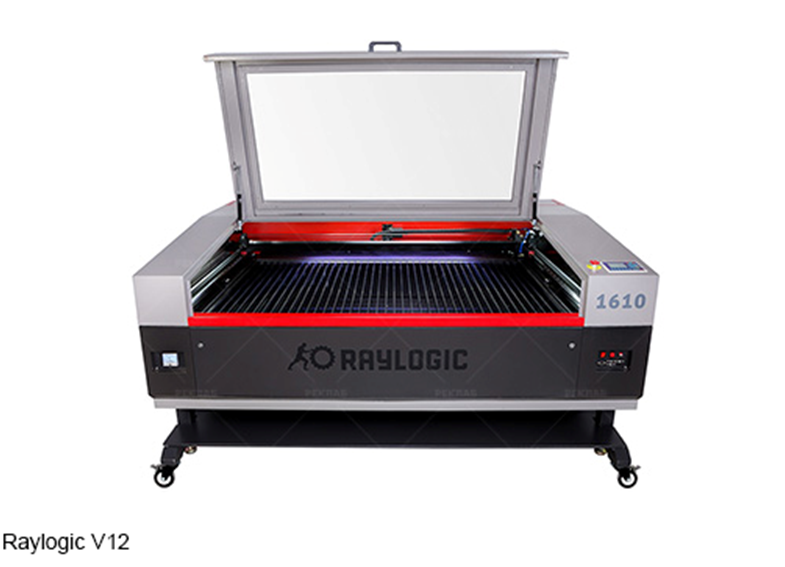

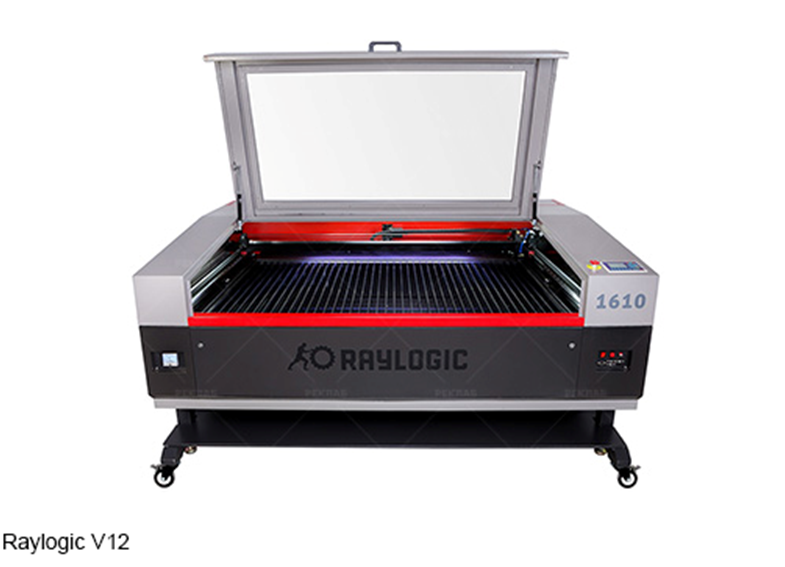

Comparison of Raylogic 11G and Raylogic V12 laser cutting machines

Good day everyone!

With you company 3Dtool . Today we decided to make for you a comparison of the Raylogic 11G and Raylogic V12 laser cutting machines. Well, more specifically, we will tell you about the changes in Raylogic laser machines.

As it turned out, when choosing a laser machine, many do not even suggest what an important role for a long-term resource and stable operation are: machine construction, reliable electronics, assembly culture and rigidity of the whole structure as a whole.

')

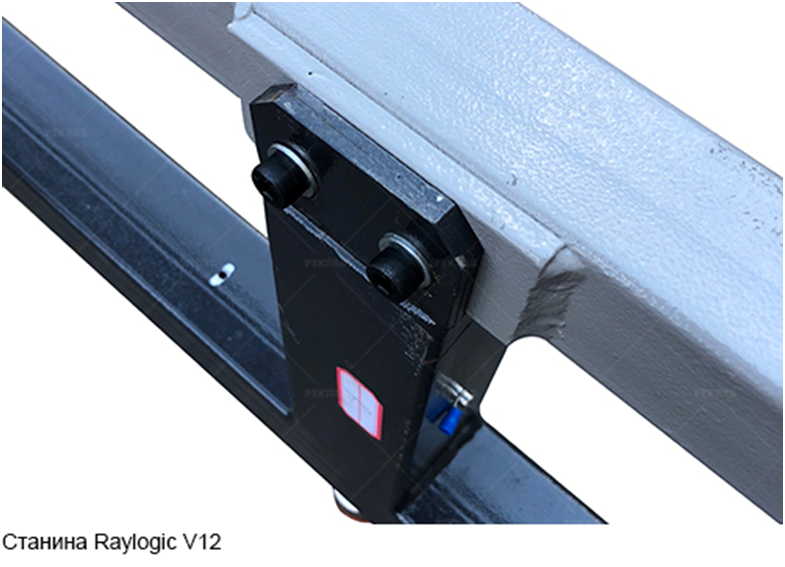

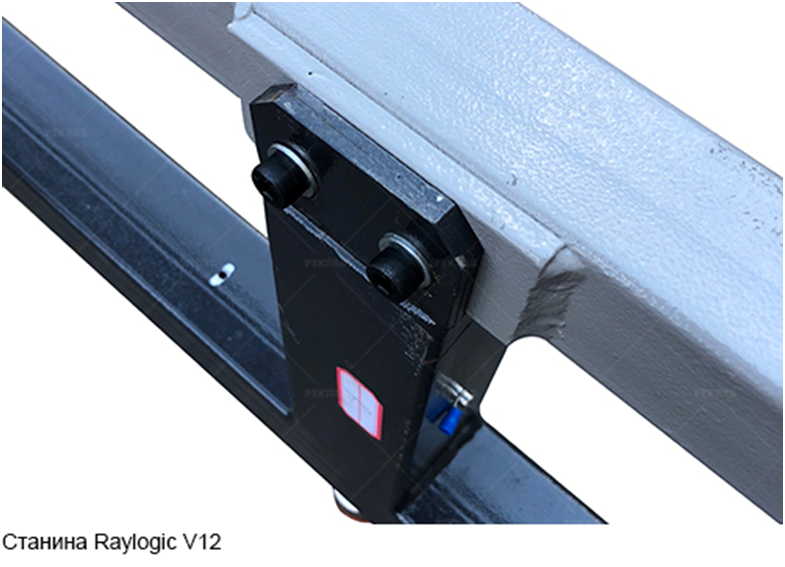

On Raylogic V12 series machines, you should immediately pay attention to the increased body weight - it has become 15% more than the previous model.

The stand for the machine is now made of thick steel, with a transverse shelf. This is done for convenient storage of consumables or various tools and devices, and a collapsible design allows you to carry machines into narrow doorways with a width of 70 cm.

Additional stiffness to the body is provided by stiffeners under the thrust bearings of the screws, made of thick steel along the entire height of the working surface.

