How NASA Contractor Employees Use Microsoft AR HoloLens Augmented Reality Glasses to Build Orion Nodes

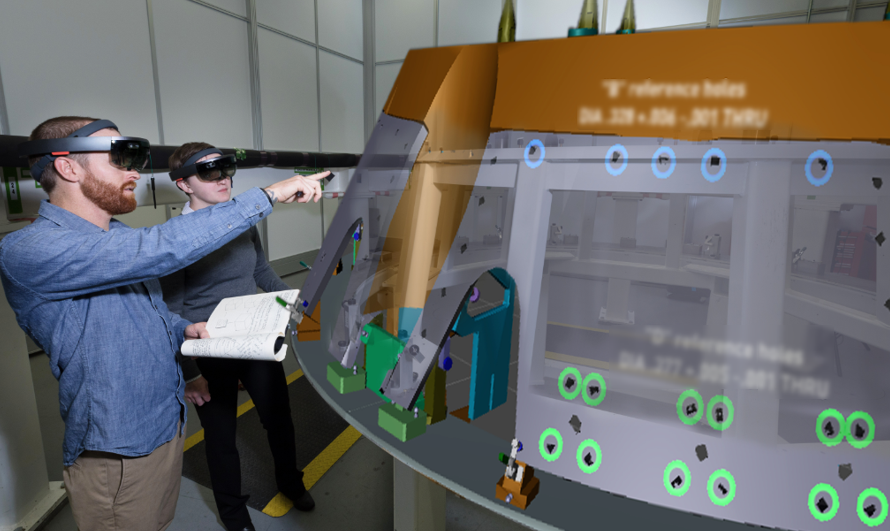

NASA contractor employees use Microsoft AR HoloLens augmented reality glasses headset to quickly and properly assemble Orion spacecraft components.

Engineers from the American aerospace company Lockheed Martin (the main contractor of NASA, who is building the Orion spacecraft designed to transport people to the Moon or Mars and deliver them back to Earth) use Microsoft HoloLens augmented reality glasses when assembling the crew cabin capsule elements for auxiliary purposes. , which significantly saves time, since there is no need to read thousands of pages of paper instructions for preparation and in the process of work.

When you work in a factory that produces thousands of items of the same type, such as an iPhone or plain shoes, you quickly become an expert in the assembly process. But when you create something unique like a spacecraft, it becomes not so easy to achieve an engineering level of comfort.

')

All the time in our work, we are creating something for the first time, ”says Brian O'Connor, vice president of manufacturing operations at Lockheed Martin Space.

Traditionally, in large aerospace organizations, there are rules for reading thousands of pages of paper instructions for their employees. In recent years, companies such as Boeing and Airbus have begun conducting experiments using equipment for augmented reality, but such complex processes of introducing new technologies rarely go beyond the testing stages.

At Lockheed Martin, this paradigm is changing. Engineers now use augmented reality equipment daily to fulfill their current work responsibilities.

Decker Jory, a spacecraft assembly technician, uses the power of the Microsoft HoloLens headset every day to work with the Orion capsule.

At the beginning of the working day, I put this device on to get used to it and get acquainted with the plan for further work in the morning, ”says Jory.

When performing the direct drilling process, he removes the device and works with the tools in the old manner only with his hands and eyes.

At the moment, the maximum time of comfortable wearing the headset is about three hours, then it feels not very comfortable for the eyes and heavy for the neck and head.

Therefore, Dekker Jory and his team of installers use an augmented reality headset to study the volumes of the next task or to check the correctness of the performed actions, and the amount of information presented in the device is limited and divided into fifteen-minute installation intervals, which is more reasonable than continuous non-stop receiving and receiving instructions.

Using the augmented reality headset, specialists can see the holographic models of the layout of the elements of a spacecraft, which are designed for engineering design using a special software product Scope AR. Virtual models of parts and marking schemes are visually superimposed on the already assembled parts of the structure.

The necessary information, for example, instructions for the tightening torques of the necessary connections are displayed directly above the holes to which they relate, and the specialist can immediately see what the finished element should look like after assembly.

Virtual elements of models around specialists using Scope AR software are also painted in different colors, in accordance with the assembly plan of the work, so that it can be seen which employee is responsible for assembling a specific node.

For Jori’s team, which is currently mounting the Orion spacecraft heat shield, this completely new installation aid technology replaces the study of thousands of five hundred pages of paper instructions for assembly and installation.

At Lockheed Martin, we were impressed with the results obtained during testing of this augmented reality system.

It turns out that when using augmented reality headsets, specialists need much less time to familiarize and prepare for performing new tasks, and the time for performing the actions themselves, both simple and complex, has also decreased.

In the near future, Lockheed Martin plans to expand the use of augmented reality devices, up to their everyday use in outer space.

The head of Lockheed Martin’s department of technology, Shelley Peterson, said that based on the new experiences that his specialists had obtained using augmented reality headsets in terrestrial conditions, conclusions can be drawn about how augmented reality can help astronauts maintain and repair complex space objects in space.

We want astronauts to have a full opportunity to maintain equipment that would be much more intuitive and effective than printouts of instructions or sets of drawings, says Shelley Peterson.

At the moment, augmented reality headsets need modifications, it is necessary to improve their durability and simplify their use before they can be used in space. Also, creating content for specialists requires a lot of effort and time to develop, but with a large amount of work done, it is becoming easier to scale up such systems and work out new data. Brian O'Connor believes that with time and the development of technology, these obstacles will be quickly overcome.

If we look at all this after five years, I don’t think that you will find an efficient production process, where augmented reality will not be used to help operators, ”said Brian O'Connor.

Scope ar

Source: https://habr.com/ru/post/427727/

All Articles