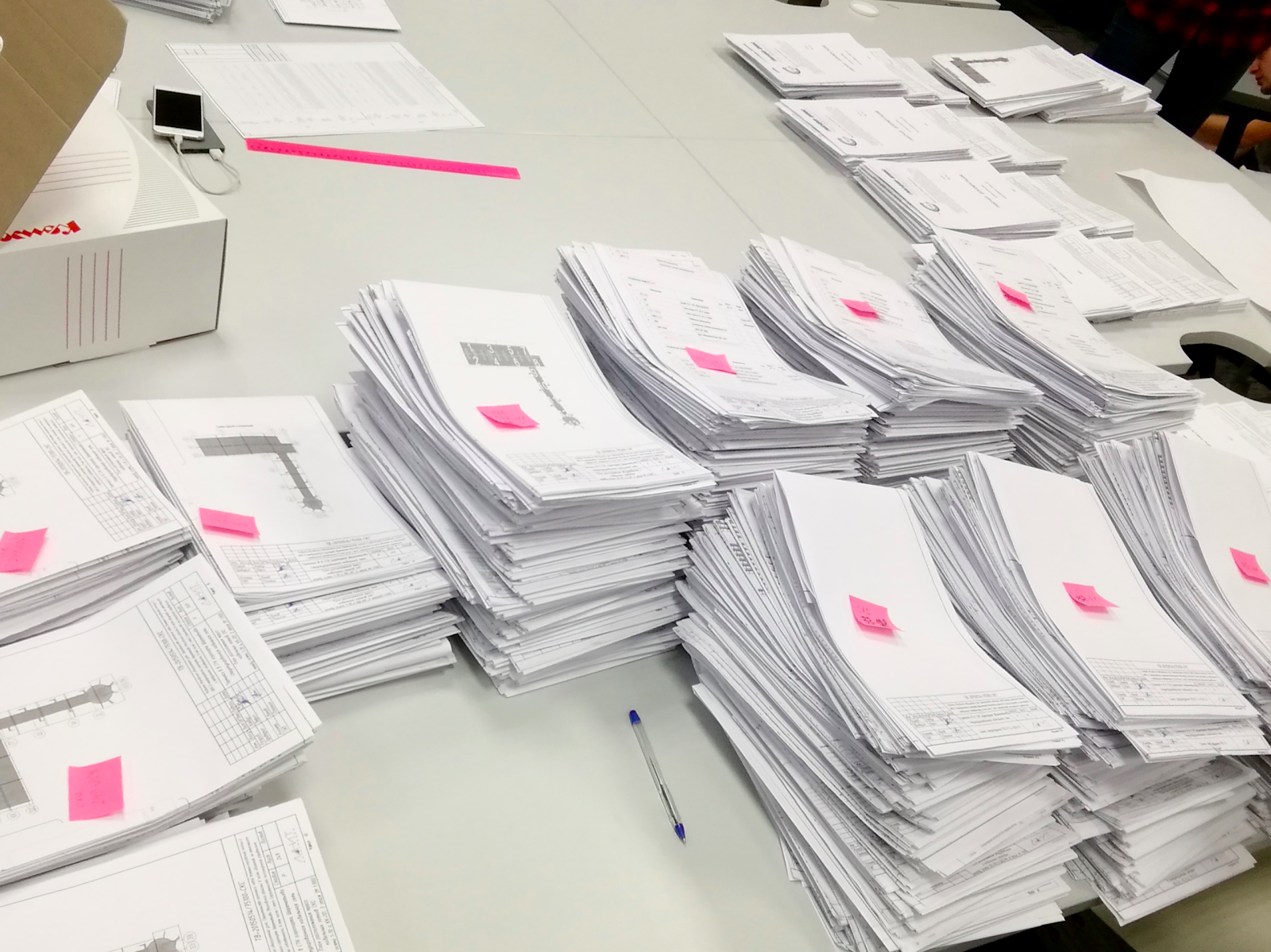

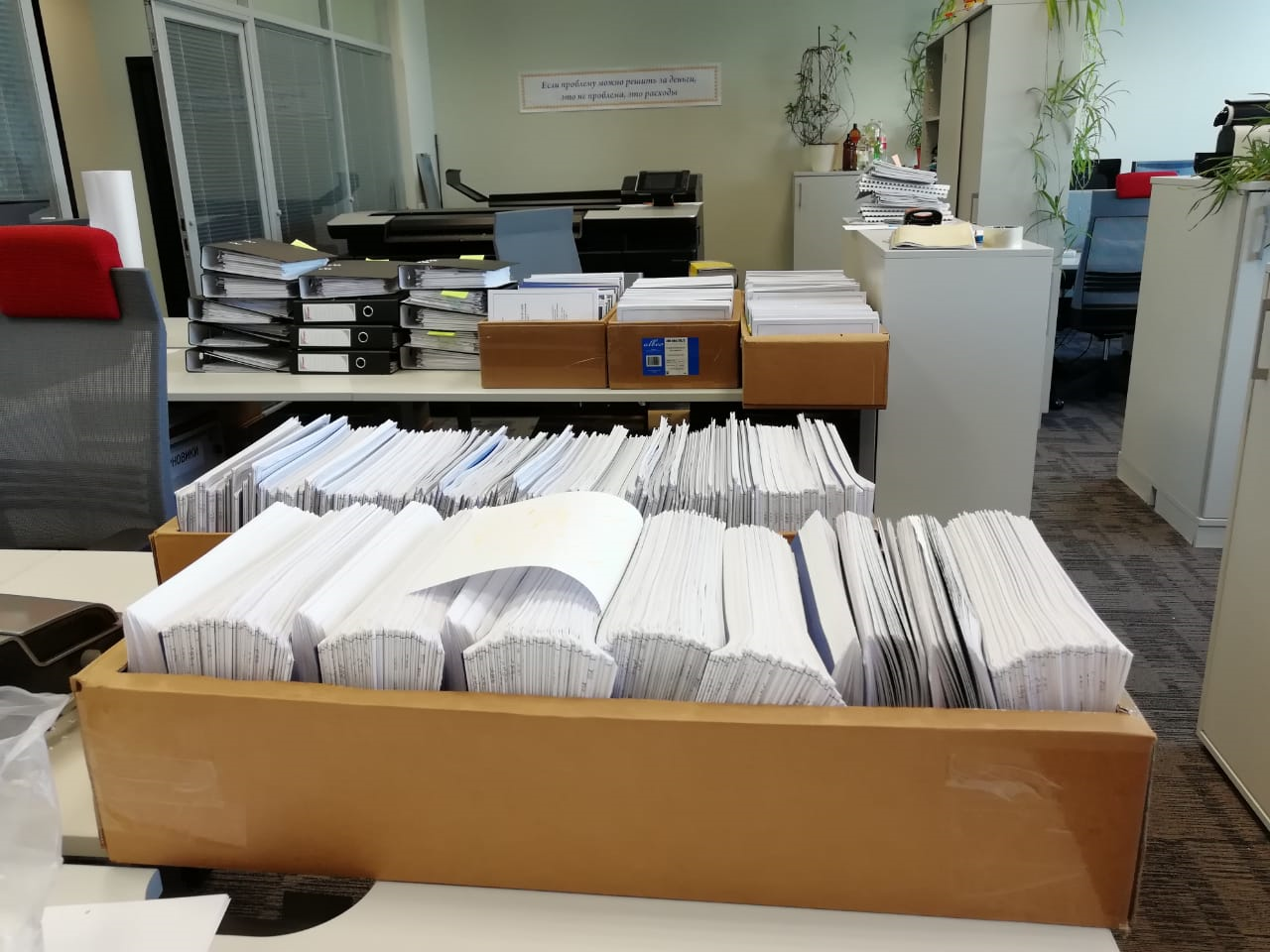

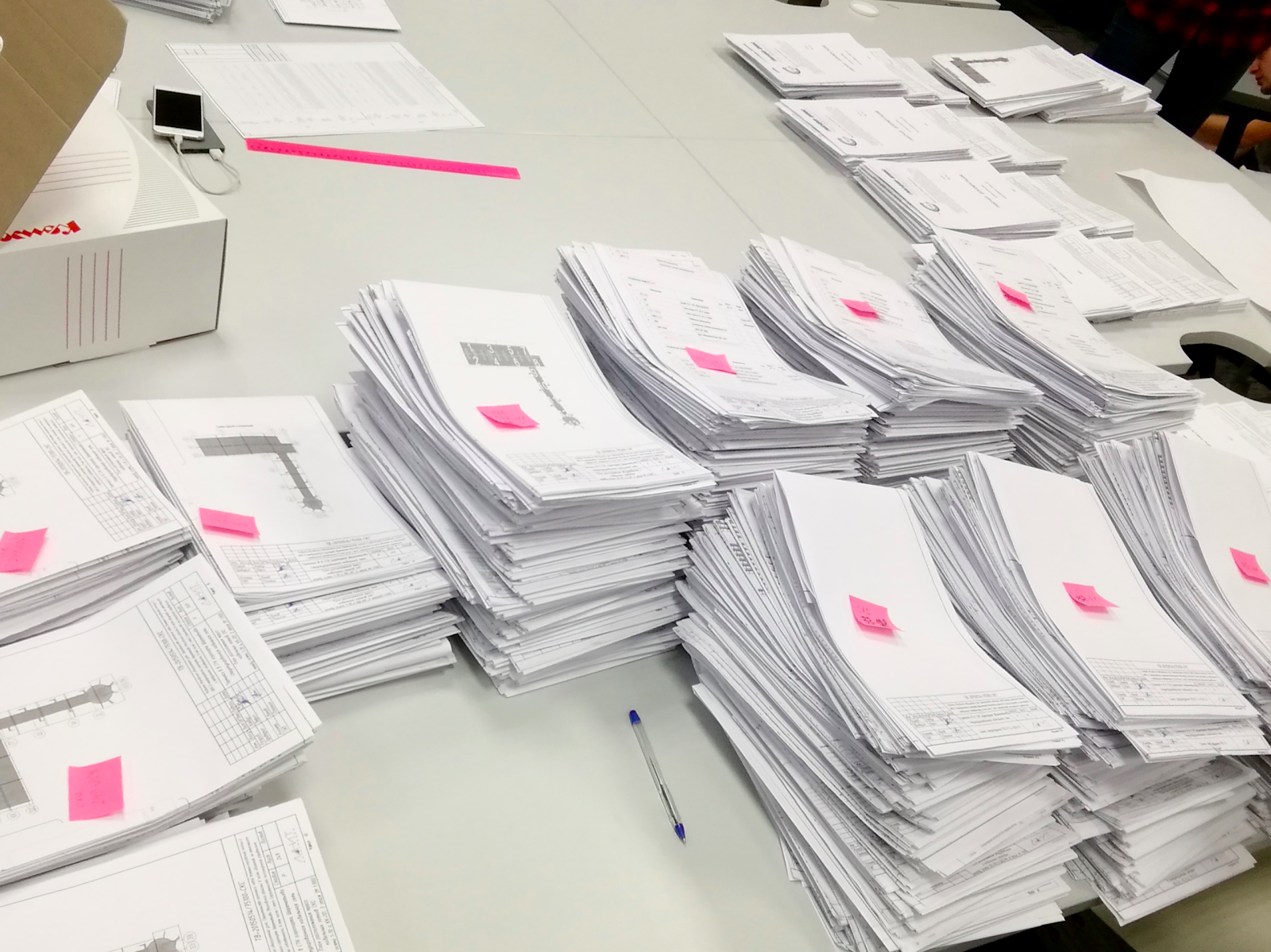

4) Pick

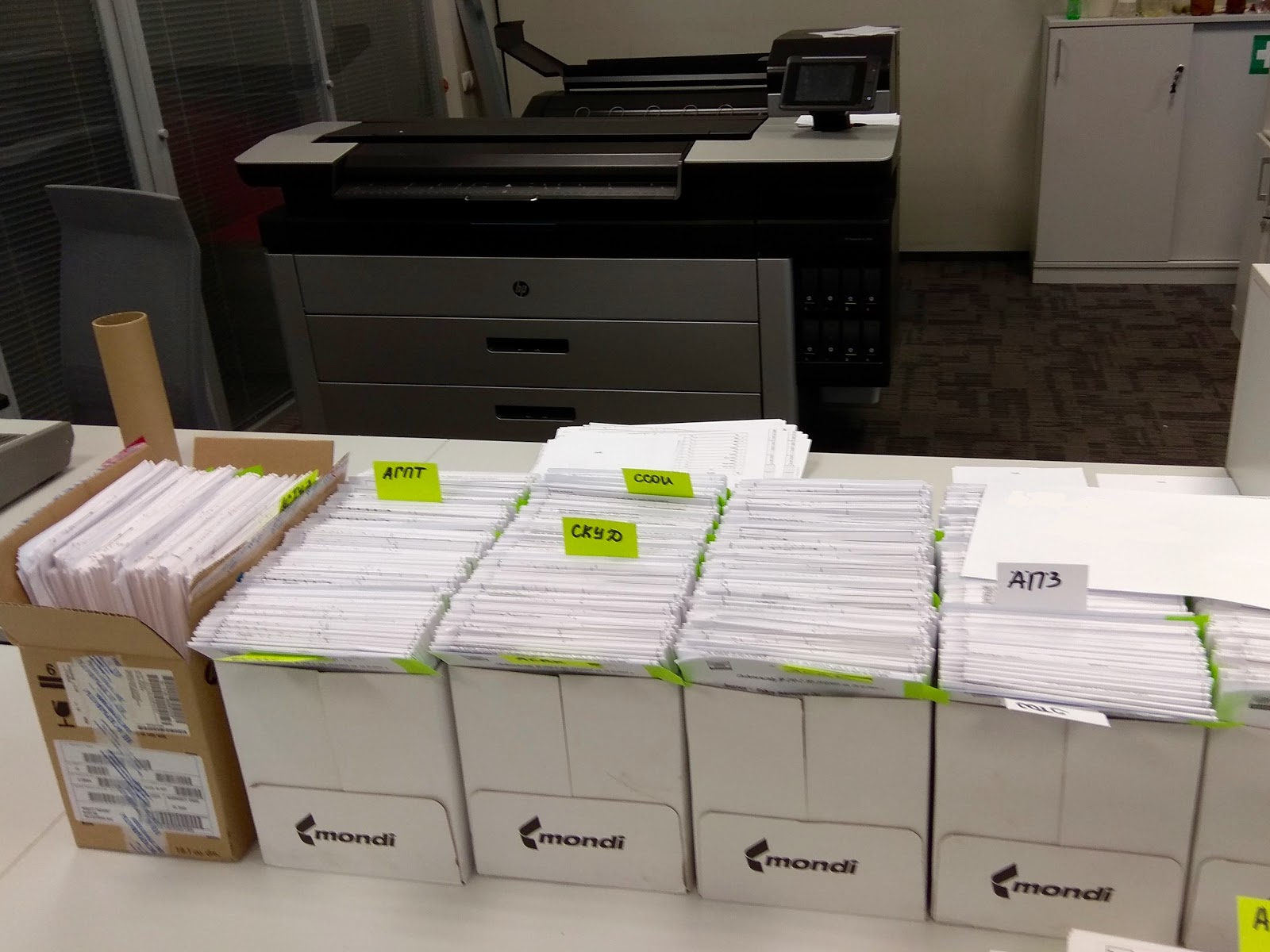

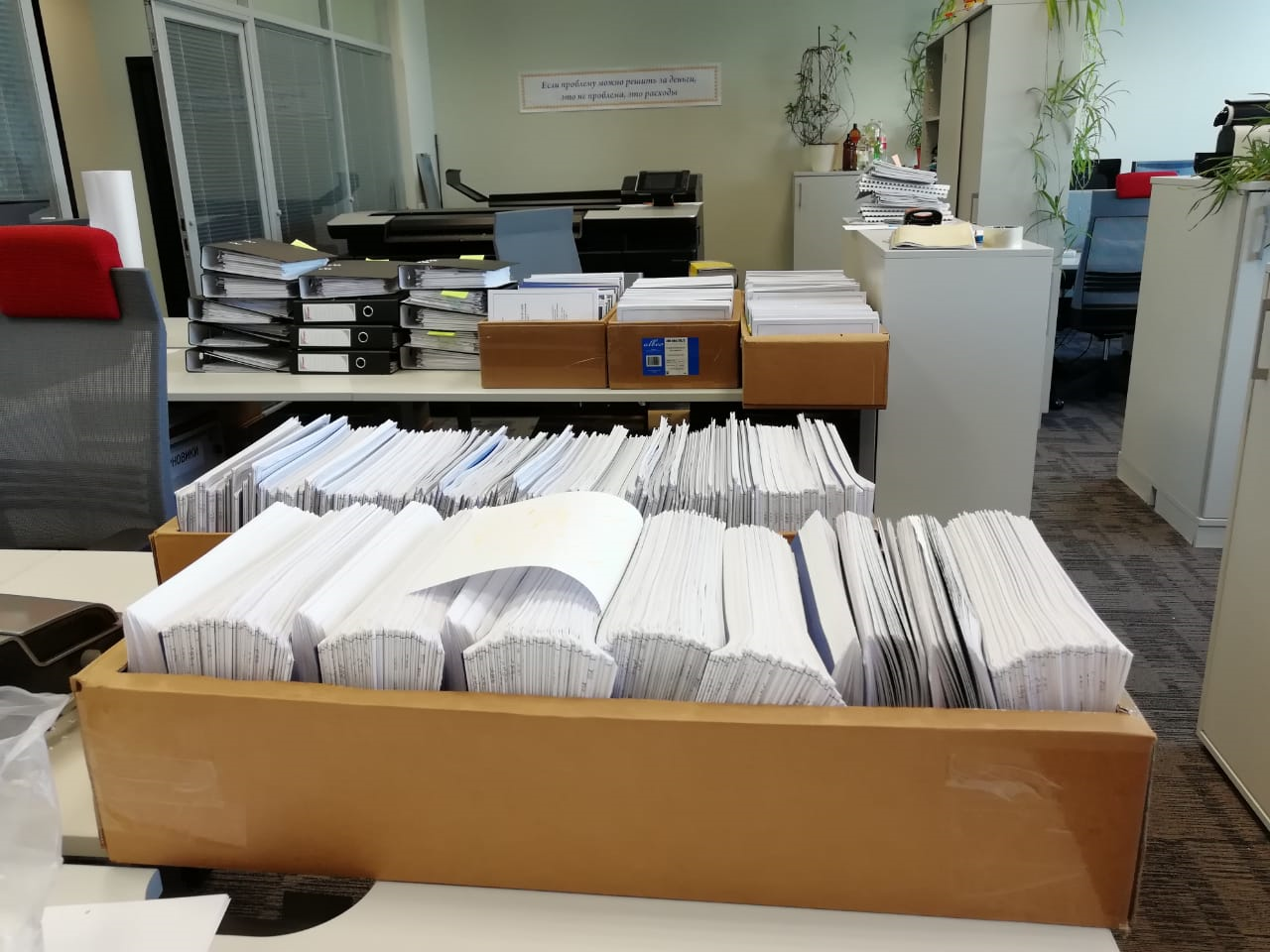

It is necessary to form a set (physical volume) from printed sheets. To do this, they must be folded (large formats of drawings are folded to the size of an A4 sheet), sorted in order, and then packed into folders (cardboard or arched), stitched to a spring or packed in cardboard boxes.

Sort documents

Sort documents

Some of the documentation remains under the "press" while we are busy interlacing

Some of the documentation remains under the "press" while we are busy interlacing

Documentation kits without stitching, which can not be completed in the evening. Sometimes documents are needed in this form at the stage of delivery of as-built documentation, when it is finally formed at the facility.

