New technological processes for the production of microcircuits are more often postponed - why?

In late August, the manufacturer of semiconductor integrated circuits GlobalFoundries (working with AMD) stopped the development of 7-nanometer process technology. A few months before, Intel announced that it was once again postponing the release of its 10-nanometer chip.

About the reasons for these decisions and the situation in the industry, we tell further.

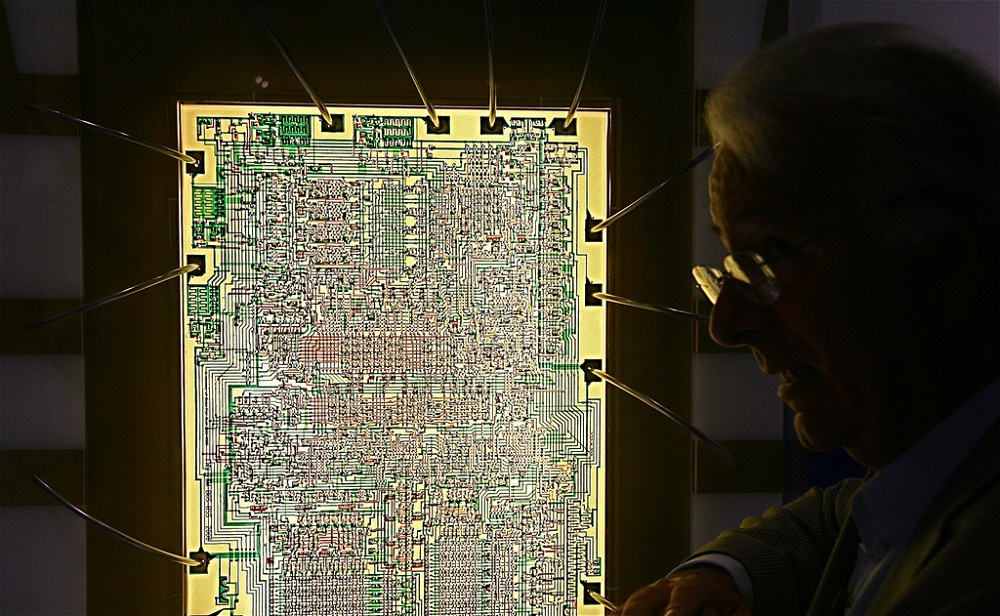

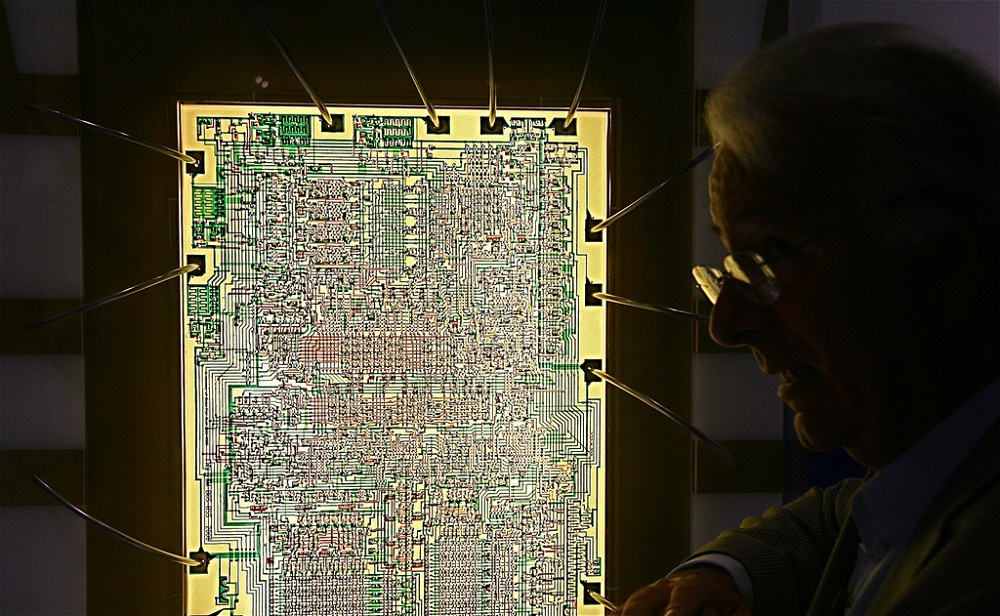

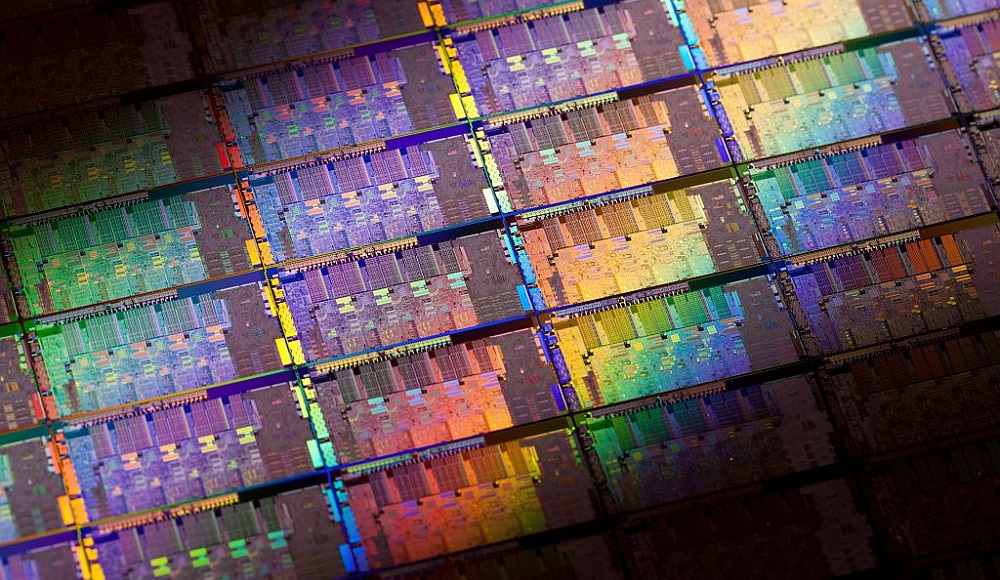

/ photo Intel Free Press CC

')

Individual transistors on a chip are formed by photolithography . In this case, a thin photosensitive polymer film, called a photoresist, is applied to the silicon substrate. Then this photo layer is treated with light (the so-called exposure is produced) through a photo pattern with the necessary pattern. The exposed areas are washed away in the developer, and then the crystals are etched.

Companies reduce manufacturing processes to increase the number of products from a single billet and reduce the energy consumption of the final chip. The manufacturer gets the opportunity to increase the speed of the chip, leaving its size at the same level.

For a long time, this trend (to reduce technical processes) remained fair. But now IT companies have begun to postpone or even stop the development of new technical processes. This is partly due to the increased cost of equipment and a high level of rejects.

More in the situation we understand further.

GlobalFoundries produce silicon wafers in eight factories around the world. The company was supposed to launch a 7-nm chip on the market in the second quarter of 2018. However, a couple of weeks before the proposed release, GlobalFoundries decided to cancel everything.

Instead, the organization will focus on the development of specialized standards for the production of 14LPP (Low-Power Plus) and 12LP (Leading-Performance) and the creation of various internal storage devices .

