3D printing in creating layouts on the example of STUDIO 911

Hello! We continue to talk about the use of 3D-printing equipment by our customers, and the next step is the STUDIO 911 mock-up workshop.

About company

STUDIO 911 creates conceptual and city-planning, architectural, industrial and interior layouts, in scales from 1:10 to 1: 2000, more than five years. Its regular customers are architects, construction and development companies, museums, creative and advertising agencies.

')

Distinguishes STUDIO 911 from other model workshops approach to production.

All necessary work is carried out within the company, without using the services of third-party contractors. The process of order fulfillment is structured so that there can be many projects at the same time, and this does not interfere with their quality execution. Such an organization of labor gives a good business scalability. And this is where 3D printing helps.

Used printers

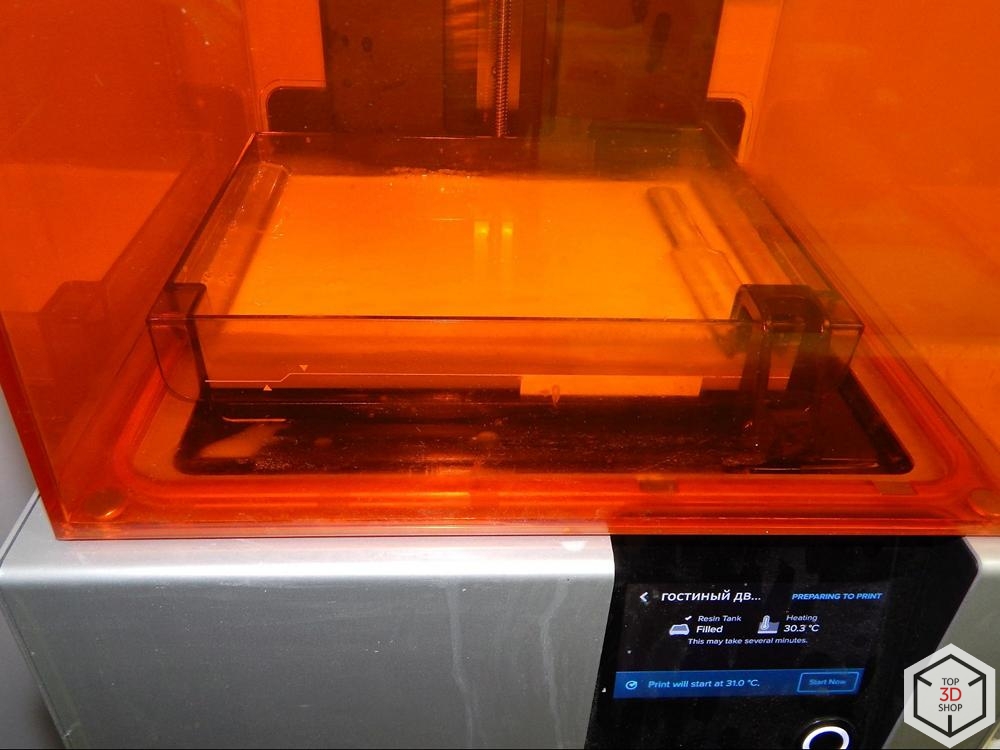

Formlabs Form 2

Specifications

- Technology: SLA

- Working chamber: 145 x 145 x 175 mm

- Layer thickness, from: 25 microns

- Dimensions, mm: 350 x 330 x 520

- Weight, kg: 13

- Specialization: Design; Architecture; Packaging; Advertising; Layout; The medicine; Souvenir industry; Jewelry; Education; Dentistry; Production

- Supported materials: photopolymer

- Interfaces: Wifi, Ethernet, USB

- Price: 317 500 p.

