An ode to “foamed” nickel, non-existent sapphires and the Soviet deputy minister: the iconic OTTO SX-P1 in Japan, the USA and the USSR

One of the most desirable acoustic systems for lovers of sound archaics, one of those that were mass produced in the second half of the 20th century, is the OTTO SX-P1 (they are also Fisher STE-1200). We can say that there is a whole cult of this acoustics, and its advantages are recognized by both hardened techies and pretentious audiophiles. It is often written that in 2000, these columns were in the TOP-20 of the best speakers of all times and according to the version of Stereophile (I could not find the issue of the magazine, but I suppose that is quite possible).

These three-lane studio monitors, created by the Japanese company SANYO in 1976, contrary to the calculations of marketers, became widespread as home acoustics. During sales, they won the reputation of one of the most “honest” acoustic systems, and the overwhelming majority of those who heard the system noted the so-called. “Presence effect”, “realistic sound”, as well as accurate localization of apparent sound sources in a wide and deep stereo panorama. Not without fairy tales - this acoustics has become one of the most mythologized audio components in history. Under the cat in detail about the OTTO SX-P1, the history of its creation, myths, reality and the Soviet copy.

To begin with, let me allow myself a couple of mythological paragraphs, in which I will gather all the legends and tales about this acoustics periodically appearing in the media.

In distant Japan, SANYO engineers decided to create the world's best serial three-way speakers. Thus, in 1976, the OTTO SX-P1 was born, with ultra-low distortion a thousand times lower than the threshold of human perception.

')

It was possible to achieve unique technical characteristics thanks to metal foamed under the influence of high temperatures, sapphire coating of midrange speakers and the use of lasers to create cuts in the RF head. Supermegaunic technologies of the past cannot be repeated, and for this reason today they do not produce analogues of unique acoustics. After 10 years in the USSR, they tried to repeat the Japanese miracle and made a terrible, incapable of Frankenstein.

I got some of the myths from this article , this video , as well as from numerous audioforums where they (myths) have been walking not for years, but for decades.

The video, by the way, is quite suitable for itself, but we could not manage without some common misconceptions and excessive pathos.

I guess with enough myths. The reality differs significantly from them. General with reality in the legend is only the year of the start of the serial release of 1976 and the fact that this speaker really sounded with low distortion (but, naturally, not less than 1000 times the threshold of human perception).

In reality, the development of a new AU began in order to consolidate a new segment of the Western market for SANYO, namely the studio equipment segment. If in Japan they were known as a reliable manufacturer, then, for export to the United States, until 1975, the company produced mostly low-priced consumer goods. Nobody set the task to create the best speaker in the world, everything was more pragmatic and trivial.

The speaker system was originally designed for studios that in the States almost everywhere used the products of JBL and other “domestic” American manufacturers. It was for the sake of a conservative and fastidious studio market that practical Japanese decided to create something extremely competitive. In the domestic market, they also competed mainly with YAMAHA (in the professional segment) and Technics (in the home audio segment).

Interestingly, despite the product, which is quite innovative for its time, the Americans at first did not hurry to buy it. The reputation of SANYO as a widely used office that is not capable of making devices for pros has made itself felt. To eliminate the prejudice went to the unthinkable for a proud Japanese company - co-branding with Fisher. After the OTTO export was renamed Fisher STE-1200, the sales went much livelier. Later, the sly Japanese bought Fisher with giblets.

The story about the technologies begin with the LF cone. It is not made of “some kind of foamed metal” (I have never met such a term anywhere, except for tales about this acoustics). In fact, the material LF-diffuser - composite, consisting of bulk-porous nickel and aluminum foil.

Such a material was chosen in order to combine the high rigidity of the diffuser, which allowed the dynamics to work in a piston mode and qualitatively new sound absorption characteristics in order to provide the damping of reflected waves. Technology has put an end to the question of a compromise between damping and impulse response, solving both problems at once.

