How NASA will use robots to create rocket fuel from Martian soil

Engineers build a prototype of a robotic factory that will create water, oxygen and fuel on the surface of Mars

Martians: an artist's idea of excavator robots that could one day earn on Mars, long before the first humans set foot on the planet

2038 After 18 months of life and work on the surface of Mars, a team of six researchers is immersed in a space transport rocket and sent to Earth. People do not remain, but the work continues without them: autonomous robots will continue mining work and chemical synthesis that they started many years before this first manned mission descended on the planet. The factory produces water, oxygen and fuel, using local resources, and it will methodically create all the necessary materials for the next Martian mission, which will arrive in two years.

This robotic factory is not science fiction. Numerous NASA teams are involved in its development. One of them is the Swamp Works Laboratory at the Kennedy Space Center in Florida, of which I am the supervisor. Officially, it is known as the in-situ resource utilization system (ISRU), but we like to call it a “dust-to-thrust] because it turns simple dust into rocket fuel. Someday this technology will allow people to live and work on Mars - and return to Earth to tell about it.

But why synthesize substances on Mars, is not it easier to deliver them from Earth? NASA explains this by the "gear ratio problem." According to some estimates, to deliver one kilogram of fuel from Earth to Mars, today's rockets will need to burn 225 kg of fuel for a flight — to the exit to Earth’s low orbit, to Mars, to slow down to Martian orbit, and to slow down to land safely. We start with 226 kg of fuel and get 1 kg, that is, the gear ratio is 226: 1. And this number does not change, regardless of what we transport. We will need 225 tons of fuel to transport tons of water, tons of oxygen, tons of equipment. The only way to get around this cruel arithmetic is to create water, oxygen and fuel in place.

')

Various research and engineering teams at NASA are working on different parts of this problem. Recently, our Swamp-Works team began to integrate many separate working modules to demonstrate the entire closed-loop system. This is still a prototype, but it demonstrates all the parts needed to make our fuel plant a reality. And although the long-term plan is a flight to Mars, the Moon will be an intermediate step. Most of the equipment will be tested and adjusted first on the lunar surface, thus reducing the risks associated with sending it directly to Mars.

Dirt or dust on any celestial body is usually called regolith . Most often it is just a volcanic stone that has been destroyed or eroded, turning into fine dust over time. On Mars, under a layer of rusting iron-bearing minerals that give the planet its famous red tint, there is a thicker layer of silicates such as feldspars, pyroxenes and olivines - all of them are composed of silicon and oxygen structures associated with metals such as iron, aluminum and magnesium .

The extraction of these materials is complicated by the fact that their density and compactness varies depending on the place on the planet. Complicating the task is also low Martian gravity, which makes it difficult to drive a shovel into the ground without using its weight to counter. On Earth, digging the soil, we often use large mechanisms, since their gravity reacts accordingly to forces acting on a much smaller bucket. However, keep in mind the gear ratios: every kilogram launched to Mars is precious and costs us very much. Therefore, we need to figure out how to dig the surface of Mars using very light equipment.

