The use of ACS in mining

Judging by the growth rate of network complexity, a huge amount of mining equipment is put into operation every day. The rates are high and companies operating mining equipment on an industrial scale do not have time to design full-fledged data centers at the proper level of security and automation.

Successful launches and operating experience of the equipment in the first days or even months gives rise to confidence in the reliability of the equipment. And customers who place equipment in mining hotels are sure that their hardware is in safe hands. Let's consider what is it, mining hotel of the 21st century?

ACS means "Automated Control System". Such a system can control both production processes, and automatic parking, and a gas boiler, and will also be useful in mining.

At the dawn of industrial development, a specialist stood next to each equipment, who managed it and monitored the health of its work. So, the elevators drove the elevator, the doormen opened the doors, and the aircraft were flight engineers.

')

Today, the mining situation is reminiscent of the last century. In mining hotels, electrical machines are used for electrical protection and it is believed that this level of protection is sufficient. Turning miners on and off is performed by service personnel, in a simple way - by pulling the plug out of the socket. The ventilation system is often automated and stabilizes the temperature in the room, which is quite enough. The most difficult situation with the fire extinguishing system. Most often, mining equipment is located in a large area of industrial premises and with high ceilings. With this approach, gas fire extinguishing systems are expensive to use, and powder systems are ineffective. For this reason, most of the mining of hotels fire extinguishing system is not provided.

Now let's imagine how a modern mining hotel of the 21st century should look like. The first thing I would like to do to improve efficiency and safety is to eliminate the human factor and use the ACS to control the entire system. Elements of the ACS are an automation cabinet, actuators, sensors and a controller. In the cabinet itself there are many blocks: PLC (Programmable Logic Controller), expansion modules of various interfaces, electrical machines, power buses, signal converters from sensors, signal converters for actuators, frequency converters and so on. The front panel of the cabinet is usually equipped with controls - buttons, switches and operating mode indicators.

The logic controller is a very reliable device. In general, the word reliability is the second name of the ACS. Imagine what would happen if the elevator suddenly decides to open the door while driving, and the plane pulls out the landing gear. That is why the safety and uninterrupted operation of the ACS is always given maximum attention.

From the ACS cabinet there is a lot of wires to the sensors and actuators. For example, in ventilation systems, one can find temperature sensors, flow rates, pressures and actuators - actuators controlling the valves.

An important element of the ACS is the PLC program. It determines the behavior of the system in various situations, controls the actuators, and processes data from external sensors.

Often, a human operator still monitors large and expensive installations. The operator sits at the console ARM (Workstation). On the screen of the monitors of such a console, the parameters of the entire system are visible. The graphic mimic reliably displays a wealth of data, and one glance at the screen is enough to understand what is happening with the equipment now. All data and controls are combined in one place, a kind of remote control of a small universe.

If you compare the ACS system with an employee who could monitor and control the system manually, you can reveal a number of obvious advantages. The ACS works 24 hours a day, does not get tired, does not come out to smoke, does not sit on social networks, does not get distracted by phone calls and does not make mistakes. And the processes performed are predictable and repeatable. Also, we must not forget that a person cannot react to the situation with the necessary speed. For example, it is difficult to imagine that it is possible to press a special button in the car to make the airbags, when necessary. Electronics does it reliably, at a given speed and only when it is really necessary; in that fraction of a second when it is safe and efficient.

For industrial mining, well-coordinated operation of all systems is necessary: ventilation and electricity distribution systems, fire extinguishing systems, local area networks, security systems, access control systems, plus reliable access to the Internet with a backup communication channel is necessary. All these systems need to be managed efficiently and in real time.

Mining is a complex process, the equipment for the extraction of cryptocurrencies is very expensive, and any downtime leads to substantial financial losses. Service and frequent repairs, again, cause a series of new downtime and lead to large losses. Also known cases of fires on mining farms with losses of millions of dollars. All these factors indicate that the industrial operation of mining equipment is a responsible and complex process and cannot be left without automation!

