CNC machines that are worth paying attention from the company 3Dtool

Hello everyone, with you 3DTool . The search for a milling machine with CNC, which could solve all the tasks before production, is a rather complicated process that takes a lot of time.

We will help you to make your choice easier by talking about 5 CNC milling machines that you should pay attention to.

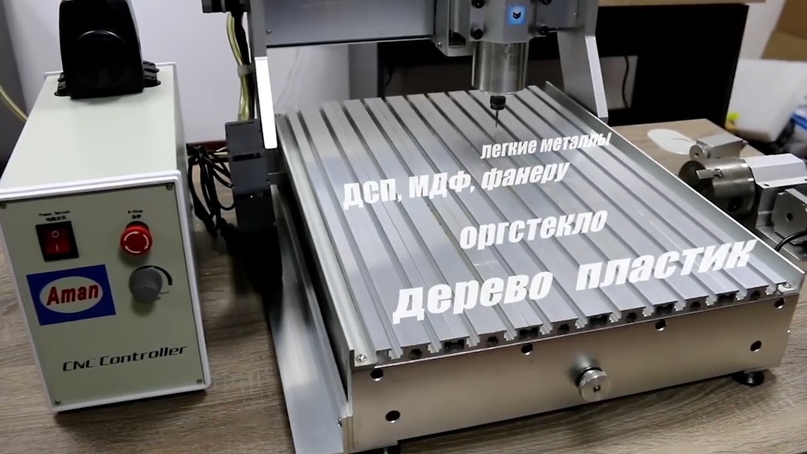

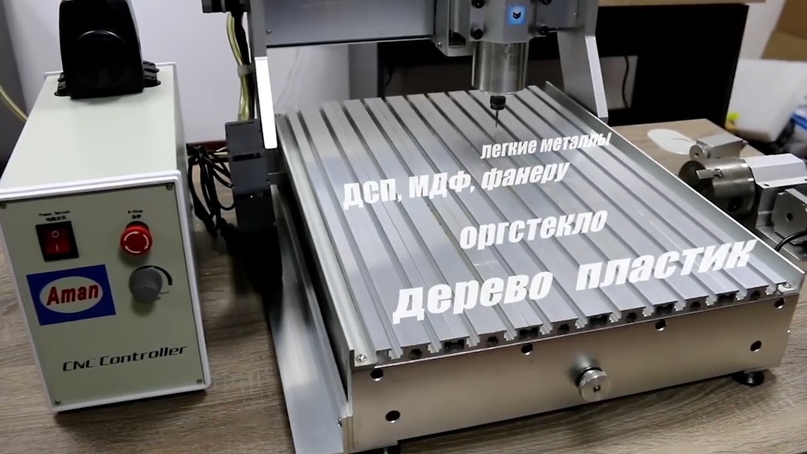

3D CNC milling machine AMAN 3040

')

This machine is used in the production of plates, promotional items, art and craft items, souvenirs and much more of wood and plastic. The rigidity and power of this machine will be enough for processing soft metals, such as aluminum, copper.

The working area is 30 by 40 cm along the X, Y axes. Z axis - 80 mm (optional up to 130 mm)

