PICASO 3D Designer XL Review

We talk about the 3D-printer PICASO 3D Designer XL - the first large-format FDM-printer PICASO 3D printing construction plastics.

Video

Story

3D printer PICASO 3D Designer XL was presented in September at the exhibition Top 3D Expo. This is the third device in the X line.

')

The company announced its new platform two years ago, and sales of the first printer of the series, the X Pro, began in 2017. In the spring of this year, PICASO 3D unveiled a single-nozzle model, PICASO 3D Designer X.

Designer XL is the company's first large-format printer capable of printing with refractory materials.

About the printer

PICASO 3D Designer XL

Specifications

- Shell Material: Steel

- Software: Polygon X

- Weight: 75 kg

- Materials used: ABS, PLA, HIPS, ULTRAN630, ULTRAN6130, ASA, ABS / PC, PET, PC, FRICTION, FLEX, CAST, RELAX, ETERNAL, PETG, CERAMO, SBS, NYLON, PEEK

- Platform Calibration: Auto

- Number of extruders: 1

- Rails XY: rail (steel), Z: cylindrical (steel)

- Working chamber, mm: 360x360x610

- Dimensions, mm: 654x565x985

- The temperature of the printing table: 150 ° C

- Extruder temperature: 410 ° C

- Printing technology: FFF

- Thread diameter: 1.75 ± 0.1 mm

- The diameter of the nozzle, mm: 0.5 / (0.2 - 0.8)

- Print speed: up to 100 cm³ / h

- Power: 300W

- Body Material: Aluminum (Composite)

- The minimum thickness of the produced layer: 10 microns

- Power supply: 220B ± 15%, 50Hz, up to 1.3kW

- Price: 239 000 rubles

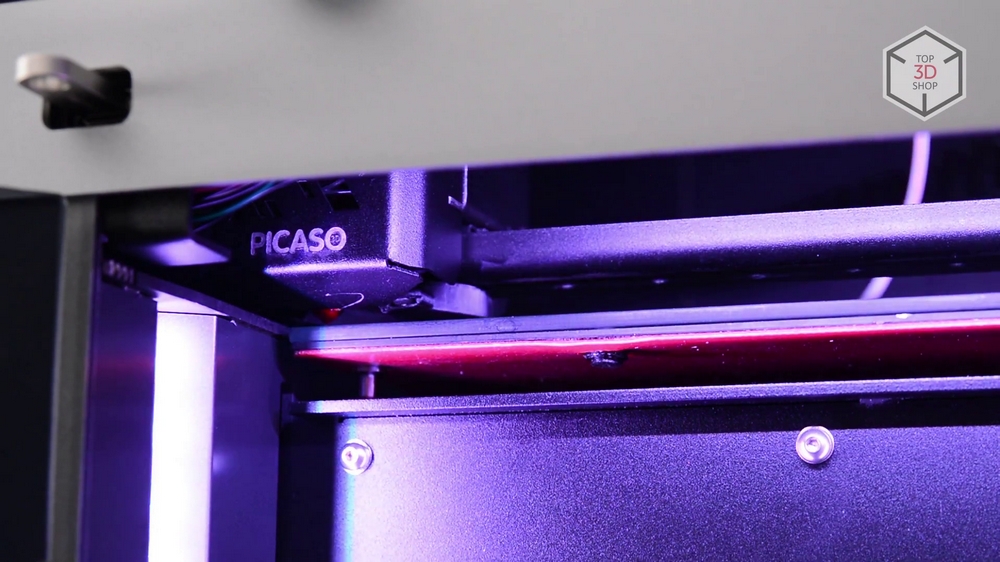

Designer XL inherits the common features of the Designer X line. This applies to both the design and the interface.

In general, platform X was conceived as a single seamless ecosystem in which devices of different levels can operate. By connecting printers to a shared network, you can create a whole 3D farm.