There are two main types of objects for industrial mining: the mining hotel and the mobile container. In the first case, the mining equipment is located on racks inside the building. As a rule, in such buildings there is a lot of free space, high ceilings, a lot of space for the placement of ventilation and electrical distribution equipment. But, from our point of view, there is one significant drawback - the stationarity of such objects. In the second case, the equipment is located inside the mobile container. There is much less space here, equipment placement is denser, ceilings are lower. The metal walls of the container have poor thermal insulation: in winter, during maintenance, the switched off container freezes through, in summer it gets very hot in the sun. In the building where mining farms are located, there usually sits a specialist who is engaged in setting parameters and monitoring equipment operation, maintaining and repairing the system. Next to the container, such a specialist cannot be, and, as a rule, he comes only when necessary for service, and in the main period of time he is at the console of the AWP.

There are two main types of objects for industrial mining: the mining hotel and the mobile container. In the first case, the mining equipment is located on racks inside the building. As a rule, in such buildings there is a lot of free space, high ceilings, a lot of space for the placement of ventilation and electrical distribution equipment. But, from our point of view, there is one significant drawback - the stationarity of such objects. In the second case, the equipment is located inside the mobile container. There is much less space here, equipment placement is denser, ceilings are lower. The metal walls of the container have poor thermal insulation: in winter, during maintenance, the switched off container freezes through, in summer it gets very hot in the sun. In the building where mining farms are located, there usually sits a specialist who is engaged in setting parameters and monitoring equipment operation, maintaining and repairing the system. Next to the container, such a specialist cannot be, and, as a rule, he comes only when necessary for service, and in the main period of time he is at the console of the AWP.

Now the market has a lot of solutions in the form of containers for industrial mining. They differ not only in their design and principle of operation of the cooling system, but also in ACS systems. Most often, inside such containers there is an electrical distribution cabinet consisting of an input automat and an electricity metering unit. From the cabinet a lot of power cables are drawn to the sockets for miners located on the shelves. Many, but not all solutions, use separate machines for each outlet. From the point of view of the rules of operation of electrical installations, individual machines for each miner are simply necessary, but manufacturers often neglect this simple rule. For example, the popular ASIC Antminer S9 consumes about 1300 W and the lack of a simple automaton in the event of a PSU malfunction can cause a fire. Thus, to increase security, the use of individual machines is necessary.

Also in the container is network switching equipment providing access to the Internet. As for the ventilation system - everything is much more interesting and more complicated. The most common cooling used for cooling. Inside the container it is necessary to maintain a constant and comfortable for mining equipment temperature of 30-40 ° C, and this can be done by adjusting the engine speed of the air handling unit. As a rule, specialized frequency converters for ventilation installations are used. And in general, the whole complex of equipment looks logical and efficient. Manufacturers assure that the container is efficient, safe and fully operational.

Let's consider the following situation. The container worked in the winter for several days, after which there was a technological blackout for 2 hours. And on the street there is a temperature of –30 ° C. During these 2 hours the container freezes through, all the electronics, respectively, cool down to the same –30 ° C and two hours later the power is supplied to the container ... By the way, this is a fairly typical situation in harsh winter conditions. In the majority of containers on the market there is no start-up cyclogram, where the system with the ACS must ensure that the temperature inside the container does not correspond to the operating temperature of the electronics, and start pre-heating. And only after reaching a positive temperature, start the launch of electronics. At high negative temperatures, most consumer electronics, such as motherboards, processors and memory will not work. There is also a risk of damage to the mining equipment.

Let's consider the following situation. The container worked in the winter for several days, after which there was a technological blackout for 2 hours. And on the street there is a temperature of –30 ° C. During these 2 hours the container freezes through, all the electronics, respectively, cool down to the same –30 ° C and two hours later the power is supplied to the container ... By the way, this is a fairly typical situation in harsh winter conditions. In the majority of containers on the market there is no start-up cyclogram, where the system with the ACS must ensure that the temperature inside the container does not correspond to the operating temperature of the electronics, and start pre-heating. And only after reaching a positive temperature, start the launch of electronics. At high negative temperatures, most consumer electronics, such as motherboards, processors and memory will not work. There is also a risk of damage to the mining equipment.