Documentation kits without stitching, which can not be completed in the evening. Sometimes documents are needed in this form at the stage of delivery of as-built documentation, when it is finally formed at the facility.

"LANIT-Integration" specializes in IT consulting, design, implementation and support of integrated IT solutions. The company designs and implements dozens of systems for each of the large projects that are impossible to implement without a large graphic part: equipment layout plans, structural and functional diagrams, wiring diagrams and connections, etc.

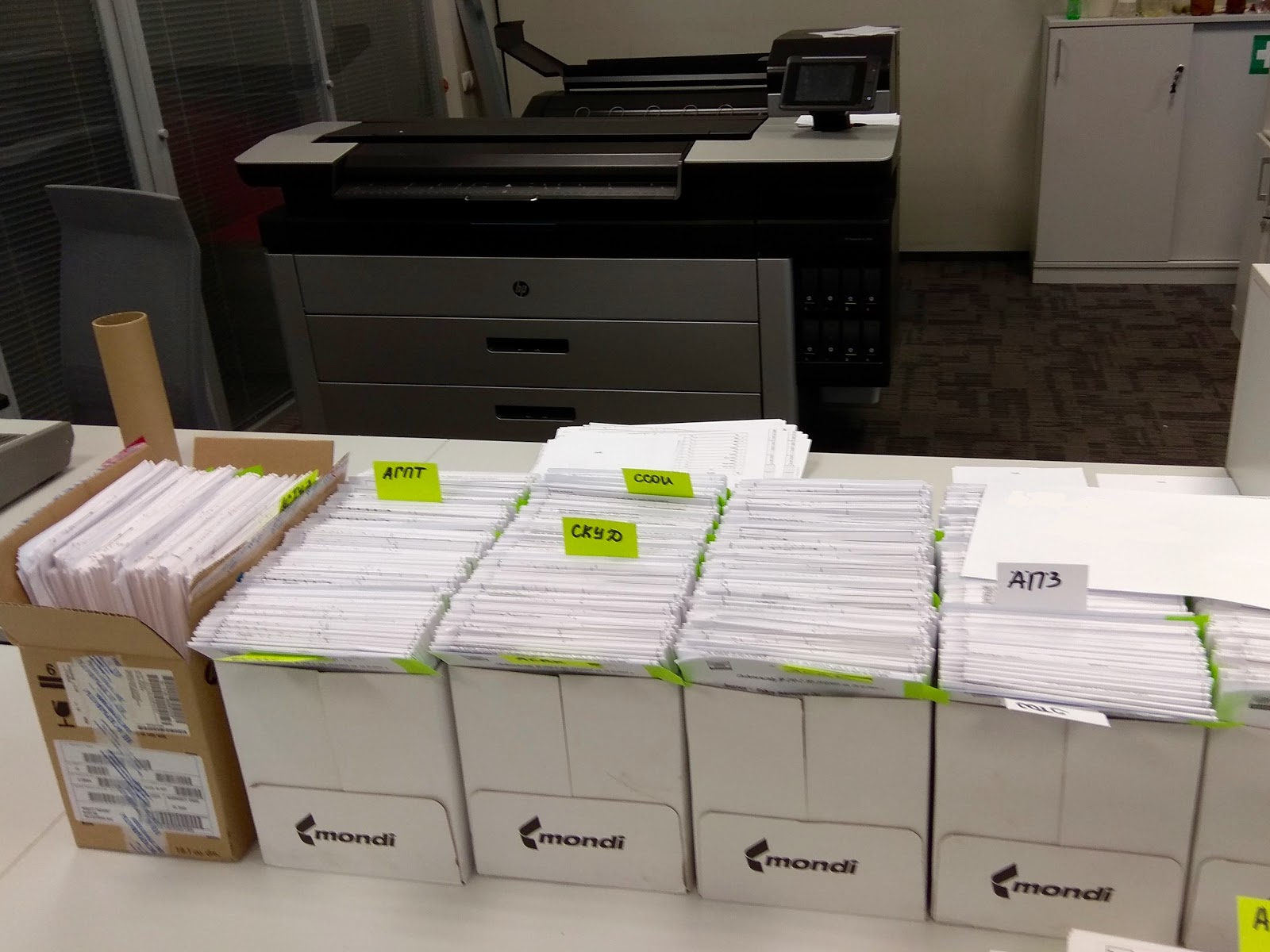

For delivery, the customer often needs to print several copies of all sets of documentation at different stages: design, work, and executive. So that you can present these volumes, I will tell you about a recent incident that occurred when Russian stadiums were actively preparing for the 2018 World Cup.

The project manager for the stadium modernization decided to deliver the documentation to the customer on his own car. We all folded and lowered to the main entrance to the office. However, after seeing and assessing the real volume of documents, the manager decided to call a third-party transport company. Several dozen boxes, each of which is a quarter cubic meter in size, clearly did not fit even into a fairly spacious "station wagon".

Before loading the documentation for transportation

Before loading the documentation for transportation

Such large volumes have to be released in limited time. Unfortunately, we, like everyone else, are not avoided by failing to meet the deadlines of contractors, inconsistency in the actions of general contractors and customers, and other problems. The more “heavier” the project, the more reefs it has to face. It is important to have plenty of time to fix problems and errors and reissue documentation in order to meet deadlines.

When the number of projects increased and the technical department of LANIT-Integration expanded, we also had to develop our department.