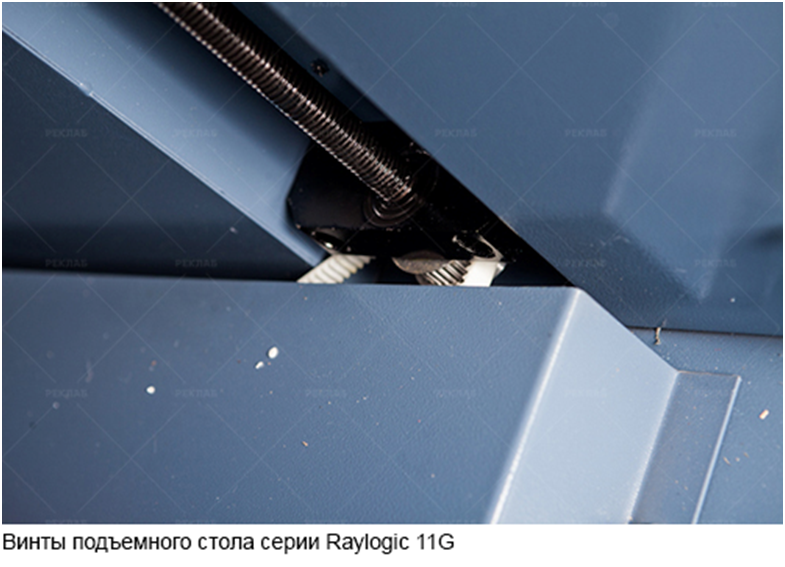

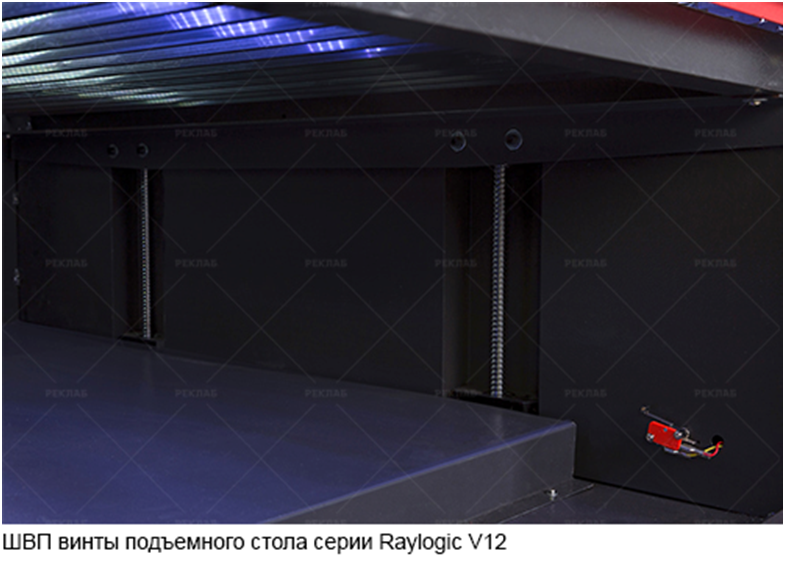

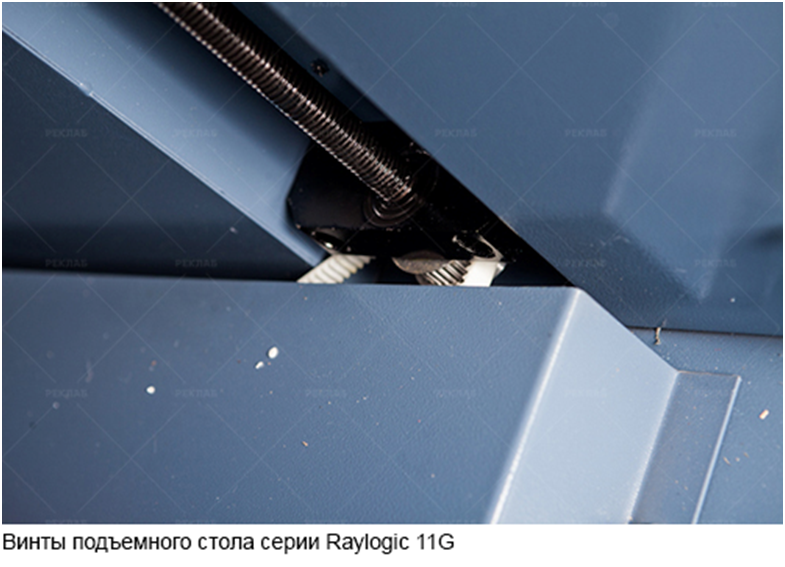

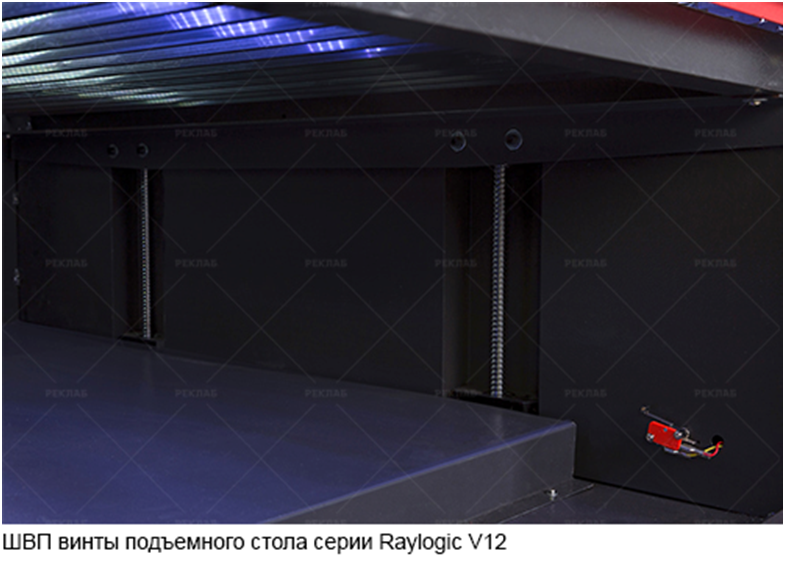

The working area has a linear rise of the engraving surface, thanks to ball-screw pairs. This increases the productivity, when filling engravable products, defocused radiation.

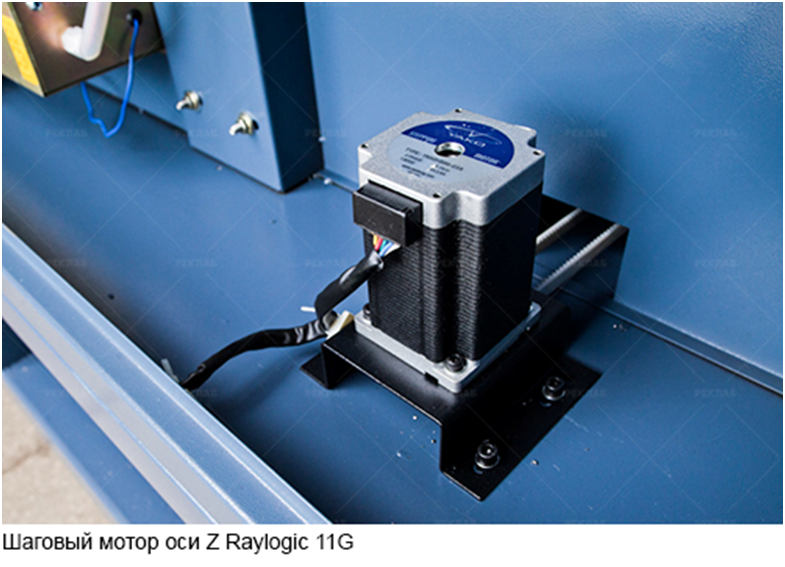

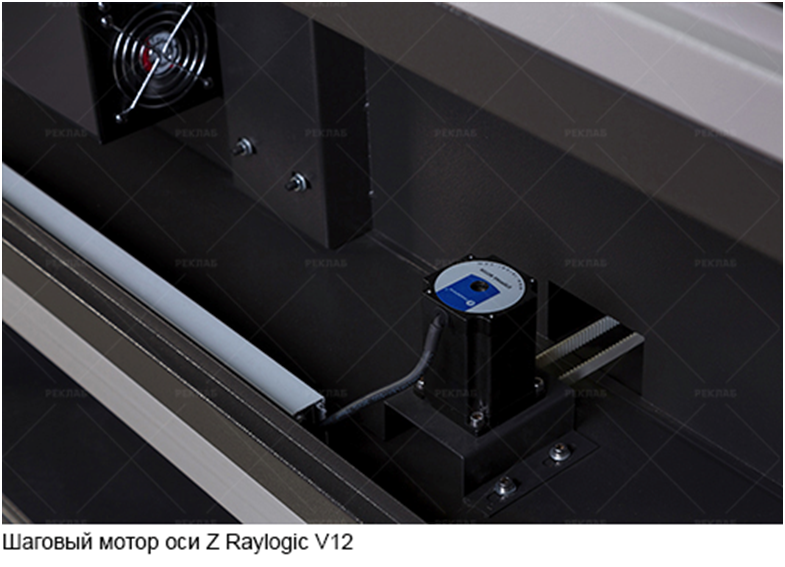

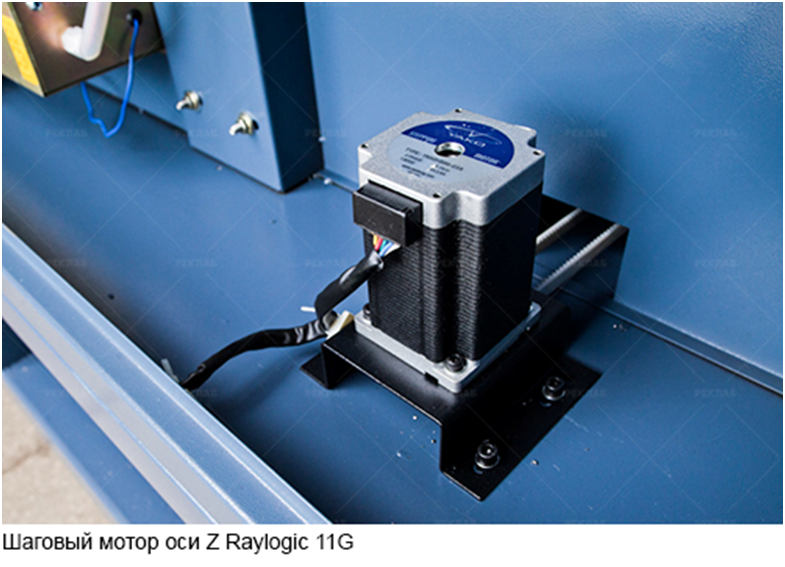

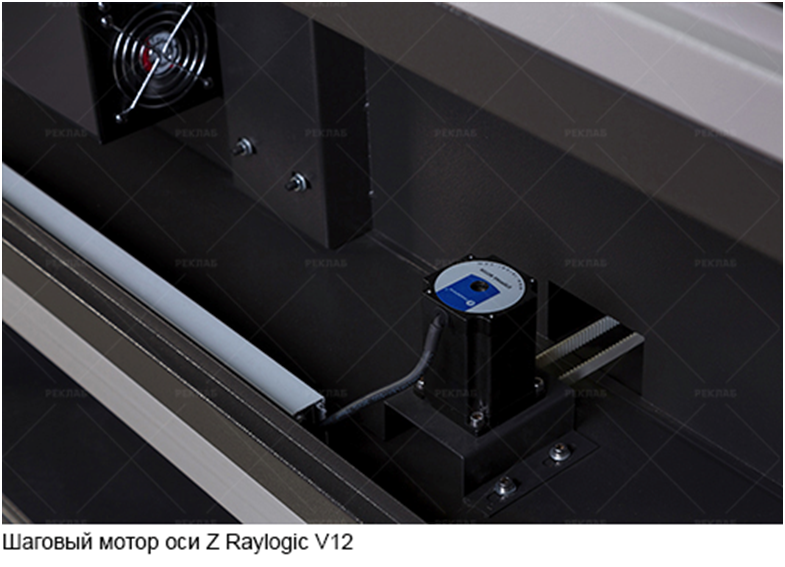

In Raylogic machines with high precision, you can control the lifting of the table. The rise itself is carried out by stepping motors.

The design of the machine has a broaching window in the back of the machine and a metal removable insert from the front side for the treatment of long materials.

The standard surface of the working surface is equipped with anodized lamellae of complex shape for perfectly clean cutting of both the front and the back of the material. Also optionally you can install a cellular table.