Another significant problem is the simultaneous connection of a large number of power supplies to the power grid. For example, on power supplies without a soft start system, the starting current is about 100 amperes, and 10 power supplies will already give 1 kA! Imagine now that you have 10 containers, each of which contains 100 power supplies. When simultaneously started, the starting current will have an unacceptable value and may damage the electrical distribution equipment. To avoid this, the ACS must turn on the computing blocks sequentially, in accordance with the launch sequence diagram.

Note. There are two types of power supplies: with soft start and without. In the first case, the rectifier capacitances are charged through a thermistor with a small current, which reduces the current pulse when connected to the mains, but it remains quite high. In the second case, at the moment of switching on the capacity, they are charged with the maximum current, which leads to the problems described above, even if several power supply units are connected. Most often, no one takes these factors into account.

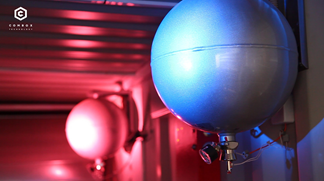

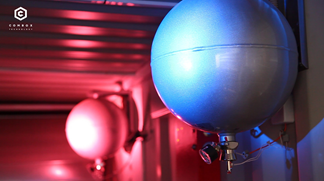

Another situation. If a fire extinguishing system is installed in the container (and many manufacturers are saving on it for some reason), then it can only work for two reasons: excessive temperature or the presence of smoke. There are solutions with the use of thermal imagers, but they have a number of limitations. The air handling unit supplies approximately 50,000 m3 of air per hour. With such a stream, the presence of even a strong source of ignition does not warm the air, and the smoke will blow out even before it reaches the sensor located under the ceiling.

Another situation. If a fire extinguishing system is installed in the container (and many manufacturers are saving on it for some reason), then it can only work for two reasons: excessive temperature or the presence of smoke. There are solutions with the use of thermal imagers, but they have a number of limitations. The air handling unit supplies approximately 50,000 m3 of air per hour. With such a stream, the presence of even a strong source of ignition does not warm the air, and the smoke will blow out even before it reaches the sensor located under the ceiling.

It turns out that the definition of ignition by standard methods in this case is impossible, and, therefore, timely extinguishing the fire is impracticable. Also, before extinguishing the fire, it will be necessary to shut off the inlet installation completely, de-energize all current consumers and, in case of using gas extinguishing systems, ensure the tightness of the container by lowering the dampers. Such an algorithm works in containers without automated control systems is simply impossible. Also, if triggered, the use of powder fire extinguishing systems will cause great damage to electronics, and the restoration of the performance of such an object will be delayed for a long time.

Consider another example. Under certain climatic conditions, a dew point occurs in the room. Inside the container, even after a slight downtime associated with technological shutdown or maintenance, moisture can accumulate, and when the temperature drops, it may manifest as dew on the surface of the miner boards. Running in such a situation threatens to damage the electronics. The ACS system should monitor the start conditions of the electronics, and prevent starting up when critical humidity occurs, in order to save expensive equipment from damage.

More frequent situations - equipment hang. If this happens to a video card miner, then a hangup will require restarting the system. To solve this problem, simple watchdog timers are usually used that are connected at one end to the USB connector of the motherboard and the other to the Reset button. However, if a video card cooler fails, it will be necessary to turn off the miner as soon as possible. If a person is sitting next to him and controls the process of mining - he will certainly be able to do this with the help of a power supply switch. But up to this point, the video card will work in overheating mode, which can damage the processor. Remote management of the power supply of each miner is absent in almost all containers on the market. At first glance, this is not significant, however, in practice, various problems in the operation of the equipment remain quite frequent and require immediate disconnection of the power supply in order to prevent damage.

For correct and long-term operation of the object, careful interaction of all systems is required. It is also necessary to install a sufficient set of actuators so that the ACS can fully control the object. It is difficult to predict all possible situations, as a rule they are not at all obvious, therefore they sometimes seem impossible and fantastic. However, the statistics of equipment repair and fires at such facilities suggests the opposite.

