Components of electric bike: motor

Greetings again!

Since my previous small essay was generally perceived positively, I want to share some of the accumulated knowledge in the process of reading forums regarding electric bicycles.

')

In this article I want to share what types of drives are used in electric, their pros, cons, and features.

I hope this will seem interesting to someone. I will only review three-phase DC motors - for the rest have not been investigated, and the rest are relatively rare.

in our time.

So, let's begin:

By and large drive elements of electric bicycles can be sorted into 3 types:

Let's start with the number of the first: mid-drive, central .

It is, by the way, quite popular in all European e-bikes.

It is located near the carriage (pedals) of the bicycle, through a chain drive, and a transmission mechanism,

if it is on a bike, it rotates the rear wheel.

Pros: if a bike with gears - a wide range of optimal application due to these very gears - you can get good traction at low revs, and high speed.

Cons: the chain and the stars become consumables, if you break the chain along the way, or if you bend the rooster, or somehow break the chain transmission, you will return home by walking pushing your transport.

Also can not all-wheel drive using a single motor.

Number Two: Reducer, geared

The electric motor is located inside the wheel hub, there is also a toothed planetary gear reduction, which allows the electric motor to rotate with greater revolutions than the wheel rim.

Gears are usually made of plastic.

There is a mechanism that transmits the moment in the wheel-to-motor system in one direction only - when the engine is engaged (freewill, overrunning clutch).

In the case when the transmission goes in the opposite direction, the system disintegrates, thus, when rolling or moving away from the pedals, the electric motor does not rotate, and thus does not impede the rotation of the wheel.

Here on the left is the direct drive, on the right is the gearbox:

gear motor:

Pros: Better efficiency in a wide range of speeds relative to the direct drive, better traction at low speeds and start, less power consumption per kilometer, smaller size and weight, lack of resistance to movement when driving from the pedals.

Disadvantages: the inability to use the recovery, a weak spot in the form of plastic gears, when cutting off the teeth of which, or deterioration of the overrunning clutch in the way, you will have to pedal.

Number Three: Direct Drive

It seems that the most reliable system by minimizing unnecessary parts is a clean electric motor, the rotor sits on an axis and is stationary relative to the fork, the stator rotates with the wheel.

Pros: a minimum of extra details, recovery is possible, easy to achieve high speeds.

Cons: relatively large diameter and weight, low efficiency at low speeds.

Now about general issues related mainly to motorcycles, because the mid drive does not interest me, so I was not very interested in it.

So, in general, the gear motor wheel is more high-torque and more economical.

Direct drive - more speed, so if you want to drive at speeds of 40 - 50 +, then you should rather look to direct drive.

Also, with the directdrive, through the controller, it is possible to implement the recovery mode - switching the electric motor to the generator mode with storing the generated energy back into the battery.

The effect of recharging the battery is rather scanty - about 2-3% increase in mileage, plus there are some nuances in the form of high charging currents, and the fact that charging a lithium acb at temperatures below +5 Celsius is to kill it (this also applies to mobile phones). and other household devices on lithium-ion and lithium-polymer, by the way), but it can be used as a brake, and thus save brake pads.

By the way, in the “big electric transport”, in the form of, for example, ER2T electric trains, regenerative braking is used exactly the same way - up to a speed of about 25 km / h the train slows down purely by introducing traction motors into the generator mode, transferring the generated electricity back to the contact network.

For economical driving it is much more useful to use minimum braking, and maximally - coasting - that is, seeing a red traffic signal, for example, do not run directly on it on the gas, and close the gas for 300 meters, and roll forward to arrive at the traffic light to have speed no more than 10-15 km / h.

What else: driving speed.

One of the most common questions for newbies is how fast will my bike drive an electric drive?

It directly depends on four things:

1. Idling speed motor-wheels at rated voltage:

Normal sold them either indicates or they can be knocked out of it.