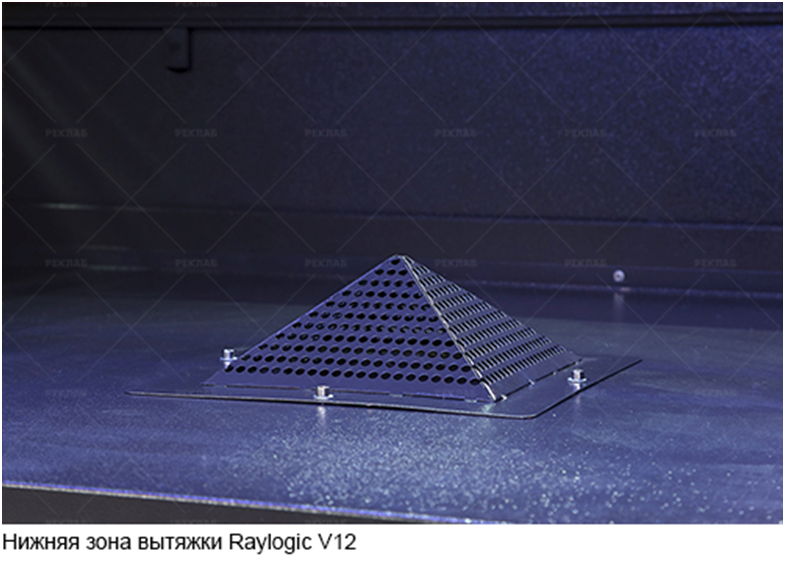

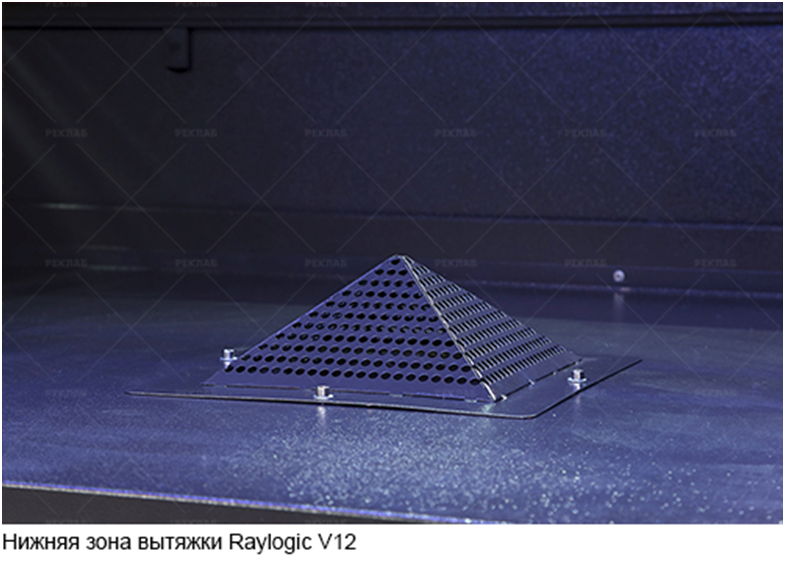

Protection of the lower exhaust window with the help of a pyramidal protective mesh allows you not to block the outflow of smoke drop-down parts.

The upper exhaust window is located above the working area to protect the optics during engraving and minimal cooling of the lens by air flow.

All mechanical components are made of anodized aluminum.