I also find it interesting how we managed to obtain porous nickel. The technology was as follows:

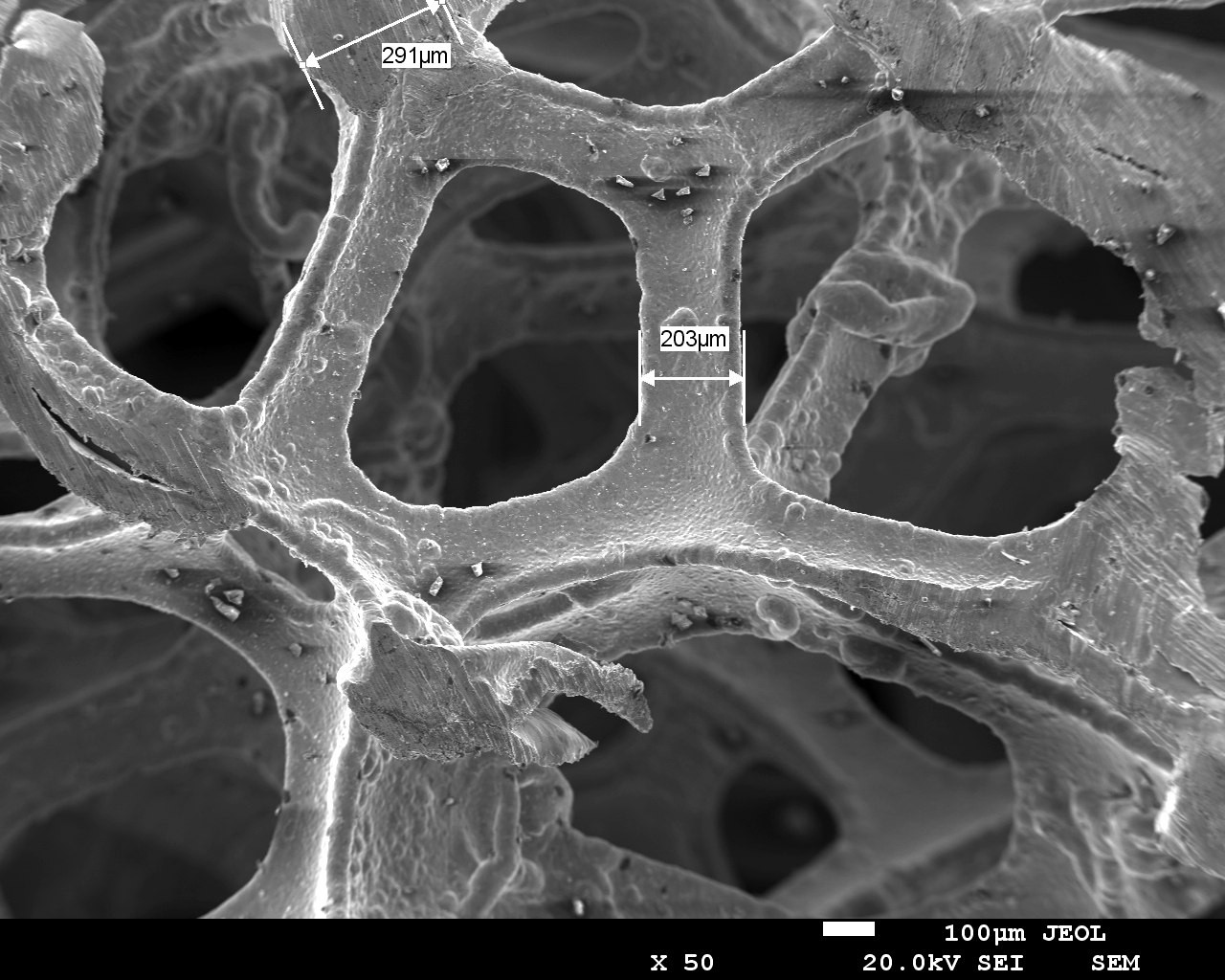

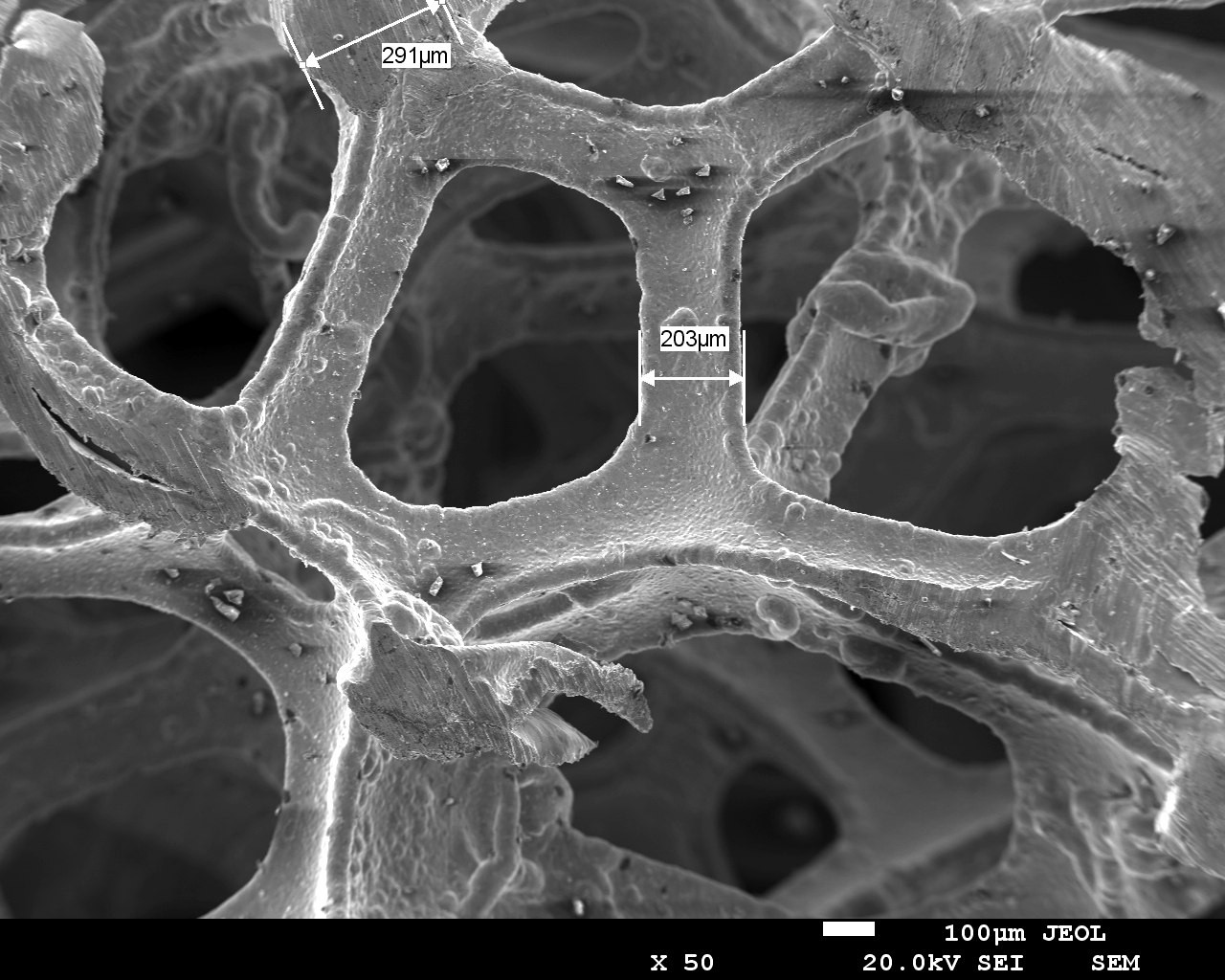

the structure of the treated foam is almost identical to the structure of the porous metal

After passing through this complex process, the volume-porous nickel was glued to the aluminum foil base, and then the composite material was used as a diffuser.