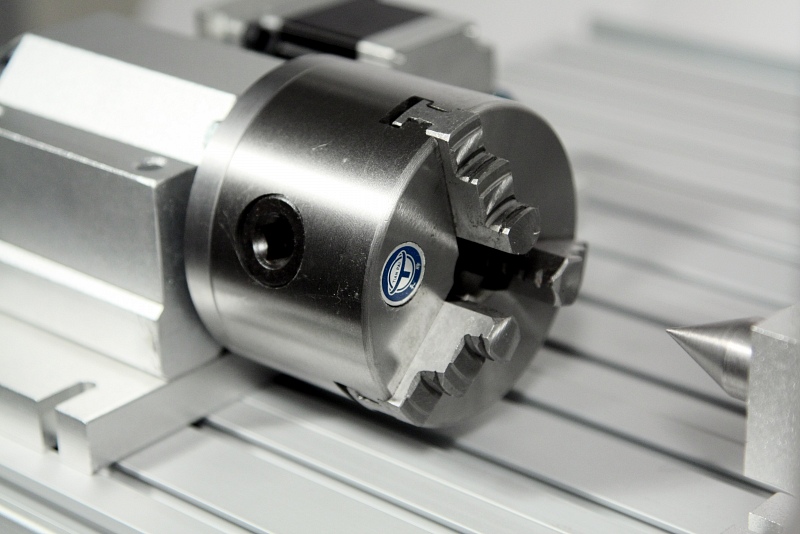

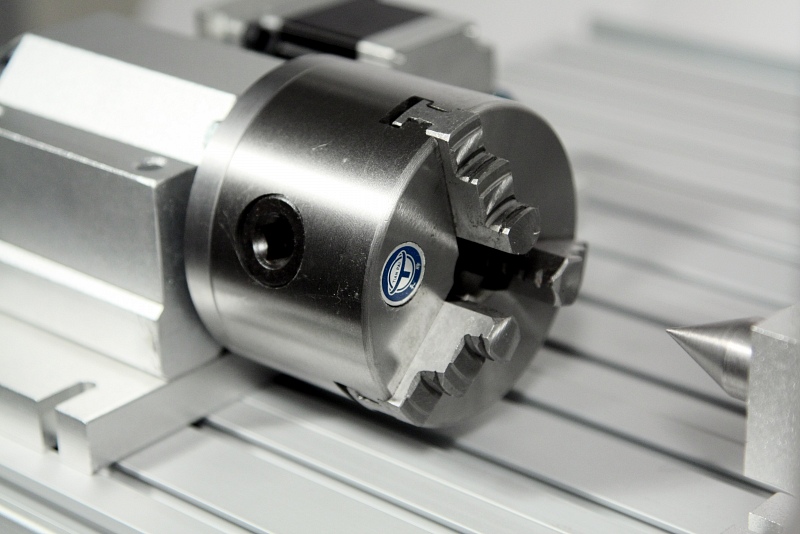

The set comes with a turning device for processing parts around the circumference, the so-called 3D processing.