Initially, the group for the preparation of technical documentation had only a common office printer, an A1 format plotter (HP DesignJet 500 with a print speed of just 1 sheet in 13 minutes) and a manual cutter. The release of documentation involved 2-3 people. Then they bought a second HP DesignJet T1300 plotter with a print speed of 1 A1 sheet in 2-3 minutes and increased staff: the department constantly employed up to five people.

In 2012, the loading of the department and the volumes of the produced documentation had already grown so much that we needed a separate area: after the move we started printing on three plotters - the HP DesignJet T2300 plotter was added to the two above-mentioned, purchased the HP Color LaserJet CM6030 MFP MFP, which allows printing format pages A4 and A3 with a speed up to 40 p./min. At that time, a maximum of 6 people worked in the department.

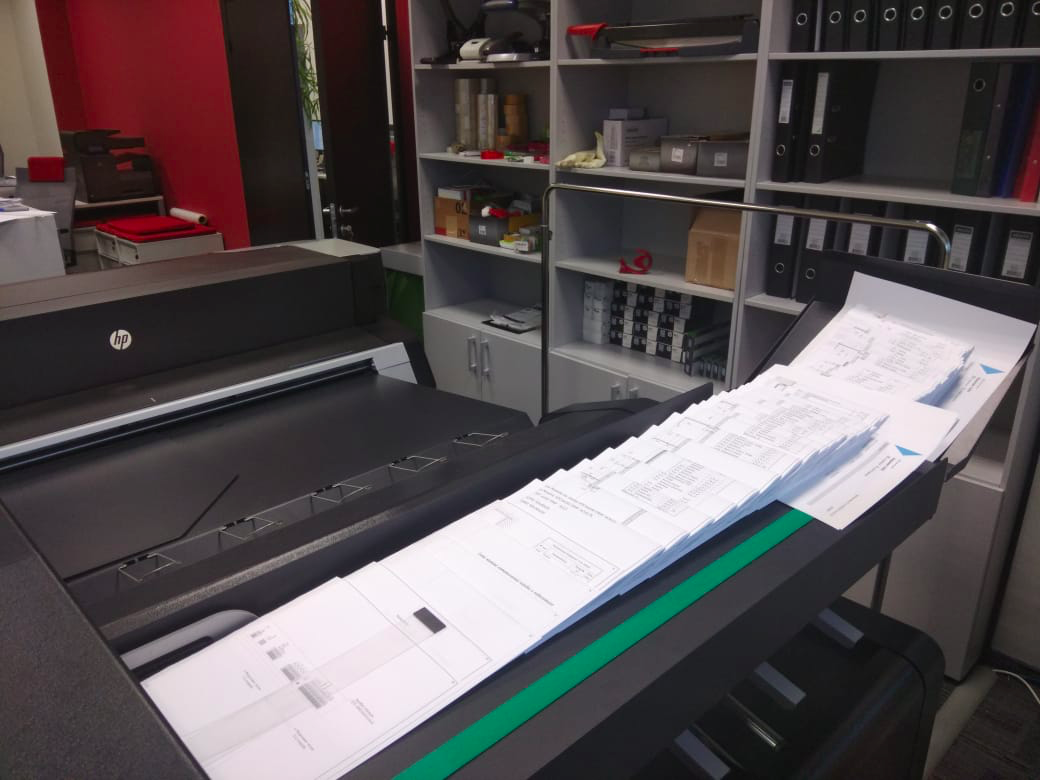

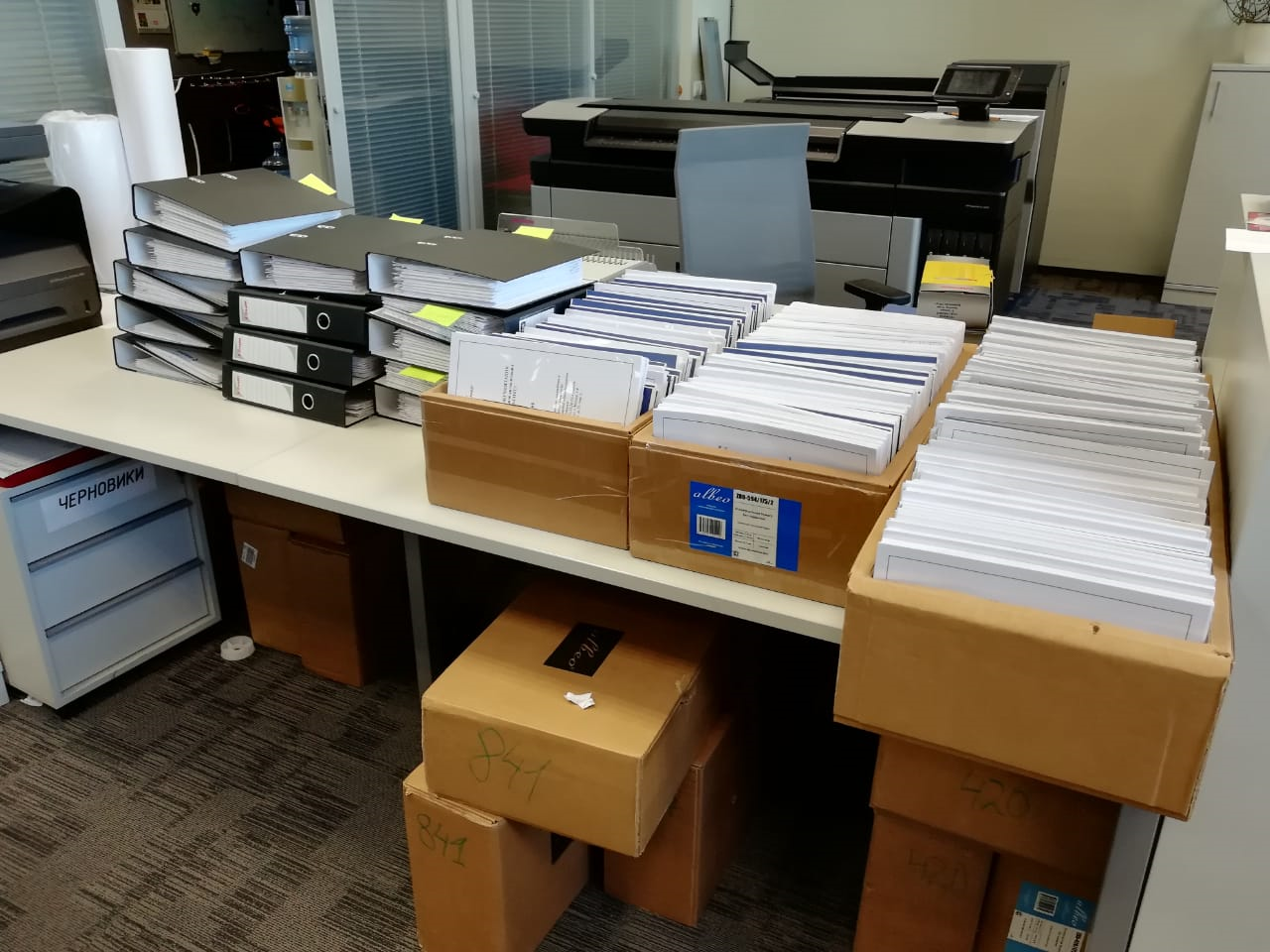

The seal was temporarily suspended because there was nowhere to lay out the documents: all the working surfaces were busy

The seal was temporarily suspended because there was nowhere to lay out the documents: all the working surfaces were busy

For the timely printing and picking up of printed documentation, the strength of our small department was sometimes not enough. Each printed sheet had to be picked up from the plotter, cut off the edges on a mechanical cutter, manually folded to A4 size, and billed. All these operations required a lot of labor and time, so sometimes colleagues from adjacent departments and interns came to the rescue. Printed sheets were hung on all available surfaces, where they waited for their turn to trim and fold.

It was necessary to fold the drawings of various formats manually, and there was a catastrophically lack of space for large volumes of documentation. In order to form volumes in several copies, we laid out sheets in the corridors, sometimes occupying the entire corridor of the multi-meter floor along the perimeter. Often, such work was carried out at night, so as not to interfere with colleagues.

In order to increase productivity and not use employees from other departments, in the second half of 2013, we purchased the Estefold Es-Te 2300 folder for folding A4-size drawings, the Neolt Electro Trim 130 electric paper cutter, and an A4 ink-jet printer / copier (MFP) HP Officejet Pro X576dw, powered by HP PageWide technology with a print speed of 42 ppm.

