"Back to the roots": why the IT giant returns 22-nm process technology

In one of our materials, we told why manufacturers are increasingly postponing the development of new process technology. There we mentioned that Intel again postponed the output of 10-nm chips - this time until 2019. Last month it became known that the company plans to go "further" and return to the 22-nm process technology. Today we decided to discuss the situation, to talk about the reasons for such a decision and about how this can turn out for users.

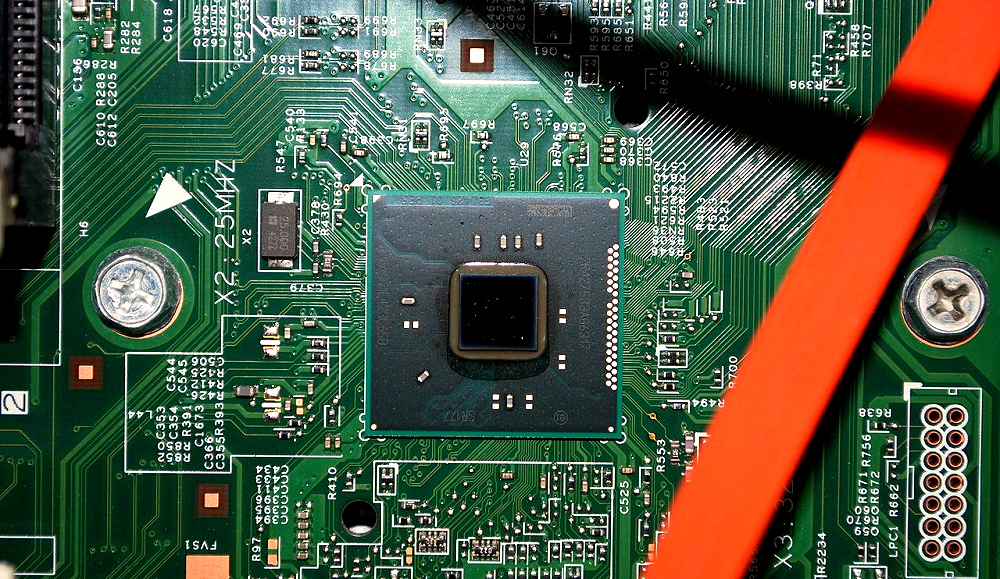

/ photo Fritzchens Fritz PD

Intel planned to release chips on the 10-nm process technology in 2016. But over the past two years, the company has regularly postponed the release. Now the release date of the new chips is scheduled for 2019 (and it remains unclear which half of it is). The company says that the delay is due to the inability to achieve a high percentage of the output of ready-made processors.

')

Despite the fact that the IT giant has thrown all its forces into the development of 10-nm chips, production volumes are growing slowly. Intel release 10-nm chips in small quantities. For example, the first Core i3-8121U processors are made on the 10-nm process technology and are already installed in Lenovo devices. However, the company does not yet talk about large-scale production.

The race for the 10-nm process technology led to a shortage of 14-nm processors on the market. PC makers who counted on 10nm devices were forced to purchase more 14nm solutions. The IT giant's production lines were unable to meet growing demand.

The problem with the shortage of chips immediately reflected in the alignment of forces in the market of processor manufacturers: Intel and AMD. In June, the share of AMD was equal to 45%, in August - already 51%, setting the number of sold CPUs at a record high. Intel's failures can also affect the market as a whole.

JP Morgan analysts say a 14nm shortage could cut PC sales by 7%.

Intel is already working out ways out of the situation. In particular, the company has invested another billion dollars in the production of 14-nm chips, and also came up with a temporary solution.

Intel has decided to return to the 22-nm process technology. With the use of this process will be released chipset H310C. This should help to redistribute the load on production capacity.