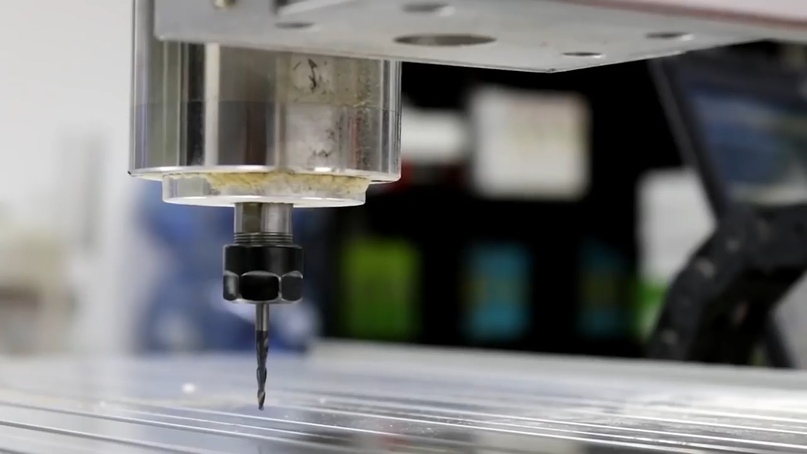

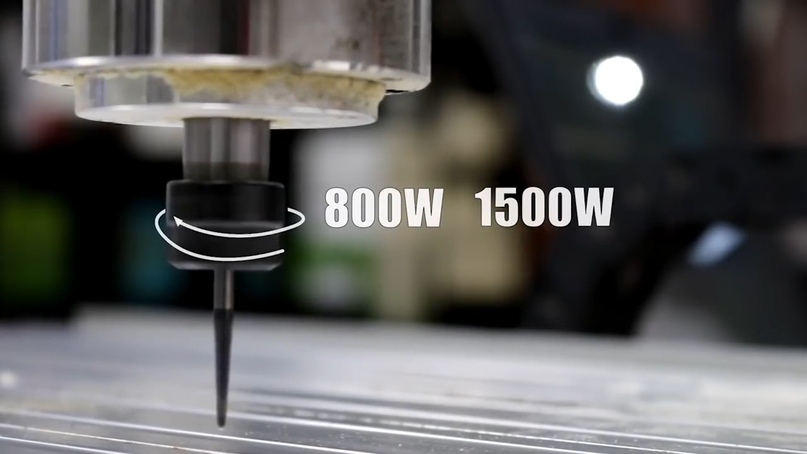

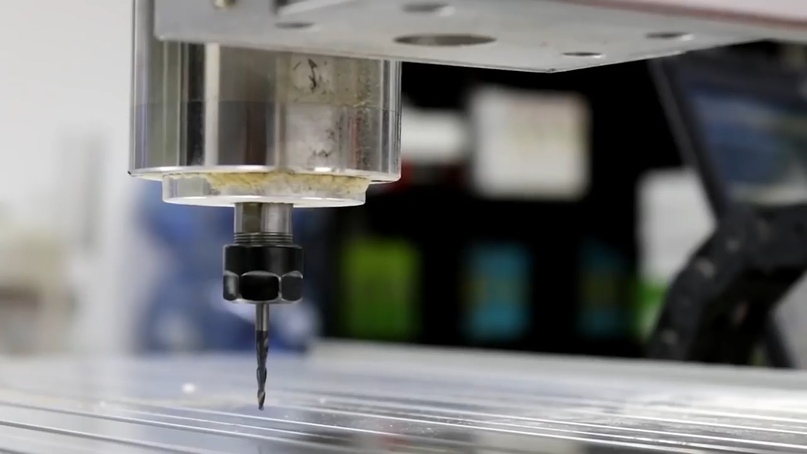

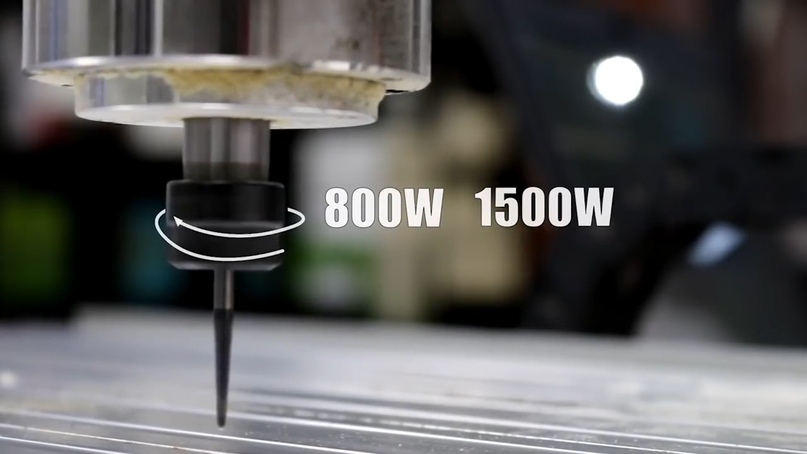

The machines come with various spindle modifications: the 500W motor is equipped with air cooling. The 800 and 1500 W spindles are water-cooled, ensuring quiet operation and long service life. The spindle is equipped with ER11 collet. Spindle speed up to 24000 rpm

