Review of a large Hercules Strong 3D printer

Hello! This is the Top 3D Shop and today we will review the updated Hercules Strong 3D printer produced by Imprint from Krasnoyarsk.

Watch the video review on our YouTube channel . For those who prefer printed text with pictures, we suggest reading further - we deciphered and illustrated the review especially for you.

Video

')

Subscribe to our channel not to miss new reviews and fresh releases of our 3D digital production.

About the printer

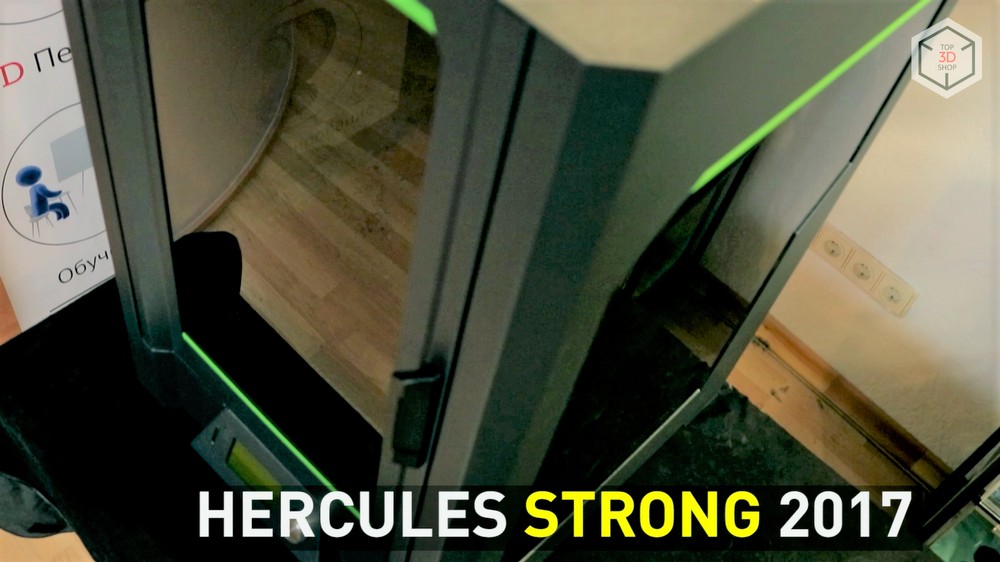

Now "Strong" looks different, comparable to the previous model.

Hercules strong

Specifications

- Printing technology: FDM

- Area of construction, mm: 300x300x400

- Layer thickness, micron, from: 20

- Extruder heating, ° C: 260

- Platform heating, ° C: 120

- Print speed, mm / s: 180

- Platform: glass

- Nozzle, mm: 0.5 complete, from 0.2 to 1.0 optional

- Power consumption, W: 300

- Price, rubles: 180 000

Description

From the simple “Hercules”, the strong version differs primarily in size. The target area of the printer is the printing of large parts, so it has a more enclosed case to ensure the correct temperature when printing. Although large products are usually printed from PLA, the printer has a universal extruder suitable for printing with all main filaments for FDM.