My motor wheel, for example, is 310 RPM at 48V. When measured with a Chinese tachometer,

it turned out 305 revolutions per minute when powered from 4 successively connected lead batteries of 12 volts (approximately 50 volts actually) on a posted wheel is acceptable.

Do not forget that it is the motor-wheel speed without load, this is important!

2. The diameter of the wheel rim. It is clear that the larger the wheel circumference, the greater will be the actual speed at equal revolutions.

The formula for the calculation: the wheel circumference in millimeters / 1000 * (motor wheel speed / 60) = speed in meters per second. For kilometers per hour, multiply by 3.6, to get the final predicted speed - all this is still divided by 1.2, because the speed under, even quite manageable load, will be lower than without load (approximately 20 percent, yes).

3. Compliance with the power to resistance to movement.

If your calculated speed turned out to be 50 km / h, in order to achieve and maintain this speed, the motor will have to develop a power of the order of a kilowatt, or 1000 watts.

If your motor develops a power of 500 watts, then due to the resistance of the rotation it cannot reach its maximum speed, of course, and you will be satisfied with a maximum speed of 37 km / h instead of 50 - while the motor will still get pretty hot due to overload if at that speed you will drive on the fully twisted gas knob.

4. Power supply.

When buying a motorcycle, it indicates the nominal supply voltage - for example, 48 volts.

But nobody feeds directly such engines - they are controlled by a controller that receives single-phase DC voltage from the battery and converts it into a three-phase “rotating” motor-wheel power supply.

So, it is not necessary to feed the motor-wheel controller and battery for the specified voltage.

You can power a 48 volt motor with a 36 volt battery and controller.

Or 24, or 60 volts - while the rotational speed of the motor-wheel at full throttle will be 0.75, 0.5, or 1.25 of the nominal, respectively.

That is, you can easily adjust the maximum speed within certain limits purely by changing the voltage of the battery and the controller.

There are double voltage controllers - for example, 36/48 volts, or 48/60 volts.

Also an important parameter of the controllers in relation to the electric motor is its amperage, through which the maximum power achieved by the motor it feeds can be set - for example, 36v 17A = ~ 612 watt, 60V 25A = ~ 1500w

The fact is that the “power in watts” indicated on the motor-wheel is rather a recommended long-term one in which it will not overheat and in which its long and happy life is guaranteed.

And so a 250 watt motor can be 500 and 800 watts, and even kilowatts to file - it is clear that in the long run, plastic gears may not like it, or frivilu, but it is considered that two or three times the forcing is relatively good for most motorcycles.

However - the controllers are worthy of a separate article, so we will not go into this jungle now.

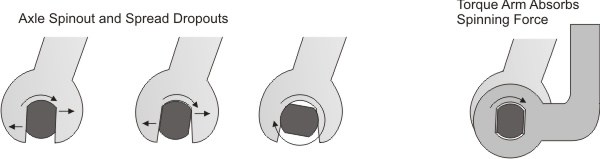

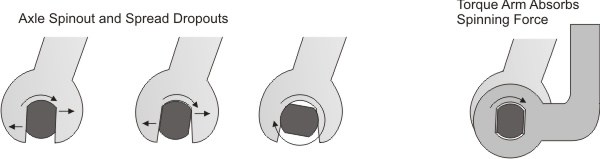

What else is important - torque arm amplifiers.

Due to the fact that the frame of ordinary bicycles is not intended to resist the axis of the wheels to twist, especially in the case of an aluminum fork / frame, it is highly recommended to take measures against turning the axis of the motor-wheel.

The fact is that according to something there any action gives rise to opposition.

The motor-wheel turns the rim, leaning on the axis, that is, the axis of the wheel in it as a point of support, which she tries to turn in the other direction.

If the fork grooves do not withstand this moment, they break, as a result - the wheel leaves separately, the bicycle is stuck at the speed with the feathers of a fork into the asphalt. What does this lead to? I hope it is not necessary to explain, bone breakdowns and even the morgue as a result are quite likely.