By that time, work had already begun on the facilities of the 2014 Winter Olympics in Sochi. The problem of lack of technical capacity, speed of printing and productivity of the department as a whole has become more urgent than ever. For urgent work (trimming, folding drawings and stitching volumes), we were forced to involve part-time workers, mostly students, since the lion’s share of labor costs in the production of documentation accounted for precisely these operations.

Cleaning after work on weekends: in one long box - 45 meters of “paper sheet”

Cleaning after work on weekends: in one long box - 45 meters of “paper sheet”

Of course, it was necessary to modernize the processes and increase the printing capacity: their shortage was growing. Just how to develop the department?

First, we wanted to expand the fleet of equipment and staff, we also needed to allocate additional space.

To increase productivity, it was only necessary to purchase as much equipment as we already had. But we could hardly arrange it.

By 2017, at the same time there were many projects in operation, and we had to provide them with documentation support. Here are the largest of them: the reconstruction of the Luzhniki Grand Sports Arena, the creation of the IT infrastructure of other stadiums for the World Cup, the creation of Zaryadye Park IT systems, the design and implementation of several dozen IT and engineering systems at one of the airports.

In order to cope with such volumes in time, we needed the power of printing equipment, far surpassing those that we already had.

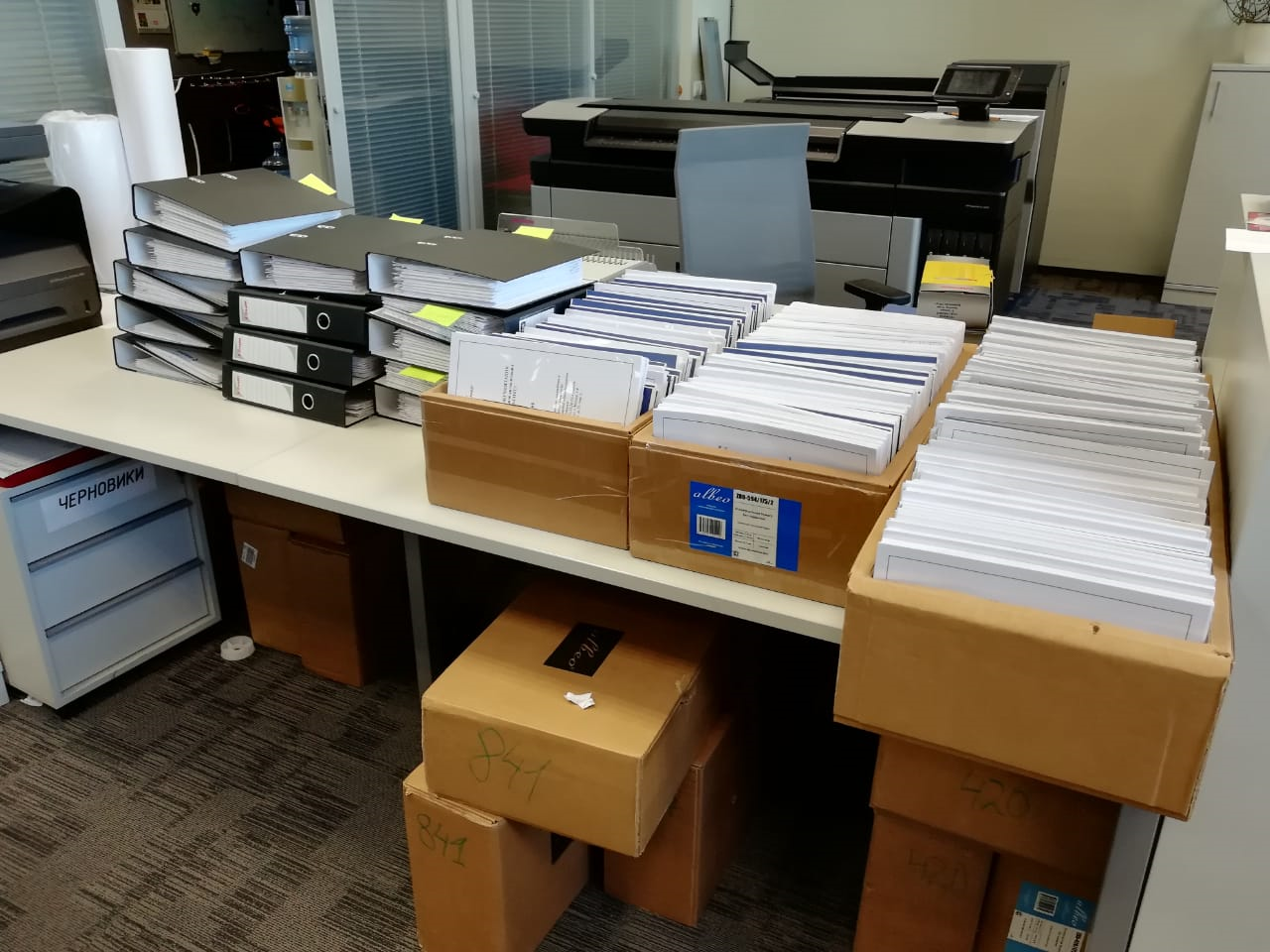

Documentation before shipping to customer

Documentation before shipping to customer

It was necessary to raise the quality and bring the speed of work to a new level not by a quantitative way (cluttering up the office with “weak” technology), but by a qualitative one. So we began to consider equipment for large format printing with professional printing capabilities.

First, we decided on the basic requirements. First of all, we needed high print quality along with top performance. Also important were the reliability of the equipment, efficiency, ease of use. Bearing in mind that the main labor costs for pruning, folding and stitching, we were looking for (in addition to a high-performance plotter) a solution to automate at least part of these operations.

The market for printers was investigated painstakingly. They immediately abandoned the options with a relatively low print speed - up to 2-3 pages A1 per minute. With the high cost of the equipment itself and its ownership, such an increase in speed was not worth the money spent.

Among the popular printing technologies that we approached in quality and speed, there are only two. One of the manufacturers suggested using water-soluble inks, unsuitable for archiving documents and not resistant to moisture. There were special requirements for the paper used. In addition, after every 100 printed pages, the operator must clean the heads of such a device, and such a break, of course, affects performance.

After weighing all the pros and cons, we ended up choosing HP PageWide technology that met most of our requirements. In addition, we have been using an HP printer based on this technology for several years, and it has proven itself to be fast, economical and reliable.

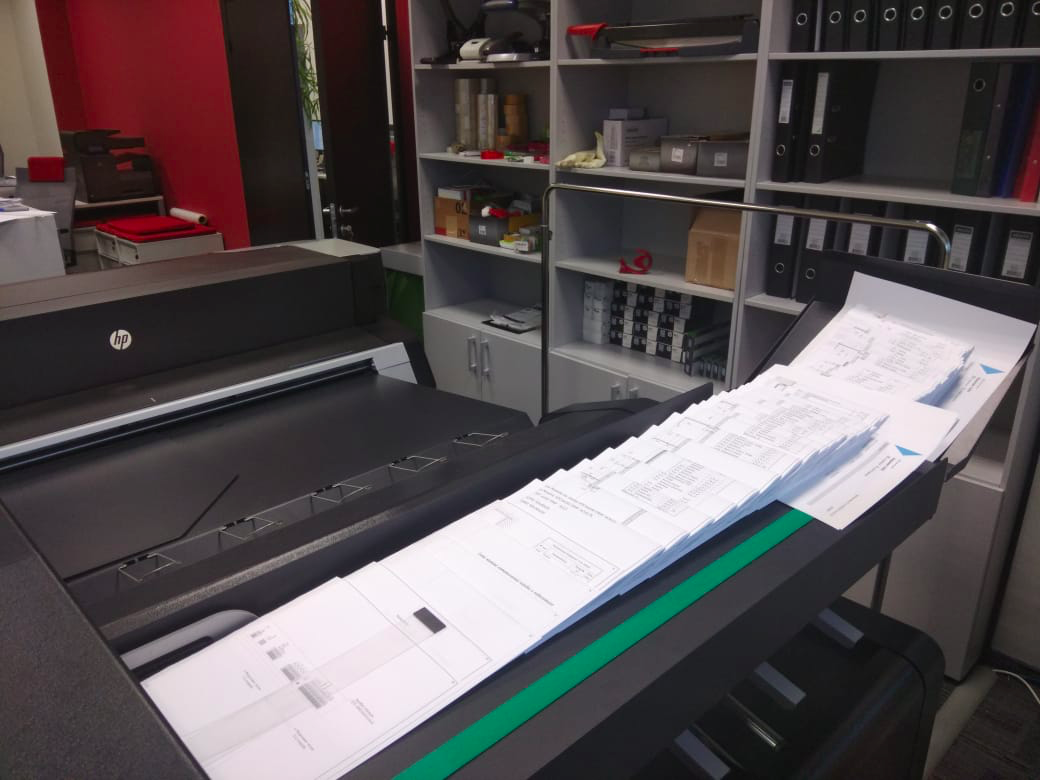

When we decided on the technology, we went to one of the print service providers to look at the printers in action. The specific model of the MFP was chosen by the ratio of "performance-price." HP produces a PageWide line of devices: as the flagship with the best parameters, but very expensive, and models that are inferior in print speed, but more affordable. Our choice fell on the HP PageWide XL 5000 MFP model with an online folder that allows you to fold large-format sheets up to A4 in real time.