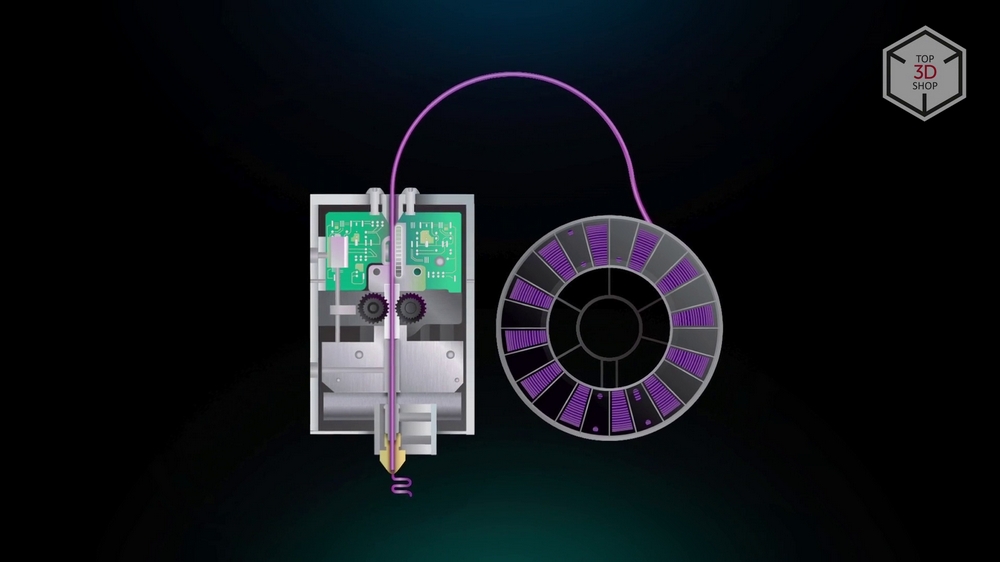

Recall the structural features of the devices on platform X: bidirectional plastic hooking, the presence of a filament guide, all-metal extruder and temperature monitoring of the radiator.

Opportunities

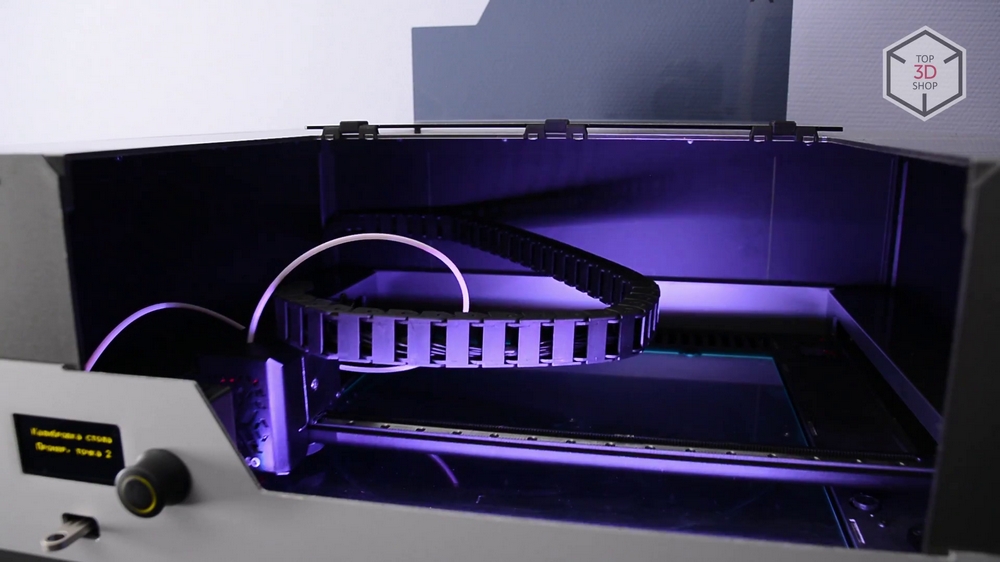

Picaso Designer XL is, above all, a large working volume. At the base is a square with a side of 36 centimeters, height is 61. Net capacity is 79 liters. That's enough to print a full size motorcycle helmet. Or wheel for the car. Or the Tower of Pisa on a scale of 1: 100, without gluing and without seams.

