Launching elements of offshore platforms. Part 1

Good day, dear habrovchane.

A quick search on Habra on the topics “offshore platforms and shipbuilding” gives, in the main, all kinds of sealed launches and drowning of data centers. I propose to dilute this topic a little.

Our company (this is a ship repair shipyard) in 2014 won the tender for the construction of the support block of the offshore drilling platform for one oil company. This company operates in two fields in the Caspian ( link 1 , link 2 )

The Caspian Sea in the place of installation of drilling platforms is rather shallow. Therefore, the platforms are installed directly on the seabed and fixed with piles. The support block is the foundation of the platform. After production at the plant, it is towed into place, then water is poured into its ballast compartments and it sinks to the bottom. The next step is to put a ready platform on it.

')

The block is made sections.

About such.

Sections are assembled in workshops, and then served on the assembly slipway, where they are joined. It turns out this:

Our support block was built 60 meters from the shore. For launching it was necessary to solve several problems. Problem number 1: a structure weighing 5,600 tons and about 100 meters long must be moved to the shore. Problem number 2. It is necessary to build a ship, calculated on the fact that these 5600 tons are pushed onto it. This vessel should be able to dive slightly (i.e., operate as a floating dock ).

To solve problem number 2, we bought two Amur-type cargo ships:

They came to our factory under their own power. Everything superfluous was removed from them. And in the end we got such a catamaran.

He is not self-propelled. In each case there are 6 ballast compartments. On the nose tower is located Central Post Office (CPA). At the bottom of the nose of each case is the engine room. Each has two diesel pumps and pneumatically-controlled butterfly valves, forced spring closures and additional manual controls.

Like these ones. Diameter - 250mm.

Pneumatics was chosen because of the ease of energy storage for emergency operation, the ease of switching to manual mode. Of course, it was possible to put valves or valves with electric drive. But in this case, the ship should have a full-time main power plant, and an emergency source of electricity. In this case, all critical equipment is powered by batteries. Everything else is powered from the shore. If necessary, we install a pair of generators on the tower (main and backup). Connecting and switching generators in the process of work itself does not interrupt.

Before installing the vessel, we checked these valves in the workshop. When the pneumatic valve is triggered, the shutter with a slight sound “pshhshsh” smoothly opened for 1.5 seconds. When you turn off the same smoothly and quietly closed. Our locksmith - men, tightening and unscrewing the nuts to 19 inclusive with their bare hands - experienced aesthetic ecstasy and together asked for more ...

6 valves control the flow of water to the ballast compartments. The rest set the operation mode of the pumps - filling or pumping. All of these are commanded by the Control Station.

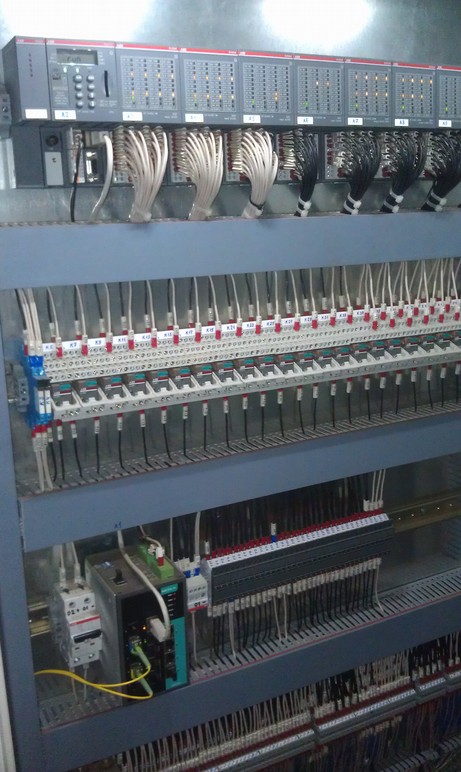

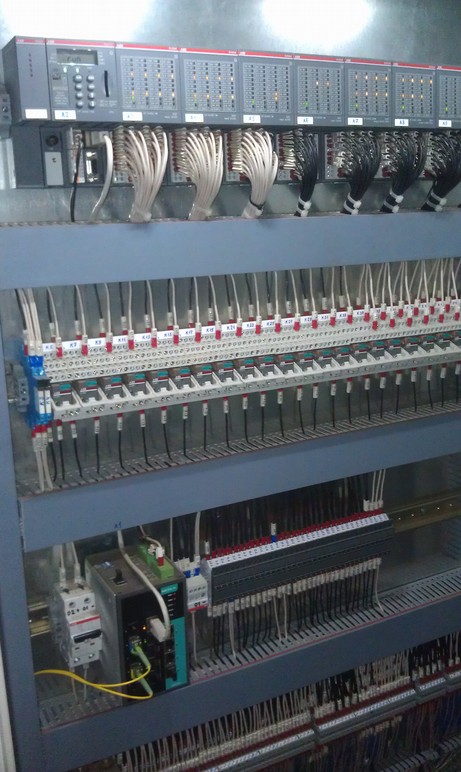

This is her giblets.