PICASO 3D Designer X

Specifications

- Technology: FDM

- Shipping Weight: 18 kg

- Dimensions with packaging: 690x500x470 mm

- Power supply: 220V ± 15% 50Hz (optional 110V ± 15% 60Hz)

- Power Consumption: 400 W

- Dimensions, mm: 490x430x390

- Weight, kg: 15

- Body Material: Steel, Aluminum

- Software: Polygon X

- File Formats: .stl, .plgx

- Number of extruders: 1

- Working chamber: 200x200x210

- The temperature of the printing table: 140 ° C

- Extruder temperature: 410

- Layer thickness from: 10 microns

- Supported materials: ABS, PLA, HIPS, PVA, ULTRAN 630, ULTRAN 6130, ASA, ABS / PC, PET, PC, FRICTION, CAST, RELAX, ETERNAL, FLEX, RUBBER, SEALANT, PETG, AEROTEX, CERAMO, WAX, SBS , SBS PRO, PROTOTYPERSOFT, PRO-FLEX, TOTAL PRO, NYLON, PEEK

- Thread Diameter: 1.75

- The diameter of the nozzle, mm: 0.3 (0.2-0.8)

- Interfaces: Ethernet, USB

- Print speed: up to 100 cm3 / h

- Price: 139 000 r.

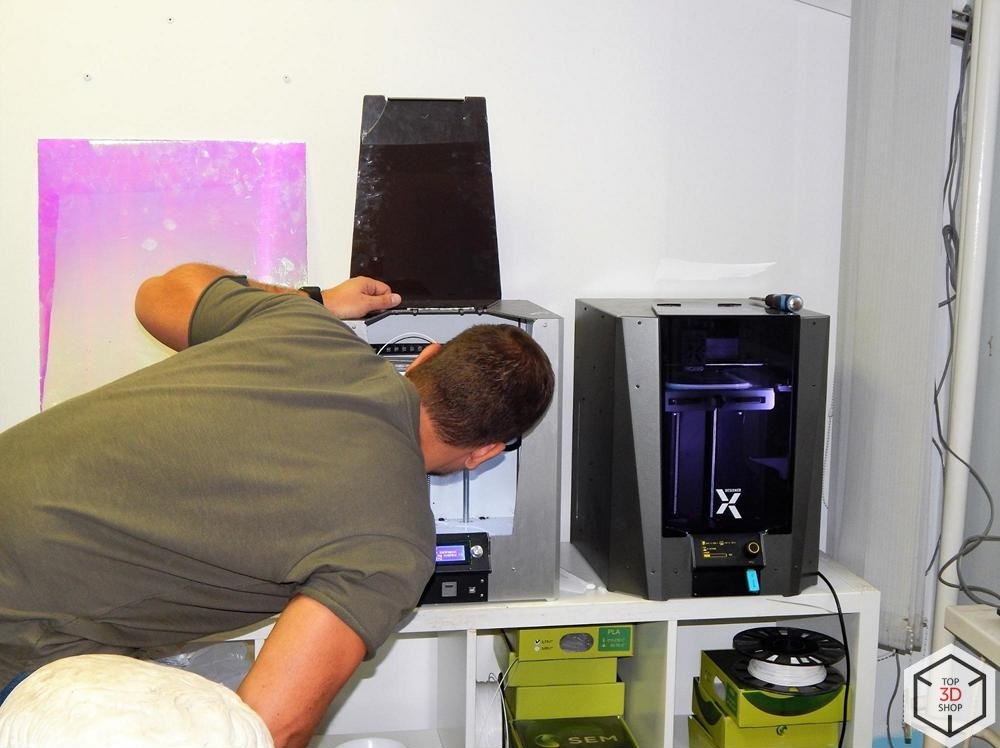

In total, the workshop has five PICASO 3D FDM printers and so far one photo polymer - Formlabs Form 2.

What are they used for?