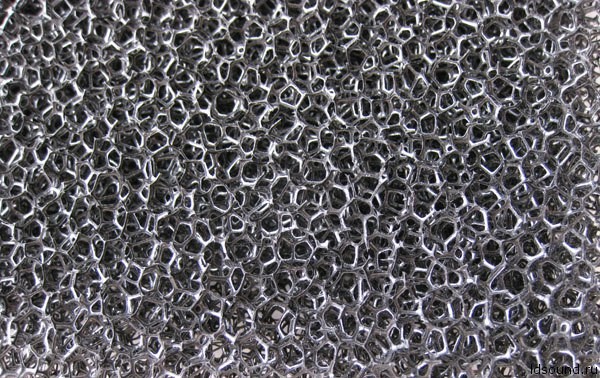

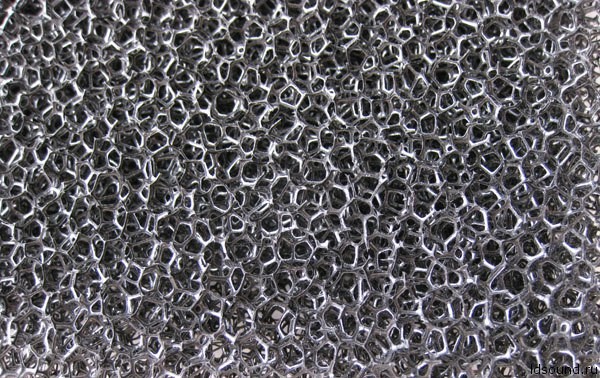

nickel foam structure

Sapphires in midrange dynamics are just as myth as “foamed metal”. There is no evidence that sapphire crystals were used. In addition to a very rare and expensive decor in an elaborate design, sapphires for the production of acoustics were not used and not used (nowhere, never, at all, if only because there is no need).