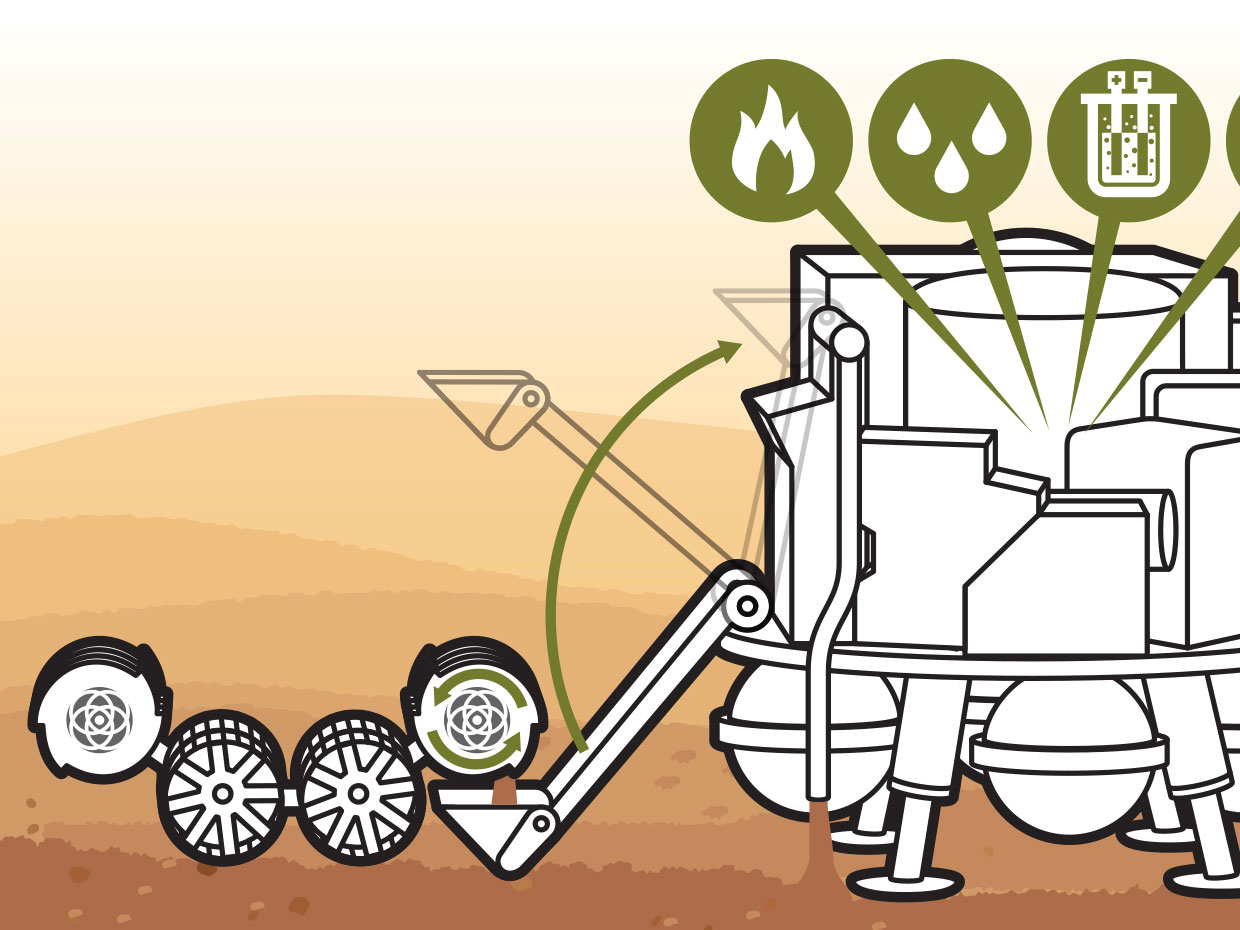

Space Digger: NASA is developing a robot excavator with opposing drum buckets capable of biting into the soil, spinning in the opposite direction. This approach eliminates most of the forces needed for digging, which allows the robot to operate at low gravity.

And here comes RASSOR (Regolith Advanced Surface Systems Operations Robot) [advanced regolith robot for surface works; pronounced razor / Razor / approx. trans.]. This is an autonomous mining device for digging out regolith in low gravity conditions. When developing RASSOR, NASA engineers paid special attention to its force transfer system. In robots, the transmission is carried out through motors, gearboxes and other mechanisms that make up a large percentage of the final weight of the system. In our scheme, we use bodyless motors, electromagnetic brakes and titanium cases printed on a 3D printer, as well as many more to minimize the volume and weight. The efforts were justified: our system has half the weight than commercial power systems with similar characteristics.