Two Control Stations and a console in the CPU are networked with the “Ring” topology in optics.

And this is our remote.

It is fundamentally made without physical buttons (well, such as "glass cabin"). Mouse on the right - to control the DVR.

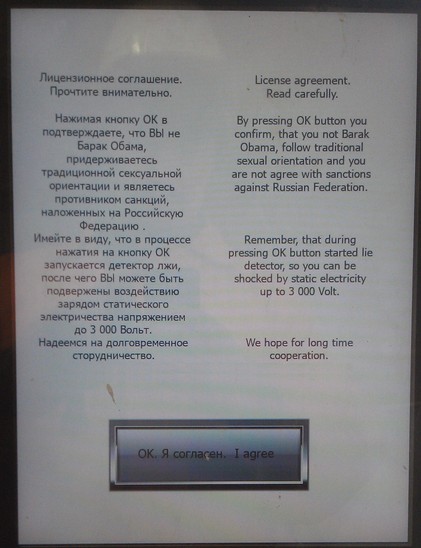

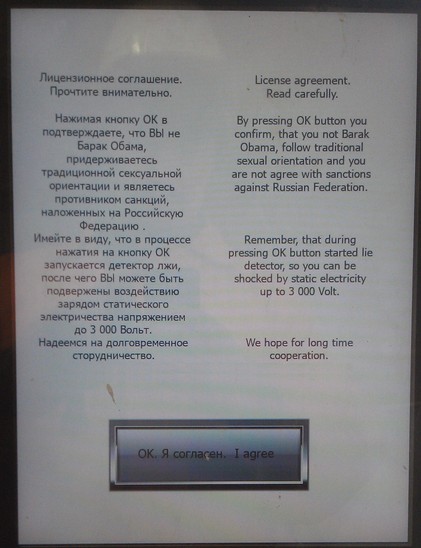

When you turn on the remote on the main (large) panels include this invitation:

What time, such and jokes. This screen saver was repeatedly shown to foreigners. They laugh, but they are afraid to press.

This screen displays the level and volume of water in each ballast compartment as well as the sediment at 6 points.

As level sensors, we used submersible hydrostatic pressure sensors from a well-known Russian “zodiac” manufacturer.

Control of the equipment of each body is carried out from this screen. In general, each panel can control any enclosure.

And this is a small panel - krenodifentorenometr. Shows the inclination of the vessel in relation to the surface of the water. The source of information for him were outboard level sensors. Further, knowing the geometrical dimensions, we calculated the angle of heel and trim.

We built - built and finally built! The time has come for testing and presentation to various supervisory authorities.

We scored some water in the ballast compartments (about a meter) and ... hydrodynamic impacts began! They arose when switching the mode of operation of the pumps, when opening and closing ballast valves. The acoustic impact on our membranes from these impacts was very sensitive.

In my presence with such a blow, a cast-iron inspection hatch with a thickness of about 7 mm was torn out of the pump. From it began to beat a powerful stream of water. I, introducing myself as a submariner and trying to force my eyes back, began to convulsively tighten the outboard valves - the Kingston. We have them on manual control.

The problem of strikes, we decided. It was a set of measures. One of them is the slowdown of the opening-closing cycle. But still, if someone bangs hard with a metal door, something in the stomach is trying to fall below the plinth.

The time has come for a test dive below the deck. As soon as the water filled it, a large free surface of the water in the ballast compartments began to show up. This led to a buildup. At that moment it was not scary, but very unpleasant. What it can lead to: link . This is a different plant and the same unit as ours. Fortunately, at that time no one was hurt. We solved this problem by installing additional floats and the method of filling the compartments.

And now it's time to go!

To do this, the unit is lowered onto the track - the slip. Each half stood on two lanes. On each track put two hydraulic cylinders. Slices thickly smeared.

But in order to go it was necessary to solve the problem of synchronization of hydraulic cylinders. The distance between the cylinders is about 100m. The distance from the hydraulic station to the cylinders is different. The weight of the blocks is different. The force of friction can also change for various reasons. If it is stupid to turn on and go without control, then we are guaranteed to get skewed and offset. You also need to remember that you will not turn on the reverse.

We solved this problem by installing video cameras and rulers over each of the four tracks. The slider operator had to maintain the same values on the rulers of all tracks by turning on and off cylinder groups. The speed was quite comfortable: 1.3 meters (one step) drove in about 15 minutes. After that, they moved the stops, set the rulers and drove on.

Finally, we drove to the edge of the shore. By this time, the catamaran was firmly moored, and its cleft tracks were connected to the tracks on the shore by moving links.