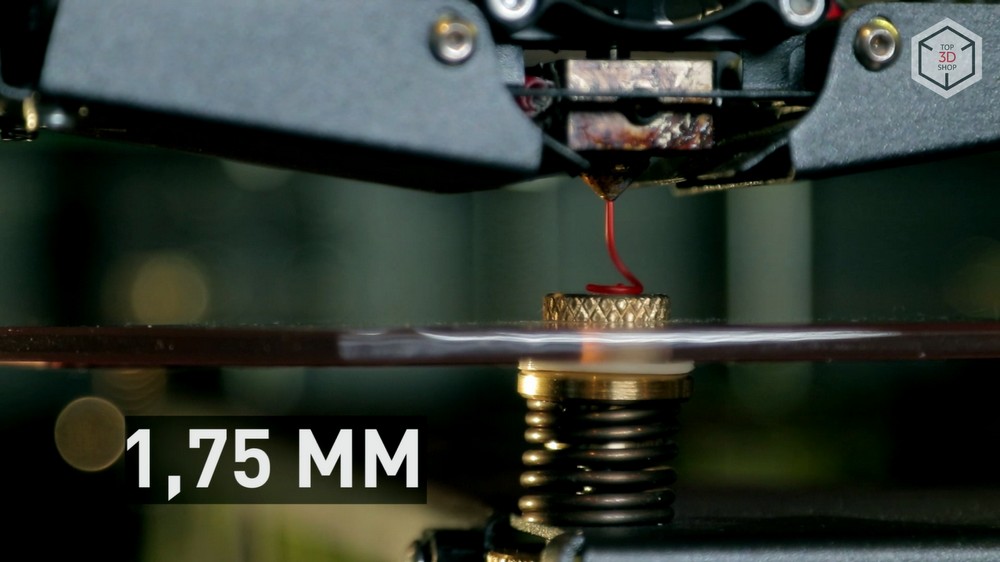

FDM is the most common and affordable 3D printing technology. Hercules Strong prints a standard 1.75 mm plastic filament. Read more about the materials below, in a separate section.

The printer does not have its own brand slicer; instead, the manufacturer recommends using Slik3r or Repetier-host open slicers, but let's talk about this a little later.

Equipment

The printer comes in a wooden box, all moving parts are securely fastened with ties. Consider a complete set of the printer.

The printer comes with a nozzle of 0.5 mm, you can also buy a nozzle with a diameter of 0.2 to 1 mm, depending on your needs.

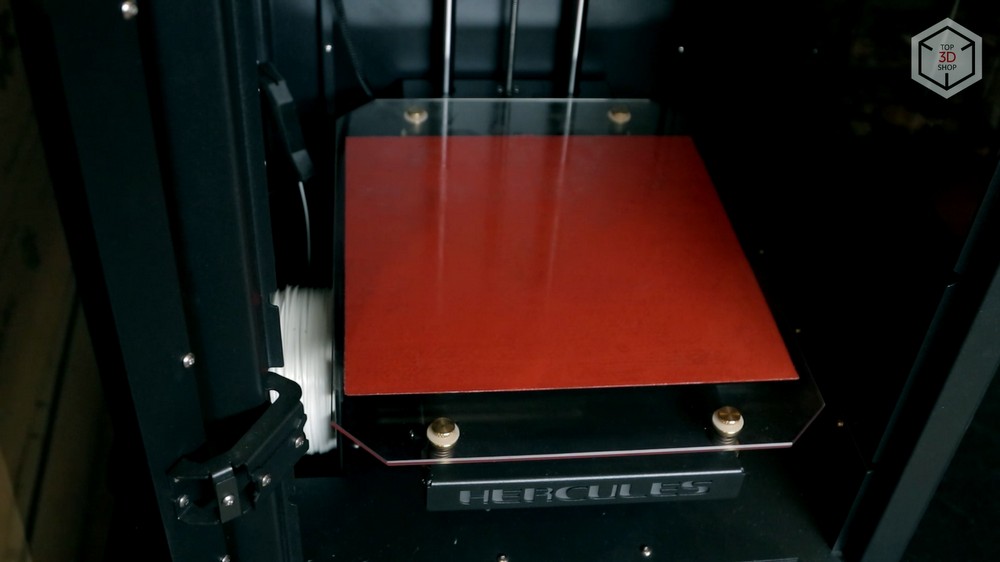

The printer platform is covered with a special film that improves adhesion. If this film is worn, it can be removed and replaced with a new one, or use glue for 3D printing.

