How to choose a 3D printer: a guide for beginners

The author of this post saw the first 3D model printed on a printer about 10 years ago. There was a meeting in a huge Russian advertising agency that used the possibilities of 3D printing to print demonstrations of a very expensive souvenir - it was to be made of copper, bronze, silver and very small pieces of gold. With the commercial director of the company at that time, we turned up in the hands of future figurines and badges of brown-gray-blue plastic, with inaccurate burrs, “failures”, etc. It seemed to us the eighth wonder of the world - and when we were given mockups for good, we were happy as children and joked in the car that it would be cool to print pancakes, cakes and sausage on the printer. We have never been so close to predicting the future.

When the owner bought a 3D printer, and you understood what hopelessness looks like

Today, 3D printers have become so affordable that almost everyone can buy their own just for fun (and buys - we at Gearbest know no one about this), for example, to print Christmas snowflakes or toys with a child, to make a model for work, an airplane for a hobby or items for some incredible DIY. Moreover, often a 3D printer takes its place of honor next to a long-standing home printer and the owner sometimes conscientiously thinks of finally printing something. Well, at least the Eiffel Tower and the Arc de Triomphe for the little sister, fascinated by the French language.

This popularity is not surprising - 3D-printers appear almost every week: affordable, with excellent consumables, multifunctional. And this trend will lead to one thing: printers will settle at home with everyone as a working tool, assistant, toy, training complex.

')

We are looking forward to a new generation of 3D printers

Although the article is for beginners, there is no escaping the terms - a long way begins with the first step. Therefore, first of all, you need to ask what kind of printing technology a 3D printer has. Most consumer-grade printers use technology called Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), or Plastic Jet Printing (PJP). The printing technology is simple and clear: layers of plastic (rarely another material) overlap and form the shape that you modeled. That is, the product seems to be made up of a set of horizontal sections formed from plastic, which is extruded from a hot nozzle (plastic thread melts) and immediately after extrusion freezes.

There are also SLA-printers, in which printing occurs due to the fact that the resin interacts with the laser and hardens as the shape is created. Such printers print ultra precise and detailed products.

The main material for amateur-DIY-home printing is colored plastic, which is most often sold in the form of threads on reels (rarely in short lengths). But, as we remember from the school chemistry course, plastic is also different, and each type of material has its own properties of strength, brittleness, transparency, plasticity, etc. Most often the material is called ABS-thread or PLA-thread. And these are not just abbreviations.

ABS plastic is quite impact resistant and durable, does not break on the folds. It is named after the first letters of the components: acrylonitrile (up to 35%), butadiene (up to 30%), styrene (up to 60%). It is a non-toxic and safe material that you can work with in the presence of children. However, in the open sun and frost, plastic may lose its appearance.

PLA (polylactide) is an extremely thermoplastic polyester that is more brittle and less “durable” than ABS. Absolutely environmentally friendly and biodegradable. PLA plastic is made from corn or sugar cane. This type of plastic keeps its shape and has good friction, so if you are collecting something from moving parts, look at the PLA.

If you divide it quite roughly, then the ABS is more for professionals, and PLA - for beginners.

The thickness of the layer is 50, 100 and 200 microns - the difference, of course, is

