What were the welders for optics (part two)

This article is a continuation of the material on the history of devices for welding optical fiber, which was published in our blog earlier. Therefore to whom it is interesting to dive under kat.

So, it seems that 1980 was not so long ago, but if you look at the years through the prism of technological development, you get the feeling that hundreds of thousands of years have passed. Then, in the first apparatus for welding optics, the operator had to examine the position of the fibers in the V-groove with a microscope and align them manually with screws. In many respects, everything depended on the experience and “curvature” of the master’s hands rather than on technology. This approach made it possible to achieve low loss when welding multimode fibers, but was poorly suited for single-mode fibers.

As we noted in the last publication, many understood that the development of a welding machine for single-mode fibers could become a separate business area and quite profitable. The development of such a device and engaged in many companies. Already by 1982, Sumitomo introduced the device, with a built-in fiber alignment mechanism using a light source and a photodetector at the far ends of each of the fibers being welded.

')

According to the authors, the light source and power meter should have been installed at the far ends of the fibers, i.e. at a distance of several hundred meters or even several kilometers from each other. With the help of the welding machine, the fibers moved and aligned with the core until the maximum light emission from the source was recorded on the meter. Of course, this idea of combining fibers required too much preparation and time and did not receive further development, however the idea itself was subsequently refined and applied in Siecor devices.

Consider further some of the previously mentioned remarkable models of devices of the twentieth century.

Fujikura FSM-01

One of the first models, about which there are practically no references.

A - Handles for moving the fibers along the Z axis.

B - Regulation of the power of an electric arc (a certain value is selected, which depends on the type and on the manufacturer of the optical fiber, in particular).

B - Switch "manual-automatic mode". In manual mode, the operator himself positions the fibers before and during the welding process.

In the automatic mode, the device during the welding process itself reduces the fibers with each other - the fibers touch and abut each other with a given pressure.

G - Turn on the microscope backlight.

D - Power on.

If the welding was carried out correctly and turned out to be of high quality, then the weld seam or any defect should not be visible through the microscope.

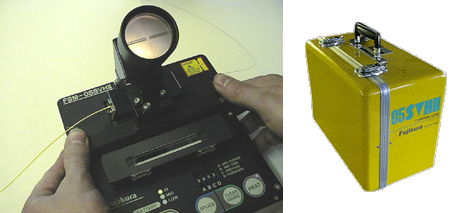

Fujikura FSM-05SVHII

Main characteristics:

Alignment of fibers using a V-groove, automatic flattening of the fibers during welding;

The average loss during fiber welding:

- multimode - 0.05 dB

- single mode - 0.12 dBK

Control of the welded fibers on the screen of the projection microscope.

The test for breaking the welded joint of the fiber;

Weight less than 2 kg.

Go

In this device, it was necessary to manually set the position of the fibers (in the photo, a person twists the screw adjusters with his thumbs), sniping for the location of their ends within the vertical bar on the lens.

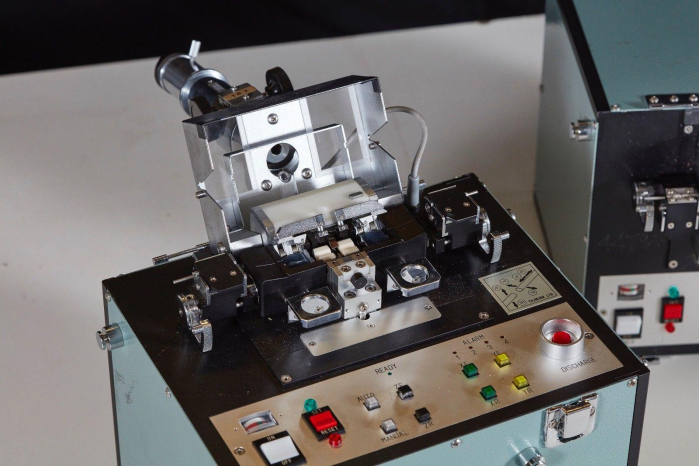

Fujikura FSM-10B (1983)