For digging, RASSOR uses two opposing drum buckets equipped with several small toothed scoops. When the drums rotate, and the arms holding them bite into the soil, they pick up a small amount of regolith into each shovel while it is moving slowly forward. The result is a shallow track instead of a deep hole. Rotating digging drums inside are empty, so that they can collect and store mined regolith. Another key feature of RASSOR is that the drums rotate in opposite directions while digging. This approach eliminates most of the forces needed for digging, which allows the robot to operate at low gravity.

Having filled the drums, RASSOR raises his hands and goes to the processing plant. To unload the regolith, the robot rotates the drums in the opposite direction, and the regolith pours from the same scoops that dug it. A special hoist delivers a portion of regolith to the platform of the factory, transferring it to the stove, which is hermetically sealed and begins to warm up. The water molecules connected to the regolith are blown off by a fan and collected in a condenser tube.

You might ask, “Isn't the Martian regolith dry?” The answer is, it's complicated. It all depends on where to dig and how deep to dig. In some parts of Mars, apparently, there are solid layers of water ice just a few meters below the surface. On the lower latitudes there are dunes of gypsum sand, which contain up to 8% of water.

The regolith freed from water is dropped on the ground so that RASSOR can collect it and take it away. These "waste" can be used for the construction of protective structures, and even roads and landing sites, using 3D printing methods currently under development at NASA.

