Spray antenna: diminutive, flexible and productive

The twenty first century is filled with many interesting and sometimes incredible inventions. Literally every day there is something new that promises to improve our life with you. One of these innovations is the Internet of things, when various physical objects around us can communicate with each other, forming a certain network. For example, your refrigerator has a list of products that you wanted to buy online. He can transfer this information to your computer, which will place an order. It sounds very unusual, but it is absolutely real. However, a stable connection must be established between the devices, and for this they need to build in certain ones, in particular, an RF antenna may be one of such parts. Today we will talk about the new look of this part, made literally from a sprayer, which is usually painted walls or cars. What this antenna is made of, what its properties and characteristics, how it will help the development of the Internet of things - we will look for these and other questions in the report of the researchers. Go.

The essence of the study

Researchers immediately draw our attention to how things are with the antennas now. Most of them consist of metals (copper, silver, aluminum), which is logical because such substances are excellent conductors, and this is extremely important for the effective transmission of radio waves. However, there is a factor that limits the capabilities of metal antennas. This is a surface effect that determines the thickness of the material at which an electric current can flow efficiently.

')

Simplified concept of the surface effect.

Researchers cite copper as an example. At a frequency of 2.4 GHz (which is usually for Wi-Fi or Bluetooth), the surface effect of copper is 1.33 microns. Silver has 1.29 microns and aluminum has 1.67 microns. Therefore, the antenna thickness of these materials must be at least 5 microns in order for them to work effectively.

But when it comes to minimizing devices, such dimensions no longer seem so small, rather the opposite.

Scientists have not forgotten about the existence of technology for the production of metal fibers, but this method is very time consuming and expensive. Therefore, a new, fundamentally different from the predecessors basis for antennas, capable of being efficient, fast in production and, of course, inexpensive, is necessary. And this can be the basis of MXene.

Future antenna material

Radio frequency antennas are often made of metals, but it is extremely difficult to make a thin, light and flexible antenna from such a material. And we remember that now minimizing the size of devices and their parts is one of the points of development of any technology. Modern nanomaterials such as graphene, carbon nanotubes and conductive polymers can solve the problem of physical size and shape. But such materials have a rather low conductivity, which severely limits their use.

If you can not find the perfect material from the existing ones, you can create one yourself. It was on this path that the scientists went. The basis of the new antennas was two-dimensional titanium carbide (TiC), which in the report has another designation - MXene * .

MXenes * - or maxenes is a class of two-dimensional inorganic compounds.The base MXene was a substance titanium-aluminum carbide (Ti 3 AlC 2 ), from which the atomic layer Al was removed by selective etching * .

Selective etching * is a method of removing one specific component from a substance system.1 gram of Ti 3 AlC 2 powder was gradually introduced into 10 ml of a solution consisting of 6 ml of hydrochloric acid, 3 ml of 49% hydrofluoric acid and 1 ml of deionized water. The resulting mixture was placed in an ice (cooling) bath for 10 minutes, and then continuously stirred for 24 hours.

After the etching process, the mixture was purified 5 times by centrifugation (3500 rpm, 2 minutes each set) until the pH reached 7-6. Next, the precipitate was added to a cold solution of lithium chloride (20%) and water (80%). Then another 10 minutes in a cooling bath and 4 hours of stirring at room temperature.

That's not all. The next step was a repeated triple cleaning to achieve a dark color, which marks the beginning of the delamination process.

So, the base substance is synthesized. Now you need to put it on a substrate of PET (thermoplastic polyethylene terephthalate) with a thickness of 4 mil (1 mil = 1/1000 ″). PET was used because of its flexibility and transparency.

Before applying MXene to the substrate, it was necessary to prepare it. First, the substrate was cleaned with ultrasound in a 5% solution of the detergent * Hellmanex III for 3 minutes. This was followed by another stage of ultrasonic cleaning (also 3 minutes), but now in deionized water and in ethanol 190 (95% pure non-denaturated ethanol and 5% H 2 O).