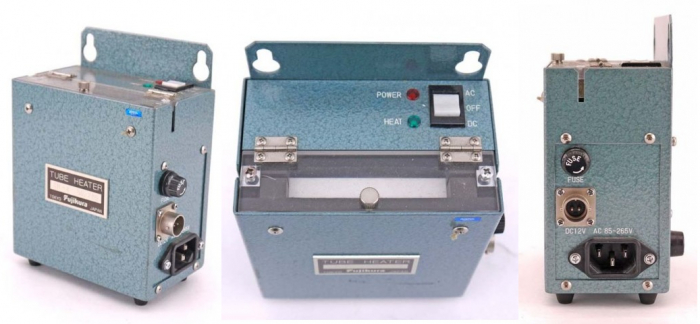

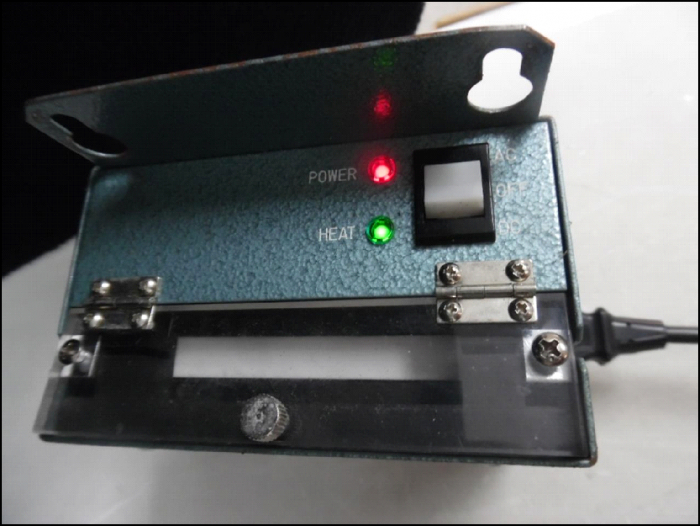

Together with the device is a separate stove module - tube heater.

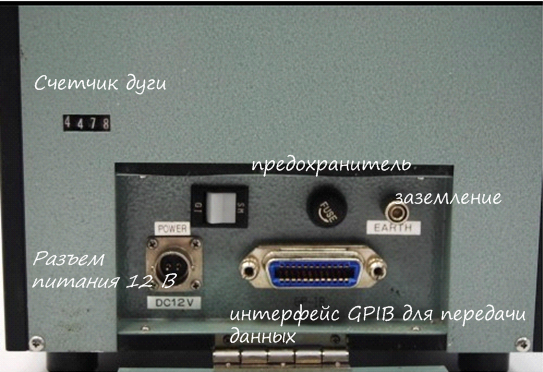

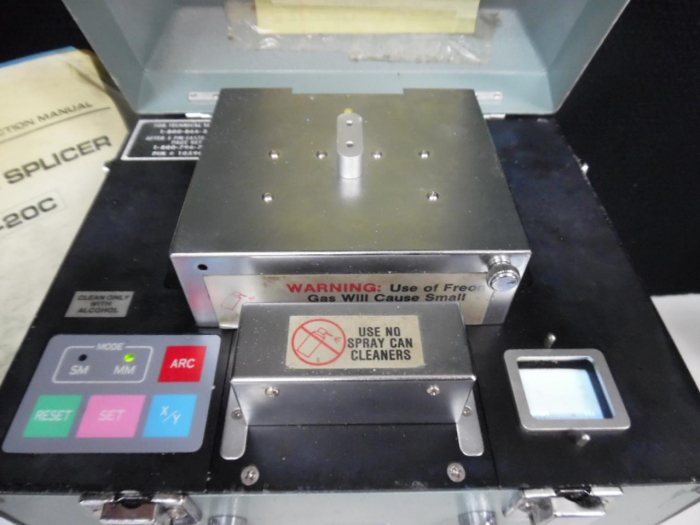

Fujikura FSM-20C (1987)

Starting with this model, all power supply units are built-in inside the device (the external stove has become more massive, but with a 220 V connector). On the device itself, the power button has become three-mode. There was a choice between the power at a constant voltage of 12 V and an alternating 220 V.

Specifications:

Able to weld polarized (PM), singlemode (SM), multimode (MM) fibers.

Actual average loss: 0.03 dB for SM and 0.02 dB for MM.

Through this tiny screen you can see the process of welding fibers

Welding of fibers on the apparatus FSM-20C

After 3 years, the FSM-20CS model was released for a multimode with a larger, more usual reclining screen (albeit in black and white) and a stove built into the device, and after 3 years in the mid-nineties, the thirty-thirds Fujikura was developed and released.