The 14LPP platform is an advanced version of a 14nm process based on a 3D FinFET transistor. It improves device performance by 55% and reduces their power consumption by 60% (compared to 28 nm). A 12LP is a process for manufacturing semiconductors, sharpened for the needs of AI systems, smartphones and automotive electronics.

According to CTO GlobalFoundries Gary Patton (Gary Patton), the cause of the strategic turn were not technical problems, but financial issues. The company has invested billions of dollars in the development of 7-nanometer chips. The first generation, which uses immersion lithography, was almost complete. But on the second and third (they required deeper UV ranges to increase the density of the transistors), the funds were not enough.

Along with the abolition of 7-nm, GlobalFoundries stopped the development of 5-nanometer and 3-nanometer process technology. Because of the change in course, GlobalFoundries will cut five percent of its employees and renegotiate agreements with AMD and IBM. In particular, the company will work with IBM until the end of the year, and then it will stop researching new technical processes.

Another organization that postponed the release of chips in a new technological process was Intel. The IT giant has been moving the scale release of 10nm circuits for two years now. This time, the start of sales of the first 10-nm products was moved to the end of 2019.

According to company representatives , the reason for the delay is the low yield of suitable processors. It is believed that the problem is related to the technology of multi-patterning and the use of cobalt.

Production volumes are growing more slowly than planned. Technically, Intel is already supplying 10nm microchips in small batches. For example, the first Core i3-8121U - 10-nm processors of the Cannon Lake family - are already working in Lenovo laptops. However, the mass production of chips can not speak.

/ photo Intel Free Press CC

Other market players are also not in a hurry to put the development of new technical processes on stream. At UMC, they have stopped at the 14-nm process technology, while Samsung promises 7-nm, but also not earlier than 2019.