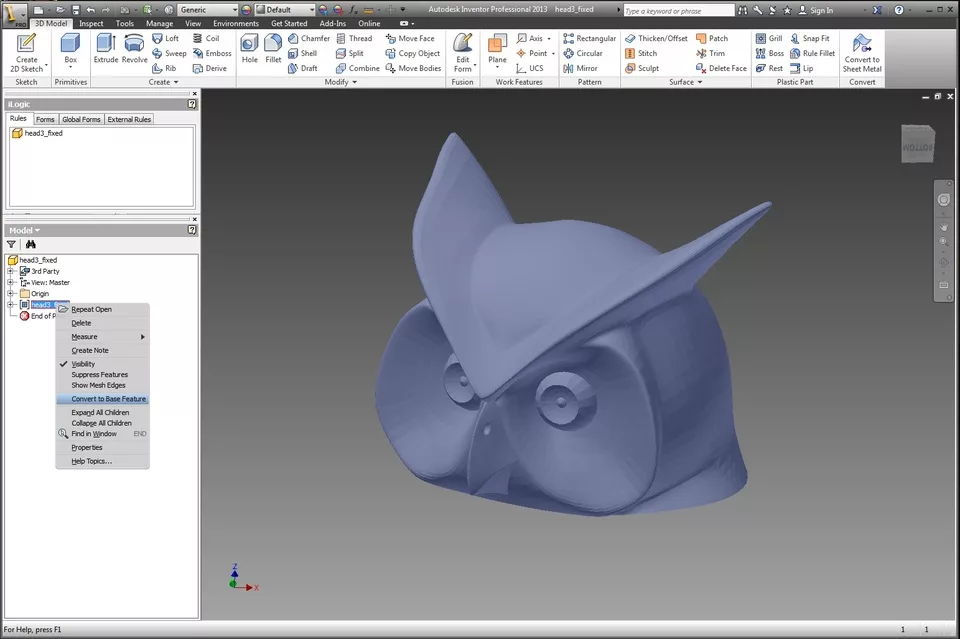

Autodesk Inventors Fusion

Well, separately it is necessary to say about the delivery model, with which you will certainly meet even in this article - the concept of “Kit”. Kit differs from Assembled in that the user must assemble the device independently (DIY). There are many advantages: the main thing is the pleasure of assembly and the opportunity to examine the printer to the screw, the second is a noticeably reduced price due to compact delivery, also due to the fact that the manufacturer did not have to assemble and calibrate your 3D machine.

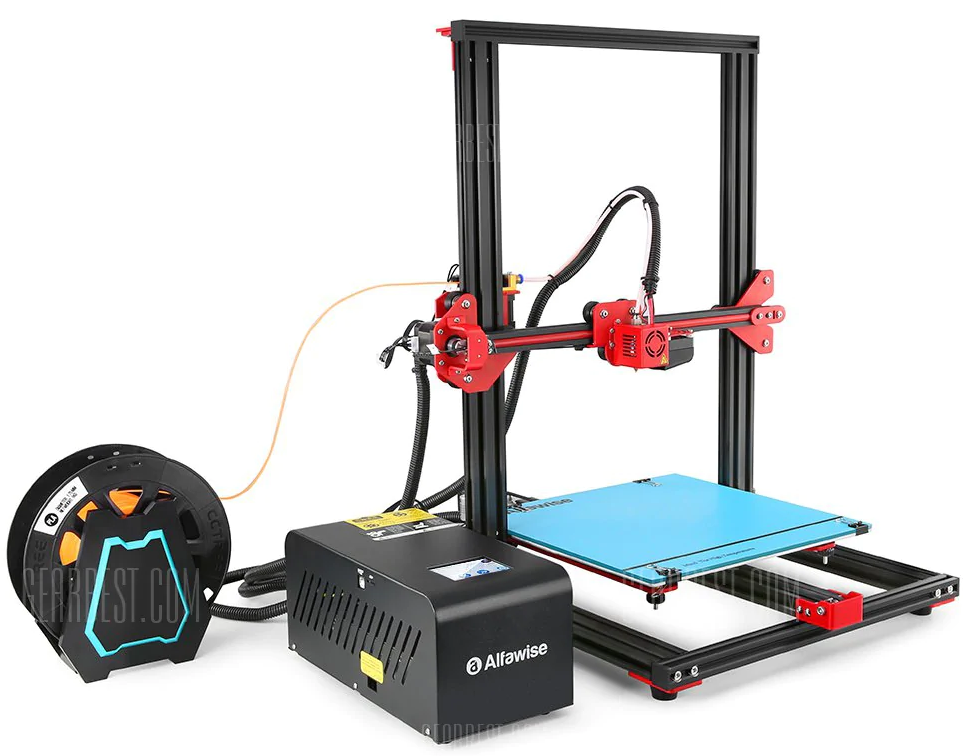

Alfawise U20 can be called a strong printer for beginners - on the one hand, it is simple and affordable ($ 299.99, and with a GBAlfawiseU20 $ 279.99 coupon - only 50 coupons), on the other - it has everything to make it almost professional. What we get from this model: a working area of 300 x 300 x 400 mm (this is enough for most amateur requests and for part of engineering), a solid aluminum frame, an extruder with a single nozzle of 0.4 mm and the ability to heat up to 250 degrees (and this choice of material!), support for a memory card, convenient LCD-screen, print speed from 20 to 150 mm / s, support for ABS, PLA, TPU (wear-resistant flexible material based on polyurethane). The printer weighs 12 kg, takes place on the table. And yes, this is the same DIY Kit, that is, you have to assemble the car yourself (not without pleasure!).