Detergent * is a substance with high surface activity, therefore it is used for cleaning, disinfection or dissolution. The remedy we wash can be called detergent.Next, the substrate was dried using compressed air and cleaned with oxygen plasma for 5 minutes and an O2 flow of 4 cm 3 / min. This made it possible to remove residual contamination and increase the degree of hydrophilicity * of the surface.

Hydrophilicity * - exaggerated, the ability of an object to absorb water. Bath sponge is a vivid example of hydrophilicity. In contrast, there is hydrophobicity when the object repels water, like an umbrella during rain.As a tool for applying MXene to PET, a conventional nebulizer has become (spray gun, for those who like more twisted names).

Hydrophilia on the example of how the dried sponge absorbs water.

Research results

As a result of the above described manufacturing process, a stable aqueous colloidal solution * with Ti 3 C 2 flakes was obtained.

A colloidal solution * is essentially something between a true solution (homogeneous) and a coarse-dispersed solution, when small particles of one of the compound substances are present in it.

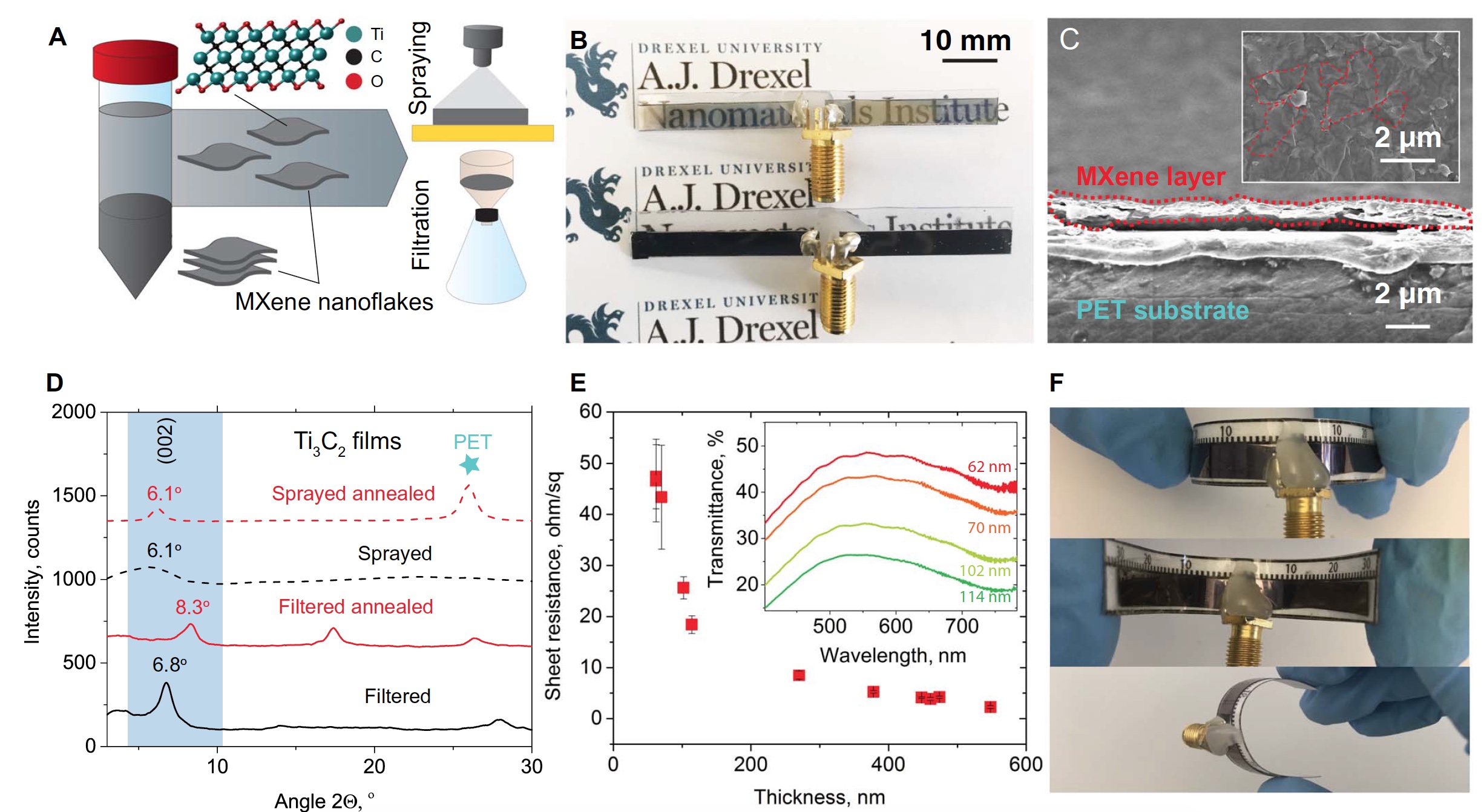

Image number 1

The image 1a schematically shows the above mentioned Ti 3 C 2 flakes. Also shown are options for applying this substance to the substrate: filtration (filtration) and spraying (spraying). In this study, attention is paid specifically to the second version of the creation of films that will become the basis of new antennas. The film thickness will be no more than 1.4 microns, if you use spray coating. If you apply filtering - more than 1 micron.

Plus spraying is also in the fact that a Ti 3 C 2 layer with a thickness of about 1 micron can be applied to the rough PET surface if the substrate is preliminarily treated with oxygen plasma. Filtration does not give such results when applied to PET.

Figure 1b shows pictures of the Hertz dipoles (antenna type) from MXene with a thickness of 62 nm (sample above) and 1.4 μm (sample below).