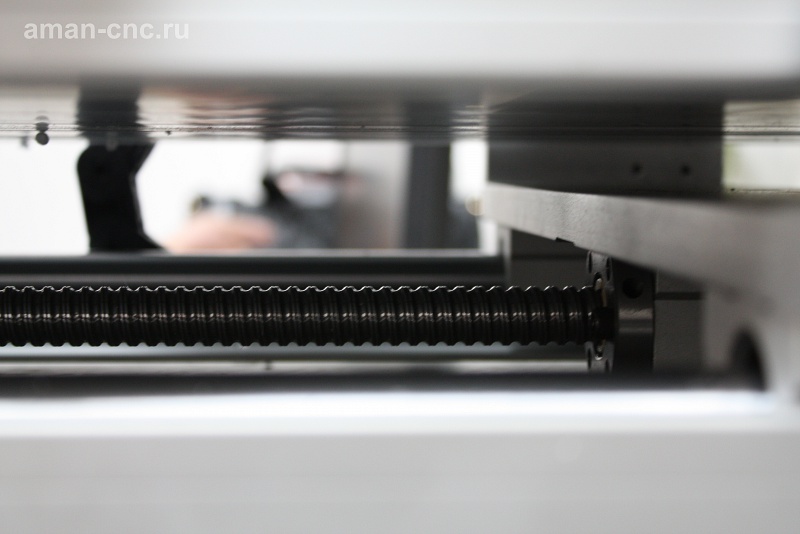

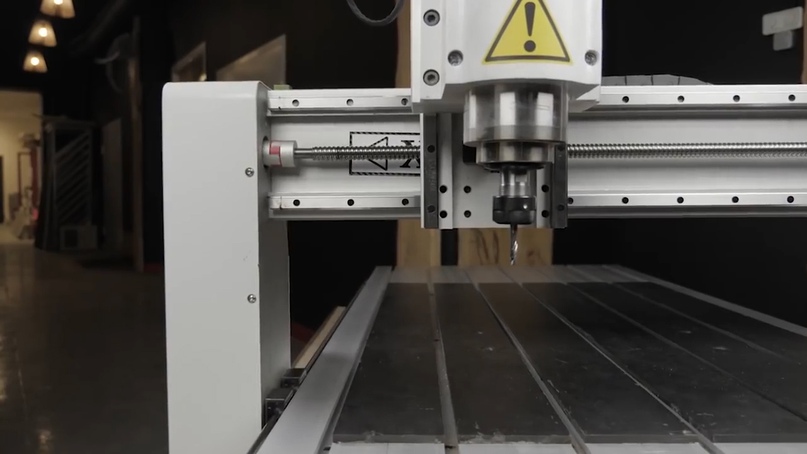

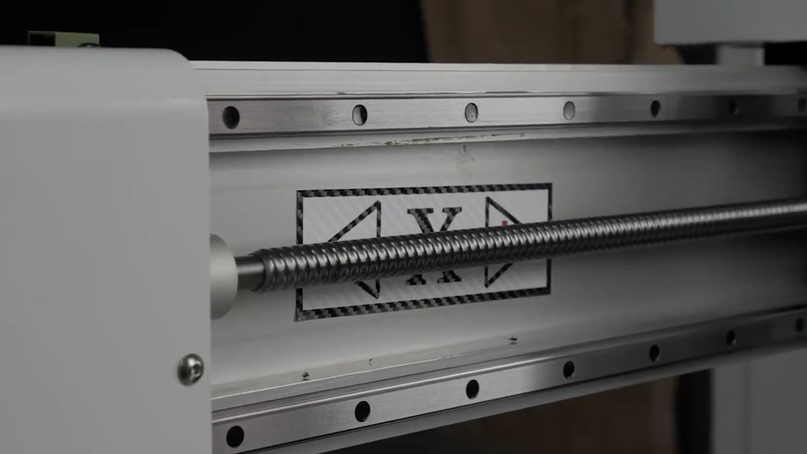

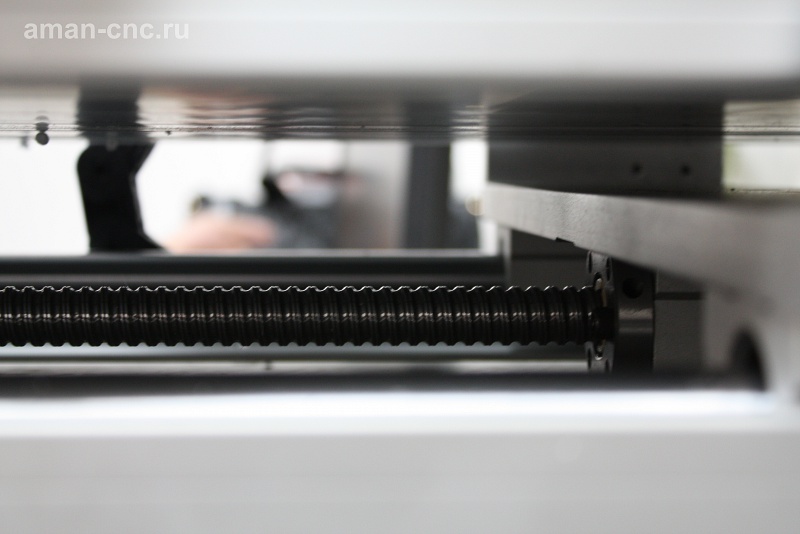

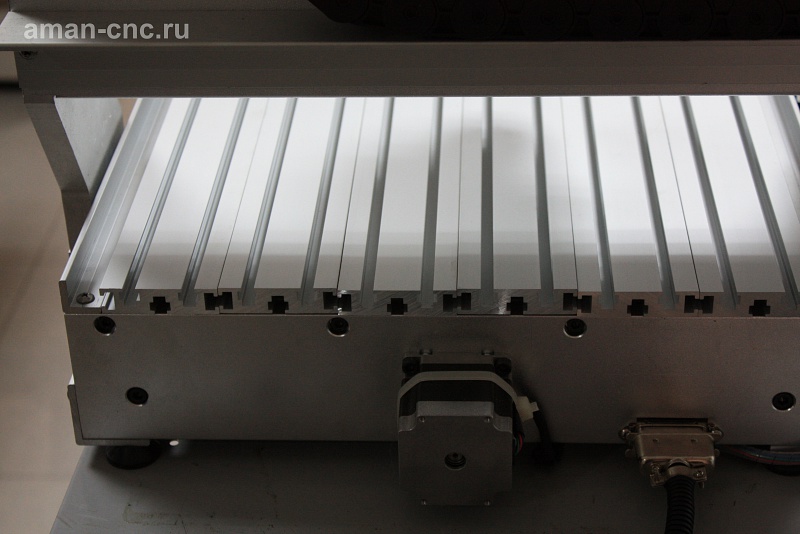

The mechanics of the machine is driven by stepper motors. Cylindrical shafts with a diameter of 20 mm and ball screws are used along the axes.

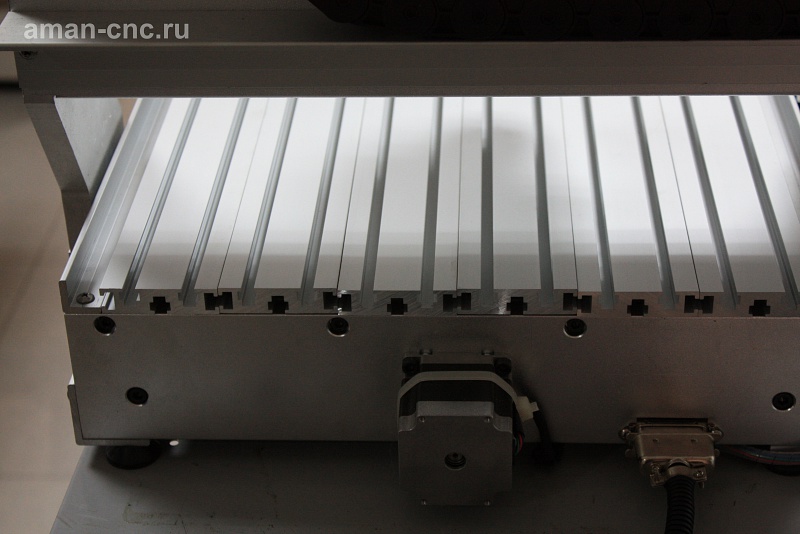

The work table is made of metal, and the T shaped slots on it make it possible to fix any workpiece without problems.

The main advantages of AMAN milling machines:

• Compact size

• Full 3D processing

• The machine is completely ready to work out of the box.

Desktop CNC milling machine Advercut K6090T

The compact dimensions of the machine make it possible to place it in a limited space. With overall dimensions of the machine 1400 x 1100 x 900 mm, and weight 200 kg, its working area is 600 x 900 x 150 mm.

Axis positioning accuracy is 0.05 mm, which is a very good indicator for its size. Along the X, U, Z axes German Ball Screws and square rail guides are used. The limit switches on the axes - induction.

The maximum spindle speed is 24,000 rpm, spindle power is 2.2 kW, the spindle is water cooled, which ensures quiet and stable operation of this machine, and the Delta frequency converter is responsible for controlling the spindle.

The machine can complete the fourth rotary axis, which allows you to perform 3D processing. This is an additional option.

All control takes place with the help of a DSP controller from a reputable manufacturer Richauto, which has proven to be a convenient and reliable system with all the necessary functions for operation.

The table is equipped with T-shaped slots, which allows you to easily secure the material with the help of clamping clamps.

Complete with the machine the nozzle brush on a spindle is delivered. When connecting the nozzle to the dust collector, you can easily remove chips and dust from the treatment area.