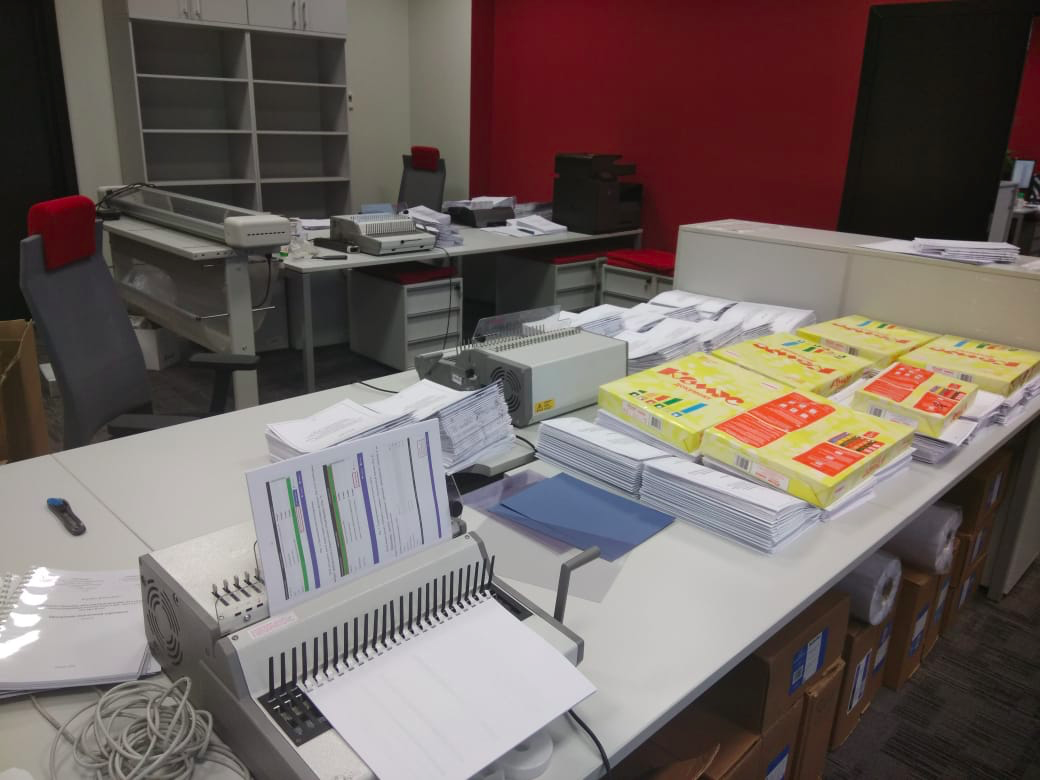

The MFP was delivered to us together with an online folder. With the help of SmartStream software, we choose the necessary type and style of folding or the option with the withdrawal of non-folded sheets. Of course, sequential printing and folding of sheets saves a lot of time: at the exit we get folded sheets of the volume of documentation in the order in which they were printed. After starting the printing of the document, we only need to periodically remove the finished sheets from the tray.

Together with the new multifunction printer, they decided to buy the HP PageWide Managed P77740dn multifunction printer - a device for printing sheets of sizes up to A3 with a printing speed of about 60 ppm.

After installing the new system, we increased the department's performance tenfold. You can say: "But such a printing system requires a lot of money." And you will be absolutely right. However, the cost of owning a device is relatively small.

Consumables for our device are only cartridges. The ink consumption when printing HP PageWide XL 5000 drawings on uncoated paper with a five percent sheet is 0.35 ml / sq. m. Based on the average cost of 8 000 rubles. black cartridge and its capacity of 400 ml, we get the price of 1 square. m black and white drawings - about 7 rubles. For comparison: a black cartridge with a capacity of 130 ml for inkjet plotters used by us costs an average of 5,000 rubles. Its resource is 800 sheets of A4 or 50 square meters. m (at 5% of the page). It turns out that the consumption of 1 square. m black and white print is 2.6 ml / sq. m, and the cost of 1 square. m - about 100 rubles. It turns out that the specific cost of the sheet on the parameters of consumables decreased by more than 10 times.

Other resource materials requiring replacement during operation of the device (service cartridge, container for collecting waste ink, print heads) have a very long working life. So, for the print head, the manufacturer gives a guarantee of one year or 10 liters of ink. HP Inc. recommended head share defines 32 liters, which is 10 times more than plotters of similar performance, but using water-soluble ink. In fact, over the course of the year of operation, the maximum consumption per head did not exceed four liters. We replaced other resource materials after 9-11 months. However, even a low cost per sheet would never justify all the equipment costs. For us, the priority was primarily the performance of the business process for the production of documentation as a whole: with our intensity of work for the year of use of the plotter, 39,719 square meters were spent on it. m or 69 039 running meters of paper, as well as 14.6 liters of ink.

The implementation of a high-tech printing process has made it possible to almost completely automate the cycle of issuing documentation on paper. In the old manner, by hand, we only complete the sheets of documentation.

Earlier, even spending money on hired workers, we did not always have time to prepare documentation for some projects. Sometimes this was due to inaccuracies in the conclusion of contracts, sometimes because of the suddenly changed deadlines for submitting documentation. There were cases when the customer “clarified” the requirements in the project and almost the next day demanded the provision of amended documentation, specifically creating situations to get discounts or penalties.

Now our department is able to cope with such challenges. New features of the device are actively used when printing and folding sheets of documents, especially for large-scale projects. For efficient operation of the unit, we have demarcated a separate production facility for printing, packing and storing documentation and an office area. And it (the room) is really necessary, because picking is still one of the most difficult processes, especially if you need to use a plastic spring. The department has four electrical booklet makers, but the process itself is laborious when it comes to formats larger than A3. Each sheet of A2 format and more must first be notched and tuck the hem for binding. Perforation is possible to carry out only one sheet (as opposed to A4 or A3 sheets). Yes, there are technical solutions that can partially automate this process, for example, the applicator of reinforcing perforated stickers as an attachment to the online folder, but in the current conditions it is not economically feasible, especially since the sheets processed in this way will be suitable only for picking into arched folders .

The reduction of labor costs for the release of documentation led to the restructuring of the department and the specialization of its activities in two areas: the first is the release of technical documentation on paper; the second is writing, designing and editing technical documentation.

The new installation does not exclude the work of previously existing plotters, cutter and folder. We not only use them as backup equipment (we launched them a couple of times a year while we waited for the service engineers of the vendor to arrive), but also create remote workplaces.

When they worked in a new terminal at one of Moscow airports, they installed their printer at the stage of project closure and preparation of as-built documentation, the plotter (as the latter a very inexpensive, compact and mobile device was purchased) and an employee’s laptop connected via VPN to the company's server in a dedicated the terminal premises. Our worker, on the spot, made corrections to the documentation and replaced the required sheets. It was faster, easier and cheaper than transporting documents from the office. Alas, transportation in Moscow is a costly business both in time and in finance.

Prior to this, the project in Tatarstan was closed in a similar way, where LANIT-Integration worked on the modernization and implementation of engineering and IT systems at Ammonium Chemical Plant. There was a similar workplace. We delivered the plotter from Moscow, the printer was purchased locally. For the preparation of as-built documentation to the plant, a department employee was seconded

The efficiency of using such remote workplaces has been confirmed at other sites, such as the Luzhniki BSA; Moscow City Duma building and many others. In some cases, we deployed only equipment at the facilities, and field engineers independently made adjustments to the documentation and printed out the required sheets.