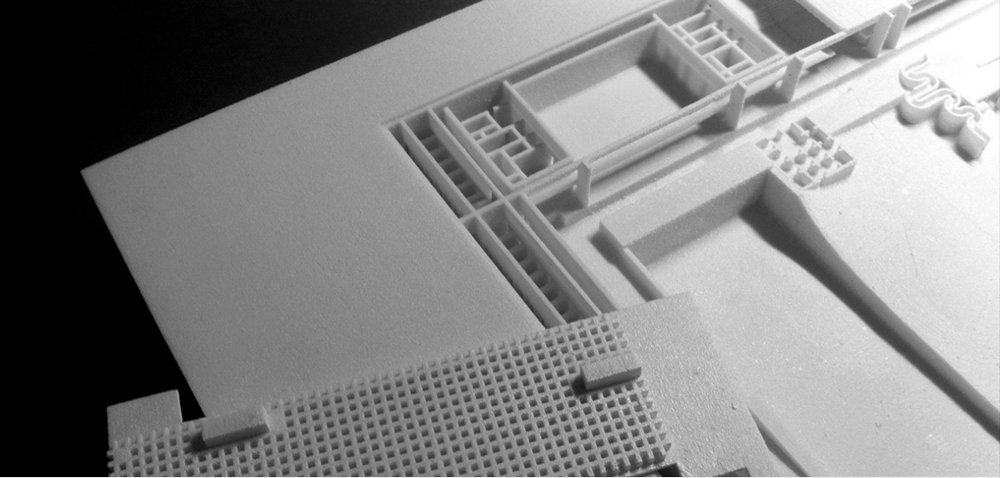

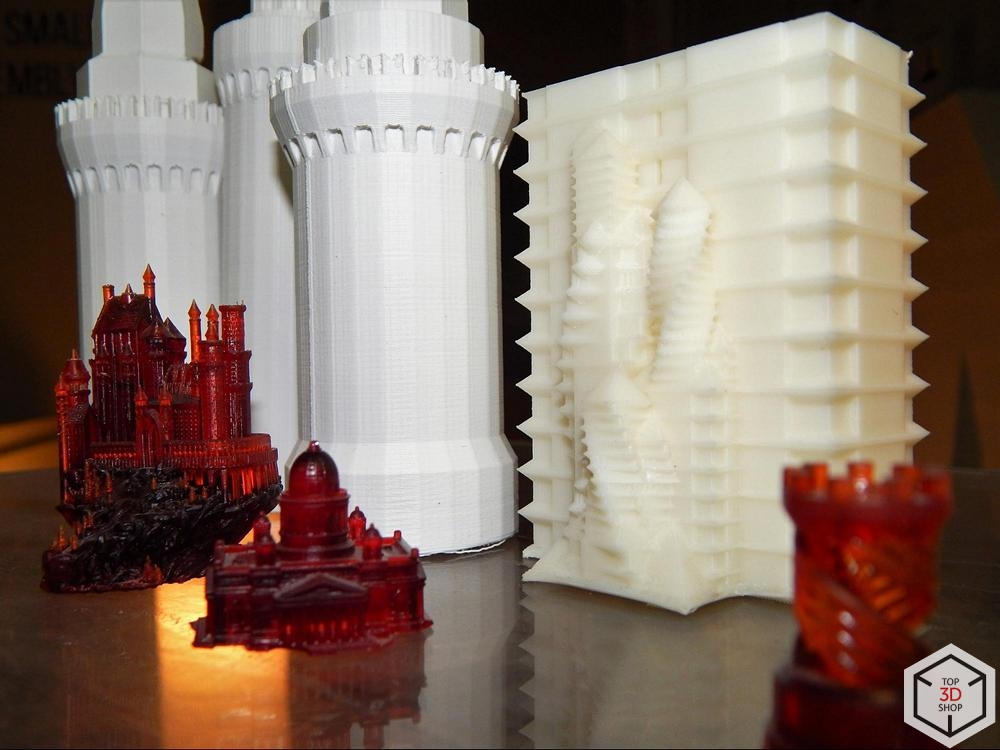

3D printers in the model workshop are used to create parts of models, FDM for large ones, SLA for miniature and highly detailed ones.