As we have said, the high cost of the transition is one of the reasons why GlobalFoundries has curtailed their projects. And according to Gartner, she is the main one. According to analysts, the cost of developing 7-nm technology is approximately $ 270 million.

Equipment for EUV lithography , nanosheets, exotic materials like ruthenium — all of these things are expensive, but some of them are already difficult to do. To recoup the investment in production, you need to produce 150 million chips per year. Therefore, the implementation of 7-, 5-, 3- and 2-nm processes may be commercially unprofitable.

At the same time, even if the microcircuit is created, the “exhaust” in performance is not always significant. For example, in Qualcomm believe that the 5-nm process does not greatly exceed the 7-nm in performance, and invest in its development will have several billion dollars.

The second reason is the probability of an error and its price. For example, the delay in the supply of 10-nm process technology Intel " flew a pretty penny " to one of the IT giants with a capitalization of $ 20 billion.

HN residents have identified other reasons for slowing progress in the semiconductor industry. For example, one user believes that reducing the size of a crystal has a bad effect on its cooling. Therefore, companies are trying to invest in the development of more energy-efficient technologies, rather than reducing the size of the crystals (this is the path taken by GlobalFoundries).

Representatives of the industry believe that it will still be necessary to reduce technical processes. This will ensure the efficient operation of the AI, MO, 5G networks and IoT systems. According to preliminary calculations by developers from TSMC, the 7-nm process technology will improve performance by 30% and half the power consumption of the processor (compared to 10-nm).

However, David Hemker, senior VP at Lam Research, a semiconductor manufacturing company, stresses that industries will need new solutions to cope with the growing difficulties of manufacturing processes.