The number of printed copies on the largest projects continues to grow. For example, at the end of August, about 200 volumes of documentation were prepared on the project for the IQ quarter within 8 days. New equipment allowed us to print 5785 drawings with a paper consumption of 3,750 sq. M. m or 8598 running meter. It is noteworthy that in parallel these days we also released documentation on four more major projects and the volumes were rather big.

As far as we know, LANIT-Integration is the only system integrator where equipment of such level is used. Now the technological capabilities of our department allow us not only to provide full documentation support for our company's projects, but also to issue documentation for third-party customers.

If you are engaged in the preparation of documentation in your company and you are interested in our experience, then we invite you to the office of LANIT-Integration to see how our “printing factory” works.

A lot of copies are very fast.

Before releasing a high-quality set of technical documentation, you need to do a serious job: agree with the customer on the documentation and the number of copies, and add the necessary effort to all stages of the documentation preparation to the general project schedule.

Diverse tasks pass through our department, but now we are talking about printing documentation. Here are the basic operations that an electronic document usually goes through before becoming a physical volume.

')

1) Editing

How long this stage will last depends not only on the volume, but also on the quality of the material we received. Editing can not be transferred to anyone - only qualified staff can edit and execute documentation. They rely on construction, design standards for automated systems and software documents.

In addition to national standards for some projects, the requirements of the regulations of the contracting authority should be taken into account. For example, corporate standardization systems have been formed in leading oil and gas companies. These documents reflect the features of the technologies used. Some companies in this sector also use international (ISO) and European (CEN) standards along with Russian ones. Special requirements are placed on documentation in the financial sector and at the enterprises of the rocket and space industry. We have already had to take into account their internal standards.

2) Conversion

The PDF format is convenient for both previewing the finished document and writing to electronic media for delivery to the customer, and for sending to print, therefore, we usually combine all the files of editable formats into a single PDF file.

3) Listing

Print speed is more dependent on the parameters and the number of equipment.

4) Pick

It is necessary to form a set (physical volume) from printed sheets. To do this, they must be folded (large formats of drawings are folded to the size of an A4 sheet), sorted in order, and then packed into folders (cardboard or arched), stitched to a spring or packed in cardboard boxes.

"LANIT-Integration" specializes in IT consulting, design, implementation and support of integrated IT solutions. The company designs and implements dozens of systems for each of the large projects that are impossible to implement without a large graphic part: equipment layout plans, structural and functional diagrams, wiring diagrams and connections, etc.

For delivery, the customer often needs to print several copies of all sets of documentation at different stages: design, work, and executive. So that you can present these volumes, I will tell you about a recent incident that occurred when Russian stadiums were actively preparing for the 2018 World Cup.

The project manager for the stadium modernization decided to deliver the documentation to the customer on his own car. We all folded and lowered to the main entrance to the office. However, after seeing and assessing the real volume of documents, the manager decided to call a third-party transport company. Several dozen boxes, each of which is a quarter cubic meter in size, clearly did not fit even into a fairly spacious "station wagon".

Such large volumes have to be released in limited time. Unfortunately, we, like everyone else, are not avoided by failing to meet the deadlines of contractors, inconsistency in the actions of general contractors and customers, and other problems. The more “heavier” the project, the more reefs it has to face. It is important to have plenty of time to fix problems and errors and reissue documentation in order to meet deadlines.

When the number of projects increased and the technical department of LANIT-Integration expanded, we also had to develop our department.

Print at night

Initially, the group for the preparation of technical documentation had only a common office printer, an A1 format plotter (HP DesignJet 500 with a print speed of just 1 sheet in 13 minutes) and a manual cutter. The release of documentation involved 2-3 people. Then they bought a second HP DesignJet T1300 plotter with a print speed of 1 A1 sheet in 2-3 minutes and increased staff: the department constantly employed up to five people.

In 2012, the loading of the department and the volumes of the produced documentation had already grown so much that we needed a separate area: after the move we started printing on three plotters - the HP DesignJet T2300 plotter was added to the two above-mentioned, purchased the HP Color LaserJet CM6030 MFP MFP, which allows printing format pages A4 and A3 with a speed up to 40 p./min. At that time, a maximum of 6 people worked in the department.

For the timely printing and picking up of printed documentation, the strength of our small department was sometimes not enough. Each printed sheet had to be picked up from the plotter, cut off the edges on a mechanical cutter, manually folded to A4 size, and billed. All these operations required a lot of labor and time, so sometimes colleagues from adjacent departments and interns came to the rescue. Printed sheets were hung on all available surfaces, where they waited for their turn to trim and fold.

It was necessary to fold the drawings of various formats manually, and there was a catastrophically lack of space for large volumes of documentation. In order to form volumes in several copies, we laid out sheets in the corridors, sometimes occupying the entire corridor of the multi-meter floor along the perimeter. Often, such work was carried out at night, so as not to interfere with colleagues.

In order to increase productivity and not use employees from other departments, in the second half of 2013, we purchased the Estefold Es-Te 2300 folder for folding A4-size drawings, the Neolt Electro Trim 130 electric paper cutter, and an A4 ink-jet printer / copier (MFP) HP Officejet Pro X576dw, powered by HP PageWide technology with a print speed of 42 ppm.

By that time, work had already begun on the facilities of the 2014 Winter Olympics in Sochi. The problem of lack of technical capacity, speed of printing and productivity of the department as a whole has become more urgent than ever. For urgent work (trimming, folding drawings and stitching volumes), we were forced to involve part-time workers, mostly students, since the lion’s share of labor costs in the production of documentation accounted for precisely these operations.

Of course, it was necessary to modernize the processes and increase the printing capacity: their shortage was growing. Just how to develop the department?

First, we wanted to expand the fleet of equipment and staff, we also needed to allocate additional space.

To increase productivity, it was only necessary to purchase as much equipment as we already had. But we could hardly arrange it.

By 2017, at the same time there were many projects in operation, and we had to provide them with documentation support. Here are the largest of them: the reconstruction of the Luzhniki Grand Sports Arena, the creation of the IT infrastructure of other stadiums for the World Cup, the creation of Zaryadye Park IT systems, the design and implementation of several dozen IT and engineering systems at one of the airports.

In order to cope with such volumes in time, we needed the power of printing equipment, far surpassing those that we already had.

It was necessary to raise the quality and bring the speed of work to a new level not by a quantitative way (cluttering up the office with “weak” technology), but by a qualitative one. So we began to consider equipment for large format printing with professional printing capabilities.

How we chose

First, we decided on the basic requirements. First of all, we needed high print quality along with top performance. Also important were the reliability of the equipment, efficiency, ease of use. Bearing in mind that the main labor costs for pruning, folding and stitching, we were looking for (in addition to a high-performance plotter) a solution to automate at least part of these operations.

The market for printers was investigated painstakingly. They immediately abandoned the options with a relatively low print speed - up to 2-3 pages A1 per minute. With the high cost of the equipment itself and its ownership, such an increase in speed was not worth the money spent.

Among the popular printing technologies that we approached in quality and speed, there are only two. One of the manufacturers suggested using water-soluble inks, unsuitable for archiving documents and not resistant to moisture. There were special requirements for the paper used. In addition, after every 100 printed pages, the operator must clean the heads of such a device, and such a break, of course, affects performance.

After weighing all the pros and cons, we ended up choosing HP PageWide technology that met most of our requirements. In addition, we have been using an HP printer based on this technology for several years, and it has proven itself to be fast, economical and reliable.

Details

The main difference between printers and PageWide plotters from the classical inkjet counterparts is a fixed print head that is wide into paper. The sheet is pulled under it and an image is formed over its entire width as a result of ultra-precise and fast drops of ink from a multitude of nozzles on the paper. HP PageWide XL series plotters use eight CMYK printheads, each containing 25,344 nozzles with a density of 1,200 nozzles per inch. Because paper moves and the print head does not, PageWide devices use technology that provides precise control of paper movement, which is necessary for the best print quality.

Special pigment inks make it possible to achieve an excellent transfer of shades of colors. The prints have light and moisture resistance: engineers and workers can use drawings and diagrams under the open sky. Such prints can be archived without fear of fading, which is valuable in all areas of application of engineering plotters.

Special pigment inks make it possible to achieve an excellent transfer of shades of colors. The prints have light and moisture resistance: engineers and workers can use drawings and diagrams under the open sky. Such prints can be archived without fear of fading, which is valuable in all areas of application of engineering plotters.