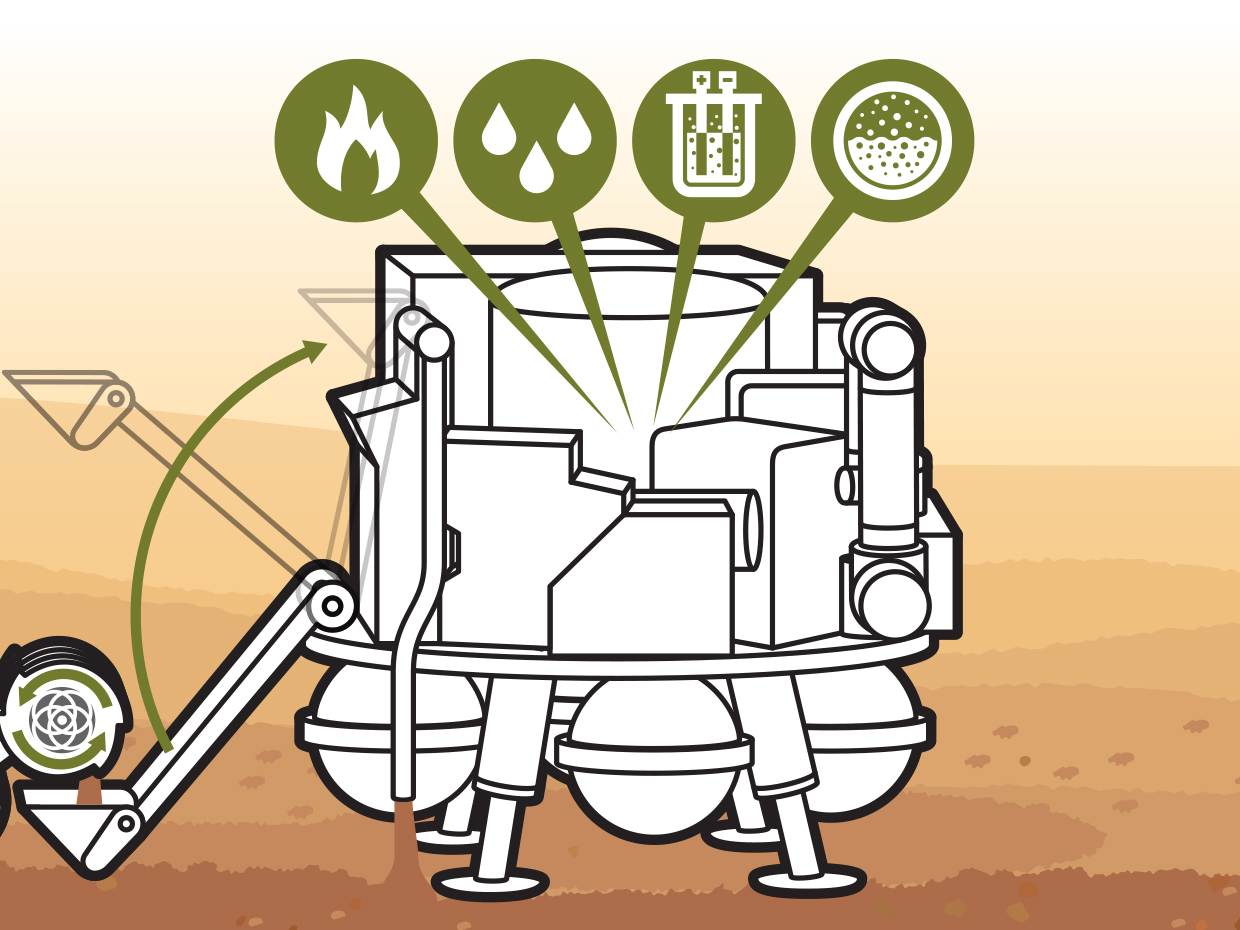

Extraction: the wheeled robot extracts regolith with the help of rotating drums equipped with toothed scoops

Transportation: rotating the drums in the opposite direction, the robot dumps the collected rock into the elevator

Recycling: the stove heats the regolith to extract water, which is divided by electrolysis into H 2 and O 2 . Using the Sabatier reaction, H 2 is combined with CO 2 collected in the atmosphere to produce methane fuel.