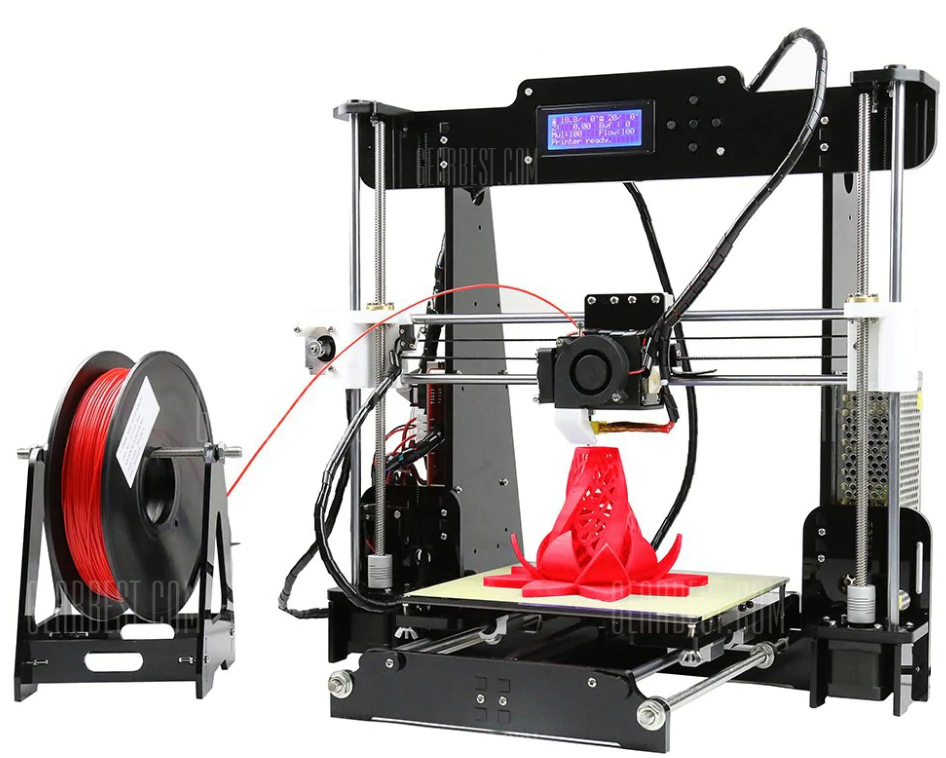

Another model that has literally become a classic for the beginner in the field of 3D printing is the Anet A8 printer (priced at $ 145.99). It is a proven by many users experience printer, reliable as a Kalashnikov and just as simple. What we have: a working volume of 220 x 220 x 240 mm (this is not very much), support for a pile of materials, including "wood", nylon and luminous threads, support for SD cards, print speed of 100 mm / s and a very modest, but informative LCD -display. Good sweet Anet because you can find almost any information and any user experience. The popularity of the model plays into its hands (or whatever it is ...).

For comparison, we give an expensive 3D printer - Creality3D CR-X , it is now pre-order for $ 789.99. And it really differs from the listed models. First of all, this is a large working space of 300 x 300 x 400 mm, resolution 50-400 microns, 4.3 'touchscreen. Well, the main feature is the support of printing in two colors due to a double extruder and work with PETG - with impact-resistant material with virtually no odor and no shrinkage. The printer comes with a set of tools, has a siliconized working platform (the chances of getting burns are almost zero) and a dual cooling system. As you can see, the difference is obvious.

By the way, in the 3D world I exist the MFP, as well as in the world of printing printers. Typically, 3D MFPs include cameras for remote monitoring of the print, conventional printers, scanners, and more.