1c is an SEM (scanning electron microscope) image where we can see how Ti 3 C 2 flakes (red dotted lines) are distributed over the substrate surface (top view), and also how the MXene layer hides the substrate (side view).

Graph 1d is the results of X-ray diffraction analysis of samples created in two ways: vacuum filtration and spraying. The black line is the film after vacuum filtration, and the red line is after heat treatment in vacuum at 150 ° C. The black dashed line is a 1.4 µm film after spraying, and the red dotted line is after additional treatment in vacuum at 150 ° C.

In the case of filtration, the vacuum treatment shifted the (002) peak from 6.8 ° to 8.3 °. And in the case of spraying - from ~ 5 ° to 6.1 °.

A very important indicator of a substance in the context of radio frequency circuits is the resistance of the film surface. On the graph 1e, we can see different indicators of resistance at different film thickness, obtained by four-point resistance measurement. When the film thickness was 1.4 microns, the resistance reached 0.77 ± 0.08 ohms per square. If the film was 62 nm thick, as a result, the resistance was 47 ± 8 ohms per square, and the transmittance of light at a wavelength of 550 nm was 49%.

An important observation of this analysis is the fact that the resistance increases when a thickness of ≤100 nm is reached. This, according to the researchers, is most likely due to the discontinuity of the bonds between the individual Ti 3 C 2 nano flakes, which is due to the inaccuracy of manual spraying.

Sample after spraying procedure.

Material properties, researchers, and with them, and we have already studied. The next step is to check the performance of devices created on the basis of the material made by MXene.

3 devices were made to check certain parameters:

- Hertz dipole to check the properties of radiation;

- transmission line to check wave propagation;

- RFID tag (radio frequency identification) to study the backscatter when the wave is reflected back to the source.