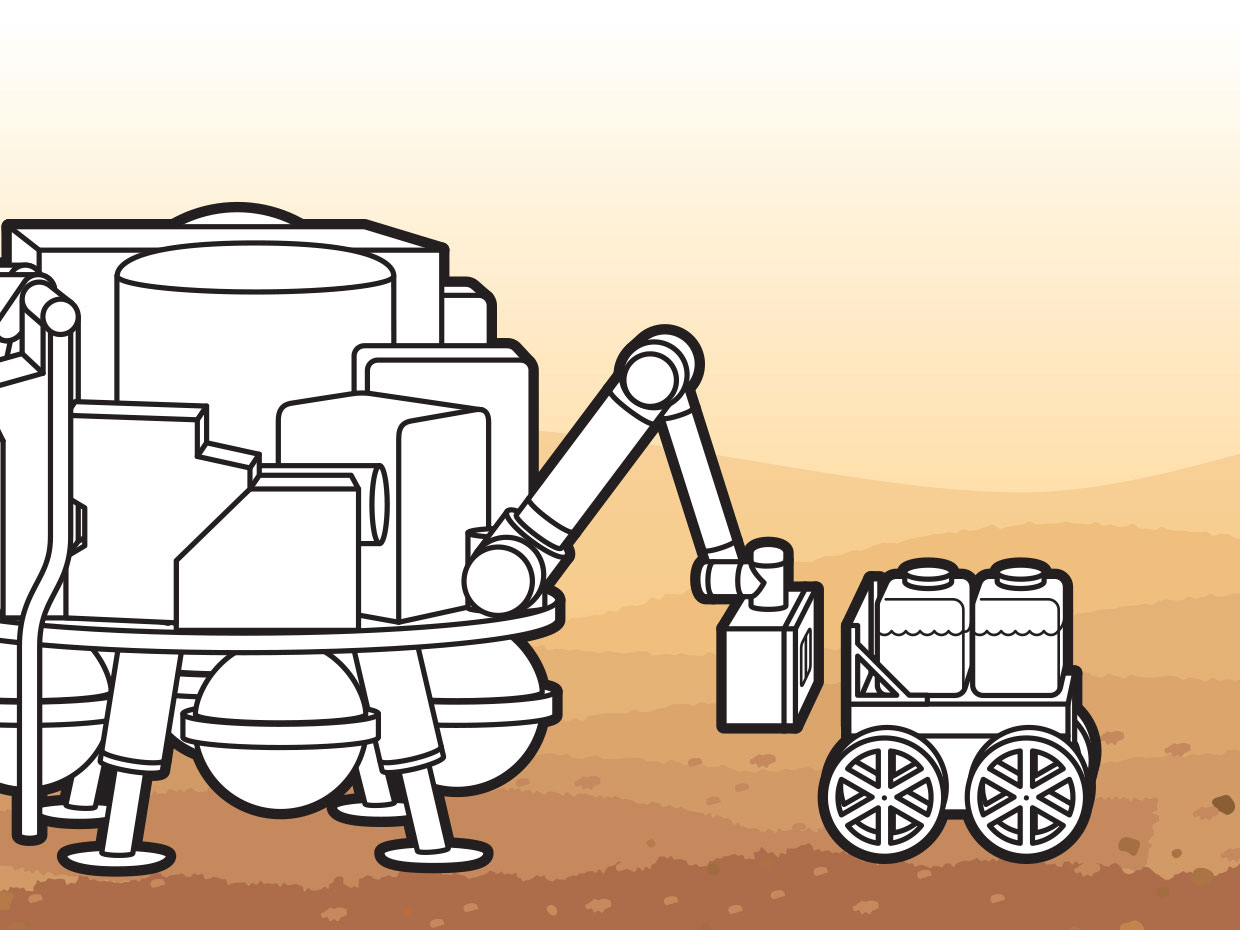

Relocation: a robotic arm with a chamber equipped with hermetic doors preventing dust penetration, moves fluids into a mobile tank

Delivery: the tank delivers water, oxygen and methane to people's habitats and long-term storage tanks.

Use and storage: astronauts consume water and oxygen, also using them for growing plants. Fuel is stored as cryogenic liquids for future use.

The water extracted from the regolith is purified. The purification plant uses a multi-stage filtration system with deionizers.

Water is required not only for drinking: it is also a key ingredient in rocket fuel. By separating the molecules of H 2 O by electrolysis into hydrogen molecules H 2 and oxygen O 2 , and then compressing and liquefying these gases separately, it is possible to synthesize fuel and oxidizer, most often used in liquid-fuel rocket engines.

The problem is that liquid hydrogen must be stored at extremely low temperatures. Therefore, NASA plans to convert hydrogen into fuel, which is much easier to store: methane (CH 4 ). It can be obtained by combining hydrogen with carbon. But where on Mars to get carbon?

Fortunately, Mars is full of carbon. The Martian atmosphere is 96% carbon dioxide. Carbon dioxide freezer is responsible for collecting carbon; it essentially produces dry ice from the air.

Having collected hydrogen from the electrolyzer and carbon dioxide from the atmosphere, we can combine them into methane due to such a chemical process as the Sabatier reaction. A special reactor being developed at NASA creates the pressure and temperature needed to support the reaction, as a result of which hydrogen and carbon dioxide are converted to methane, releasing water as waste.

The next machine in the factory is a robotic arm with an airtight chamber that moves liquids to an external tank. Unusually, the camera is specifically designed to prevent dust from getting inside. The regolith dust is very fine and penetrates everywhere. Since regolith consists of crushed volcanic stone, it is very abrasive and harmful to equipment. NASA's lunar missions showed that the regolith was responsible for a host of problems, including incorrect instrument readings, mechanism contamination, isolation failure, and temperature control failure. Therefore, it is critically important not to allow it to penetrate into robotic arms, electrical contacts, conductive pipe fluids, and sensitive electronics.

Kurt Loit programs a roboruku to connect the charging hose to the mobile tank. The hose is designed to fill the tank with liquid fuel, water and oxygen.

On each side of the roboruki there is a set of doors, working in the manner of an air lock, and not allowing dust inside. Three steps are required for the connection: in the first stage, closed doors are closed against each other, and a seal along the perimeter creates a barrier that is impermeable to dust. At the second stage, the doors protected by a compactor open, exposing the connectors fixed on the movable platform. In the final stage, the platforms are shifted, connecting all electrical and fluid connectors.