The kit includes:

- Nozzle 0.5 mm

- Plastic coil from the manufacturer

- Power cable

- USB cable

- A set of keys for service

- Warranty card, instruction and flash card

- Anti-vibration feet

Printer and mechanics overview

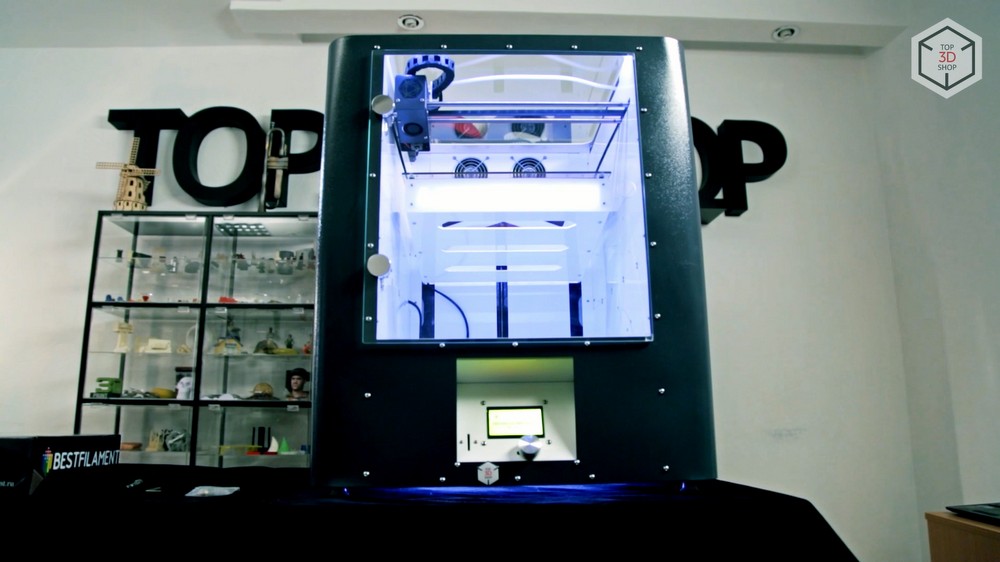

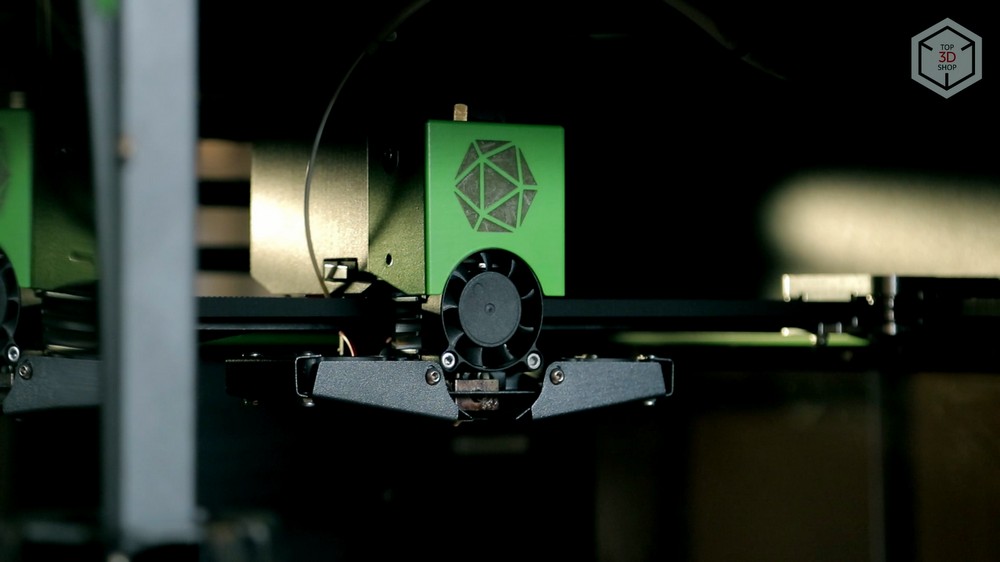

We now turn to the most noticeable difference, this is a new design. No more furniture hinges. The body is made of steel and looks completely different, the glazing is made of translucent plastic.

The top cover can not be removed now, you can watch the print through plastic-lined windows, front and sides. In general, the body is now more similar to the body of a simple "Hercules" and it has become more closed, it has fewer slots and holes, which is good if you are printing not only PLA.