Image number 2

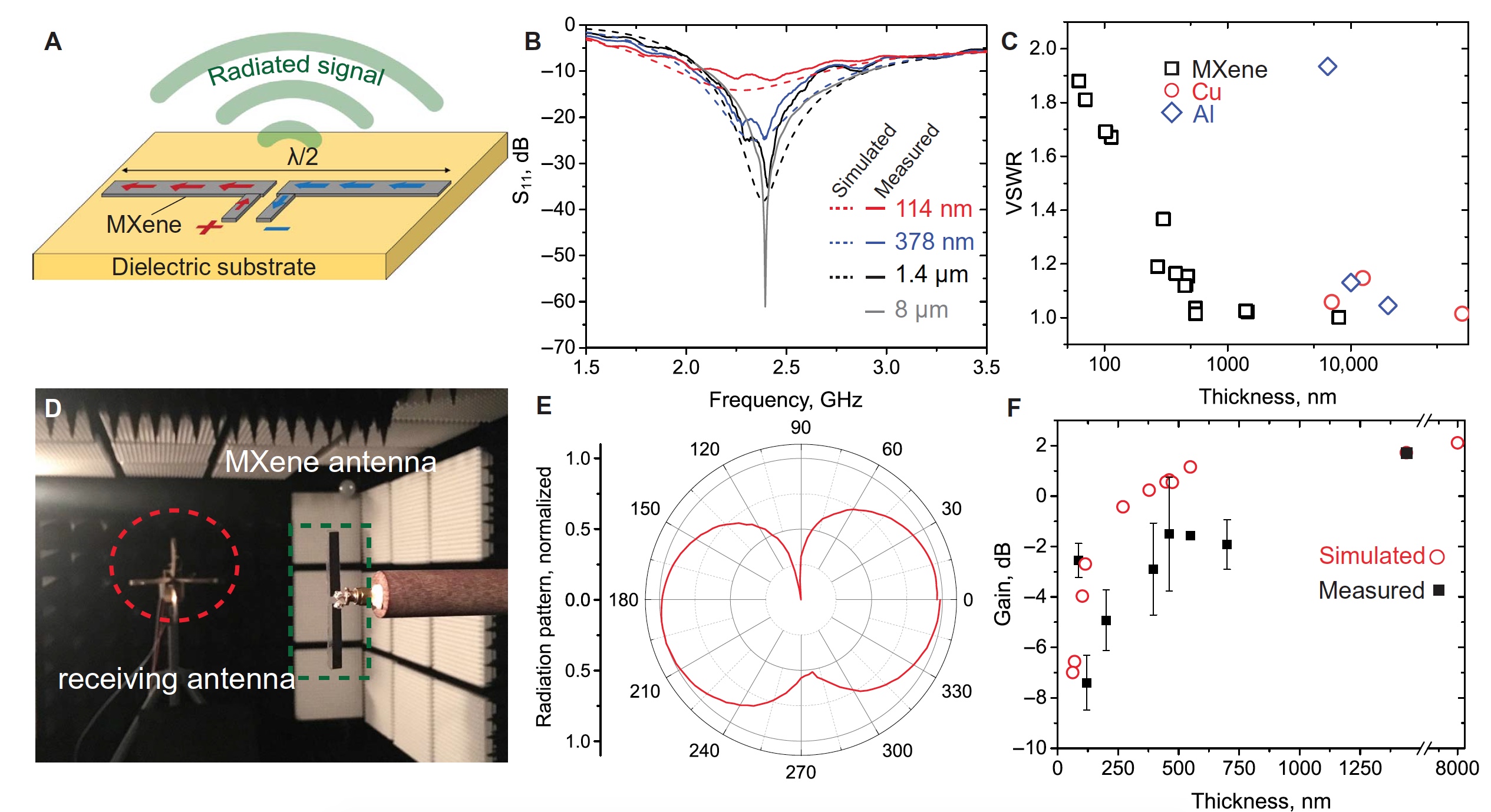

Half-wave dipole antennas are extremely common in different areas (broadcasting, mobile phones, wireless connection, etc.) because they propagate waves in all directions. Therefore, this type of antenna was chosen to test the wave characteristics.

Figure 2a shows a diagram of such an antenna made from the tested MXene, with a frequency of 2.4 GHz. The total length of the dipole is 62 nm, which is half the wavelength at such an operating frequency. The main indicators that were analyzed were return loss and radiation characteristics.

Return loss indicators vary with thickness: from –12 dB at 114 nm to –65 dB at 8 μm. It is clear that the return loss increases with the antenna thickening. Researchers point to the connection of this trend with the correlation of thickness and surface resistance, as mentioned earlier. It is also noted that the return loss can directly depend on the resistance changes due to different lengths, which decrease when the antenna gets thinner. This, again, is due to the MXene manual spraying method on the substrate.