Some sources, such as the video above, refer to the “precipitation method”. In fact, this method is not applied to cover something with a layer of crystals, but to produce artificial sapphires and is called the Verneuil Method. The use of a 3-layer diaphragm, 80% composed of aluminum oxide, was quite enough for the implementation of the tasks in the MF range, there are simply no sapphires there. This is not to mention the astronomical increase in cost.

With tweeters, too, not everything goes smoothly. So the concentric slots on the corrugation of the tweeter allegedly made by a laser. However, smart people told me that in the 70s in Japan, probably there were no 50-70 watt lasers. They were in the world with a similar power at that time could be counted on fingers.

In addition, to create such slits with a laser, a coordinate machine was needed for cutting control, which did not exist at that time or 10 years after that. And this is not all the problems that would have appeared when trying to use lasers. In other words, theoretically it was possible, but it would cost a lot of money and make senseless production.

The answer was simple. As the people who participated in copying the legend in the USSR write, the method of electroerosive processing was used for the slots. Those. it was just that the voltage was sufficient to form a breakdown, and the discharge in the form of a conducting column with an extremely high temperature burned through the holes in the aluminum corrugation better than any laser.

The design of the AU deserves special attention. The speakers have a rather large volume - 110 liters, which corresponds to the axiom: good acoustics - great acoustics. ” The case had rather thick (30 mm) walls and was made of a special, acoustically designed chipboard.

SANYO engineers carefully approached the acoustic design. They made the case phasoline, dividing it with a panel of acoustic resistance (PAS) into two compartments, one of which plays the role of a resonator, and the second (LF section) is equipped with two phase inverters, the openings of which go to the front panel.

A characteristic feature of the design is the absence of turbulent overtones, characteristic of almost all phase inverter speakers. This is due to the small progress of the speaker, even at high volume and using the PASS.

In addition to the mythologized composite materials, there are many features in the design of the speakers. So the 30 cm woofer was fitted with a 1.4 kg magnet with a flux density of 11000 Gaus. The suspensions (unlike the late Soviet copies) were made of fabric, which guaranteed them durability.