Such a set of characteristics allows processing: Wood, plastic, plexiglas, chipboard, fiberboard, MDF, light metals (aluminum, brass, copper).

Universal machine Adverkat K6090T is used in advertising and souvenir industries, furniture production, interior and exterior decoration, molding production.

For the machine does not need a separate computer. The task is saved in the G-code format, which allows you to pause production and start from the same place, if suddenly you did not have time to do the work right away.

The main advantages of the machine Advercut K6090T

• Service center in Moscow

• Reliable kinematic scheme

• In the basic configuration DSP remote

• Advercut machines are mass production, not piece production.

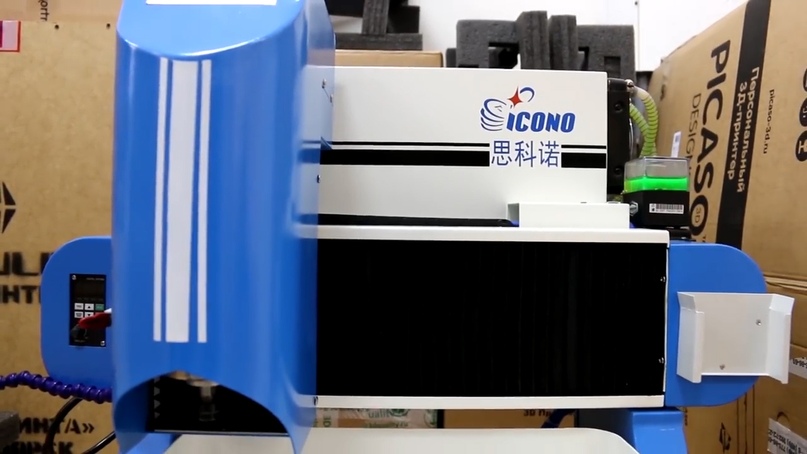

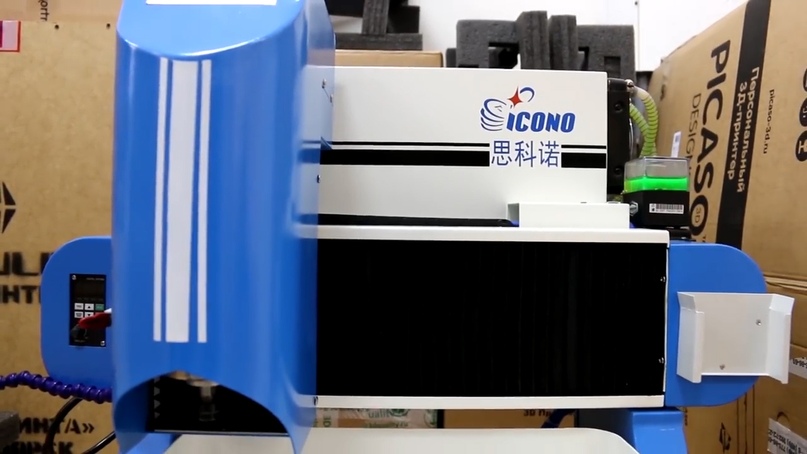

CNC milling machine for metal Sicono SIC 330

This milling machine for metal processing, easy to operate, reliable and not least important is of low cost.

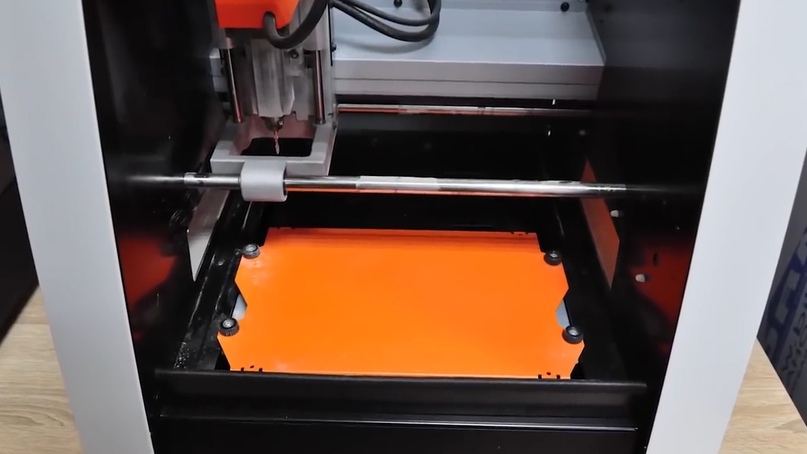

A distinctive feature of this machine is very high precision, thanks to the use of high-precision ball screws and linear guides. All moving parts of the machine (relative to the axes and the spindle) - are reliably protected from chips with special casings.