Good luck with your electrification, friends!

PS Something is unkind to me here - for the first time I noticed it myself, in the big picture ...

but generally I’m white and fluffy, if it’s too early to go to work early in the morning ...: D

Since my previous small essay was generally perceived positively, I want to share some of the accumulated knowledge in the process of reading forums regarding electric bicycles.

')

In this article I want to share what types of drives are used in electric, their pros, cons, and features.

I hope this will seem interesting to someone. I will only review three-phase DC motors - for the rest have not been investigated, and the rest are relatively rare.

in our time.

So, let's begin:

By and large drive elements of electric bicycles can be sorted into 3 types:

- Four-wheel electric motor, electric motor with a central location.

- Geared motor-wheel (geared hub motor).

- Direct-drive motor-wheel.

Let's start with the number of the first: mid-drive, central .

It is, by the way, quite popular in all European e-bikes.

It is located near the carriage (pedals) of the bicycle, through a chain drive, and a transmission mechanism,

if it is on a bike, it rotates the rear wheel.

Pros: if a bike with gears - a wide range of optimal application due to these very gears - you can get good traction at low revs, and high speed.

Cons: the chain and the stars become consumables, if you break the chain along the way, or if you bend the rooster, or somehow break the chain transmission, you will return home by walking pushing your transport.

Also can not all-wheel drive using a single motor.

Number Two: Reducer, geared

The electric motor is located inside the wheel hub, there is also a toothed planetary gear reduction, which allows the electric motor to rotate with greater revolutions than the wheel rim.

Gears are usually made of plastic.

There is a mechanism that transmits the moment in the wheel-to-motor system in one direction only - when the engine is engaged (freewill, overrunning clutch).

In the case when the transmission goes in the opposite direction, the system disintegrates, thus, when rolling or moving away from the pedals, the electric motor does not rotate, and thus does not impede the rotation of the wheel.

Here on the left is the direct drive, on the right is the gearbox:

gear motor:

Pros: Better efficiency in a wide range of speeds relative to the direct drive, better traction at low speeds and start, less power consumption per kilometer, smaller size and weight, lack of resistance to movement when driving from the pedals.

Disadvantages: the inability to use the recovery, a weak spot in the form of plastic gears, when cutting off the teeth of which, or deterioration of the overrunning clutch in the way, you will have to pedal.

Number Three: Direct Drive

It seems that the most reliable system by minimizing unnecessary parts is a clean electric motor, the rotor sits on an axis and is stationary relative to the fork, the stator rotates with the wheel.

Pros: a minimum of extra details, recovery is possible, easy to achieve high speeds.

Cons: relatively large diameter and weight, low efficiency at low speeds.

Now about general issues related mainly to motorcycles, because the mid drive does not interest me, so I was not very interested in it.

So, in general, the gear motor wheel is more high-torque and more economical.

Direct drive - more speed, so if you want to drive at speeds of 40 - 50 +, then you should rather look to direct drive.

Also, with the directdrive, through the controller, it is possible to implement the recovery mode - switching the electric motor to the generator mode with storing the generated energy back into the battery.

The effect of recharging the battery is rather scanty - about 2-3% increase in mileage, plus there are some nuances in the form of high charging currents, and the fact that charging a lithium acb at temperatures below +5 Celsius is to kill it (this also applies to mobile phones). and other household devices on lithium-ion and lithium-polymer, by the way), but it can be used as a brake, and thus save brake pads.

By the way, in the “big electric transport”, in the form of, for example, ER2T electric trains, regenerative braking is used exactly the same way - up to a speed of about 25 km / h the train slows down purely by introducing traction motors into the generator mode, transferring the generated electricity back to the contact network.

For economical driving it is much more useful to use minimum braking, and maximally - coasting - that is, seeing a red traffic signal, for example, do not run directly on it on the gas, and close the gas for 300 meters, and roll forward to arrive at the traffic light to have speed no more than 10-15 km / h.