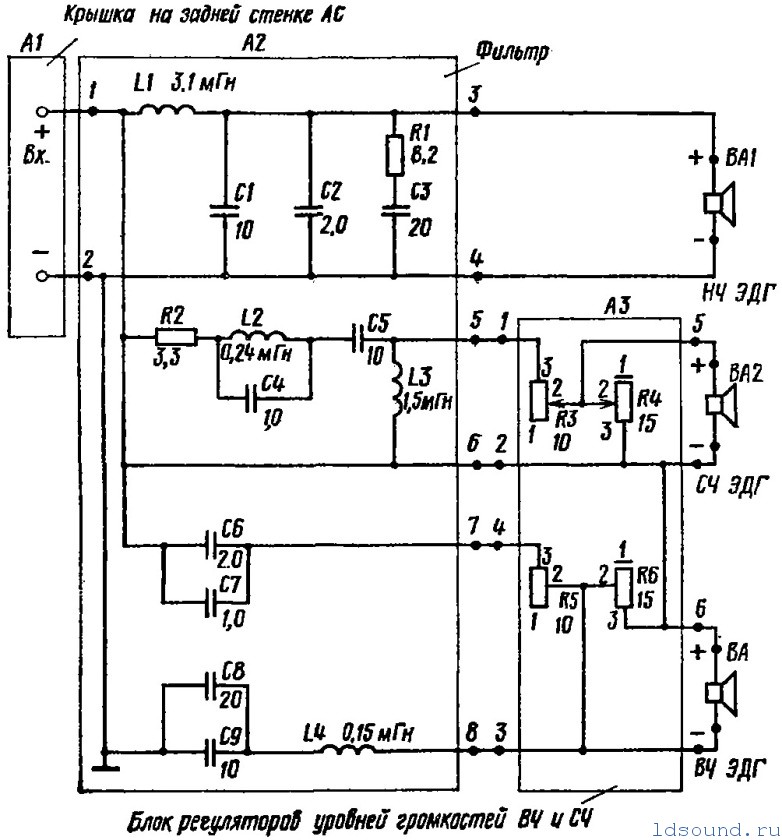

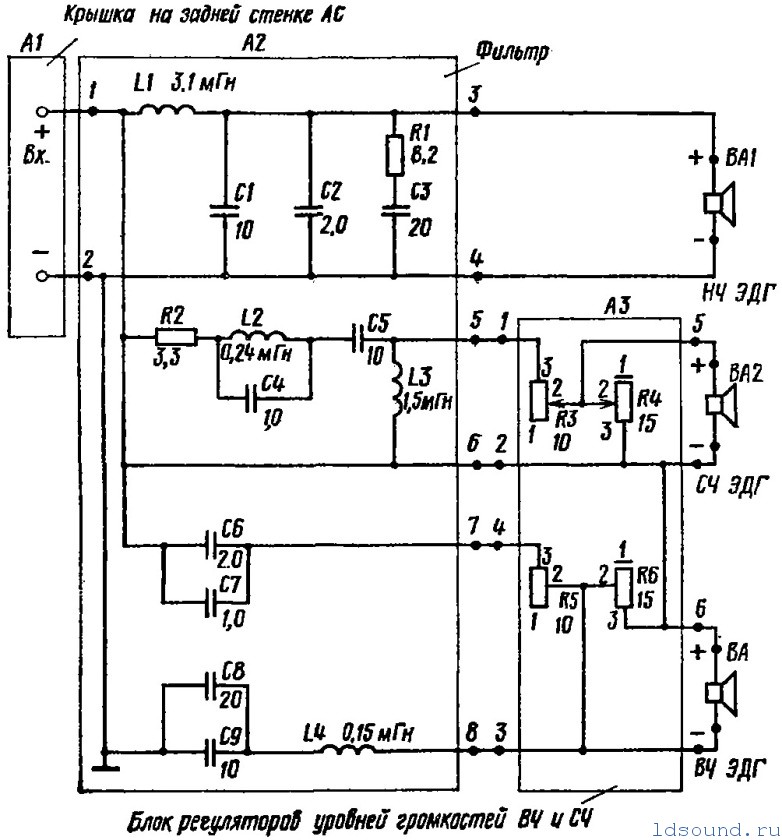

The filters that received high-quality components deserve high marks. Collectors who own this acoustics, note that the parameters of the elements correspond to the nominal values even after 30 years and almost never require replacement. Subsequently, the original filter scheme was completely copied in the Soviet version and adapted to the domestic element base.

All these technical solutions allowed the system to provide more than competitive technical characteristics:

In accordance with the unconfirmed and unconfirmed legend, the deputy. Alexander N. Usanov, Minister of Medium Machine Building of the USSR, was an avid music lover. On one of his business trips abroad, he was impressed with the OTTO SX-P1 and returned to the USSR with two sets of this acoustics.

The official got an idea to give the Soviet people a similar device. A few years later, the Moscow Defense NPO Torii was tasked with copying a device brought from the “decaying west.” This legend is very similar to many others. Perhaps because such a story was typical for the USSR, or it is just a beautiful myth.

There is an opinion that defense enterprises were tasked with developing such equipment solely because the rest were not able to produce anything suitable, but this is not entirely true. Employees of the NGO “Tory” recalled that even before the start of Gorbachev's restructuring, the number of defense orders began to decrease, and budgets were cut down and civilian devices were developed just to increase the financial efficiency of the organization’s activities.

One of the samples, transferred to the “Thorium”, was disassembled to a screw and scrupulously studied. As a result, for 2 years, Soviet engineers unraveled and were able to repeat in the conditions of NGOs almost all the technological processes used to create this acoustics.

OTTO SX-P1 has been copied almost completely. Only a few decisions were considered not entirely rational. So the Soviet version 100AC-060:

Described, despite these differences, the result exceeded the expectations of developers. Prototypes had characteristics unattainable for Soviet acoustics:

Non-observance of some technological standards in production reduced the fidelity of reproduction and “repeatability” in serial samples. But even in spite of this, “Electronics 10060” could have fallen with any Soviet analogue and many Western models.

The bottom line is that the OTTO SX-P1 is truly one of the best examples of its time, in which bold and unusual technical solutions were used that made it possible to solve a lot of complex technical problems.

At the same time, all the stories about the “boiling” (foaming) of sodium, sapphires and lasers are nothing more than myths that are not really needed, because the acoustics and without them is a fairly high-tech product with excellent characteristics.

The Soviet copy of the Japanese legend was inferior to the latter in a number of characteristics and was made a little easier. At the same time, 100AC-060 managed to replicate most of the significant competitive advantages of the OTTO SX-P1, in particular, porous nickel, metal speakers and unique acoustic design, phase linearity, and excellent damping.