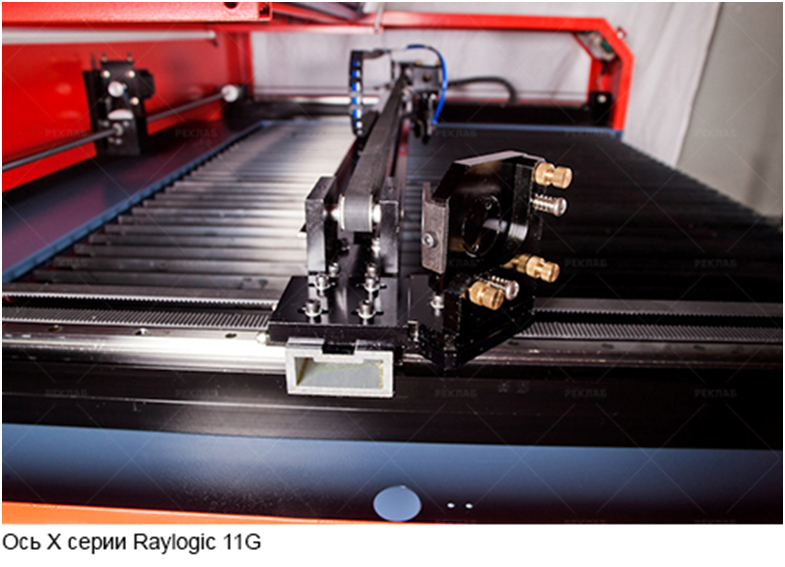

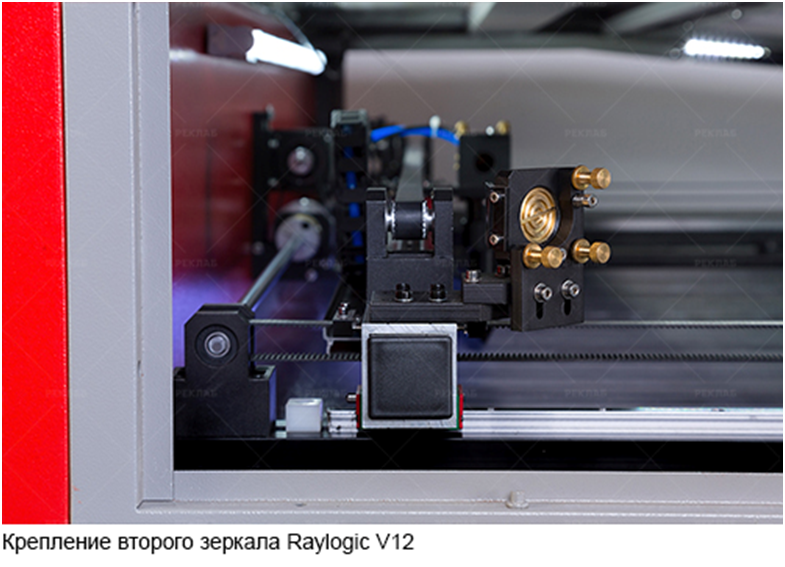

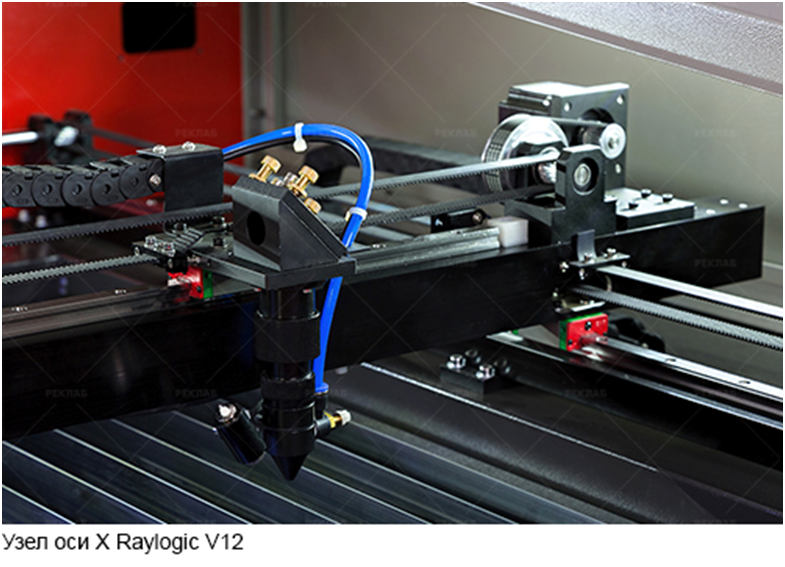

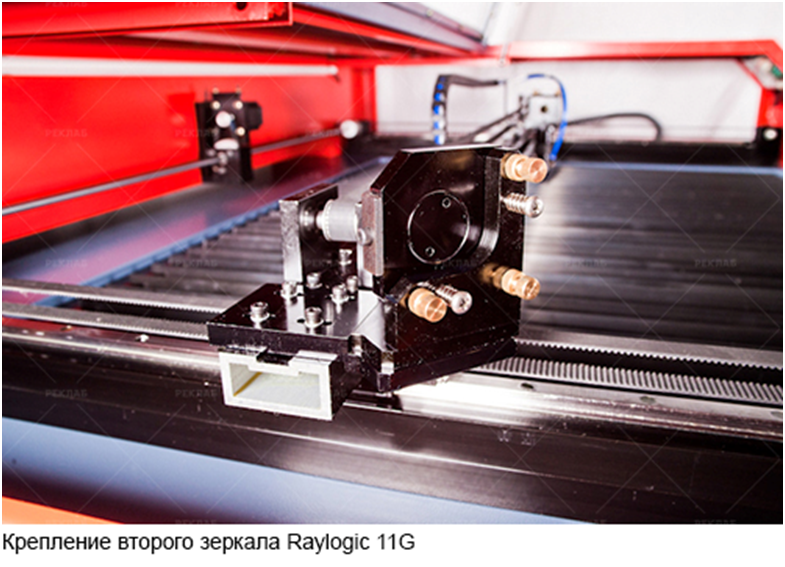

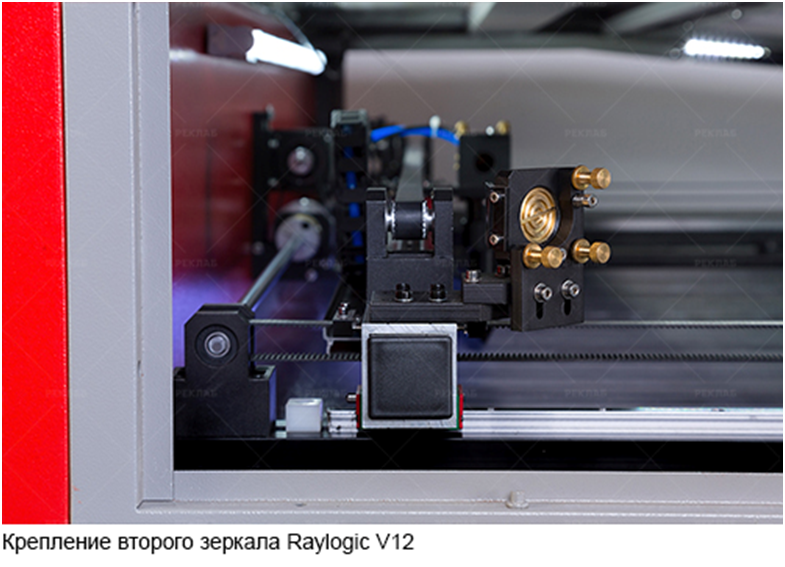

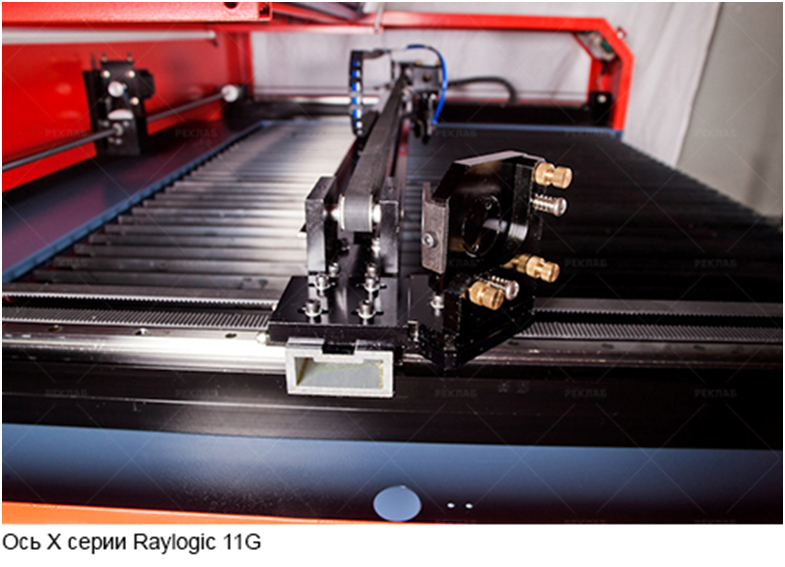

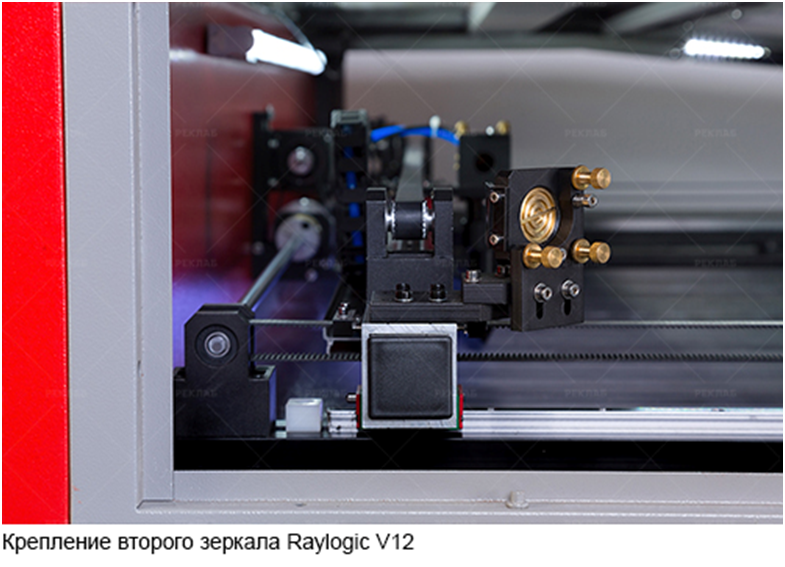

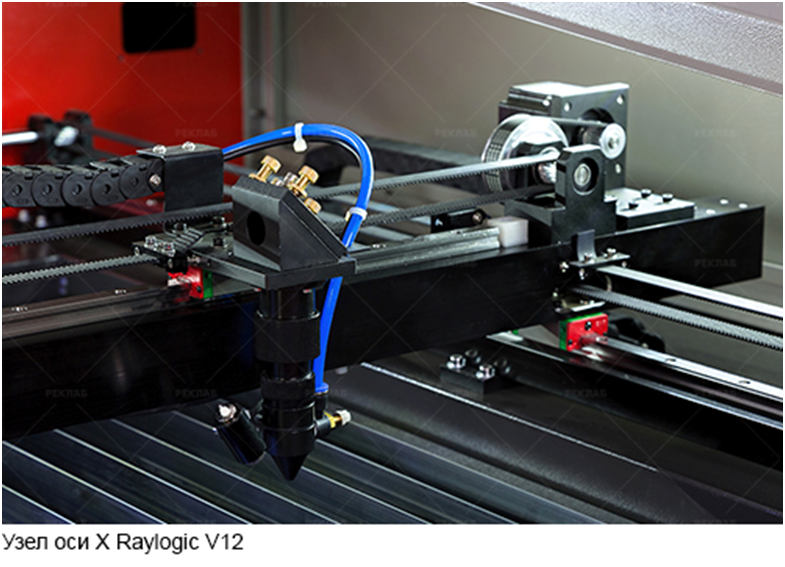

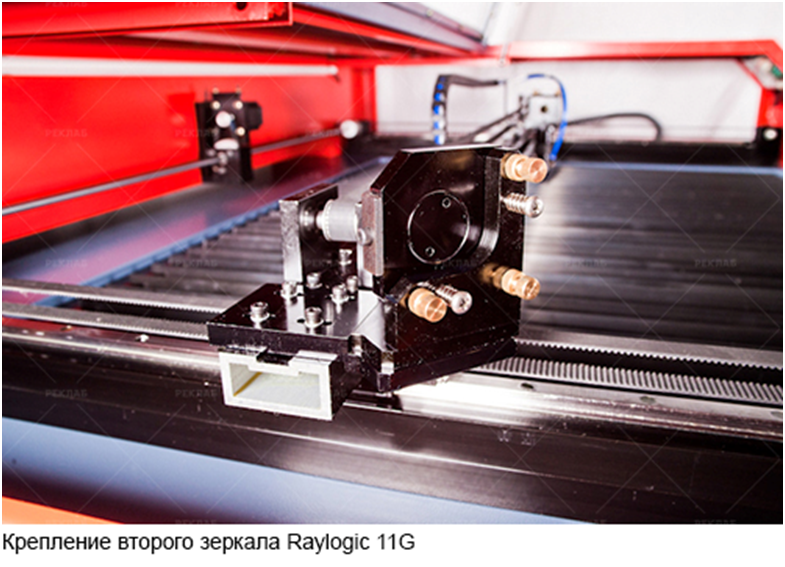

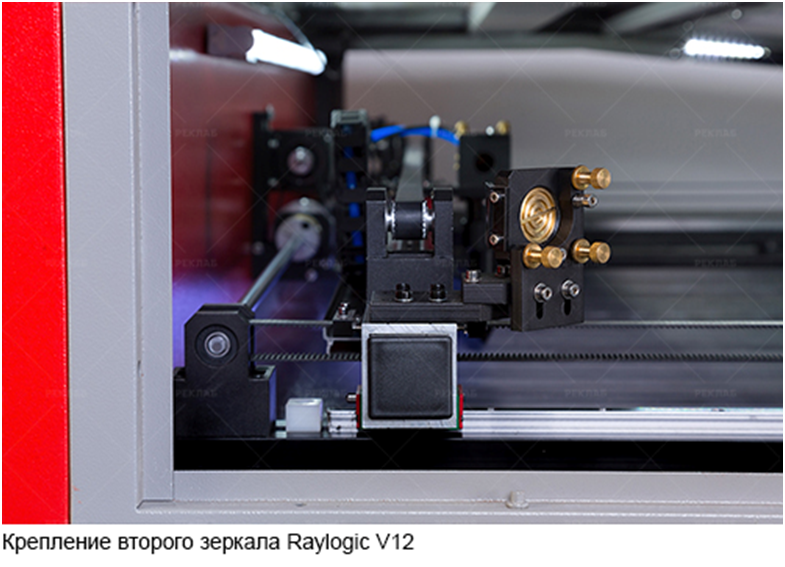

All elements of the X and Y axes are regulated in six planes, the Z axis in three planes.