For correct and long-term operation of the object, careful interaction of all systems is required. It is also necessary to install a sufficient set of actuators so that the ACS can fully control the object. It is difficult to predict all possible situations, as a rule they are not at all obvious, therefore they sometimes seem impossible and fantastic. However, the statistics of equipment repair and fires at such facilities suggests the opposite.

The correct operation of the equipment is possible only if there are well-designed cyclograms programmed into the PLC. These cyclograms should provide automatic transition from one mode to another. For example, after the power supply, it would be logical to check the voltage levels of the power grid, check the temperature and humidity inside the container and, if necessary, turn on the heating with heat guns. And until all parameters come back to normal, it is inadmissible to apply power to the mining equipment.

The inclusion of miners should be carried out in stages, alternately applying power to each miner. At the same time, it is necessary to ensure the operation of the air handling unit in the required mode. The fact is that in winter the air temperature sometimes drops to –40 ... –30 ° . It is impossible to blow equipment that is just beginning to mine with such cold air. It is necessary to maintain a balance between the heating of the air by the miners inside the container and the influx of cold air.

Also, the ACS system should interact with the fire extinguishing system and, if necessary, immediately turn off the intake ventilation, removing power from all equipment and closing the valves.

For accurate operation of all modes and error-free transitions from mode to mode upon request of the operator or upon the occurrence of certain readings from the sensors, an appropriate cyclogram should be compiled. It is important to foresee all possible situations in which a container with equipment may be located and to ensure the correct transition from one state to another. Only when all the situations are described, the logic of the container operation has been worked out and all the tests have been performed, it can be said that the object will function properly in all possible situations and the human factor will not affect the timeliness of actions taken. Since all systems regularly exchange data with each other, any one of them will be immediately detected. For example, if the engine of the air handling unit fails, it will be possible to find out about this even before the equipment overheats in the container, since the automated control system will automatically respond.

As for the cost of such ACS systems, their price is relatively low - at least in comparison with the cost of all miners and their possible repairs. And with the right approach to the design of the ACS, the control system will not only respond to events that have already occurred, but also predict possible equipment failures, comparing the readings of various sensors with the information already accumulated. Thus, the cost of operating equipment will be significantly reduced, and the management of such an object will be truly remote and effective.

Successful launches and operating experience of the equipment in the first days or even months gives rise to confidence in the reliability of the equipment. And customers who place equipment in mining hotels are sure that their hardware is in safe hands. Let's consider what is it, mining hotel of the 21st century?

ACS in Mining

ACS means "Automated Control System". Such a system can control both production processes, and automatic parking, and a gas boiler, and will also be useful in mining.

At the dawn of industrial development, a specialist stood next to each equipment, who managed it and monitored the health of its work. So, the elevators drove the elevator, the doormen opened the doors, and the aircraft were flight engineers.

')

Today, the mining situation is reminiscent of the last century. In mining hotels, electrical machines are used for electrical protection and it is believed that this level of protection is sufficient. Turning miners on and off is performed by service personnel, in a simple way - by pulling the plug out of the socket. The ventilation system is often automated and stabilizes the temperature in the room, which is quite enough. The most difficult situation with the fire extinguishing system. Most often, mining equipment is located in a large area of industrial premises and with high ceilings. With this approach, gas fire extinguishing systems are expensive to use, and powder systems are ineffective. For this reason, most of the mining of hotels fire extinguishing system is not provided.

Now let's imagine how a modern mining hotel of the 21st century should look like. The first thing I would like to do to improve efficiency and safety is to eliminate the human factor and use the ACS to control the entire system. Elements of the ACS are an automation cabinet, actuators, sensors and a controller. In the cabinet itself there are many blocks: PLC (Programmable Logic Controller), expansion modules of various interfaces, electrical machines, power buses, signal converters from sensors, signal converters for actuators, frequency converters and so on. The front panel of the cabinet is usually equipped with controls - buttons, switches and operating mode indicators.

The logic controller is a very reliable device. In general, the word reliability is the second name of the ACS. Imagine what would happen if the elevator suddenly decides to open the door while driving, and the plane pulls out the landing gear. That is why the safety and uninterrupted operation of the ACS is always given maximum attention.