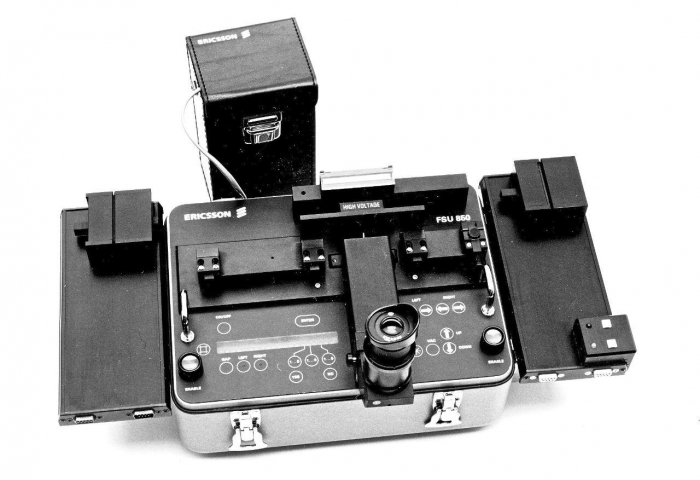

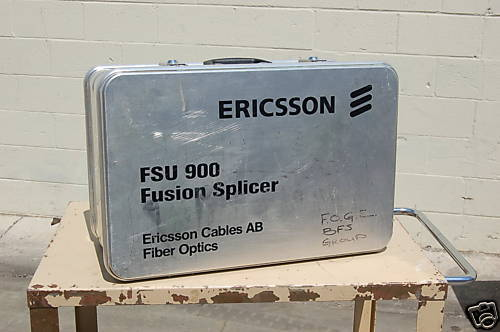

Ericsson devices

Engineer Uwe Betcher, working for Sieverts Kabelverk (which later changed its name to Ericsson Cables, and later to Ericsson Fiber Optics) developed a number of welding machines. In the late 1990s, approximately 800 units were sold per year. Ericsson welding machines were considered competitors to the best welding machines in the world at that time. Uwe Betcher and his team have developed many models: FSU 790, FSU 800, FSU 820, FSU 830, FSU 850, FSU 900 and FSU 905.

December 12, 1979 - the model FSU 790 is developed.

This is the first welding machine Ericsson (with fixed v-shaped ditches for multimode fibers). Used in field trials for splicing Sweden's first optical cable installed in Stockholm. It was released in a single copy.

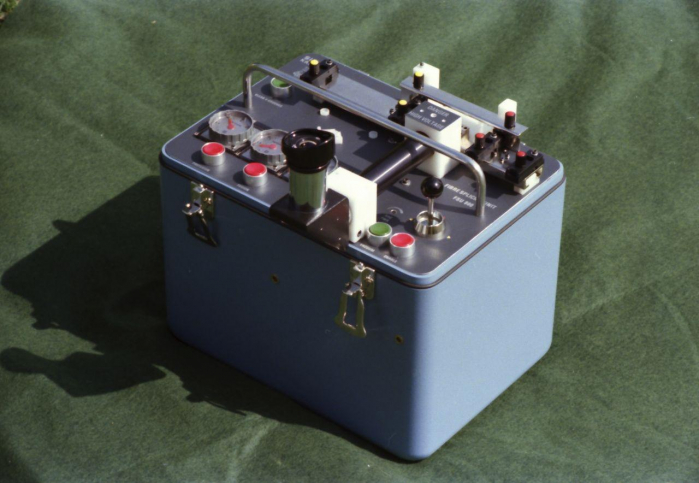

December 1980 - developed model FSU-800

He became the first device Ericsson, entered the commercial implementation. Approximately 100 vehicles were released.

1985 - Ericsson FSU 830 model released

He became the first Ericsson device for welding single-mode fiber. This device has become at one time the industry standard, winning a British contract for the supply of equipment for the construction of networks. In total, several thousand such devices were produced.

June 1986 - the model FSU 900 is released

The first model with alignment of fibers by the method of thermal images.

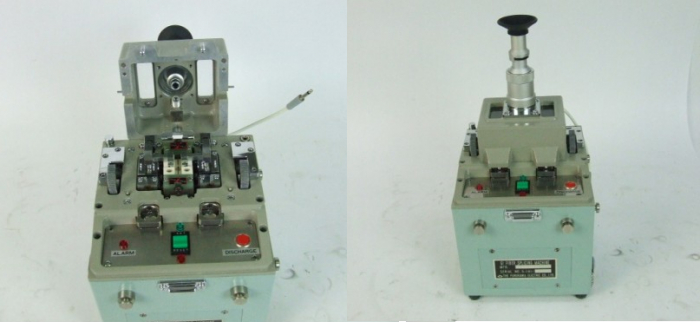

Apparatus Fitel S141 (1986)

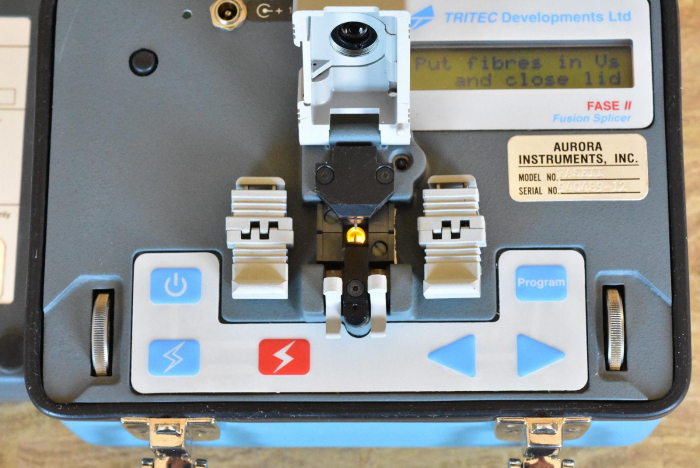

British apparatus Tritec FASE II

Compact welding machine with a microscope, weighing only 2.5 kg. Provides connection loss of 0.05 dB (maximum 0.1 dB) for single-mode and multimode optical fiber.

Contains a microscope with a magnification of 75 times.

Source: https://habr.com/ru/post/423881/

All Articles