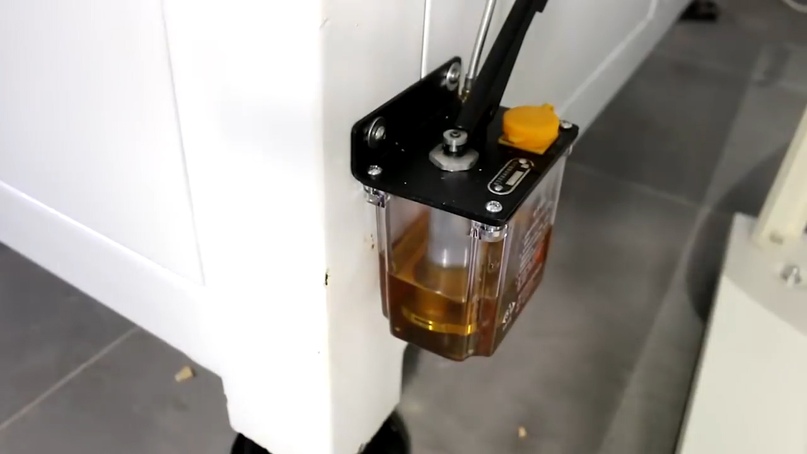

The machine is equipped with a coolant system for cooling the cutter during machining.

Perfect for work on the metal.

On the SICONO (Sicono) SIC 330 DSP machine, you can make: stamping plates, badges, medals, small molds for casting and stamping, seals for sealers, tags and small plates, equipment shields, master models from jewelry wax and other materials, small dashboards, woodwork, etc.

The processing area along the X and Y axes is 290 × 290 mm, along the Z axis - 95 mm;

The weight of the machine is 125 kg, which is enough to ensure rigidity in the processing of metals.

Installed a powerful spindle with water cooling 1.5 kW, with a rotational speed of 6000-24000 rpm; The spindle cooling system is a closed fluid circulation system (i.e., without access to open air).

DSP control system provides high speed data processing and stability of the entire system.

Software resolution of the machine is 0.001 mm; mechanical resolution - 0.02 mm;

Positioning accuracy: 0.05 mm / 300 mm;

Main advantages of the Sicono SIC 330:

• High quality of assembly and components

• In the basic configuration DSP remote, coolant system

• Specialized in metal processing with high accuracy

Roland SRM20 CNC Milling Machine

Roland SRM 20 is the latest generation machine for studio and educational environments. It supports modern software to control the machine at the level of machining centers. What is very important for education. As students when working with this machine, will receive the necessary knowledge to work in modern production.

The overall dimensions of this machine are 451 x 426 x 426 mm and weight is 19 kg, which makes it one of the most compact CNC milling machines on the market.

Despite the small dimensions of this machine, its working area is 203 x 152 x 60 mm; this allows you to solve a wide range of different tasks, be it prototyping, milling, the creation of printed circuit boards, jewelry production or woodworking of varying complexity

The machine mechanics are as follows: railways are used along the XY axes, and gear belts driven by stepper motors are used as drives.

The maximum spindle speed is 7000 rpm, and the movement speed is from 6 to 1800 mm / min. The spindle is equipped with collet ZC-23 -6mm

Accurate and high-quality prototyping is the main task of this machine, and high dimensional accuracy of products allows you to create complex assembled and functional prototypes. A large selection of materials to be processed, not only plastics, but also easily machined metals, opens up tremendous opportunities for you, and the closed compact case and low noise level make it possible to put this machine anywhere, be it a home, school, university or factory.

Main advantages of the Roland SRM-20 machine

• High level of automation and security.