From the ACS cabinet there is a lot of wires to the sensors and actuators. For example, in ventilation systems, one can find temperature sensors, flow rates, pressures and actuators - actuators controlling the valves.

An important element of the ACS is the PLC program. It determines the behavior of the system in various situations, controls the actuators, and processes data from external sensors.

ACS or operator?

Often, a human operator still monitors large and expensive installations. The operator sits at the console ARM (Workstation). On the screen of the monitors of such a console, the parameters of the entire system are visible. The graphic mimic reliably displays a wealth of data, and one glance at the screen is enough to understand what is happening with the equipment now. All data and controls are combined in one place, a kind of remote control of a small universe.

If you compare the ACS system with an employee who could monitor and control the system manually, you can reveal a number of obvious advantages. The ACS works 24 hours a day, does not get tired, does not come out to smoke, does not sit on social networks, does not get distracted by phone calls and does not make mistakes. And the processes performed are predictable and repeatable. Also, we must not forget that a person cannot react to the situation with the necessary speed. For example, it is difficult to imagine that it is possible to press a special button in the car to make the airbags, when necessary. Electronics does it reliably, at a given speed and only when it is really necessary; in that fraction of a second when it is safe and efficient.

For industrial mining, well-coordinated operation of all systems is necessary: ventilation and electricity distribution systems, fire extinguishing systems, local area networks, security systems, access control systems, plus reliable access to the Internet with a backup communication channel is necessary. All these systems need to be managed efficiently and in real time.

Mining is a complex process, the equipment for the extraction of cryptocurrencies is very expensive, and any downtime leads to substantial financial losses. Service and frequent repairs, again, cause a series of new downtime and lead to large losses. Also known cases of fires on mining farms with losses of millions of dollars. All these factors indicate that the industrial operation of mining equipment is a responsible and complex process and cannot be left without automation!

Objects for industrial mining

There are two main types of objects for industrial mining: the mining hotel and the mobile container. In the first case, the mining equipment is located on racks inside the building. As a rule, in such buildings there is a lot of free space, high ceilings, a lot of space for the placement of ventilation and electrical distribution equipment. But, from our point of view, there is one significant drawback - the stationarity of such objects. In the second case, the equipment is located inside the mobile container. There is much less space here, equipment placement is denser, ceilings are lower. The metal walls of the container have poor thermal insulation: in winter, during maintenance, the switched off container freezes through, in summer it gets very hot in the sun. In the building where mining farms are located, there usually sits a specialist who is engaged in setting parameters and monitoring equipment operation, maintaining and repairing the system. Next to the container, such a specialist cannot be, and, as a rule, he comes only when necessary for service, and in the main period of time he is at the console of the AWP.

There are two main types of objects for industrial mining: the mining hotel and the mobile container. In the first case, the mining equipment is located on racks inside the building. As a rule, in such buildings there is a lot of free space, high ceilings, a lot of space for the placement of ventilation and electrical distribution equipment. But, from our point of view, there is one significant drawback - the stationarity of such objects. In the second case, the equipment is located inside the mobile container. There is much less space here, equipment placement is denser, ceilings are lower. The metal walls of the container have poor thermal insulation: in winter, during maintenance, the switched off container freezes through, in summer it gets very hot in the sun. In the building where mining farms are located, there usually sits a specialist who is engaged in setting parameters and monitoring equipment operation, maintaining and repairing the system. Next to the container, such a specialist cannot be, and, as a rule, he comes only when necessary for service, and in the main period of time he is at the console of the AWP.ACS for mining container

Now the market has a lot of solutions in the form of containers for industrial mining. They differ not only in their design and principle of operation of the cooling system, but also in ACS systems. Most often, inside such containers there is an electrical distribution cabinet consisting of an input automat and an electricity metering unit. From the cabinet a lot of power cables are drawn to the sockets for miners located on the shelves. Many, but not all solutions, use separate machines for each outlet. From the point of view of the rules of operation of electrical installations, individual machines for each miner are simply necessary, but manufacturers often neglect this simple rule. For example, the popular ASIC Antminer S9 consumes about 1300 W and the lack of a simple automaton in the event of a PSU malfunction can cause a fire. Thus, to increase security, the use of individual machines is necessary.