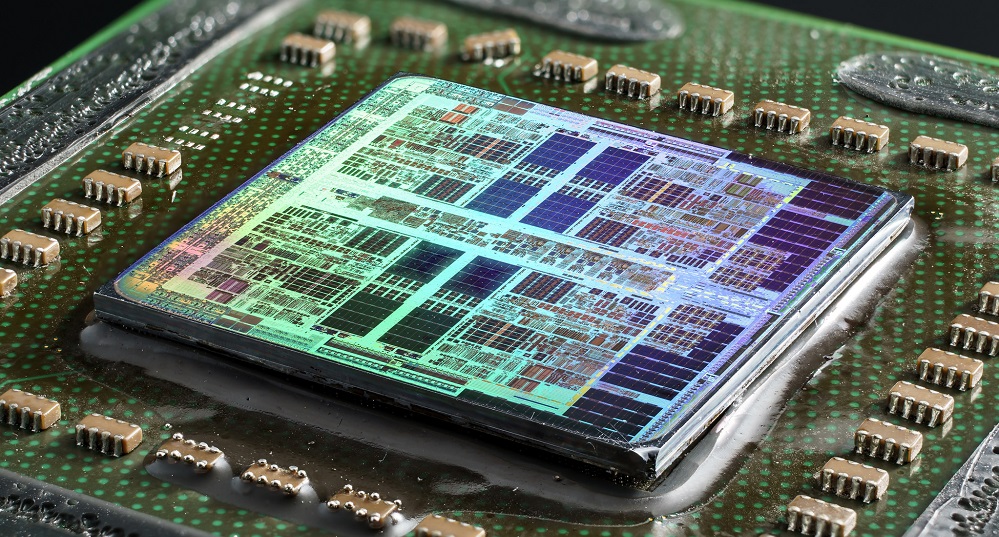

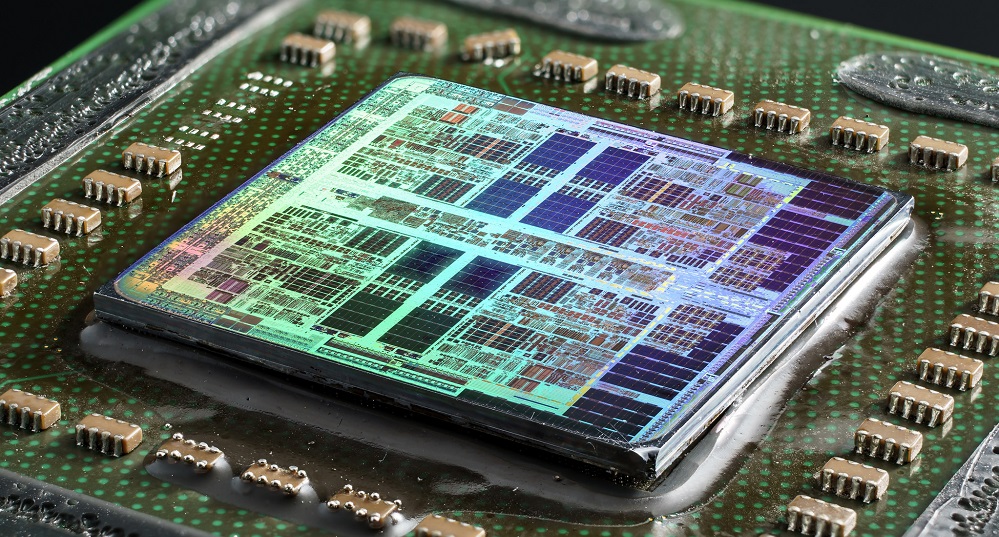

/ photo Fritzchens Fritz PD

So far, EUV lithography has been generating too many defects in chip production . But if you continue to improve the technology, it should reduce the time and cost of developing new technical processes.

Despite all the difficulties of production, some representatives of the industry are already making predictions for processes of less than 5 nm and are talking about the timing of production of such chips. For example, in TSMC - also engaged in the production of semiconductors - are already making plans to develop 3- and 2-nm process technology. And the Imec research center, together with the company Cadence Design Systems, even developed test samples of microprocessors using the 3-nm technology.

Therefore, in the future we will definitely see the use of these technologies, only this moment may come a little later than originally thought.

PS Additional materials from the First Corporate IaaS Blog:

PPS Related articles from our blog on Habré:

What we do in IT-GRAD: • IaaS • PCI DSS hosting • Cloud FZ-152

About the reasons for these decisions and the situation in the industry, we tell further.

/ photo Intel Free Press CC

')

A few words about the technological processes

Individual transistors on a chip are formed by photolithography . In this case, a thin photosensitive polymer film, called a photoresist, is applied to the silicon substrate. Then this photo layer is treated with light (the so-called exposure is produced) through a photo pattern with the necessary pattern. The exposed areas are washed away in the developer, and then the crystals are etched.

Companies reduce manufacturing processes to increase the number of products from a single billet and reduce the energy consumption of the final chip. The manufacturer gets the opportunity to increase the speed of the chip, leaving its size at the same level.

For a long time, this trend (to reduce technical processes) remained fair. But now IT companies have begun to postpone or even stop the development of new technical processes. This is partly due to the increased cost of equipment and a high level of rejects.

More in the situation we understand further.

Why GlobalFoundries canceled 7nm

GlobalFoundries produce silicon wafers in eight factories around the world. The company was supposed to launch a 7-nm chip on the market in the second quarter of 2018. However, a couple of weeks before the proposed release, GlobalFoundries decided to cancel everything.

Instead, the organization will focus on the development of specialized standards for the production of 14LPP (Low-Power Plus) and 12LP (Leading-Performance) and the creation of various internal storage devices .

The 14LPP platform is an advanced version of a 14nm process based on a 3D FinFET transistor. It improves device performance by 55% and reduces their power consumption by 60% (compared to 28 nm). A 12LP is a process for manufacturing semiconductors, sharpened for the needs of AI systems, smartphones and automotive electronics.

According to CTO GlobalFoundries Gary Patton (Gary Patton), the cause of the strategic turn were not technical problems, but financial issues. The company has invested billions of dollars in the development of 7-nanometer chips. The first generation, which uses immersion lithography, was almost complete. But on the second and third (they required deeper UV ranges to increase the density of the transistors), the funds were not enough.

Along with the abolition of 7-nm, GlobalFoundries stopped the development of 5-nanometer and 3-nanometer process technology. Because of the change in course, GlobalFoundries will cut five percent of its employees and renegotiate agreements with AMD and IBM. In particular, the company will work with IBM until the end of the year, and then it will stop researching new technical processes.

Who else postponed development

Another organization that postponed the release of chips in a new technological process was Intel. The IT giant has been moving the scale release of 10nm circuits for two years now. This time, the start of sales of the first 10-nm products was moved to the end of 2019.

According to company representatives , the reason for the delay is the low yield of suitable processors. It is believed that the problem is related to the technology of multi-patterning and the use of cobalt.

Production volumes are growing more slowly than planned. Technically, Intel is already supplying 10nm microchips in small batches. For example, the first Core i3-8121U - 10-nm processors of the Cannon Lake family - are already working in Lenovo laptops. However, the mass production of chips can not speak.

/ photo Intel Free Press CC

Other market players are also not in a hurry to put the development of new technical processes on stream. At UMC, they have stopped at the 14-nm process technology, while Samsung promises 7-nm, but also not earlier than 2019.

Main reasons

As we have said, the high cost of the transition is one of the reasons why GlobalFoundries has curtailed their projects. And according to Gartner, she is the main one. According to analysts, the cost of developing 7-nm technology is approximately $ 270 million.