Today, the market and the interests of manufacturers dictate their conditions, people want cheap acoustics, and manufacturers earn more by spending less resources. Profit This leads to what seems to be not too complicated for the present, but more expensive technologies remain in the past, giving way to more utilitarian ones.

Photo content used:

donex-ua.narod.ru

forum.doctorhead.ru

ldsound.ru

donex-ua.narod.ru

Jeans

The Pult.ru catalog presents a wide range of acoustic systems.

These three-lane studio monitors, created by the Japanese company SANYO in 1976, contrary to the calculations of marketers, became widespread as home acoustics. During sales, they won the reputation of one of the most “honest” acoustic systems, and the overwhelming majority of those who heard the system noted the so-called. “Presence effect”, “realistic sound”, as well as accurate localization of apparent sound sources in a wide and deep stereo panorama. Not without fairy tales - this acoustics has become one of the most mythologized audio components in history. Under the cat in detail about the OTTO SX-P1, the history of its creation, myths, reality and the Soviet copy.

Set of myths

To begin with, let me allow myself a couple of mythological paragraphs, in which I will gather all the legends and tales about this acoustics periodically appearing in the media.

In distant Japan, SANYO engineers decided to create the world's best serial three-way speakers. Thus, in 1976, the OTTO SX-P1 was born, with ultra-low distortion a thousand times lower than the threshold of human perception.

')

It was possible to achieve unique technical characteristics thanks to metal foamed under the influence of high temperatures, sapphire coating of midrange speakers and the use of lasers to create cuts in the RF head. Supermegaunic technologies of the past cannot be repeated, and for this reason today they do not produce analogues of unique acoustics. After 10 years in the USSR, they tried to repeat the Japanese miracle and made a terrible, incapable of Frankenstein.

I got some of the myths from this article , this video , as well as from numerous audioforums where they (myths) have been walking not for years, but for decades.

The video, by the way, is quite suitable for itself, but we could not manage without some common misconceptions and excessive pathos.

Reasons, history of creation and co-branding

I guess with enough myths. The reality differs significantly from them. General with reality in the legend is only the year of the start of the serial release of 1976 and the fact that this speaker really sounded with low distortion (but, naturally, not less than 1000 times the threshold of human perception).

In reality, the development of a new AU began in order to consolidate a new segment of the Western market for SANYO, namely the studio equipment segment. If in Japan they were known as a reliable manufacturer, then, for export to the United States, until 1975, the company produced mostly low-priced consumer goods. Nobody set the task to create the best speaker in the world, everything was more pragmatic and trivial.

The speaker system was originally designed for studios that in the States almost everywhere used the products of JBL and other “domestic” American manufacturers. It was for the sake of a conservative and fastidious studio market that practical Japanese decided to create something extremely competitive. In the domestic market, they also competed mainly with YAMAHA (in the professional segment) and Technics (in the home audio segment).

Interestingly, despite the product, which is quite innovative for its time, the Americans at first did not hurry to buy it. The reputation of SANYO as a widely used office that is not capable of making devices for pros has made itself felt. To eliminate the prejudice went to the unthinkable for a proud Japanese company - co-branding with Fisher. After the OTTO export was renamed Fisher STE-1200, the sales went much livelier. Later, the sly Japanese bought Fisher with giblets.

Technology

The story about the technologies begin with the LF cone. It is not made of “some kind of foamed metal” (I have never met such a term anywhere, except for tales about this acoustics). In fact, the material LF-diffuser - composite, consisting of bulk-porous nickel and aluminum foil.

Such a material was chosen in order to combine the high rigidity of the diffuser, which allowed the dynamics to work in a piston mode and qualitatively new sound absorption characteristics in order to provide the damping of reflected waves. Technology has put an end to the question of a compromise between damping and impulse response, solving both problems at once.

I also find it interesting how we managed to obtain porous nickel. The technology was as follows:

- Polyurethane foam (aka foam rubber) of a cubic form was processed using a controlled explosion in a special reticulation chamber. As a result, an open-cell PUF was obtained.

- Glowed string foam rubber cut into thin plates, getting blanks.

- The blanks were degreased in chemical baths using trisodium phosphate and washed.

- Then these blanks underwent chemical precipitation with tin salts and copper plating.