Also in the container is network switching equipment providing access to the Internet. As for the ventilation system - everything is much more interesting and more complicated. The most common cooling used for cooling. Inside the container it is necessary to maintain a constant and comfortable for mining equipment temperature of 30-40 ° C, and this can be done by adjusting the engine speed of the air handling unit. As a rule, specialized frequency converters for ventilation installations are used. And in general, the whole complex of equipment looks logical and efficient. Manufacturers assure that the container is efficient, safe and fully operational.

Our experience of force majeure situations in mining

Let's consider the following situation. The container worked in the winter for several days, after which there was a technological blackout for 2 hours. And on the street there is a temperature of –30 ° C. During these 2 hours the container freezes through, all the electronics, respectively, cool down to the same –30 ° C and two hours later the power is supplied to the container ... By the way, this is a fairly typical situation in harsh winter conditions. In the majority of containers on the market there is no start-up cyclogram, where the system with the ACS must ensure that the temperature inside the container does not correspond to the operating temperature of the electronics, and start pre-heating. And only after reaching a positive temperature, start the launch of electronics. At high negative temperatures, most consumer electronics, such as motherboards, processors and memory will not work. There is also a risk of damage to the mining equipment.

Let's consider the following situation. The container worked in the winter for several days, after which there was a technological blackout for 2 hours. And on the street there is a temperature of –30 ° C. During these 2 hours the container freezes through, all the electronics, respectively, cool down to the same –30 ° C and two hours later the power is supplied to the container ... By the way, this is a fairly typical situation in harsh winter conditions. In the majority of containers on the market there is no start-up cyclogram, where the system with the ACS must ensure that the temperature inside the container does not correspond to the operating temperature of the electronics, and start pre-heating. And only after reaching a positive temperature, start the launch of electronics. At high negative temperatures, most consumer electronics, such as motherboards, processors and memory will not work. There is also a risk of damage to the mining equipment.Another significant problem is the simultaneous connection of a large number of power supplies to the power grid. For example, on power supplies without a soft start system, the starting current is about 100 amperes, and 10 power supplies will already give 1 kA! Imagine now that you have 10 containers, each of which contains 100 power supplies. When simultaneously started, the starting current will have an unacceptable value and may damage the electrical distribution equipment. To avoid this, the ACS must turn on the computing blocks sequentially, in accordance with the launch sequence diagram.

Note. There are two types of power supplies: with soft start and without. In the first case, the rectifier capacitances are charged through a thermistor with a small current, which reduces the current pulse when connected to the mains, but it remains quite high. In the second case, at the moment of switching on the capacity, they are charged with the maximum current, which leads to the problems described above, even if several power supply units are connected. Most often, no one takes these factors into account.

What if we burn?

Another situation. If a fire extinguishing system is installed in the container (and many manufacturers are saving on it for some reason), then it can only work for two reasons: excessive temperature or the presence of smoke. There are solutions with the use of thermal imagers, but they have a number of limitations. The air handling unit supplies approximately 50,000 m3 of air per hour. With such a stream, the presence of even a strong source of ignition does not warm the air, and the smoke will blow out even before it reaches the sensor located under the ceiling.

Another situation. If a fire extinguishing system is installed in the container (and many manufacturers are saving on it for some reason), then it can only work for two reasons: excessive temperature or the presence of smoke. There are solutions with the use of thermal imagers, but they have a number of limitations. The air handling unit supplies approximately 50,000 m3 of air per hour. With such a stream, the presence of even a strong source of ignition does not warm the air, and the smoke will blow out even before it reaches the sensor located under the ceiling.It turns out that the definition of ignition by standard methods in this case is impossible, and, therefore, timely extinguishing the fire is impracticable. Also, before extinguishing the fire, it will be necessary to shut off the inlet installation completely, de-energize all current consumers and, in case of using gas extinguishing systems, ensure the tightness of the container by lowering the dampers. Such an algorithm works in containers without automated control systems is simply impossible. Also, if triggered, the use of powder fire extinguishing systems will cause great damage to electronics, and the restoration of the performance of such an object will be delayed for a long time.