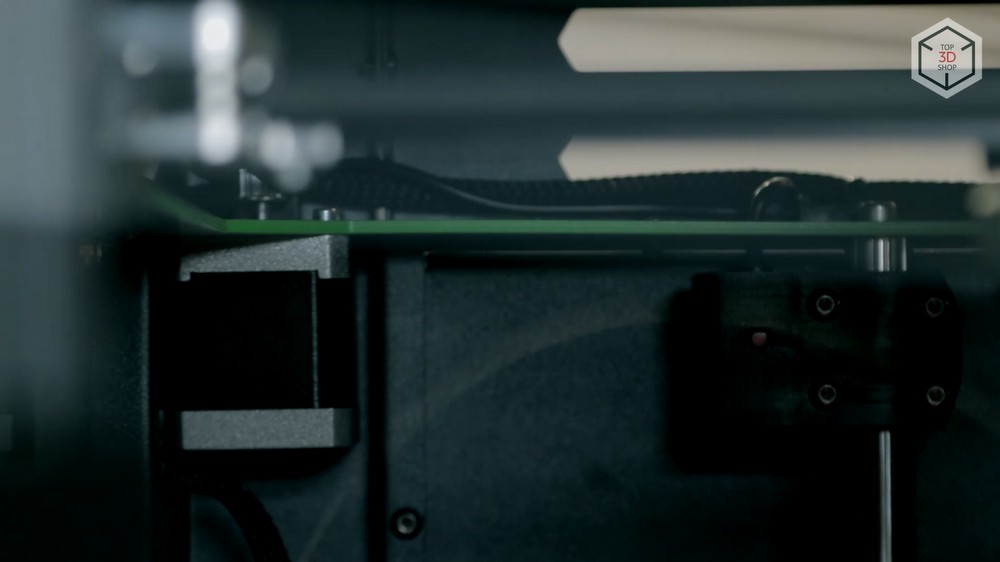

The printer is equipped with kinematics like H-bot, like most other FDM printers. The platform moves with the help of ball screws and a pair of cylindrical guides.

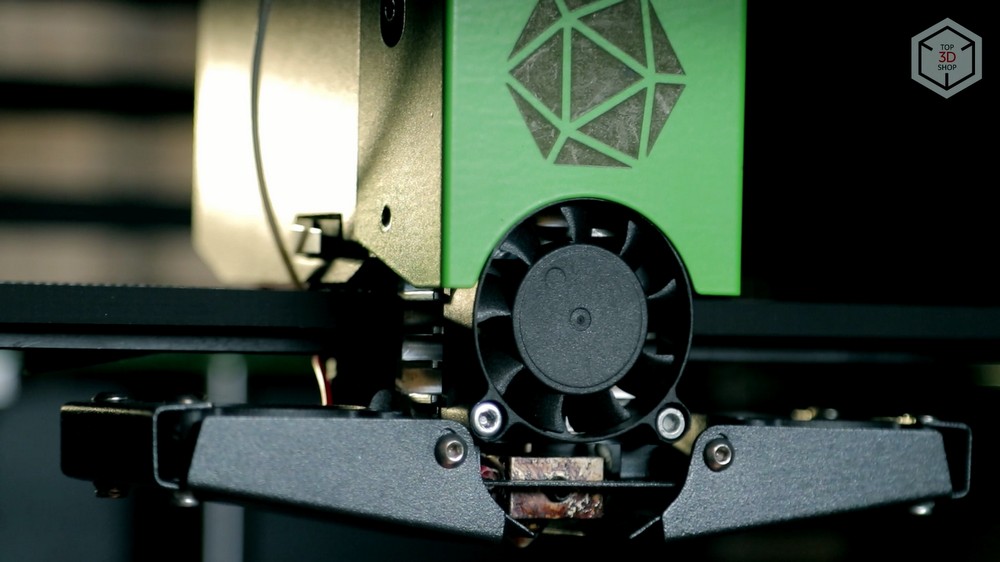

Guides for the remaining axles are rails. Printer mechanics are standard, the extruder is located on the top and moves along the X and Y axes, the platform moves along the Z axis.