- At the last stage, nickel was applied to the foam rubber using matte galvanic nickel plating, after which the base was burned in a hydrogen furnace and annealing was performed simultaneously.

the structure of the treated foam is almost identical to the structure of the porous metal

After passing through this complex process, the volume-porous nickel was glued to the aluminum foil base, and then the composite material was used as a diffuser.

nickel foam structure

Sapphires in midrange dynamics are just as myth as “foamed metal”. There is no evidence that sapphire crystals were used. In addition to a very rare and expensive decor in an elaborate design, sapphires for the production of acoustics were not used and not used (nowhere, never, at all, if only because there is no need).

Some sources, such as the video above, refer to the “precipitation method”. In fact, this method is not applied to cover something with a layer of crystals, but to produce artificial sapphires and is called the Verneuil Method. The use of a 3-layer diaphragm, 80% composed of aluminum oxide, was quite enough for the implementation of the tasks in the MF range, there are simply no sapphires there. This is not to mention the astronomical increase in cost.

With tweeters, too, not everything goes smoothly. So the concentric slots on the corrugation of the tweeter allegedly made by a laser. However, smart people told me that in the 70s in Japan, probably there were no 50-70 watt lasers. They were in the world with a similar power at that time could be counted on fingers.

In addition, to create such slits with a laser, a coordinate machine was needed for cutting control, which did not exist at that time or 10 years after that. And this is not all the problems that would have appeared when trying to use lasers. In other words, theoretically it was possible, but it would cost a lot of money and make senseless production.

The answer was simple. As the people who participated in copying the legend in the USSR write, the method of electroerosive processing was used for the slots. Those. it was just that the voltage was sufficient to form a breakdown, and the discharge in the form of a conducting column with an extremely high temperature burned through the holes in the aluminum corrugation better than any laser.

Design and specifications

The design of the AU deserves special attention. The speakers have a rather large volume - 110 liters, which corresponds to the axiom: good acoustics - great acoustics. ” The case had rather thick (30 mm) walls and was made of a special, acoustically designed chipboard.

SANYO engineers carefully approached the acoustic design. They made the case phasoline, dividing it with a panel of acoustic resistance (PAS) into two compartments, one of which plays the role of a resonator, and the second (LF section) is equipped with two phase inverters, the openings of which go to the front panel.

A characteristic feature of the design is the absence of turbulent overtones, characteristic of almost all phase inverter speakers. This is due to the small progress of the speaker, even at high volume and using the PASS.

In addition to the mythologized composite materials, there are many features in the design of the speakers. So the 30 cm woofer was fitted with a 1.4 kg magnet with a flux density of 11000 Gaus. The suspensions (unlike the late Soviet copies) were made of fabric, which guaranteed them durability.

The filters that received high-quality components deserve high marks. Collectors who own this acoustics, note that the parameters of the elements correspond to the nominal values even after 30 years and almost never require replacement. Subsequently, the original filter scheme was completely copied in the Soviet version and adapted to the domestic element base.

All these technical solutions allowed the system to provide more than competitive technical characteristics:

- Conical woofer with a diameter of 300 mm made of porous nickel.

- Mid-range speaker with a rigid dome with a diameter of 67 mm from a composite material based on aluminum oxide.

- Tweeter - ring tweeter with a diameter of 38 mm of aluminum oxide.

- Nominal resistance: 8 ohms.

- Rated power: 100 W (RMS: 150 W).

- Sensitivity: 93 dB / W / 1m.

- Frequency range: 35 ~ 35 kHz ± 3 dB.

- Crossover section frequency: 500 Hz, 5 kHz.

- Dimensions: Width: 450 mm. Height: 910 mm. Depth: 430 mm. Volume: 110 liters.

- Mass of one system: 51 kg.

Soviet clone

In accordance with the unconfirmed and unconfirmed legend, the deputy. Alexander N. Usanov, Minister of Medium Machine Building of the USSR, was an avid music lover. On one of his business trips abroad, he was impressed with the OTTO SX-P1 and returned to the USSR with two sets of this acoustics.

The official got an idea to give the Soviet people a similar device. A few years later, the Moscow Defense NPO Torii was tasked with copying a device brought from the “decaying west.” This legend is very similar to many others. Perhaps because such a story was typical for the USSR, or it is just a beautiful myth.

There is an opinion that defense enterprises were tasked with developing such equipment solely because the rest were not able to produce anything suitable, but this is not entirely true. Employees of the NGO “Tory” recalled that even before the start of Gorbachev's restructuring, the number of defense orders began to decrease, and budgets were cut down and civilian devices were developed just to increase the financial efficiency of the organization’s activities.