You can buy an extra mobile phone “to see what the shell is”, a couple of external disks, headphones out of curiosity, and even a second DVR, but to buy a 3D printer from the bay is a dubious story: it's big, it takes a lot of space, it costs normal money and in general requires a responsible approach and the realization that it will need kilometers of consumables (fortunately, mostly inexpensive). It's almost like with a cat - you take it once and for all. But not because it is difficult to resell in case of anything, but because you are seething with your soul.

Your house will be filled with cute and funny figures.

Your house will be filled with cute and funny figures.

So, what you need to decide.

For example, there is a very nice model Alfawise X6A . Firstly, it is stylish and looks somewhat better than the usual "skeletons", and secondly, it has a very compact work area - 220 x 220 x 220 mm. At the same time, it is open for any experiments and supports ABS, HIPS, PC, PLA, PVC, Wood materials, has a print speed of 20 to 150 mm, a good print resolution of 0.06 to 0.4 mm, supports SD and USB, is equipped with excellent working display. And at the same time its overall dimensions are 41.5 x 40.8 x 44.5 cm - that is, it just takes an angle on the desktop. This is a really compact home model. And it costs only $ 289.99 (with coupon GBX6A - $ 285.99).

For the first level user of a 3D printer, this information will be truly useful, much more useful than numerous videos with the “magic” of printing. The fact is that the printer itself is just a tool and the main magic you create - with your imagination, skill, taste. But that process is exciting is a fact. Even if the model from the Internet, even if the material is the most inexpensive, and the printer is not fancy. Because the nature of creatine creates miracles with each of us.

If you have special tips that can supplement the article, please write in the comments - as Habr's experience shows, comments often give +500 to the usefulness of the publication. Let's understand the wilds of 3D printing together!

A few more models that we really like:

When the owner bought a 3D printer, and you understood what hopelessness looks like

Today, 3D printers have become so affordable that almost everyone can buy their own just for fun (and buys - we at Gearbest know no one about this), for example, to print Christmas snowflakes or toys with a child, to make a model for work, an airplane for a hobby or items for some incredible DIY. Moreover, often a 3D printer takes its place of honor next to a long-standing home printer and the owner sometimes conscientiously thinks of finally printing something. Well, at least the Eiffel Tower and the Arc de Triomphe for the little sister, fascinated by the French language.

This popularity is not surprising - 3D-printers appear almost every week: affordable, with excellent consumables, multifunctional. And this trend will lead to one thing: printers will settle at home with everyone as a working tool, assistant, toy, training complex.

')

We are looking forward to a new generation of 3D printers

The theory that is needed to understand what it is, your 3D printer

Although the article is for beginners, there is no escaping the terms - a long way begins with the first step. Therefore, first of all, you need to ask what kind of printing technology a 3D printer has. Most consumer-grade printers use technology called Fused Deposition Modeling (FDM), or Fused Filament Fabrication (FFF), or Plastic Jet Printing (PJP). The printing technology is simple and clear: layers of plastic (rarely another material) overlap and form the shape that you modeled. That is, the product seems to be made up of a set of horizontal sections formed from plastic, which is extruded from a hot nozzle (plastic thread melts) and immediately after extrusion freezes.

There are also SLA-printers, in which printing occurs due to the fact that the resin interacts with the laser and hardens as the shape is created. Such printers print ultra precise and detailed products.

The main material for amateur-DIY-home printing is colored plastic, which is most often sold in the form of threads on reels (rarely in short lengths). But, as we remember from the school chemistry course, plastic is also different, and each type of material has its own properties of strength, brittleness, transparency, plasticity, etc. Most often the material is called ABS-thread or PLA-thread. And these are not just abbreviations.

ABS plastic is quite impact resistant and durable, does not break on the folds. It is named after the first letters of the components: acrylonitrile (up to 35%), butadiene (up to 30%), styrene (up to 60%). It is a non-toxic and safe material that you can work with in the presence of children. However, in the open sun and frost, plastic may lose its appearance.

PLA (polylactide) is an extremely thermoplastic polyester that is more brittle and less “durable” than ABS. Absolutely environmentally friendly and biodegradable. PLA plastic is made from corn or sugar cane. This type of plastic keeps its shape and has good friction, so if you are collecting something from moving parts, look at the PLA.

If you divide it quite roughly, then the ABS is more for professionals, and PLA - for beginners.