Lyrical digression. Imagine that you want to ride on such a catamaran:

It costs exactly and beautifully. You step on him - and he heels. You change to the middle - and the roll goes. But the sediment has increased. You move to the other end - and he rolls already there.

The same processes should occur in our country. Only the scale is different and the consequences. Our task was to prevent this. To do this, we had to have a certain draft with a supply of water in the ballast compartments. At each step, we had to pump water from one body and pour it into another. At a certain step, on the contrary - fill in the first one and pump it out of the second one. At the same time watching the roll, trim, position in relation to the shore and coordinating all actions with the coastal team that goes to visit us.

Our guys performed the calculations of the amount of water in the compartments for each step. These calculations we used when sliding.

The whole process continued uninterruptedly for 18 hours and ended successfully late at night.

The catamaran's ballast compartments are fully pumped out. He himself was taken to another place. There he stood for another year. All this time, the block continued work. A year later we launched it into the water. But this is the next story.

After moving the catamaran to a new place, we were faced with an unexplained (hopefully so far) phenomenon. As I said above, the angle of heel and trim was calculated based on the readings of the sensors of the outboard level. This system worked perfectly when sliding as well as other level sensors. But after moving to a new place (300 m downstream), all three outboard hull sensors standing farther from the coast (the “core case”) began to show a draft of about 20 cm more! Accordingly, our electronic device began to show roll! But the emergency device (simple construction plummet) did not confirm this! Sensors and all electronics have been re-checked. Found nothing. It has been suggested that this is the work of dark energy - hydrodynamic. Sensors stand in the flat part of the vessel in the bow, middle and stern. They have separate valves welded directly to the bottom. In the new place, the more gentle profile of the river bottom, and this building (the bottom of which is for the most part flat), protrudes stronger into the rod. And, in my opinion, the rate of flow of the river in the area of this building is higher. Maybe this is the case? I have a timid assumption that has not yet been refuted, but I would not like to voice it yet. Maybe someone from the habrovchan can explain this phenomenon?

A quick search on Habra on the topics “offshore platforms and shipbuilding” gives, in the main, all kinds of sealed launches and drowning of data centers. I propose to dilute this topic a little.

Our company (this is a ship repair shipyard) in 2014 won the tender for the construction of the support block of the offshore drilling platform for one oil company. This company operates in two fields in the Caspian ( link 1 , link 2 )

The Caspian Sea in the place of installation of drilling platforms is rather shallow. Therefore, the platforms are installed directly on the seabed and fixed with piles. The support block is the foundation of the platform. After production at the plant, it is towed into place, then water is poured into its ballast compartments and it sinks to the bottom. The next step is to put a ready platform on it.

')

The block is made sections.

About such.

Sections are assembled in workshops, and then served on the assembly slipway, where they are joined. It turns out this:

Our support block was built 60 meters from the shore. For launching it was necessary to solve several problems. Problem number 1: a structure weighing 5,600 tons and about 100 meters long must be moved to the shore. Problem number 2. It is necessary to build a ship, calculated on the fact that these 5600 tons are pushed onto it. This vessel should be able to dive slightly (i.e., operate as a floating dock ).

To solve problem number 2, we bought two Amur-type cargo ships:

They came to our factory under their own power. Everything superfluous was removed from them. And in the end we got such a catamaran.

He is not self-propelled. In each case there are 6 ballast compartments. On the nose tower is located Central Post Office (CPA). At the bottom of the nose of each case is the engine room. Each has two diesel pumps and pneumatically-controlled butterfly valves, forced spring closures and additional manual controls.

Like these ones. Diameter - 250mm.

Pneumatics was chosen because of the ease of energy storage for emergency operation, the ease of switching to manual mode. Of course, it was possible to put valves or valves with electric drive. But in this case, the ship should have a full-time main power plant, and an emergency source of electricity. In this case, all critical equipment is powered by batteries. Everything else is powered from the shore. If necessary, we install a pair of generators on the tower (main and backup). Connecting and switching generators in the process of work itself does not interrupt.

Before installing the vessel, we checked these valves in the workshop. When the pneumatic valve is triggered, the shutter with a slight sound “pshhshsh” smoothly opened for 1.5 seconds. When you turn off the same smoothly and quietly closed. Our locksmith - men, tightening and unscrewing the nuts to 19 inclusive with their bare hands - experienced aesthetic ecstasy and together asked for more ...

6 valves control the flow of water to the ballast compartments. The rest set the operation mode of the pumps - filling or pumping. All of these are commanded by the Control Station.

This is her giblets.

Two Control Stations and a console in the CPU are networked with the “Ring” topology in optics.

And this is our remote.

It is fundamentally made without physical buttons (well, such as "glass cabin"). Mouse on the right - to control the DVR.