When we decided on the technology, we went to one of the print service providers to look at the printers in action. The specific model of the MFP was chosen by the ratio of "performance-price." HP produces a PageWide line of devices: as the flagship with the best parameters, but very expensive, and models that are inferior in print speed, but more affordable. Our choice fell on the HP PageWide XL 5000 MFP model with an online folder that allows you to fold large-format sheets up to A4 in real time.

Learn more about HP PageWide XL 5000

This MFP prints one sheet of A0 in 8.6 seconds, sheet A1 in 4.3 seconds. The available wide-format scanner (also with increased performance) allows, regardless of other current operations, to scan high-resolution drawings.

For convenience and to increase the speed of sending print jobs complete with a plotter, we purchased special HP SmartStream software. This program works with PDF files, automatically analyzing the format of sheets, chromaticity and other parameters. Using SmartStream, the operator can quickly set the necessary print parameters, select the folding method, as well as with the help of the preview window, see possible printing errors and how the folded sheet will look.

The MFP itself also has a built-in full-featured control center, which allows, if necessary, to perform the full range of available operations without using a PC.

The continuity of the printing process on the device is provided by two sets of cartridges, allowing replacement of consumed, without stopping printing, on the fly. In addition, self-cleaning of the heads occurs every 500 sheets.

The device uses at the same time four rolls of paper of different sizes, so you can print together sheets of different formats. The selection of the desired roll is automatic. It should be noted the convenience and ease of loading rolls, which allows you to quickly change the media to perform any special print jobs. HP PageWide XL 5000 can work with different types of paper and even matte polypropylene film. We use standard paper with a density of 80 g / sq. For printing drawings. m series of formats A with a width, regulated by GOST, without additional fields. This allowed us to refuse to trim the edges of the drawings.

For convenience and to increase the speed of sending print jobs complete with a plotter, we purchased special HP SmartStream software. This program works with PDF files, automatically analyzing the format of sheets, chromaticity and other parameters. Using SmartStream, the operator can quickly set the necessary print parameters, select the folding method, as well as with the help of the preview window, see possible printing errors and how the folded sheet will look.

The MFP itself also has a built-in full-featured control center, which allows, if necessary, to perform the full range of available operations without using a PC.

The continuity of the printing process on the device is provided by two sets of cartridges, allowing replacement of consumed, without stopping printing, on the fly. In addition, self-cleaning of the heads occurs every 500 sheets.

The device uses at the same time four rolls of paper of different sizes, so you can print together sheets of different formats. The selection of the desired roll is automatic. It should be noted the convenience and ease of loading rolls, which allows you to quickly change the media to perform any special print jobs. HP PageWide XL 5000 can work with different types of paper and even matte polypropylene film. We use standard paper with a density of 80 g / sq. For printing drawings. m series of formats A with a width, regulated by GOST, without additional fields. This allowed us to refuse to trim the edges of the drawings.

The MFP was delivered to us together with an online folder. With the help of SmartStream software, we choose the necessary type and style of folding or the option with the withdrawal of non-folded sheets. Of course, sequential printing and folding of sheets saves a lot of time: at the exit we get folded sheets of the volume of documentation in the order in which they were printed. After starting the printing of the document, we only need to periodically remove the finished sheets from the tray.

Together with the new multifunction printer, they decided to buy the HP PageWide Managed P77740dn multifunction printer - a device for printing sheets of sizes up to A3 with a printing speed of about 60 ppm.

After installing the new system, we increased the department's performance tenfold. You can say: "But such a printing system requires a lot of money." And you will be absolutely right. However, the cost of owning a device is relatively small.

Justified expenses

Consumables for our device are only cartridges. The ink consumption when printing HP PageWide XL 5000 drawings on uncoated paper with a five percent sheet is 0.35 ml / sq. m. Based on the average cost of 8 000 rubles. black cartridge and its capacity of 400 ml, we get the price of 1 square. m black and white drawings - about 7 rubles. For comparison: a black cartridge with a capacity of 130 ml for inkjet plotters used by us costs an average of 5,000 rubles. Its resource is 800 sheets of A4 or 50 square meters. m (at 5% of the page). It turns out that the consumption of 1 square. m black and white print is 2.6 ml / sq. m, and the cost of 1 square. m - about 100 rubles. It turns out that the specific cost of the sheet on the parameters of consumables decreased by more than 10 times.

Other resource materials requiring replacement during operation of the device (service cartridge, container for collecting waste ink, print heads) have a very long working life. So, for the print head, the manufacturer gives a guarantee of one year or 10 liters of ink. HP Inc. recommended head share defines 32 liters, which is 10 times more than plotters of similar performance, but using water-soluble ink. In fact, over the course of the year of operation, the maximum consumption per head did not exceed four liters. We replaced other resource materials after 9-11 months. However, even a low cost per sheet would never justify all the equipment costs. For us, the priority was primarily the performance of the business process for the production of documentation as a whole: with our intensity of work for the year of use of the plotter, 39,719 square meters were spent on it. m or 69 039 running meters of paper, as well as 14.6 liters of ink.

The implementation of a high-tech printing process has made it possible to almost completely automate the cycle of issuing documentation on paper. In the old manner, by hand, we only complete the sheets of documentation.

Earlier, even spending money on hired workers, we did not always have time to prepare documentation for some projects. Sometimes this was due to inaccuracies in the conclusion of contracts, sometimes because of the suddenly changed deadlines for submitting documentation. There were cases when the customer “clarified” the requirements in the project and almost the next day demanded the provision of amended documentation, specifically creating situations to get discounts or penalties.

Now our department is able to cope with such challenges. New features of the device are actively used when printing and folding sheets of documents, especially for large-scale projects. For efficient operation of the unit, we have demarcated a separate production facility for printing, packing and storing documentation and an office area. And it (the room) is really necessary, because picking is still one of the most difficult processes, especially if you need to use a plastic spring. The department has four electrical booklet makers, but the process itself is laborious when it comes to formats larger than A3. Each sheet of A2 format and more must first be notched and tuck the hem for binding. Perforation is possible to carry out only one sheet (as opposed to A4 or A3 sheets). Yes, there are technical solutions that can partially automate this process, for example, the applicator of reinforcing perforated stickers as an attachment to the online folder, but in the current conditions it is not economically feasible, especially since the sheets processed in this way will be suitable only for picking into arched folders .

The reduction of labor costs for the release of documentation led to the restructuring of the department and the specialization of its activities in two areas: the first is the release of technical documentation on paper; the second is writing, designing and editing technical documentation.

The new installation does not exclude the work of previously existing plotters, cutter and folder. We not only use them as backup equipment (we launched them a couple of times a year while we waited for the service engineers of the vendor to arrive), but also create remote workplaces.

When they worked in a new terminal at one of Moscow airports, they installed their printer at the stage of project closure and preparation of as-built documentation, the plotter (as the latter a very inexpensive, compact and mobile device was purchased) and an employee’s laptop connected via VPN to the company's server in a dedicated the terminal premises. Our worker, on the spot, made corrections to the documentation and replaced the required sheets. It was faster, easier and cheaper than transporting documents from the office. Alas, transportation in Moscow is a costly business both in time and in finance.

Prior to this, the project in Tatarstan was closed in a similar way, where LANIT-Integration worked on the modernization and implementation of engineering and IT systems at Ammonium Chemical Plant. There was a similar workplace. We delivered the plotter from Moscow, the printer was purchased locally. For the preparation of as-built documentation to the plant, a department employee was seconded

The efficiency of using such remote workplaces has been confirmed at other sites, such as the Luzhniki BSA; Moscow City Duma building and many others. In some cases, we deployed only equipment at the facilities, and field engineers independently made adjustments to the documentation and printed out the required sheets.

Numbers grow

The number of printed copies on the largest projects continues to grow. For example, at the end of August, about 200 volumes of documentation were prepared on the project for the IQ quarter within 8 days. New equipment allowed us to print 5785 drawings with a paper consumption of 3,750 sq. M. m or 8598 running meter. It is noteworthy that in parallel these days we also released documentation on four more major projects and the volumes were rather big.

As far as we know, LANIT-Integration is the only system integrator where equipment of such level is used. Now the technological capabilities of our department allow us not only to provide full documentation support for our company's projects, but also to issue documentation for third-party customers.

If you are engaged in the preparation of documentation in your company and you are interested in our experience, then we invite you to the office of LANIT-Integration to see how our “printing factory” works.

And we have jobs!

Source: https://habr.com/ru/post/430884/

All Articles