Roboruka fuel factory will take the camera and lower it to the mobile tank, connect to it and unload the final products. In this sense, the processing system is similar to gas stations, but instead of gasoline, it can pour water. Or liquid oxygen. Or liquid methane. Or all this together!

We recently demonstrated this factory at Swamp Works. At the moment we had to simulate the stove and electrolysis to reduce the cost and complexity of the project. We also simulated final products using water in all cases. But for all other parts, working prototypes of hardware and software were used.

Having gathered all the subsystems together, we studied the problems and failures, and learned a few important lessons that would elude us, we collected our system entirely only by the end of development and testing. This is one of the main principles of Swamp Works: rapid prototyping and early integration, which allows you to quickly prove the efficiency of circuits and catch failures at an early stage.

The idea of the Martian fuel laboratory is to pack it in a neat box, send it to Mars, deploy it and launch it on the surface of the planet long before people arrive. Manned missions to Mars will depend on the launch of autonomous production and storage of fuel on the way back before the astronauts are launched from Earth. NASA also has teams that are thinking about how to grow different products during the flight and on Mars. Including potatoes.

What else should happen up to this point? A lot of things.

NASA has many years of experience in using individual descent vehicles and independent all-terrain vehicles operating on the surface of Mars. The recent all-terrain vehicles — the Curiosity, which floated to the surface in 2012, and the all-terrain vehicle Mars 2020, which will be launched in 2020 — have a certain amount of autonomy. But the complexity of this Martian fuel factory, the long operating time and level of autonomy required from such a system raises the task to a completely new level.

Tons of Dust: NASA uses an enclosed area to test for excavator robots with more than 100 tons of crushed volcanic rock. The material serves as an analogue of extremely fine and abrasive dust located on the surface of Mars.

Before such a mission begins, we need to overcome many technical obstacles. One of the most critical questions is whether each subsystem of our processing plant can be scaled to meet the requirements of a manned mission. Recent studies show that such a system will need to produce about 7 tons of liquid methane and 22 tons of liquid oxygen in 16 months. Then you need to figure out where you need to plant the module and start processing to maximize the output, how many RASSOR excavators we need, and how many hours a day they will have to work. We also need to find out the necessary dimensions of the carbon dioxide freezer and Sabatier reactor and the amount of energy consumed by all the equipment.

In addition, it is necessary to anticipate possible problems, specifying exactly which failures may interrupt the processing mission, postponing the arrival of a manned mission. We will have to evaluate the probability of each of the failures in order to add the necessary redundancy and duplication to the system.

To make sure that robotics can work for years without maintenance and repair, we need to make it according to very precise specifications. All moving parts must either not be exposed to destructive particles of regolith dust, or withstand it. It is necessary either to improve the seals, or to increase the moving parts, and this will add complexity and weight to the equipment, unless we come up with some ingenious way of circumventing this problem.

We also need to find out how dense the mixture of regolith and ice is under the surface of Mars, and accordingly develop mining equipment. Available excavators work best on dense regolith mixed with ice pieces. But such a scheme is not suitable for breaking large layers of strong ice. We will need convincing evidence of the composition of ice and regolith beneath the surface of Mars in order to develop the most appropriate situation and effective mining equipment. Or we will have to develop more sophisticated and reliable tools that can cope with different densities of soil and ice.

We also need to solve the problems of long-term storage of very cold liquids. Storage tanks under pressure and insulation are constantly being improved, but can current technologies work for a long time on the surface of Mars?

Over the next few years, NASA will look into all these issues. We will continue to increase the capabilities and availability of all prototypes. We will make the robot RASSOR stronger and easier, and we will test it in conditions similar to the Martian ones. We will continue to test and integrate the stove and the electrolyzer, and try to scale the carbon dioxide freezer and the Sabatier reactor to confirm that they can meet the needs of the manned mission to Mars. All this work will continue so that our prototype of the fuel-burning factory could one day become a fully operational system on Mars.

Source: https://habr.com/ru/post/429624/

All Articles