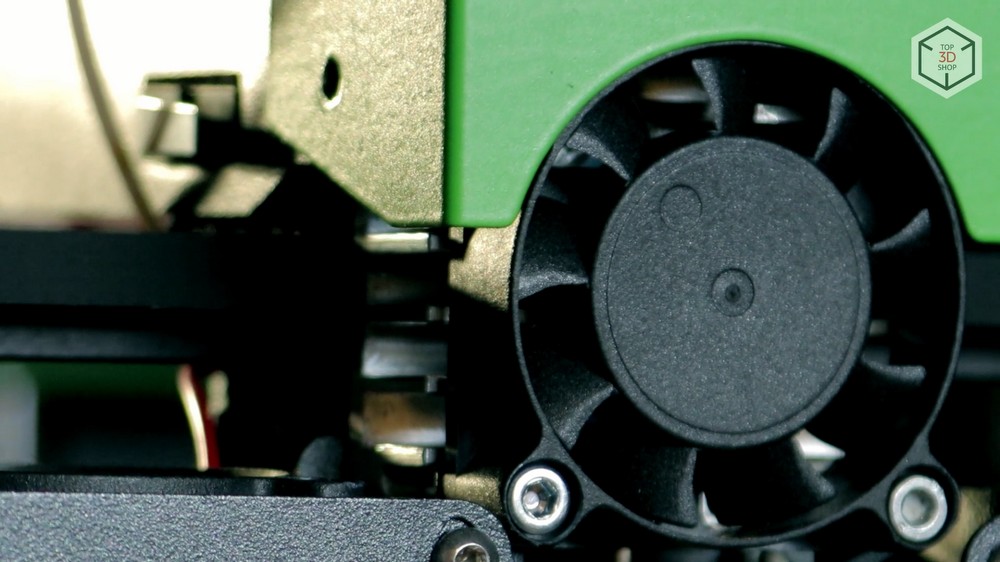

In the back of the case there are two coolers that are responsible for cooling the chamber.

On the extruder coolers are located to cool the plastic during printing. This is the standard layout for closed-case 3D printers.

The coil mount looks quite interesting: the coil is simply placed on two rollers, which removes many restrictions on its size and weight, the main thing is that it should fit in width.

Software Review

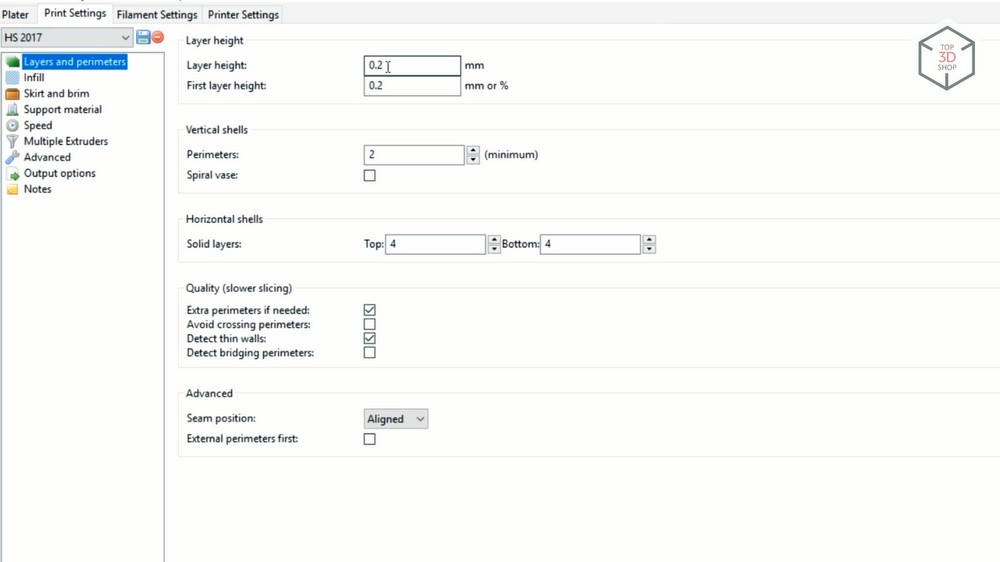

The printer does not have its own slicer, the manufacturer recommends using Slik3r.