Equipment for EUV lithography , nanosheets, exotic materials like ruthenium — all of these things are expensive, but some of them are already difficult to do. To recoup the investment in production, you need to produce 150 million chips per year. Therefore, the implementation of 7-, 5-, 3- and 2-nm processes may be commercially unprofitable.

At the same time, even if the microcircuit is created, the “exhaust” in performance is not always significant. For example, in Qualcomm believe that the 5-nm process does not greatly exceed the 7-nm in performance, and invest in its development will have several billion dollars.

The second reason is the probability of an error and its price. For example, the delay in the supply of 10-nm process technology Intel " flew a pretty penny " to one of the IT giants with a capitalization of $ 20 billion.

HN residents have identified other reasons for slowing progress in the semiconductor industry. For example, one user believes that reducing the size of a crystal has a bad effect on its cooling. Therefore, companies are trying to invest in the development of more energy-efficient technologies, rather than reducing the size of the crystals (this is the path taken by GlobalFoundries).

Why updates are still needed

Representatives of the industry believe that it will still be necessary to reduce technical processes. This will ensure the efficient operation of the AI, MO, 5G networks and IoT systems. According to preliminary calculations by developers from TSMC, the 7-nm process technology will improve performance by 30% and half the power consumption of the processor (compared to 10-nm).

However, David Hemker, senior VP at Lam Research, a semiconductor manufacturing company, stresses that industries will need new solutions to cope with the growing difficulties of manufacturing processes.

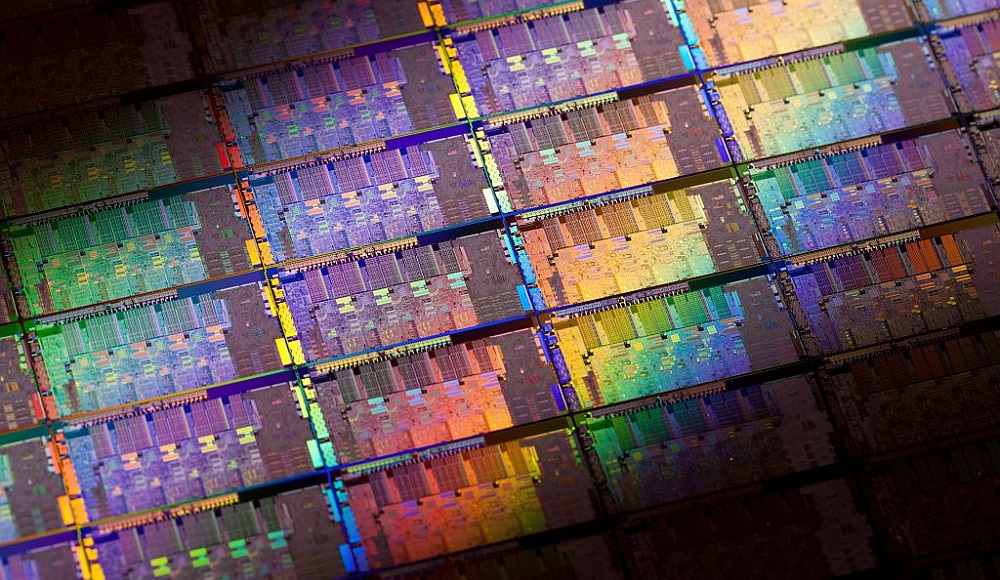

/ photo Fritzchens Fritz PD

So far, EUV lithography has been generating too many defects in chip production . But if you continue to improve the technology, it should reduce the time and cost of developing new technical processes.

Despite all the difficulties of production, some representatives of the industry are already making predictions for processes of less than 5 nm and are talking about the timing of production of such chips. For example, in TSMC - also engaged in the production of semiconductors - are already making plans to develop 3- and 2-nm process technology. And the Imec research center, together with the company Cadence Design Systems, even developed test samples of microprocessors using the 3-nm technology.

Therefore, in the future we will definitely see the use of these technologies, only this moment may come a little later than originally thought.

PS Additional materials from the First Corporate IaaS Blog:

- New functionality in VMware vSphere 6.7

- Examples of using NetApp storage systems in various business areas

- Testing a disk system in the cloud

PPS Related articles from our blog on Habré:

- The Japanese introduced a prototype processor for an ex-flop supercomputer

- IBM introduced the world's first 5-nanometer chip

- Why computer chips become faster to "grow old" and what to do about it

What we do in IT-GRAD: • IaaS • PCI DSS hosting • Cloud FZ-152

Source: https://habr.com/ru/post/422501/

All Articles