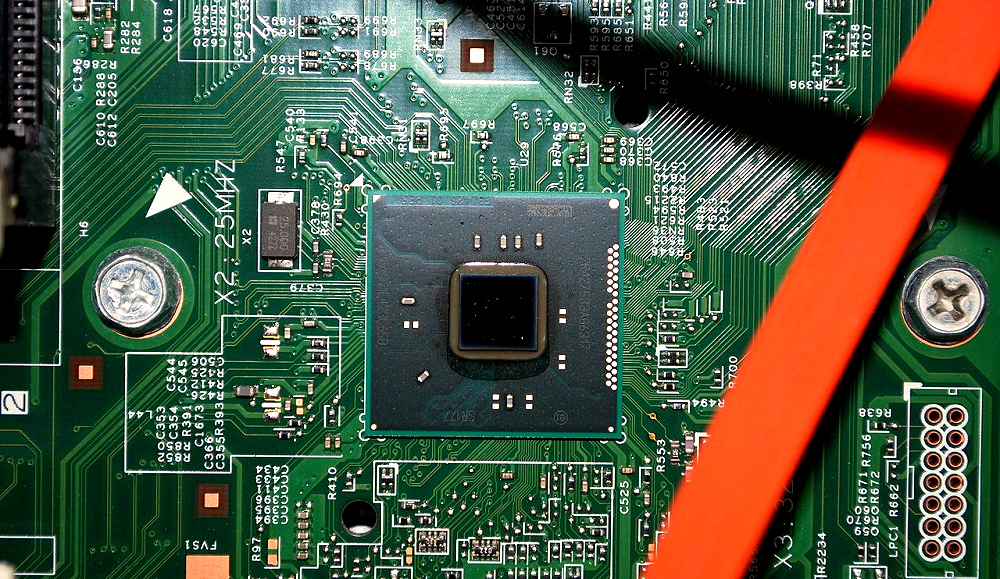

/ photo Jpogi CC

Plus, this will allow "to ease financial pressure" on the budget of the IT giant, since the cost of producing 22-nm microcircuits is significantly less than 14-nm. In Gartner, it is estimated that designing a chip using a 14nm process technology costs $ 80 million, and using a 28nm process costs $ 30 million (22nm is likely to be a bit more expensive).

The production of 22nm chipsets will allow the company to regain market share. These devices will cost less and, as the manufacturer claims, will not lose much in performance. Therefore, they are quite able to become a temporary alternative to the 14-nm for office and home PCs.

Note that when Intel announced that they could still supply the required number of chips and satisfy the demand, AMD shares fell by 5.2%, while Intel shares rose by 3.1%. In addition, according to Acting Intel CEO Bob Swan (Bob Swan), the company has enough power to regain its position in the market before the end of the year.

PS We also write about IaaS and not only in our Telegram channel :

/ photo Fritzchens Fritz PD

Why did it happen

Intel planned to release chips on the 10-nm process technology in 2016. But over the past two years, the company has regularly postponed the release. Now the release date of the new chips is scheduled for 2019 (and it remains unclear which half of it is). The company says that the delay is due to the inability to achieve a high percentage of the output of ready-made processors.

')

Despite the fact that the IT giant has thrown all its forces into the development of 10-nm chips, production volumes are growing slowly. Intel release 10-nm chips in small quantities. For example, the first Core i3-8121U processors are made on the 10-nm process technology and are already installed in Lenovo devices. However, the company does not yet talk about large-scale production.

How it turned out

The race for the 10-nm process technology led to a shortage of 14-nm processors on the market. PC makers who counted on 10nm devices were forced to purchase more 14nm solutions. The IT giant's production lines were unable to meet growing demand.

As a result, processor prices began to rise. Resident Reddit has calculated that in recent months, one of the German retailers, the cost of Intel processors has increased by 25% (third graph).Intel has had an impact on the situation and on the supply of cellular modems for Apple. In particular, the latest models of the iPhone - XS and XS Max - have Intel PMB9955 modems , which are implemented on the 14-nm process technology. Considering that Apple sells millions of new smartphones annually, Intel’s production facilities have been heavily loaded.

The problem with the shortage of chips immediately reflected in the alignment of forces in the market of processor manufacturers: Intel and AMD. In June, the share of AMD was equal to 45%, in August - already 51%, setting the number of sold CPUs at a record high. Intel's failures can also affect the market as a whole.

JP Morgan analysts say a 14nm shortage could cut PC sales by 7%.

Intel is already working out ways out of the situation. In particular, the company has invested another billion dollars in the production of 14-nm chips, and also came up with a temporary solution.

What will do

Intel has decided to return to the 22-nm process technology. With the use of this process will be released chipset H310C. This should help to redistribute the load on production capacity.

/ photo Jpogi CC

Plus, this will allow "to ease financial pressure" on the budget of the IT giant, since the cost of producing 22-nm microcircuits is significantly less than 14-nm. In Gartner, it is estimated that designing a chip using a 14nm process technology costs $ 80 million, and using a 28nm process costs $ 30 million (22nm is likely to be a bit more expensive).

Effects

The production of 22nm chipsets will allow the company to regain market share. These devices will cost less and, as the manufacturer claims, will not lose much in performance. Therefore, they are quite able to become a temporary alternative to the 14-nm for office and home PCs.

Note that when Intel announced that they could still supply the required number of chips and satisfy the demand, AMD shares fell by 5.2%, while Intel shares rose by 3.1%. In addition, according to Acting Intel CEO Bob Swan (Bob Swan), the company has enough power to regain its position in the market before the end of the year.

PS We also write about IaaS and not only in our Telegram channel :

Source: https://habr.com/ru/post/425781/

All Articles