What other materials are there?When choosing materials, pay attention to the coil size and thread diameter - they must meet the specifications of your printer.

- Stainless steel - an alloy of stainless steel and bronze. Very cool stuff, but not used in amateur 3D printers.

- Wood is a mixture of recycled wood and polymer. Products from a good, expensive thread of such a plan look like wood and are pleasant in their hands. Printing such a thread is no more difficult than others.

- Resin - expensive material with a high degree of smoothness, accuracy, excellent texture. Products may become cloudy from sunlight.

- Nylon is a popular material for 3D printing, but is more commonly used in industry and medicine.

- The print area - in simple terms, the size of the shape that can be printed on a 3D printer. This value is usually indicated in cubic centimeters or in the ratio of depth, height and width in mm.

- Print speed is an important parameter that determines how quickly the nozzle releases the melted filament (mm per second). A good speed is not always worth enjoying - sometimes it goes to the detriment of print resolution. Also, the print material and the structure of the model you are trying to make affects the speed.

- The resolution of the layer - in fact, the thickness of the layer: high resolution - thin layers, almost imperceptible relief, smooth product; low resolution - rough work with thicker layers. Often, 3D printers provide the user with the option to select a resolution.

The thickness of the layer is 50, 100 and 200 microns - the difference, of course, is

- The extruder is the part of the printer that warms up and gives away the material. The material melts in the nozzle and is extruded from it (fed to the seal). In addition to the nozzle, the extruder includes a filing mechanism, a temperature sensor and a cooling system (in normal models). If the printer has one extruder, then printing is pretty monotonous — one color at a time. But two or more extruders allow you to combine colors and materials. Printers with a double nozzle on one extruder are rare, expensive - at home this is an excess opportunity.

During extrusion, the thermoplastic filament is extruded in the form of a molten material and this same material is deposited along the X and Y coordinates, and the object itself is “formed” along the Z coordinate (hence the 3D printing).

- Memory device support — printers can support memory cards, USB, smartphones, Wi-Fi devices, etc. An external PC for 3D printing is not always needed.

- Software for a 3D printer usually comes with the hardware itself. Its main task is to be able to open and process STL files (used for printing models and transferring some parameters). But do not forget that for 3D-modeling you need specialized software such as Sketchup, Autodesk Inventors Fusion, etc. It is these programs that will help you design the model and generate the STL file.

Autodesk Inventors Fusion

- Options - beautiful display, function buttons, material recognition, etc. - this is a matter of taste and convenience, which, however, affects the price.

Well, separately it is necessary to say about the delivery model, with which you will certainly meet even in this article - the concept of “Kit”. Kit differs from Assembled in that the user must assemble the device independently (DIY). There are many advantages: the main thing is the pleasure of assembly and the opportunity to examine the printer to the screw, the second is a noticeably reduced price due to compact delivery, also due to the fact that the manufacturer did not have to assemble and calibrate your 3D machine.