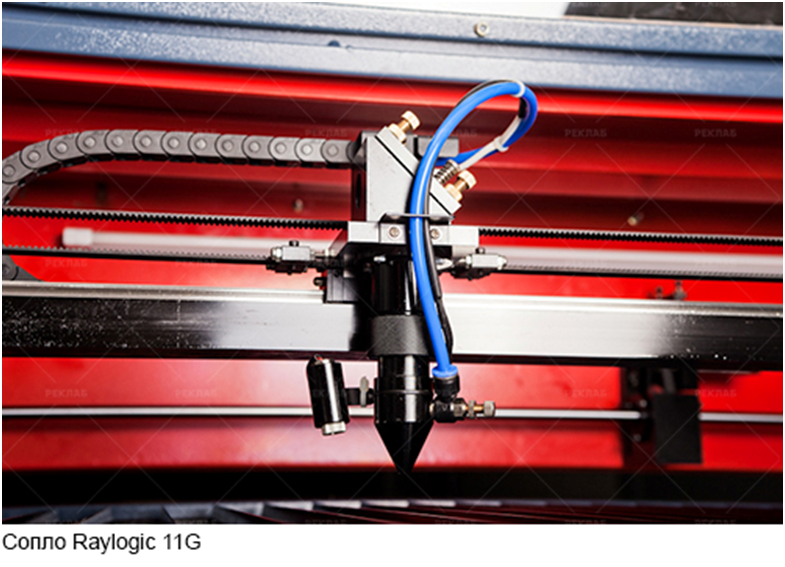

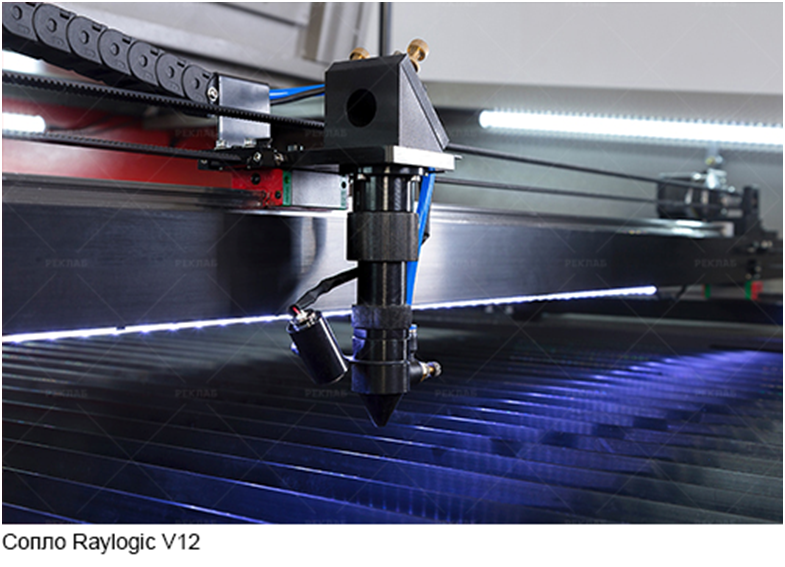

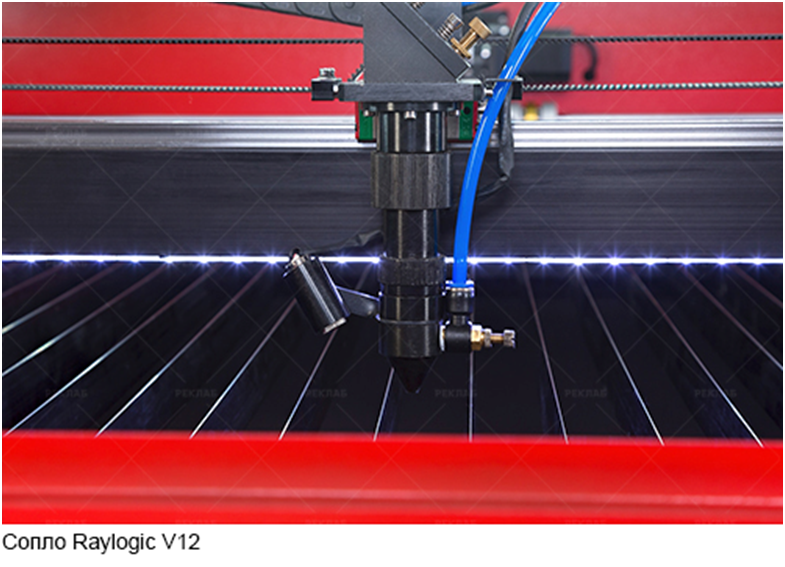

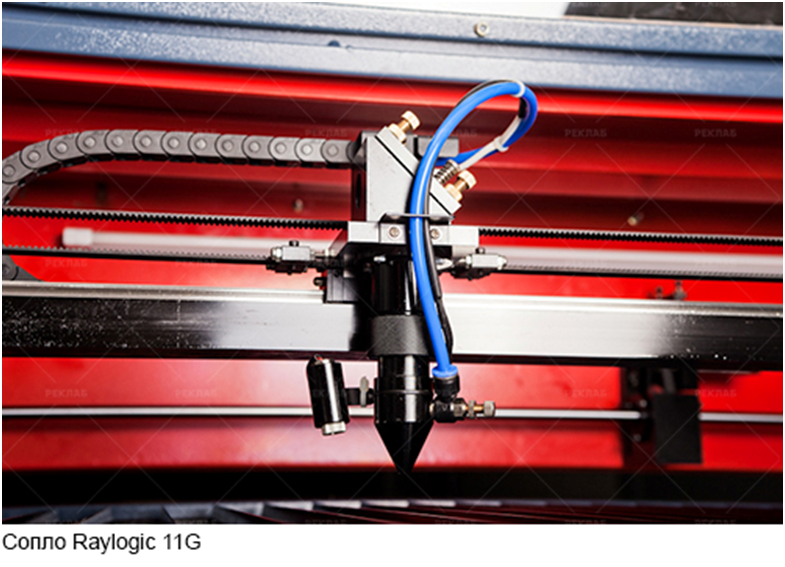

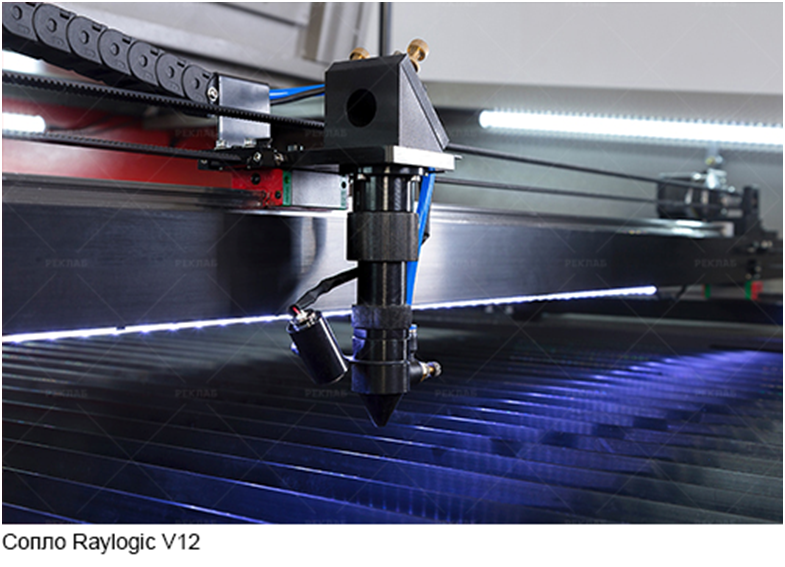

Nozzles are easy to change for the desired material without any problems, and without replacing the optics inside.

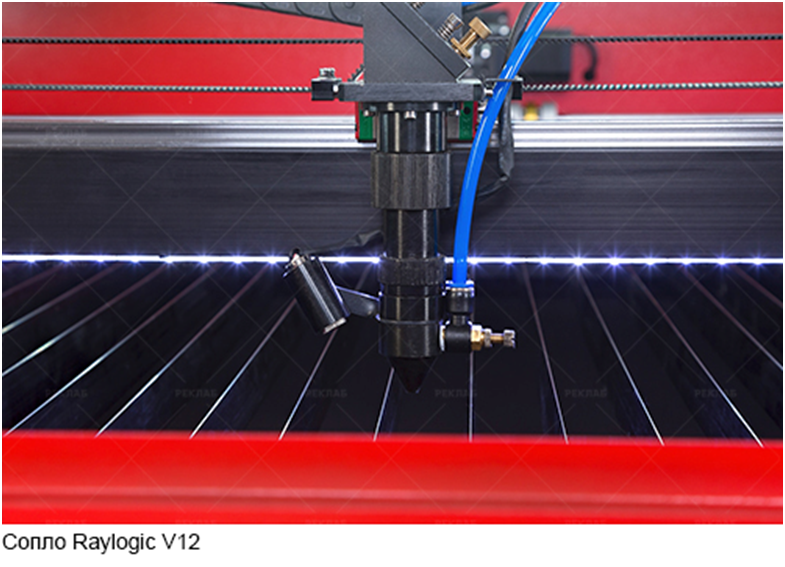

The entire working area is illuminated by a bright waterproof diode backlight.

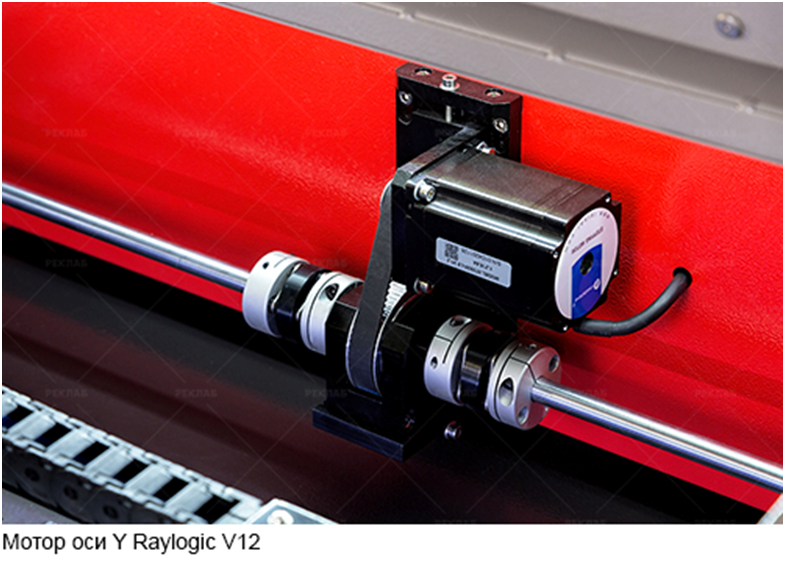

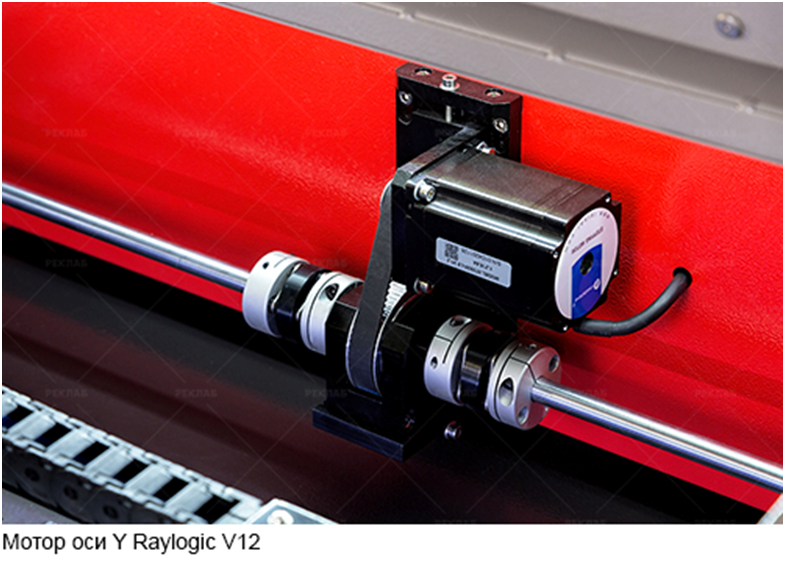

Raylogic V12 laser machines are equipped with Leadshine smooth three-phase stepping motors with a rotor angle of 1.2 degrees per step. The drive data is time-tested, they provide step-division accuracy and long-term operational reliability.