How to choose printers

Form 2 was chosen for its convenient software, high build quality and excellent design. At the time of purchase, he had no decent competitors in terms of price to quality.

The printers of PICASO 3D were chosen precisely for what they are made in Russia. With constant professional exploitation, the issues of maintenance, warranty and repair are much more relevant than with private use, and it is much more convenient to communicate with them with a company from Zelenograd than with foreign manufacturers.

As it was done before

Previously, the details of the layouts were cut from foam plastic, glued from sheet plastic, machined and milled on machines of various materials, including stone.

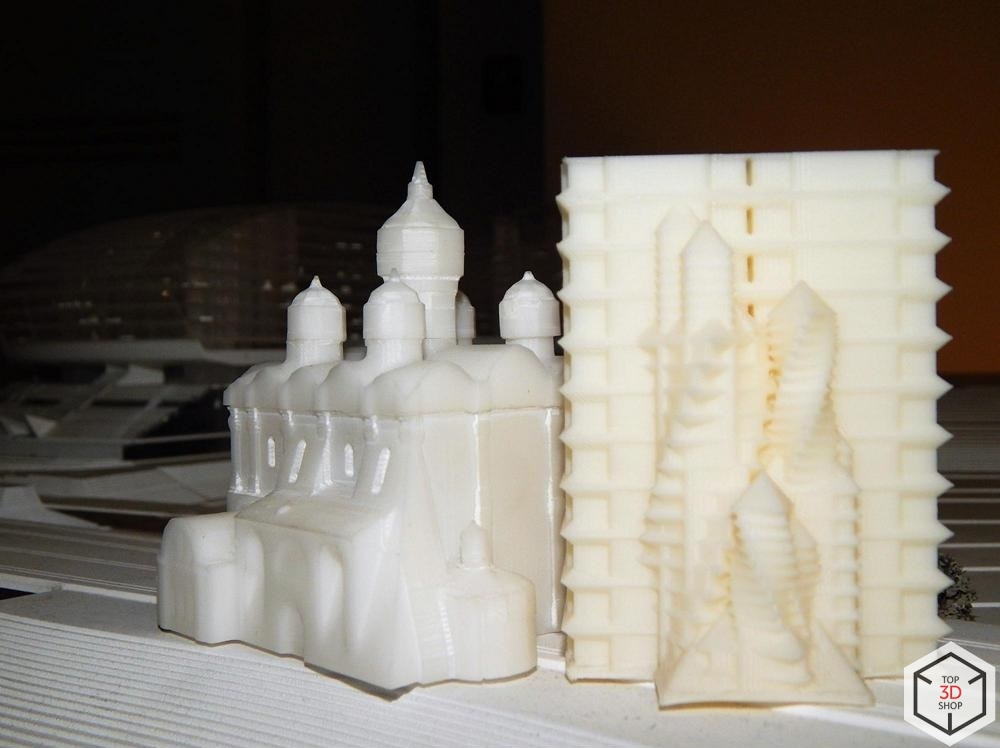

The model on the left is cut out of stone, on the right - printed on a 3D printer.

All these technologies are used now, but 3D printing has greatly expanded the capabilities of the creators of the models.

Most of the details that are printed on Form 2, previously it was impossible to create for reasonable money - only a jeweler would have coped with such painstaking work, and not everyone would have spent time breaking through and asking for appropriate payment. Now they are printed with a photopolymer printer with consistently high quality.