When you turn on the remote on the main (large) panels include this invitation:

What time, such and jokes. This screen saver was repeatedly shown to foreigners. They laugh, but they are afraid to press.

This screen displays the level and volume of water in each ballast compartment as well as the sediment at 6 points.

As level sensors, we used submersible hydrostatic pressure sensors from a well-known Russian “zodiac” manufacturer.

Control of the equipment of each body is carried out from this screen. In general, each panel can control any enclosure.

And this is a small panel - krenodifentorenometr. Shows the inclination of the vessel in relation to the surface of the water. The source of information for him were outboard level sensors. Further, knowing the geometrical dimensions, we calculated the angle of heel and trim.

We built - built and finally built! The time has come for testing and presentation to various supervisory authorities.

We scored some water in the ballast compartments (about a meter) and ... hydrodynamic impacts began! They arose when switching the mode of operation of the pumps, when opening and closing ballast valves. The acoustic impact on our membranes from these impacts was very sensitive.

In my presence with such a blow, a cast-iron inspection hatch with a thickness of about 7 mm was torn out of the pump. From it began to beat a powerful stream of water. I, introducing myself as a submariner and trying to force my eyes back, began to convulsively tighten the outboard valves - the Kingston. We have them on manual control.

The problem of strikes, we decided. It was a set of measures. One of them is the slowdown of the opening-closing cycle. But still, if someone bangs hard with a metal door, something in the stomach is trying to fall below the plinth.

The time has come for a test dive below the deck. As soon as the water filled it, a large free surface of the water in the ballast compartments began to show up. This led to a buildup. At that moment it was not scary, but very unpleasant. What it can lead to: link . This is a different plant and the same unit as ours. Fortunately, at that time no one was hurt. We solved this problem by installing additional floats and the method of filling the compartments.

And now it's time to go!

To do this, the unit is lowered onto the track - the slip. Each half stood on two lanes. On each track put two hydraulic cylinders. Slices thickly smeared.

But in order to go it was necessary to solve the problem of synchronization of hydraulic cylinders. The distance between the cylinders is about 100m. The distance from the hydraulic station to the cylinders is different. The weight of the blocks is different. The force of friction can also change for various reasons. If it is stupid to turn on and go without control, then we are guaranteed to get skewed and offset. You also need to remember that you will not turn on the reverse.

We solved this problem by installing video cameras and rulers over each of the four tracks. The slider operator had to maintain the same values on the rulers of all tracks by turning on and off cylinder groups. The speed was quite comfortable: 1.3 meters (one step) drove in about 15 minutes. After that, they moved the stops, set the rulers and drove on.

Finally, we drove to the edge of the shore. By this time, the catamaran was firmly moored, and its cleft tracks were connected to the tracks on the shore by moving links.

Lyrical digression. Imagine that you want to ride on such a catamaran:

It costs exactly and beautifully. You step on him - and he heels. You change to the middle - and the roll goes. But the sediment has increased. You move to the other end - and he rolls already there.

The same processes should occur in our country. Only the scale is different and the consequences. Our task was to prevent this. To do this, we had to have a certain draft with a supply of water in the ballast compartments. At each step, we had to pump water from one body and pour it into another. At a certain step, on the contrary - fill in the first one and pump it out of the second one. At the same time watching the roll, trim, position in relation to the shore and coordinating all actions with the coastal team that goes to visit us.

Our guys performed the calculations of the amount of water in the compartments for each step. These calculations we used when sliding.

The whole process continued uninterruptedly for 18 hours and ended successfully late at night.

The catamaran's ballast compartments are fully pumped out. He himself was taken to another place. There he stood for another year. All this time, the block continued work. A year later we launched it into the water. But this is the next story.

After moving the catamaran to a new place, we were faced with an unexplained (hopefully so far) phenomenon. As I said above, the angle of heel and trim was calculated based on the readings of the sensors of the outboard level. This system worked perfectly when sliding as well as other level sensors. But after moving to a new place (300 m downstream), all three outboard hull sensors standing farther from the coast (the “core case”) began to show a draft of about 20 cm more! Accordingly, our electronic device began to show roll! But the emergency device (simple construction plummet) did not confirm this! Sensors and all electronics have been re-checked. Found nothing. It has been suggested that this is the work of dark energy - hydrodynamic. Sensors stand in the flat part of the vessel in the bow, middle and stern. They have separate valves welded directly to the bottom. In the new place, the more gentle profile of the river bottom, and this building (the bottom of which is for the most part flat), protrudes stronger into the rod. And, in my opinion, the rate of flow of the river in the area of this building is higher. Maybe this is the case? I have a timid assumption that has not yet been refuted, but I would not like to voice it yet. Maybe someone from the habrovchan can explain this phenomenon?

Source: https://habr.com/ru/post/423191/

All Articles