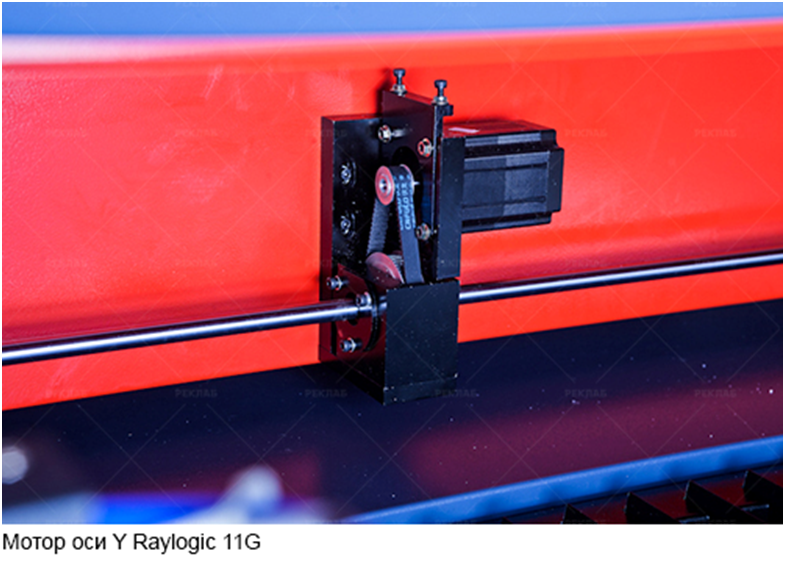

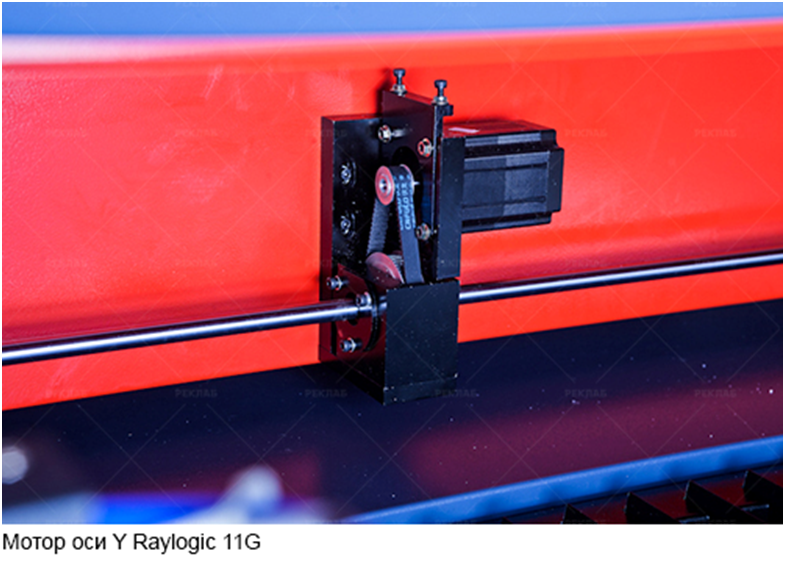

The installed shafts along the Y-axis are shortened and connected by elastic plate-type couplings of directional bending to damp any oscillations. The seat of the gearbox is reinforced with a metal insert.

The machine is controlled by Ruida based on Linux OS with Russian Rdworks for Windows software and convenient CorelDraw plugin.

Not unimportant role in the moving parts of laser machines Raylogic V12, played by German electric cables Helukabel. They are located in special cable channels connected to stepper motors and all electronics.