2b is a measurement of the reflection coefficient (S 11 ) of a dipole antenna of various thickness (from 114 nm to 8 μm). Measurements of the standing wave ratio, which shows how efficiently the power is transmitted to the antenna and the impedance matching, are shown in graph 2c . The black squares are MXene, the red circles are copper, and the blue diamonds are aluminum.

The radiation directivity of the dipole antenna was measured in a special anechoic chamber, and Vivaldi antenna was used as a signal receiver. View of the test room is shown in image 2d .

An example of a Vivaldi antenna.

On the adjacent graph ( 2e ) we already see the MXene antenna pattern at a thickness of 8 μm. Finally, a 2f graph showing the maximum directivity of the MXene antenna.

Researchers point out a very important characteristic of the new antenna, its reflection coefficient. This figure was -65 dB for an antenna with a thickness of 8 μm, which is significantly better than that of antennas made from other nanomaterials of a corresponding thickness.

Even with a thickness of 1.4 microns, the coefficient obtained (-36 dB) is better than that of antennas of 7 microns from printed graphene, laminated graphene, or from silver ink.

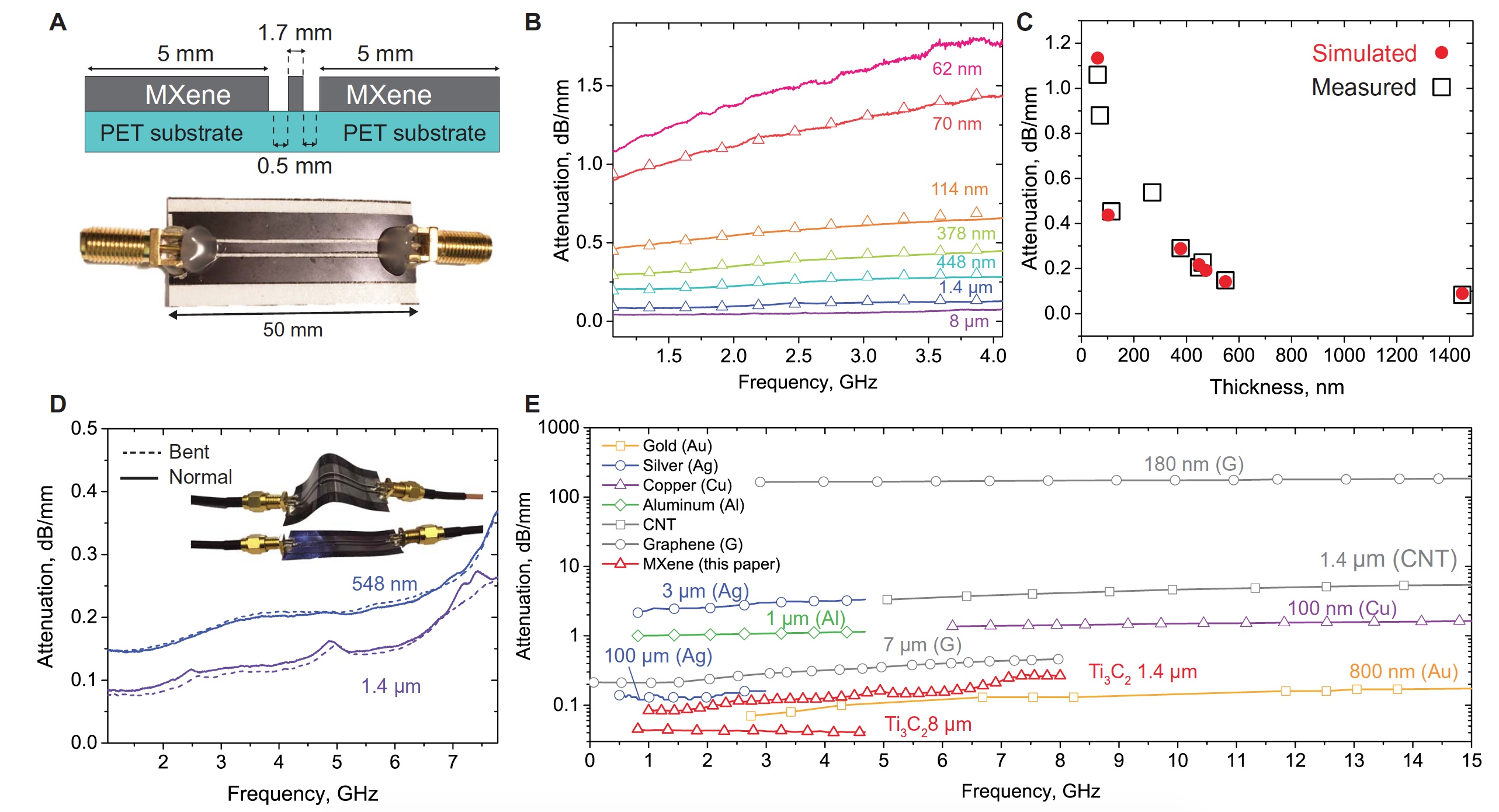

Image number 3

So now go to checking the second device from the test material, to the transmission line. This is a very important, one might say, main component of various radio frequency devices. They are needed to transmit radio frequency signals from point A to point B with minimal energy loss.