pros

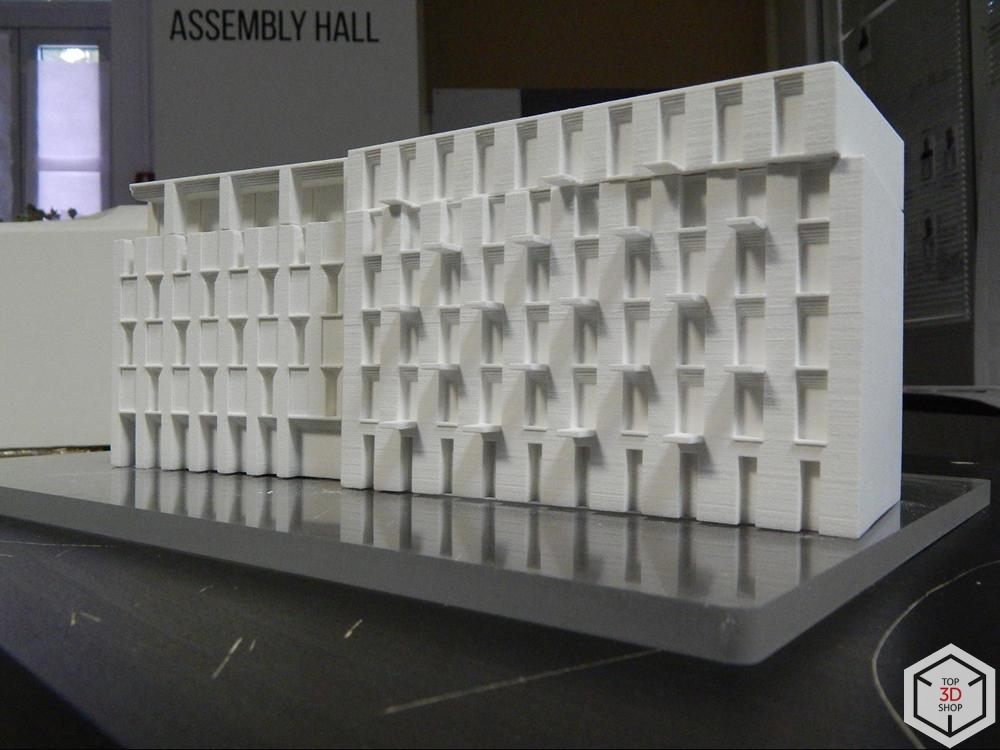

The advantages of FDM printers for model making are obvious - in the case of an order for a large object, you can always load several printers with printing of its parts and get the finished parts much faster than living experts could cope with, no matter what machine tools they work on. The same is true in the manufacture of a batch of identical parts.

The main advantage of SLA is a serious expansion of the scale available for manufacturing. Before the advent of stereolithographic printers, the minimum scale was 1: 500, and it was very difficult to make high-level detail on it - buildings on such a scale were shown only in general shape and volume, without details. Now, without any problems, models are made on a scale of 1: 1000 and 1: 2000, with the ability to reflect the appearance of the facades and other previously inaccessible parts.

The model of the center of Moscow on a scale of 1: 6000, a seven-meter-high monument to Vladimir, 3 mm in size, with stars visible on the towers of the Kremlin.

Minuses

To create large single parts, on which smoothness of the surface is important, traditional methods are still preferable - FDM gives a pronounced texture of the layers, for its elimination, serious post-processing is needed, which negatively affects the accuracy and increases the manufacturing time, and SLA prints such parts for too long and unprofitable, even in parts.

For an example: the model made by traditional methods. Large smooth linear parts, such as facades of panel houses and other simple architectural forms, are easier to cut by hand.

findings

3D printing brought a lot of new things to the layout business and seriously expanded its capabilities - both quantitative and qualitative: it accelerated the production of layouts, increased their accuracy and the range of available scales.

While it is impossible to replace with 3D printing all the processes in the prototyping workshop, this is not yet economically justified, but it is already impossible to imagine a self-respecting prototyping studio without them. This is particularly well illustrated by the example of STUDIO 911, where they strive not only to produce high-quality layouts, but also to put this business “on the conveyor”.

3D printers take on the routine part of the work, leaving the specialists more creative, and thus increasing the efficiency of their work, and hence the productivity of the workshop as a whole.

Miniature sights of Moscow, the disk size of a saucer.

You can buy a 3D printer for a model workshop in the Top 3D Shop - our experts will help you choose equipment for solving any production and creative tasks.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/425925/

All Articles