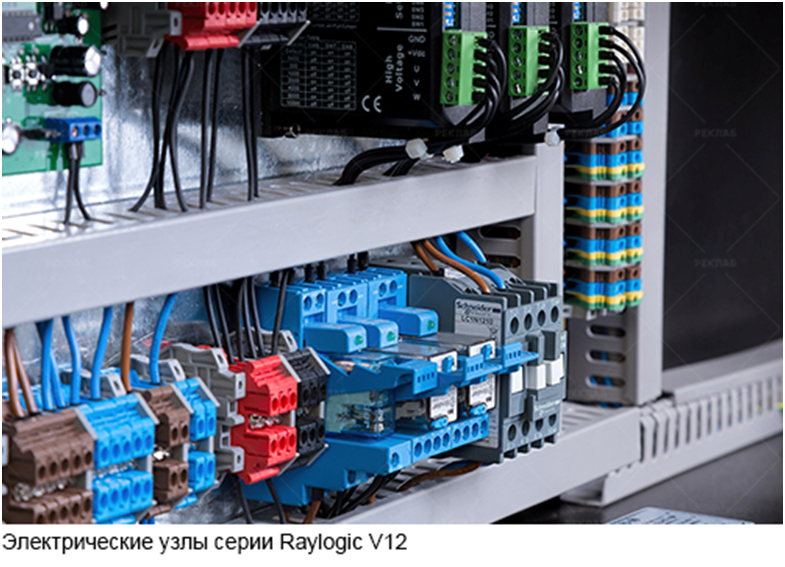

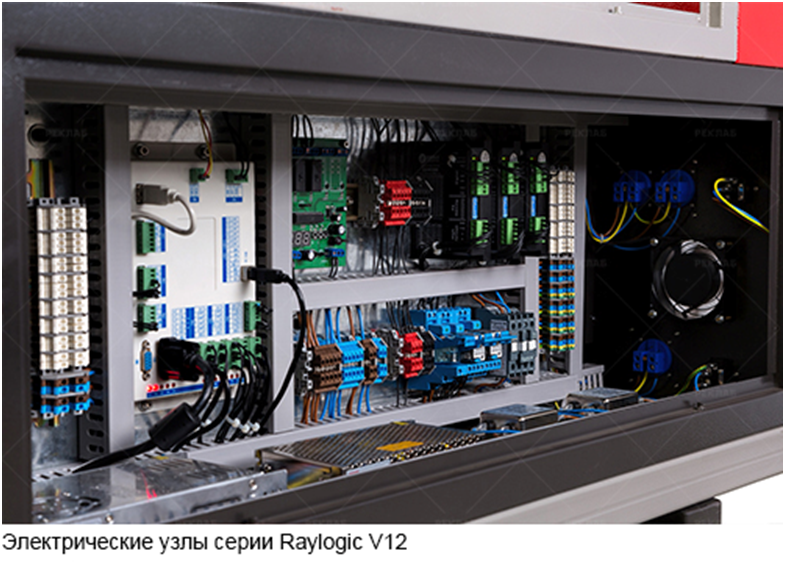

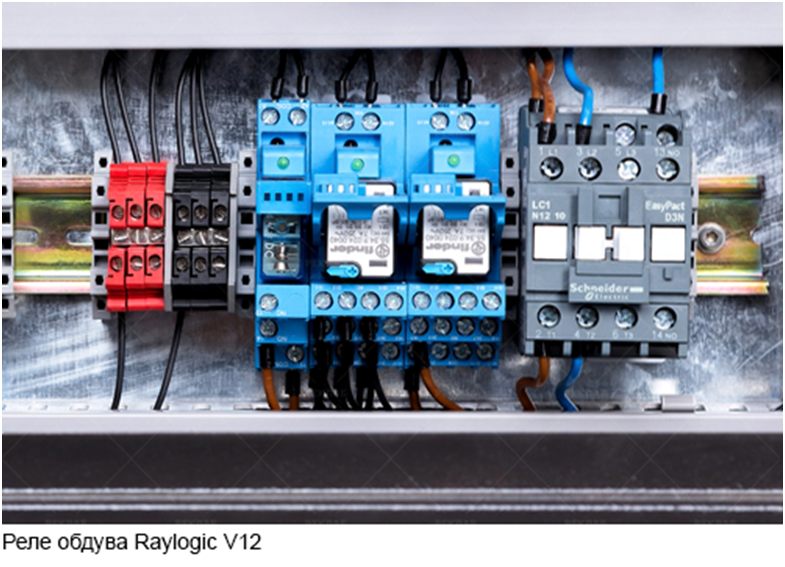

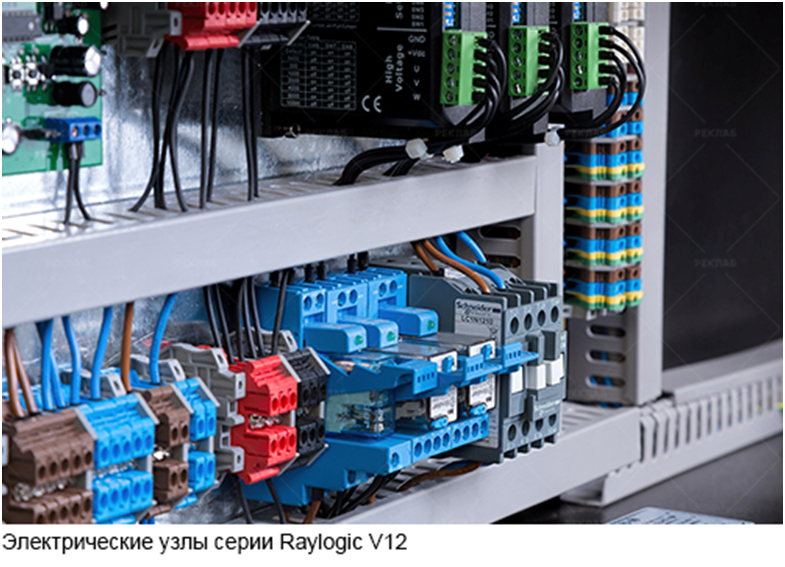

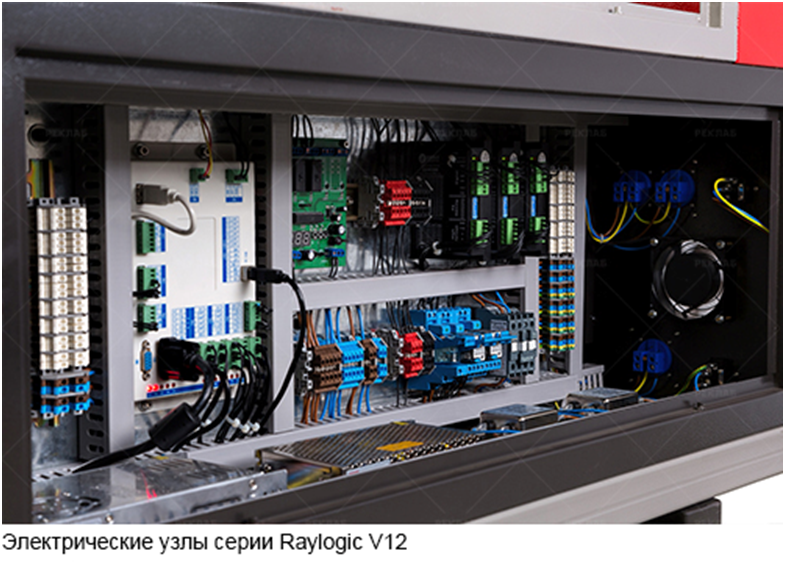

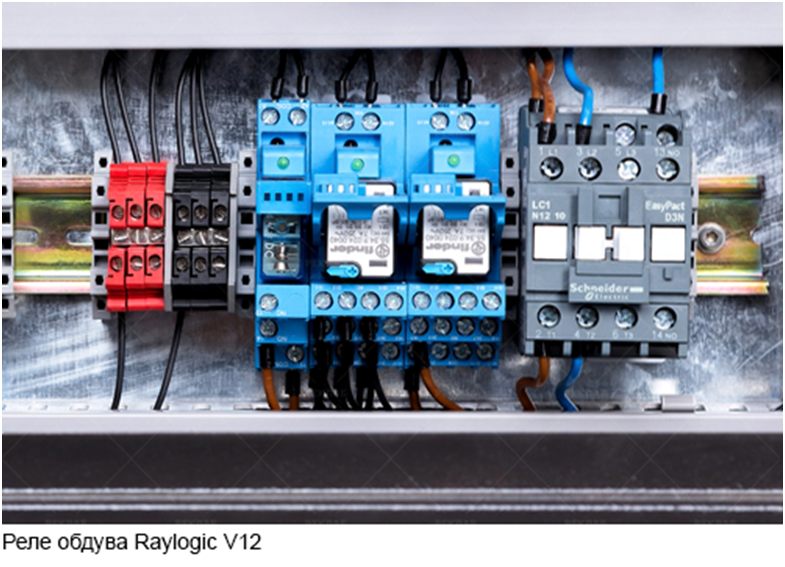

Reliability and quality of electronics assembly provide components of the French company Shneider.

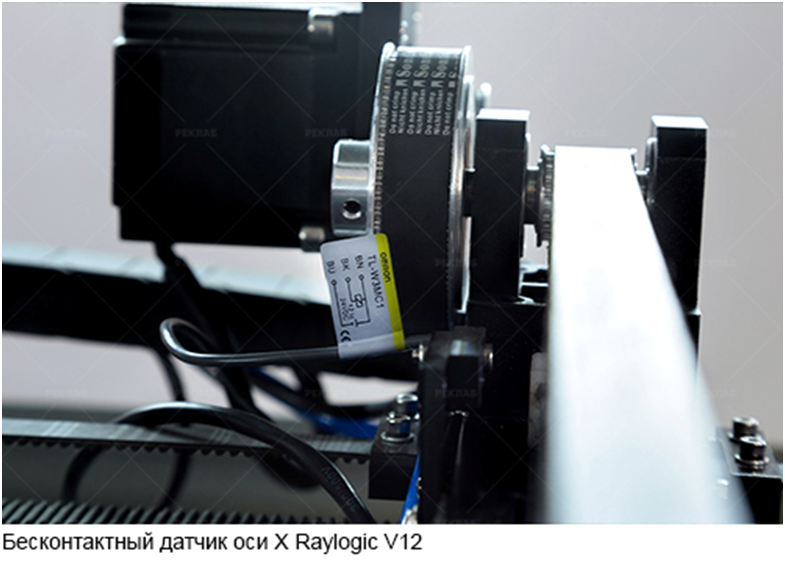

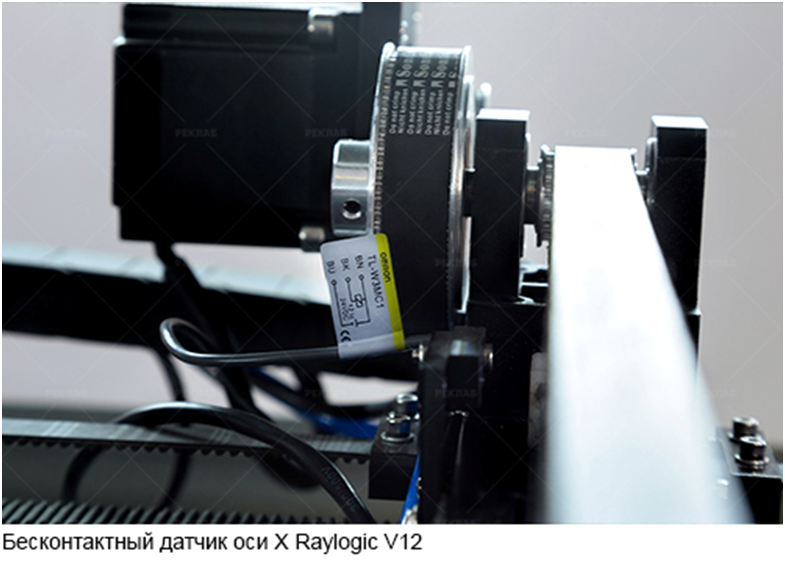

Accurate positioning for repetition is accomplished by Omron's non-contact end sensors.

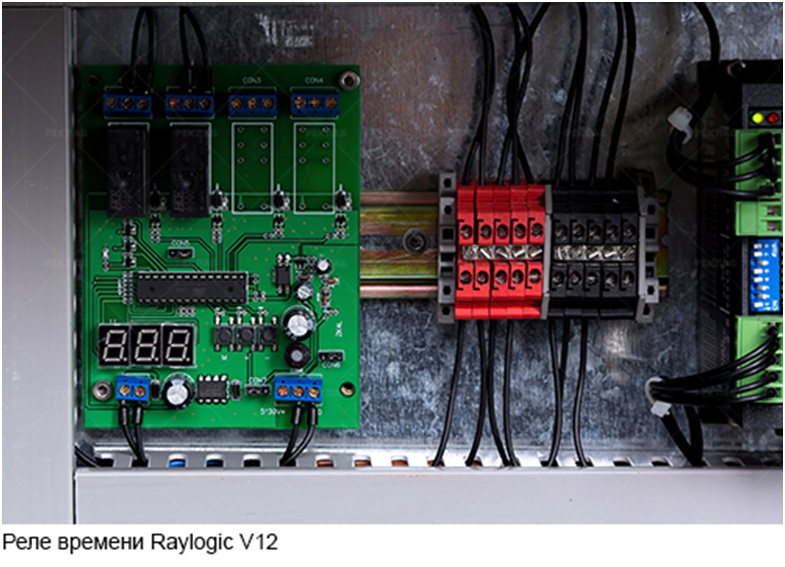

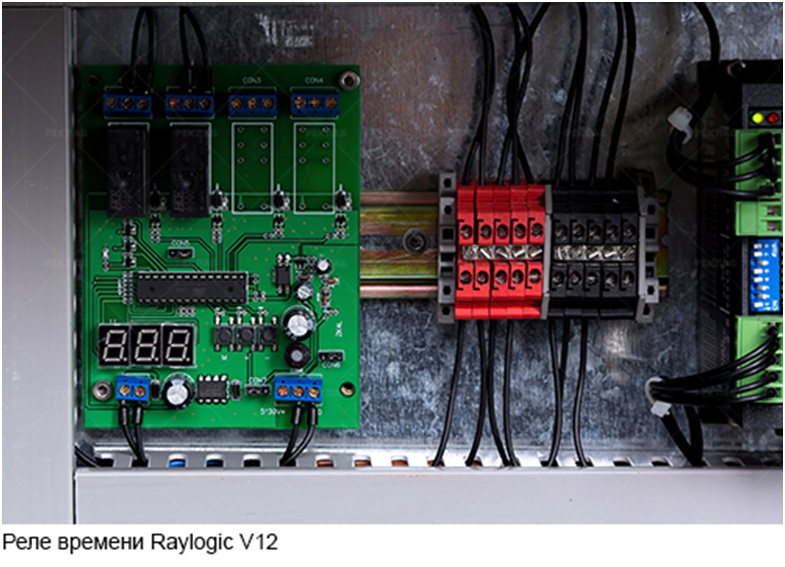

Adjacent to it, the relay of automatic switching of the Y axis to a circular engraving device makes it possible not to think about switching connectors and complex wiring. The hood is turned on when the task is started, and is turned off by timer. This function provides complete removal of combustion products from the workspace.

The laser tube is located on two rubber adjustable supports and easily changes to a more powerful and long.