The closed case allows you to work with the most capricious plastics. Robust steel frame and reliable kinematics ensure stable printing.

Extruder Designer XL is heated to 410 degrees, the surface of the table - up to 150. And this means that the new printer is ready to work with engineering and refractory plastics - like PEEK or Ultran .

A very useful innovation is the table auto level. And this setting is really automatic. No half measures - the printer aligns the platform with the help of four leading motors that move the table along the Z axis.

The process starts independently before each print. It can be switched to manual start mode with one button or completely disabled.

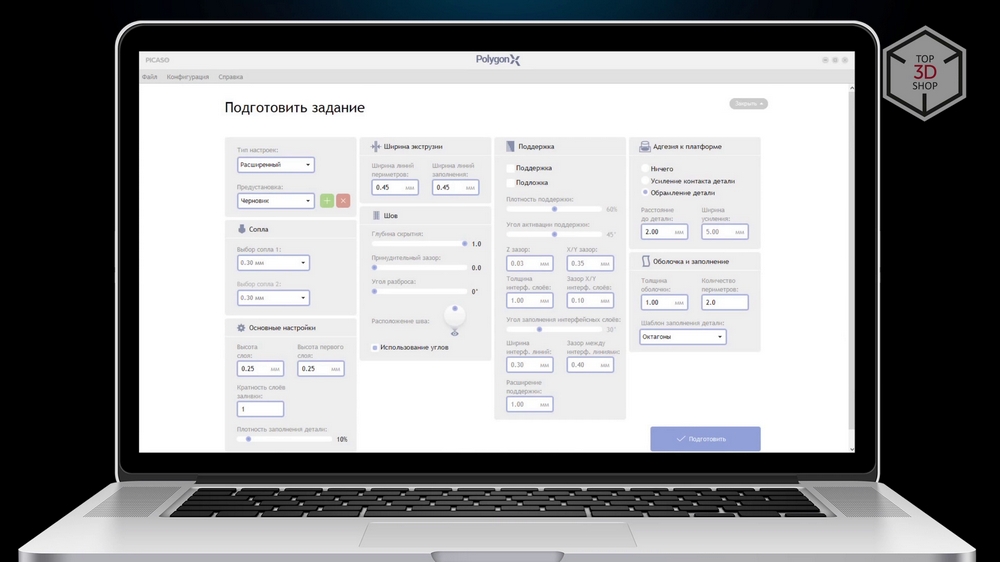

Polygon X, a proprietary control software, can switch between two modes of preparing models for printing: “Fast” - with a minimum number of settings - for beginners, “Advanced” - with access to all the settings already - for experienced users.

Like all printers in the range, Designer XL has a built-in profile system — the material is selected just before printing.

The second generation of the Flow Control control system is integrated into Designer XL. It instantly, for tenths of a second, monitors problems with the supply of plastic - breakage, clogging, filament ending, etc.

An interesting option is the drawer.

Its height is specially selected for convenient work with a 3D-printer. Two options for the cabinet will be on sale: a drying cabinet for the filament and a container for storing plastic. In the second case, it will be possible not only to place a large 5-kilogram coil in the cabinet, but also to print directly from it.

Application

A design agency, a military industrial complex enterprise, a design office, a prosthetics clinic - PICASO 3D Designer XL can find the widest application in various industries. It is especially useful where the standard print sizes are small - the working volume of the Designer XL is 10 times larger than that of the models common on the market. In addition, Designer XL quality fulfills detailed products - post-processing will require a minimum.

The ability to work with refractory engineering plastics significantly increases the applicability of the printer, not only for prototyping, but also for the manufacture of durable, heavily loaded functional parts.

Buy PICASO 3D Designer XL with delivery and warranty, you can in the Top 3D Shop. Subscribe to our blogs and YouTube channel not to miss new interesting materials.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/429188/

All Articles