One of the samples, transferred to the “Thorium”, was disassembled to a screw and scrupulously studied. As a result, for 2 years, Soviet engineers unraveled and were able to repeat in the conditions of NGOs almost all the technological processes used to create this acoustics.

OTTO SX-P1 has been copied almost completely. Only a few decisions were considered not entirely rational. So the Soviet version 100AC-060:

- did not get a three-layer composite in midrange dynamics (limited to just aluminum oxide);

- the speakers were equipped with magnets with a lower flux density, which affected the sensitivity;

- with the same circuitry, the quality of the elements used for the filter was significantly different;

- for the case they did not develop a special chipboard and limited the amount available, the thickness was also reduced to 29 mm;

- for suspensions of woofer diffusers, foam rubber was used instead of the impregnated fabric, which made them extremely short-lived;

- for the tweeter, they did not use aluminum oxide, limiting themselves to high-temperature pressing food foil, and therefore, at a high volume in the RF spectrum, subtle but characteristic metallic overtones can be subjectively distinguished.

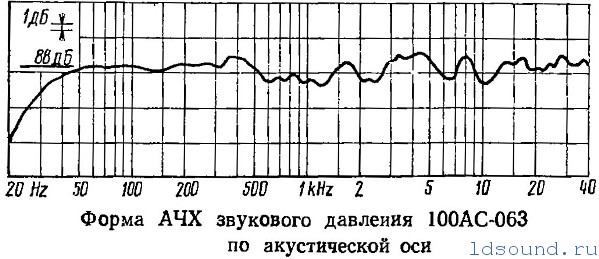

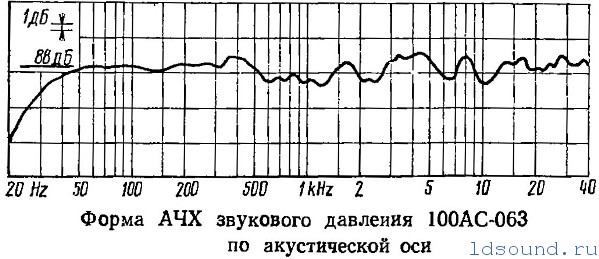

Described, despite these differences, the result exceeded the expectations of developers. Prototypes had characteristics unattainable for Soviet acoustics:

- Frequency range: 31.5 - 25000 Hz;

- Sensitivity: 88 dB;

- Irregularity of frequency response of sound pressure in the frequency range of 100 - 8000 Hz relative to the level of the average sound pressure in the range of 50 - 20000 Hz: ± 4 dB;

- Direction at angles to the acoustic axis:

- in the vertical plane ± 7 °: ± 4 dB;

- in the horizontal plane ± 25 °: ± 4 dB;

- Harmonic coefficient in the frequency range:

- 63 - 1000 Hz (with a sound pressure of 96 dB): 2%;

- 1000 - 2000 Hz (with a sound pressure of 93 dB): 1.6%;

- 2000 - 8000 Hz (with a sound pressure of 90 dB): 1.4%;

- Resistance: 8 Ohm;

- The minimum impedance: 6.4 ohms;

- Passport power: 100 W;

- Weight: 51 kg;

- Dimensions (HxWxD): 915455475 mm.

Non-observance of some technological standards in production reduced the fidelity of reproduction and “repeatability” in serial samples. But even in spite of this, “Electronics 10060” could have fallen with any Soviet analogue and many Western models.

Total

The bottom line is that the OTTO SX-P1 is truly one of the best examples of its time, in which bold and unusual technical solutions were used that made it possible to solve a lot of complex technical problems.

At the same time, all the stories about the “boiling” (foaming) of sodium, sapphires and lasers are nothing more than myths that are not really needed, because the acoustics and without them is a fairly high-tech product with excellent characteristics.

The Soviet copy of the Japanese legend was inferior to the latter in a number of characteristics and was made a little easier. At the same time, 100AC-060 managed to replicate most of the significant competitive advantages of the OTTO SX-P1, in particular, porous nickel, metal speakers and unique acoustic design, phase linearity, and excellent damping.

Today, the market and the interests of manufacturers dictate their conditions, people want cheap acoustics, and manufacturers earn more by spending less resources. Profit This leads to what seems to be not too complicated for the present, but more expensive technologies remain in the past, giving way to more utilitarian ones.

Photo content used:

donex-ua.narod.ru

forum.doctorhead.ru

ldsound.ru

donex-ua.narod.ru

Jeans

The Pult.ru catalog presents a wide range of acoustic systems.

Source: https://habr.com/ru/post/421419/

All Articles