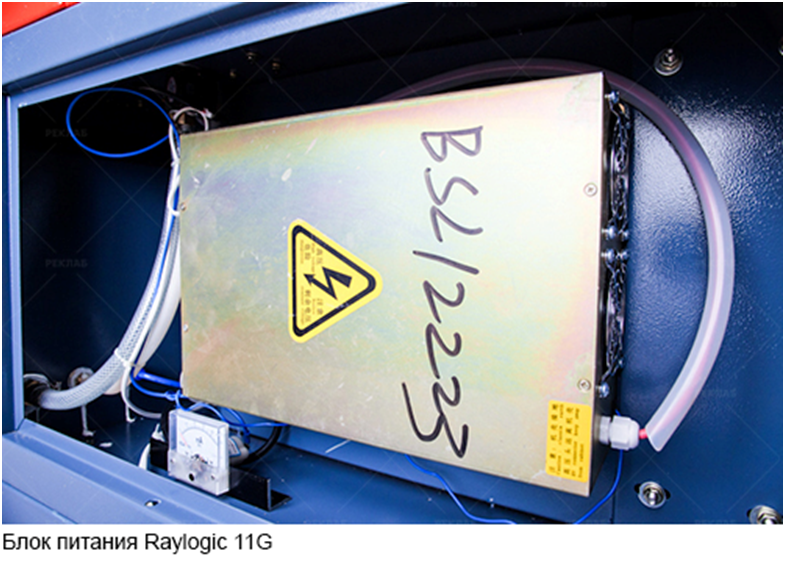

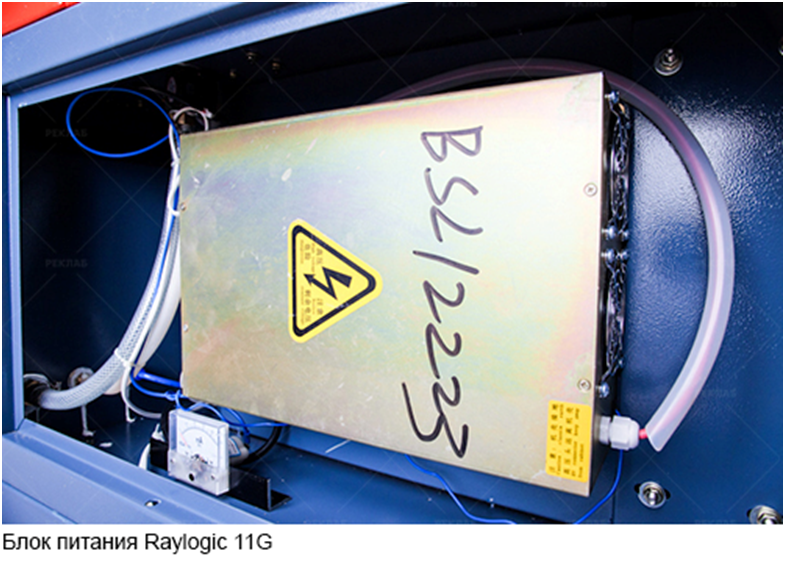

For igniting the laser tube, an Ampetech power supply unit with a long service life, an electronic circuit protected from breakdowns and high-capacity transformers is responsible.

Under the compartment with a tube is a sensor control the flow of coolant.

On the back and front panel you can see a milliammeter, USB ports, Ethernet, power buttons.

The emergency shutdown button is located on the top panel, under the operator’s right hand.

The fixing supports are equipped with non-skid polyurethane washers with cross notch, the threaded places and their fastenings to the stand are boiled with special reinforcements.

On the stands under the machine are powerful wheels with rigid locking fixation. This is done to ensure that during the work the product does not swing, even without twisted support legs.

In our opinion, the manufacturer Raylogic have done significant work to improve their machines. Gathering all the best solutions for constructive machine tools, electronic reliability, and rigidity of the whole structure as a whole.

You can buy Raylogic V12 machines in our company:

Raylogic Laser Machines

General catalog of CNC laser machines

Video about laser machines:

YouTube

With you company 3Dtool . Today we decided to make for you a comparison of the Raylogic 11G and Raylogic V12 laser cutting machines. Well, more specifically, we will tell you about the changes in Raylogic laser machines.

As it turned out, when choosing a laser machine, many do not even suggest what an important role for a long-term resource and stable operation are: machine construction, reliable electronics, assembly culture and rigidity of the whole structure as a whole.

')

On Raylogic V12 series machines, you should immediately pay attention to the increased body weight - it has become 15% more than the previous model.

The stand for the machine is now made of thick steel, with a transverse shelf. This is done for convenient storage of consumables or various tools and devices, and a collapsible design allows you to carry machines into narrow doorways with a width of 70 cm.

Additional stiffness to the body is provided by stiffeners under the thrust bearings of the screws, made of thick steel along the entire height of the working surface.

The working area has a linear rise of the engraving surface, thanks to ball-screw pairs. This increases the productivity, when filling engravable products, defocused radiation.

In Raylogic machines with high precision, you can control the lifting of the table. The rise itself is carried out by stepping motors.

The design of the machine has a broaching window in the back of the machine and a metal removable insert from the front side for the treatment of long materials.

The standard surface of the working surface is equipped with anodized lamellae of complex shape for perfectly clean cutting of both the front and the back of the material. Also optionally you can install a cellular table.

Protection of the lower exhaust window with the help of a pyramidal protective mesh allows you not to block the outflow of smoke drop-down parts.

The upper exhaust window is located above the working area to protect the optics during engraving and minimal cooling of the lens by air flow.

All mechanical components are made of anodized aluminum.

All elements of the X and Y axes are regulated in six planes, the Z axis in three planes.

Nozzles are easy to change for the desired material without any problems, and without replacing the optics inside.

The entire working area is illuminated by a bright waterproof diode backlight.

Raylogic V12 laser machines are equipped with Leadshine smooth three-phase stepping motors with a rotor angle of 1.2 degrees per step. The drive data is time-tested, they provide step-division accuracy and long-term operational reliability.

The installed shafts along the Y-axis are shortened and connected by elastic plate-type couplings of directional bending to damp any oscillations. The seat of the gearbox is reinforced with a metal insert.

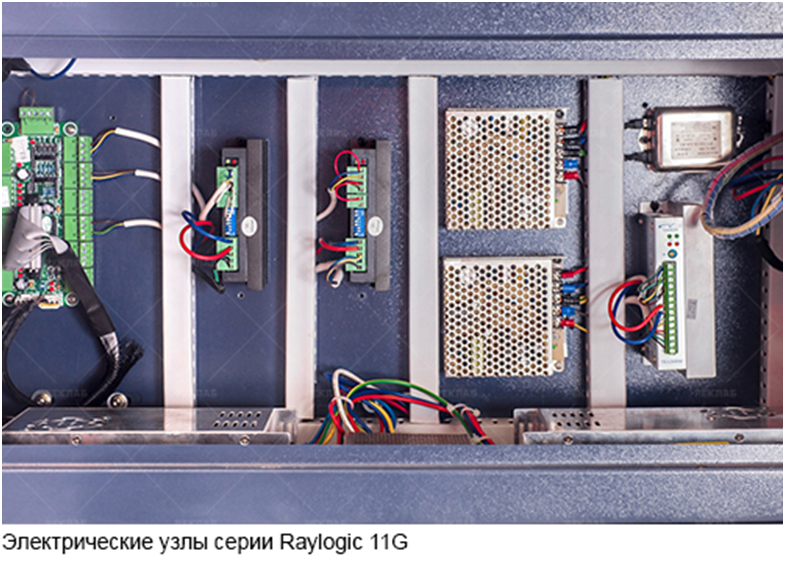

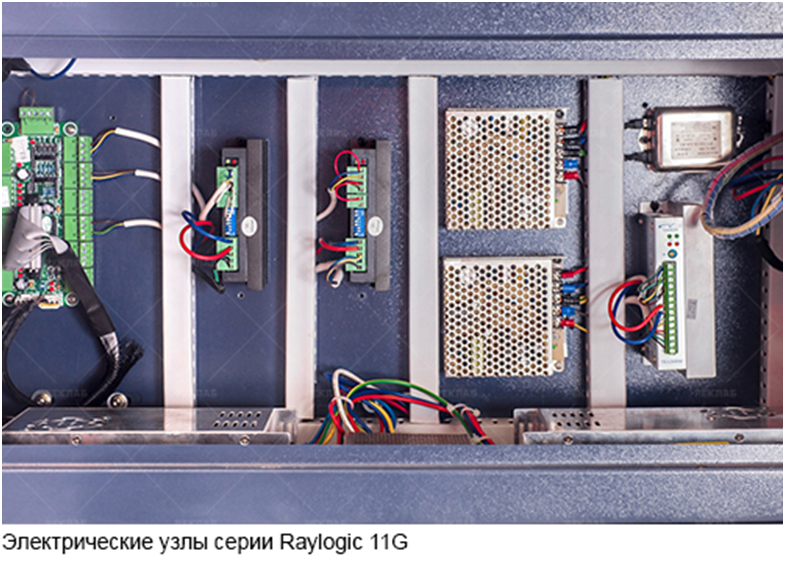

The machine is controlled by Ruida based on Linux OS with Russian Rdworks for Windows software and convenient CorelDraw plugin.

Not unimportant role in the moving parts of laser machines Raylogic V12, played by German electric cables Helukabel. They are located in special cable channels connected to stepper motors and all electronics.

Reliability and quality of electronics assembly provide components of the French company Shneider.

Accurate positioning for repetition is accomplished by Omron's non-contact end sensors.

Adjacent to it, the relay of automatic switching of the Y axis to a circular engraving device makes it possible not to think about switching connectors and complex wiring. The hood is turned on when the task is started, and is turned off by timer. This function provides complete removal of combustion products from the workspace.

The laser tube is located on two rubber adjustable supports and easily changes to a more powerful and long.

For igniting the laser tube, an Ampetech power supply unit with a long service life, an electronic circuit protected from breakdowns and high-capacity transformers is responsible.

Under the compartment with a tube is a sensor control the flow of coolant.

On the back and front panel you can see a milliammeter, USB ports, Ethernet, power buttons.

The emergency shutdown button is located on the top panel, under the operator’s right hand.

The fixing supports are equipped with non-skid polyurethane washers with cross notch, the threaded places and their fastenings to the stand are boiled with special reinforcements.

On the stands under the machine are powerful wheels with rigid locking fixation. This is done to ensure that during the work the product does not swing, even without twisted support legs.

In our opinion, the manufacturer Raylogic have done significant work to improve their machines. Gathering all the best solutions for constructive machine tools, electronic reliability, and rigidity of the whole structure as a whole.

You can buy Raylogic V12 machines in our company:

Raylogic Laser Machines

General catalog of CNC laser machines

Video about laser machines:

YouTube

Source: https://habr.com/ru/post/420475/

All Articles