You can also use any open slicer that supports profiles, such as CURA or Simplify. We usually use just “simplifay”.

You can find the profile on the Internet, make it yourself (if you have the qualifications) or customize it with the help of a service department.

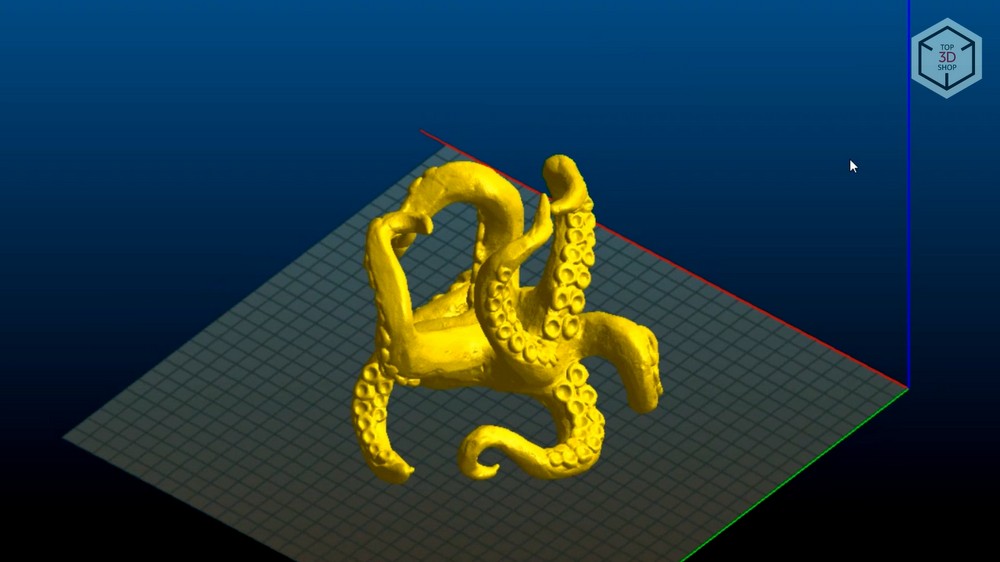

When the slicer is configured, we load the model in STL format, set up parameters such as layer thickness and fill percentage, and launch the model for rendering. When the g-code is ready, we save it to the SD card and carry it to the printer.