Of the variety of transmission line types, one was selected for testing: a strip waveguide. In such a waveguide, electromagnetic waves propagate along two or more conductors located in the same plane. The layout and appearance of the waveguide is shown in image 3a . The signal is transmitted through the center conductor (1.7 microns in width), and two on either side of it at a distance of 0.5 microns are grounding.

Waveguides with a thickness of 62 nm to 8 μm were tested, as were the previous subjects, dipole antennas. With decreasing thickness, the attenuation coefficient increased, as shown in graph 3b . But the 3c chart shows that the measured data almost completely coincides with the calculated in advance.

The flexibility of such a waveguide ( 3d ) was also tested. Changing the shape of the waveguide did not lead to any changes in its characteristics, which makes MXene an excellent material for flexible, compact devices. However, with constant bending, an increase in the surface resistance by 14% is observed, which can be solved by applying the centrifuging method for applying Ti 3 C 2 on the substrate, which will allow more uniform distribution of nanoflakes over the surface.

Next, the researchers compared the attenuation coefficients of their creation with those that were created earlier. Thus, at 1 GHz, the attenuation coefficient MXene (1.4 µm) is 50 times less than that of a graphene waveguide with a thickness of 7.7 µm, and 300 times less than that of a silver ink waveguide. Details of the comparison can be seen on the chart 3e .

Finally, the third MXene-based device, an RFID tag, was tested.