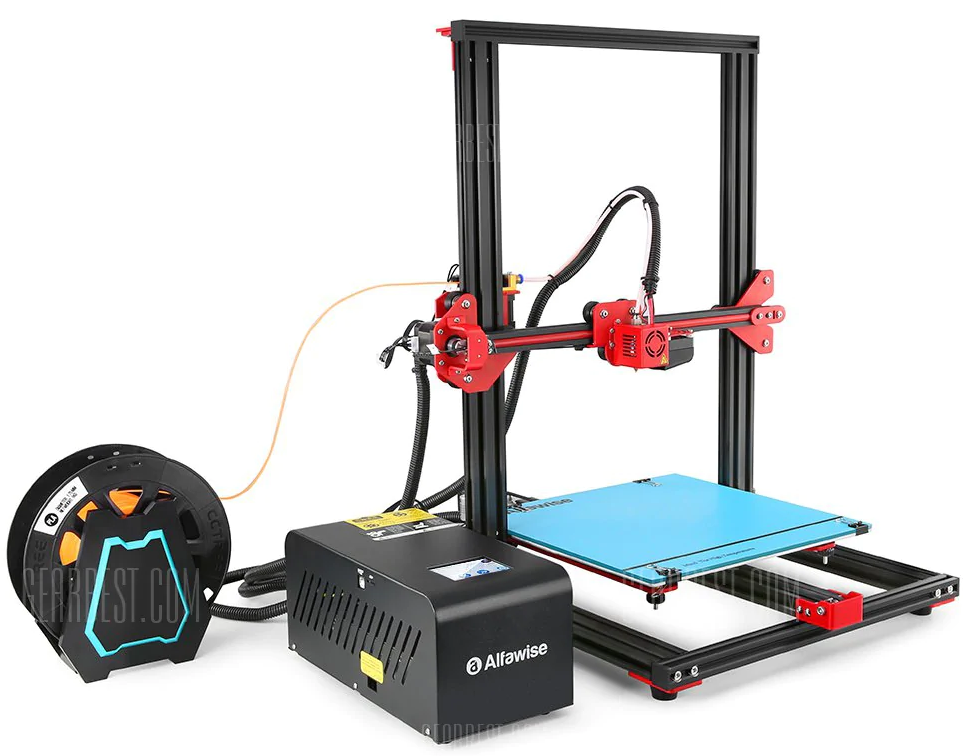

Alfawise U20 can be called a strong printer for beginners - on the one hand, it is simple and affordable ($ 299.99, and with a GBAlfawiseU20 $ 279.99 coupon - only 50 coupons), on the other - it has everything to make it almost professional. What we get from this model: a working area of 300 x 300 x 400 mm (this is enough for most amateur requests and for part of engineering), a solid aluminum frame, an extruder with a single nozzle of 0.4 mm and the ability to heat up to 250 degrees (and this choice of material!), support for a memory card, convenient LCD-screen, print speed from 20 to 150 mm / s, support for ABS, PLA, TPU (wear-resistant flexible material based on polyurethane). The printer weighs 12 kg, takes place on the table. And yes, this is the same DIY Kit, that is, you have to assemble the car yourself (not without pleasure!).

Another model that has literally become a classic for the beginner in the field of 3D printing is the Anet A8 printer (priced at $ 145.99). It is a proven by many users experience printer, reliable as a Kalashnikov and just as simple. What we have: a working volume of 220 x 220 x 240 mm (this is not very much), support for a pile of materials, including "wood", nylon and luminous threads, support for SD cards, print speed of 100 mm / s and a very modest, but informative LCD -display. Good sweet Anet because you can find almost any information and any user experience. The popularity of the model plays into its hands (or whatever it is ...).

For comparison, we give an expensive 3D printer - Creality3D CR-X , it is now pre-order for $ 789.99. And it really differs from the listed models. First of all, this is a large working space of 300 x 300 x 400 mm, resolution 50-400 microns, 4.3 'touchscreen. Well, the main feature is the support of printing in two colors due to a double extruder and work with PETG - with impact-resistant material with virtually no odor and no shrinkage. The printer comes with a set of tools, has a siliconized working platform (the chances of getting burns are almost zero) and a dual cooling system. As you can see, the difference is obvious.

By the way, in the 3D world I exist the MFP, as well as in the world of printing printers. Typically, 3D MFPs include cameras for remote monitoring of the print, conventional printers, scanners, and more.

What you need to decide before you order your 3D-printer?

You can buy an extra mobile phone “to see what the shell is”, a couple of external disks, headphones out of curiosity, and even a second DVR, but to buy a 3D printer from the bay is a dubious story: it's big, it takes a lot of space, it costs normal money and in general requires a responsible approach and the realization that it will need kilometers of consumables (fortunately, mostly inexpensive). It's almost like with a cat - you take it once and for all. But not because it is difficult to resell in case of anything, but because you are seething with your soul.

So, what you need to decide.

- Budget. 3D printers cost from $ 150 to several thousand dollars. Accordingly, decide on how much you are willing to spend, how much consumables will have to be purchased. Choose a printer according to your goals, but do not strive to save at any cost - if you decide to approach 3D printing seriously, in an inexpensive model you may not have enough important functions.

- Your projects. What are you going to do? How loaded will your printer be (for example, one thing is rare crafts for school or circles, the other is the production service of hand-made gifts and gizmos for earning)? What materials will you need?

- Required materials and their properties - ask for materials and consumables, make a list and calculate the amount of threads that you need. If your project involves some commercial component, consider the fact that the delivery of materials will take some time. Be sure to check if the selected printer supports the required types of plastic.