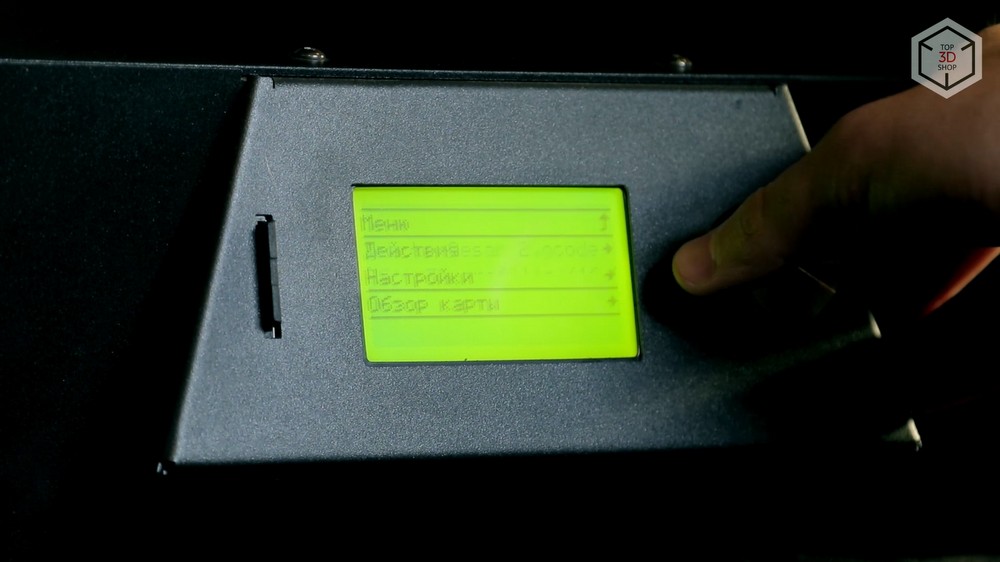

After we cut our model into layers and translate it all into machine code, you can load this code into the printer and start printing.

Most 3D printers can be connected to a computer with a USB cable and can start printing from a computer, but it is not recommended to do so, because any hanging is fraught with stopping printing and defective. It is better to always start printing from the media or from the internal memory of the printer.

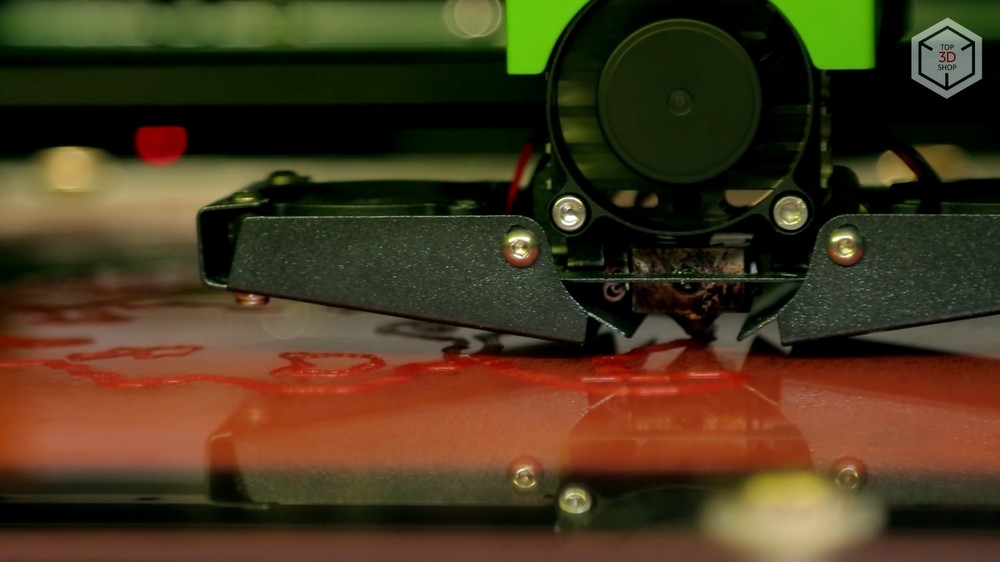

Before printing, we cover the platform with a special 3D glue. This is an adhesive for adhesion (sticking) of the first layer of the model to the platform.

Spraying the glue inside the printer is strictly prohibited, because it polymerizes on the elements of kinematics and this can lead to malfunctions. It is necessary to sprinkle glue on a napkin or cloth and spread the table.

You can also use a special glue stick or plastic solution in a solvent, but the latter option is better not to apply on platforms with a special coating.

The mechanics of the printer allows you to print with a thickness of from 20 to 800 microns. It must be remembered that if you print something large, with a layer thickness of 50 microns and a nozzle with a diameter of 0.3 mm, then you will have hundreds of hours to print. Larger parts are better to print with a larger diameter nozzle, which saves time.

The printer has a housing that is closed on all sides, which, together with a heated platform, allows printing with shrinkable plastic materials, such as ABS. Unlike the previous version of the printer, it is not possible to lift the top glass here, for better cooling when printing a PLA. Now the printer has a closed top case. You can open the door, or leave the task of cooling exhaust system.