What else: driving speed.

One of the most common questions for newbies is how fast will my bike drive an electric drive?

It directly depends on four things:

1. Idling speed motor-wheels at rated voltage:

Normal sold them either indicates or they can be knocked out of it.

My motor wheel, for example, is 310 RPM at 48V. When measured with a Chinese tachometer,

it turned out 305 revolutions per minute when powered from 4 successively connected lead batteries of 12 volts (approximately 50 volts actually) on a posted wheel is acceptable.

Do not forget that it is the motor-wheel speed without load, this is important!

2. The diameter of the wheel rim. It is clear that the larger the wheel circumference, the greater will be the actual speed at equal revolutions.

The formula for the calculation: the wheel circumference in millimeters / 1000 * (motor wheel speed / 60) = speed in meters per second. For kilometers per hour, multiply by 3.6, to get the final predicted speed - all this is still divided by 1.2, because the speed under, even quite manageable load, will be lower than without load (approximately 20 percent, yes).

3. Compliance with the power to resistance to movement.

If your calculated speed turned out to be 50 km / h, in order to achieve and maintain this speed, the motor will have to develop a power of the order of a kilowatt, or 1000 watts.

If your motor develops a power of 500 watts, then due to the resistance of the rotation it cannot reach its maximum speed, of course, and you will be satisfied with a maximum speed of 37 km / h instead of 50 - while the motor will still get pretty hot due to overload if at that speed you will drive on the fully twisted gas knob.

4. Power supply.

When buying a motorcycle, it indicates the nominal supply voltage - for example, 48 volts.

But nobody feeds directly such engines - they are controlled by a controller that receives single-phase DC voltage from the battery and converts it into a three-phase “rotating” motor-wheel power supply.

So, it is not necessary to feed the motor-wheel controller and battery for the specified voltage.

You can power a 48 volt motor with a 36 volt battery and controller.

Or 24, or 60 volts - while the rotational speed of the motor-wheel at full throttle will be 0.75, 0.5, or 1.25 of the nominal, respectively.

That is, you can easily adjust the maximum speed within certain limits purely by changing the voltage of the battery and the controller.

There are double voltage controllers - for example, 36/48 volts, or 48/60 volts.

Also an important parameter of the controllers in relation to the electric motor is its amperage, through which the maximum power achieved by the motor it feeds can be set - for example, 36v 17A = ~ 612 watt, 60V 25A = ~ 1500w

The fact is that the “power in watts” indicated on the motor-wheel is rather a recommended long-term one in which it will not overheat and in which its long and happy life is guaranteed.

And so a 250 watt motor can be 500 and 800 watts, and even kilowatts to file - it is clear that in the long run, plastic gears may not like it, or frivilu, but it is considered that two or three times the forcing is relatively good for most motorcycles.

However - the controllers are worthy of a separate article, so we will not go into this jungle now.

What else is important - torque arm amplifiers.

Due to the fact that the frame of ordinary bicycles is not intended to resist the axis of the wheels to twist, especially in the case of an aluminum fork / frame, it is highly recommended to take measures against turning the axis of the motor-wheel.

The fact is that according to something there any action gives rise to opposition.

The motor-wheel turns the rim, leaning on the axis, that is, the axis of the wheel in it as a point of support, which she tries to turn in the other direction.

If the fork grooves do not withstand this moment, they break, as a result - the wheel leaves separately, the bicycle is stuck at the speed with the feathers of a fork into the asphalt. What does this lead to? I hope it is not necessary to explain, bone breakdowns and even the morgue as a result are quite likely.

Good luck with your electrification, friends!

PS Something is unkind to me here - for the first time I noticed it myself, in the big picture ...

but generally I’m white and fluffy, if it’s too early to go to work early in the morning ...: D

Source: https://habr.com/ru/post/429384/

All Articles