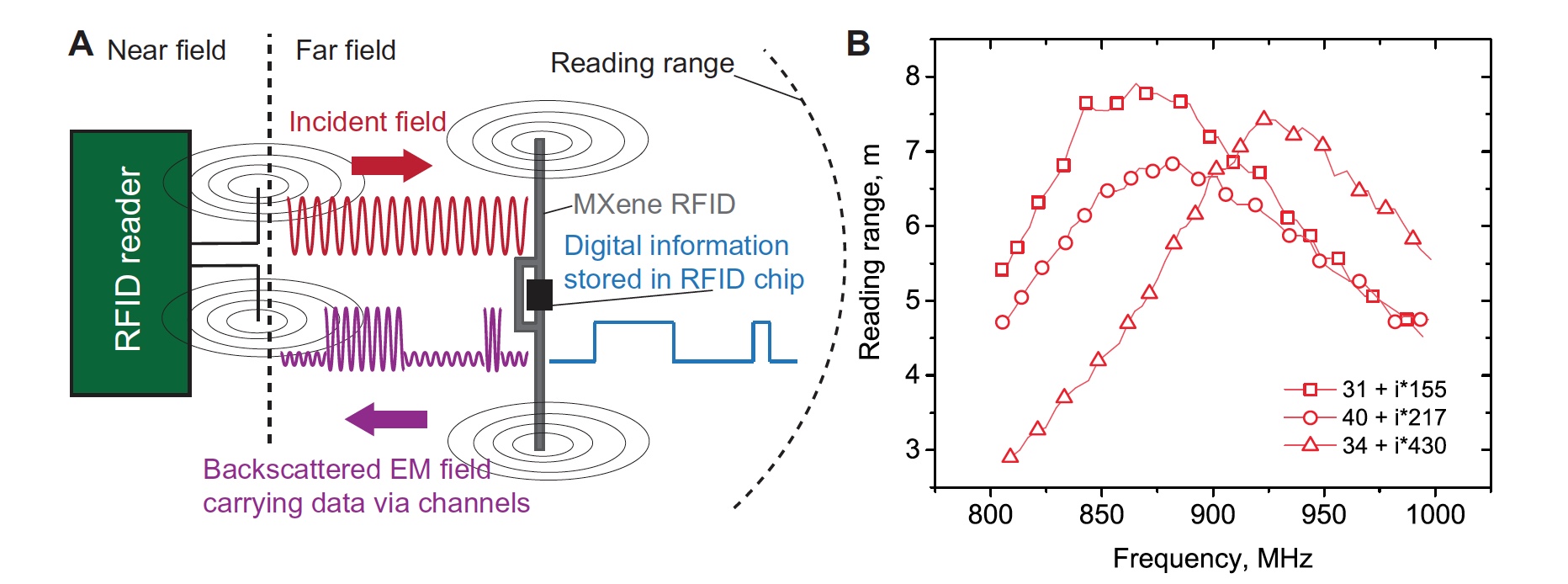

Image number 4

4a shows the scheme and principle of operation of the RFID antenna. Graph 4b shows the downlink reading distances of three different RFID antennas. All three samples show a read range of 6 m. When the maximum matching of the input impedance of the RFID chip is reached, the range expands to 8 m.

The above indicators are extremely encouraging, but Ti 3 C 2 has an important drawback - oxidation. Nanometer flakes Ti 3 C 2 are absolutely stable only in an inert atmosphere. Argon (Ar) was used in this study. If the film enters the oxygen-containing environment, it begins to slowly collapse. Measurements have shown that for 70 hours Ti 3 C 2 retains its properties in normal air. This refers to individual flakes, individual. If there are a lot of them, and they form groups, then such a combination of nano-flaps can survive without negative changes in the air for up to 30 days. This is due to their accuracy, because tightly adjacent to each other, they protect the interior from oxidation, which extends their service life.

According to scientists, the problem of oxidation can now be solved by lamination of parts based on Ti 3 C 2 or by placing them inside sealed devices.

Details of calculations, tests and measurements are available in the report of scientists and in additional materials to it.

Epilogue

The above material fully deserves special attention, given its characteristics, if you believe the tests and trials. Lightness, flexibility, small size and at the same time good performance are the factors that many companies can attract in the future. The devices around us are getting smarter, some of them are becoming smaller. Changing the size of something, you expect its performance to deteriorate. Therefore, many research groups are working on the creation of new devices, new parts, the search for new materials or on their synthesis. All that the future technology performance does not depend on their physical characteristics or the environment of their use.

In addition, the "antenna from the sprayer" - the phrase itself sounds as futuristic as Isaac Asimov could imagine. But modern scientists will not be surprised. Rather, on the contrary, it is they who do not cease to amaze us, and we do not cease to be surprised and rejoice at their discoveries, for the majority are aimed at the common good.

Thank you for staying with us. Do you like our articles? Want to see more interesting materials? Support us by placing an order or recommending to friends, 30% discount for Habr users on a unique analogue of the entry-level servers that we invented for you: The whole truth about VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps from $ 20 or how to share the server? (Options are available with RAID1 and RAID10, up to 24 cores and up to 40GB DDR4).

VPS (KVM) E5-2650 v4 (6 Cores) 10GB DDR4 240GB SSD 1Gbps until December for free if you pay for a period of six months, you can order here .

Dell R730xd 2 times cheaper? Only we have 2 x Intel Dodeca-Core Xeon E5-2650v4 128GB DDR4 6x480GB SSD 1Gbps 100 TV from $ 249 in the Netherlands and the USA! Read about How to build an infrastructure building. class c using servers Dell R730xd E5-2650 v4 worth 9000 euros for a penny?

Source: https://habr.com/ru/post/424467/

All Articles