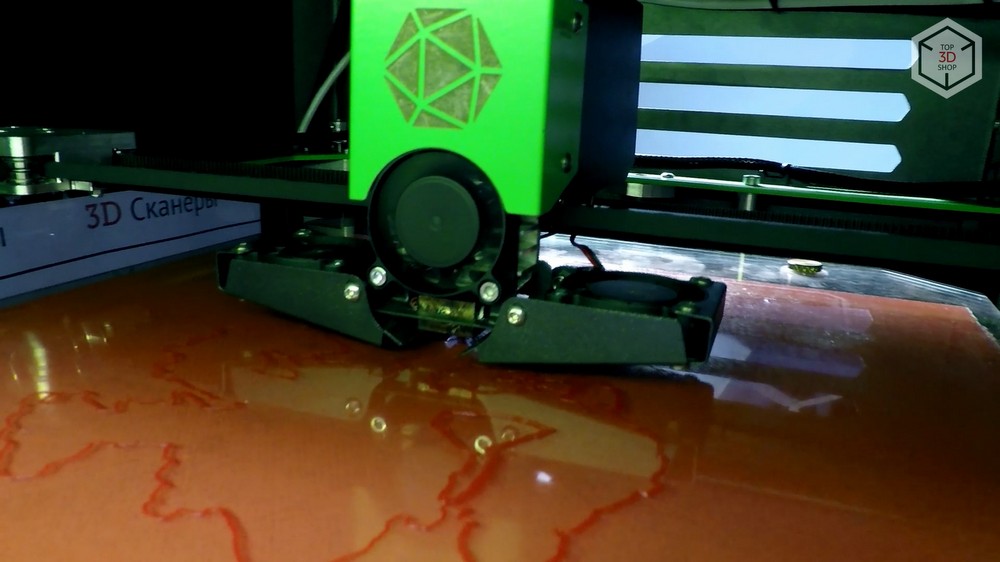

One of the characteristic features of Hercules Strong is the large print area, which is 300x300x400 mm, which is significantly larger than that of most FDM printers. The printer thread uses a standard diameter of 1.75 mm.

Here is our model and ready. When printing PLA, it sticks quite strongly to the table, you should wait until the platform has completely cooled down and removed it manually. ABS models usually bounce off the table after it cools down to 40 degrees.

The manufacturer does not recommend using a spatula to remove the model.

Materials

There are many types of filaments that can be printed on Hercules Strong. These are ABS, made from petroleum products and widely used in industry, PLA bioplastic, FLEX and RUBBER rubber-like, and exotic composite plastics such as LAYWOOD (with wood) and BRONSEFILL (with metal particles).

In fact, the printer supports printing by the vast majority of filaments. More precisely: by all, for which its temperature conditions are suitable.

The easiest way, of course, is to type PLA. If you need to create something big, then this is your choice. ABS is more suitable for small functional parts. Also, the printer prints very well with flexible materials such as FLEX and RUBBER. For composite plastics, it is better to take a larger nozzle.

Advantages and disadvantages

Pros:

- Large print area

- High stability

- Durable and resistant steel case

- The thought-over cooling system of the printer

- Ability to work with most publicly available materials

Minuses:

- Compared with the previous model, the view is degraded, the non-removable opaque top cover

- Large and heavy printer, can be installed not in any workplace

- Lack of own proprietary slicer

Conclusion

According to the results of the test print, we can say that Hercules Strong is a very vigorous and high-quality printer designed for stable printing of large products. The stability of the work is confirmed by the manufacturer’s tests and is declared as at least 150 hours of continuous printing without interruptions, which is facilitated by the air circulation system in the printer chamber. In addition, the new Strong is noticeably prettier in appearance.

We can recommend Hercules Strong to work in architectural prototyping, prototyping technological products and art objects, for printing finished products to order.

To purchase Hercules Strong, make an order online. If you have any questions, please contact us by phone 8 (499) 322-23-19 or e-mail sales@top3dshop.ru , we will give an exhaustive consultation and select a 3D printer for your goals and objectives.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/419497/

All Articles