- Multi-color printing - if you need several colors, you need a printer with several extruders, and this is another price category.

- Print targets generally determine the size of the printer you need. If you are going to just “play around” or buy a toy for a child, then it is better not to bother and choose a compact printer with a small working volume. It will be quite enough for just for fun.

For example, there is a very nice model Alfawise X6A . Firstly, it is stylish and looks somewhat better than the usual "skeletons", and secondly, it has a very compact work area - 220 x 220 x 220 mm. At the same time, it is open for any experiments and supports ABS, HIPS, PC, PLA, PVC, Wood materials, has a print speed of 20 to 150 mm, a good print resolution of 0.06 to 0.4 mm, supports SD and USB, is equipped with excellent working display. And at the same time its overall dimensions are 41.5 x 40.8 x 44.5 cm - that is, it just takes an angle on the desktop. This is a really compact home model. And it costs only $ 289.99 (with coupon GBX6A - $ 285.99).

- Place for the printer - most often it is a desktop or any stable surface. However, we would recommend not to choose completely closed rooms (if it is an apartment, not a garage). The fact is that working with hot plastic implies a certain smell (intensity depends on the material) and the room must be aired.

- Your experience with 3D printing will determine the time from switching on the network to the first result in your hands (this is an indescribable feeling - to keep the first figure made!). You need to get comfortable with the equipment, with the appropriate software, with memory cards, working with a PC, etc. However, in modern man such tasks are a matter of a very short time.

- Who else will use the 3D printer. If your peer (brother, sister, friend, colleague) joins you, then this is one thing and you can share responsibility for the condition and operation of the printer. If this is your curious teenager, it is better to work with the printer together, and the model to choose more stable and reliable.

- Be prepared to handle models. Alas, there is no perfection in the world (although the TEVO Little Monster Delta 3D Printer DIY Kit seems so to us - just look at this design!) And you will have to work with a file with nail scissors and knives of various stripes to bring the figure to perfection. From finished products often have to remove excess threads, flows, protrusions, etc.

For the first level user of a 3D printer, this information will be truly useful, much more useful than numerous videos with the “magic” of printing. The fact is that the printer itself is just a tool and the main magic you create - with your imagination, skill, taste. But that process is exciting is a fact. Even if the model from the Internet, even if the material is the most inexpensive, and the printer is not fancy. Because the nature of creatine creates miracles with each of us.

If you have special tips that can supplement the article, please write in the comments - as Habr's experience shows, comments often give +500 to the usefulness of the publication. Let's understand the wilds of 3D printing together!

A few more models that we really like:

- Alfawise U20 - $ 299.99 ($ 279.99 with coupon GB- $ 20OFF) - support for many materials of the thread, screen, speed 20 - 150 mm / s.

- Alfawise U10 - $ 439.99 ($ 429.99 with coupon GBU10EU) - large working volume, 4 materials, printing speed 10 -150 mm / s, high accuracy

- Anet E12 - $ 279.99 ($ 269.99 with coupon GBE12) - high resolution, 3 filament materials, print speed of 40-120 mm / s, the same non-killed Anet model, but with a large work area

- Creality3D CR-10 - $ 389.99 - DIY Kit Goes Very Fast, Excellent Print Detailing

- Creality3D CR-10S4 - $ 599.99 ($ 559.99 with coupon CR10S4) - a huge amount of working area (400 x 400 x 400 mm)!

- A very popular printer among our users - now the price is generally a fairy tale - $ 175.99

- Flyingbear Shine Megacool 3D Photopolymer Printer (DLP UV Resin) - a small $ 10 discount is offered on the GBFlyingbear coupon. The total price is $ 569.99 including free shipping (as up to 10 kg). And yes, for a photopolymer printer this is a really low price.

- A small photopolymer kid for beginners - we have prepared a GBSparkMaker coupon for it and the price at a discount on the coupon will be $ 259.99.

- DLP printer - with coupon GBLD001 price $ 569.99.

- Alfawise U10 3D Printer - with a huge print area of 40 x 40 x 50 cm. Now comes with a 25 %% discount, for a total of $ 419.99

Source: https://habr.com/ru/post/420011/

All Articles