Consider another example. Under certain climatic conditions, a dew point occurs in the room. Inside the container, even after a slight downtime associated with technological shutdown or maintenance, moisture can accumulate, and when the temperature drops, it may manifest as dew on the surface of the miner boards. Running in such a situation threatens to damage the electronics. The ACS system should monitor the start conditions of the electronics, and prevent starting up when critical humidity occurs, in order to save expensive equipment from damage.

More frequent situations - equipment hang. If this happens to a video card miner, then a hangup will require restarting the system. To solve this problem, simple watchdog timers are usually used that are connected at one end to the USB connector of the motherboard and the other to the Reset button. However, if a video card cooler fails, it will be necessary to turn off the miner as soon as possible. If a person is sitting next to him and controls the process of mining - he will certainly be able to do this with the help of a power supply switch. But up to this point, the video card will work in overheating mode, which can damage the processor. Remote management of the power supply of each miner is absent in almost all containers on the market. At first glance, this is not significant, however, in practice, various problems in the operation of the equipment remain quite frequent and require immediate disconnection of the power supply in order to prevent damage.

Fundamentals of effective work of ACS in mining

For correct and long-term operation of the object, careful interaction of all systems is required. It is also necessary to install a sufficient set of actuators so that the ACS can fully control the object. It is difficult to predict all possible situations, as a rule they are not at all obvious, therefore they sometimes seem impossible and fantastic. However, the statistics of equipment repair and fires at such facilities suggests the opposite.

For correct and long-term operation of the object, careful interaction of all systems is required. It is also necessary to install a sufficient set of actuators so that the ACS can fully control the object. It is difficult to predict all possible situations, as a rule they are not at all obvious, therefore they sometimes seem impossible and fantastic. However, the statistics of equipment repair and fires at such facilities suggests the opposite.The correct operation of the equipment is possible only if there are well-designed cyclograms programmed into the PLC. These cyclograms should provide automatic transition from one mode to another. For example, after the power supply, it would be logical to check the voltage levels of the power grid, check the temperature and humidity inside the container and, if necessary, turn on the heating with heat guns. And until all parameters come back to normal, it is inadmissible to apply power to the mining equipment.

The inclusion of miners should be carried out in stages, alternately applying power to each miner. At the same time, it is necessary to ensure the operation of the air handling unit in the required mode. The fact is that in winter the air temperature sometimes drops to –40 ... –30 ° . It is impossible to blow equipment that is just beginning to mine with such cold air. It is necessary to maintain a balance between the heating of the air by the miners inside the container and the influx of cold air.

Also, the ACS system should interact with the fire extinguishing system and, if necessary, immediately turn off the intake ventilation, removing power from all equipment and closing the valves.

For accurate operation of all modes and error-free transitions from mode to mode upon request of the operator or upon the occurrence of certain readings from the sensors, an appropriate cyclogram should be compiled. It is important to foresee all possible situations in which a container with equipment may be located and to ensure the correct transition from one state to another. Only when all the situations are described, the logic of the container operation has been worked out and all the tests have been performed, it can be said that the object will function properly in all possible situations and the human factor will not affect the timeliness of actions taken. Since all systems regularly exchange data with each other, any one of them will be immediately detected. For example, if the engine of the air handling unit fails, it will be possible to find out about this even before the equipment overheats in the container, since the automated control system will automatically respond.

As for the cost of such ACS systems, their price is relatively low - at least in comparison with the cost of all miners and their possible repairs. And with the right approach to the design of the ACS, the control system will not only respond to events that have already occurred, but also predict possible equipment failures, comparing the readings of various sensors with the information already accumulated. Thus, the cost of operating equipment will be significantly reduced, and the management of such an object will be truly remote and effective.

Source: https://habr.com/ru/post/422195/

All Articles