• Mobility

• Advanced software included

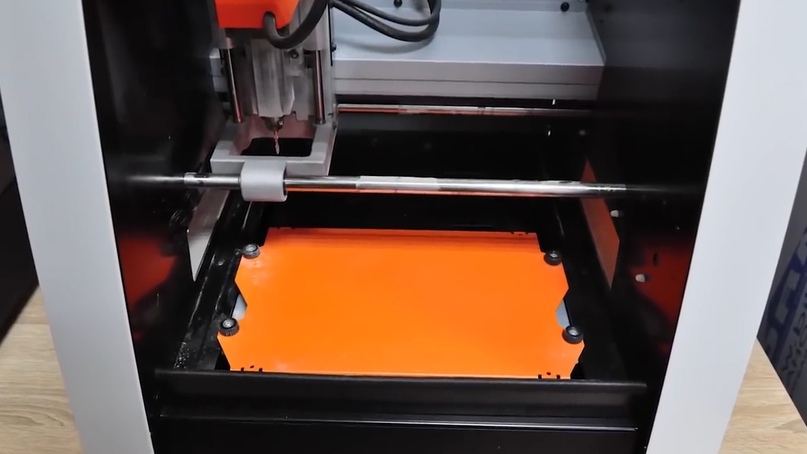

CNC milling machine Advercut K30MT / 1212

This machine has very serious technical characteristics and is deservedly popular with manufacturers.

The weight of the machine reaches 900 kg, which guarantees good vibration resistance and rigidity.

The size of the working area is 1200 mm by 1200 mm. Also Advercut machines can be equipped with a working field up to 4 meters .

The machining height along the Z axis is 200 mm. Optionally, you can order a machine with a height of processing up to 300 mm. The machine is primarily focused on the processing of sheet materials, composite materials and light metals.

The machine in the base configuration - is completed with a vacuum work table with T-slots. This is a universal solution for any tasks. Whether it is cutting sheet material, or work with blanks that need to be further strengthened by mechanical fastening to the table with T-slots.

The mechanics of the machine is made on the basis of rails. This allows you to achieve a higher accuracy of positioning of the cutter and the quality of processing. Currently, the declared accuracy is 0.05 mm.

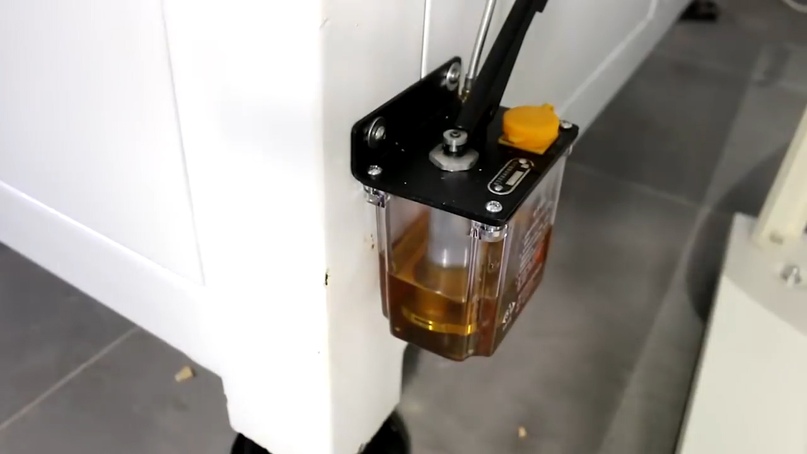

The machine is equipped with a centralized lubrication system.

Also in the database, the machine is controlled via a DSP console.

As the drives along the axes X and Y, Z, Stepper motors are used with transmission by means of a rack. End sensors - inductive. Also included is an auto level to determine the "zero" point along the Z axis, relative to the workpiece.

The Advercut K30MT / 1212 is equipped with a 3000 W spindle, which can output up to 24,000 revolutions per minute. It is enough for high-quality processing of wood and plastics, lightweight materials. The spindle has water cooling, which allows to avoid overheating, provides round-the-clock operation with service interruptions.

The spindle is equipped with an ER20 collet chuck. Depending on the collet used, this allows you to install a cutting tool (cutter) with a shank diameter of up to 13 mm.

Main advantages of Advercut machines:

• Focuses on high load production.

• Reliable kinematics

• Service center in Moscow.

• Advercut machines is a batch production, not a piece publication.

Our company is the official supplier of machines Advercut, Roland, Sicono, Aman. In Moscow there is a showroom, and a service center.

Catalog of CNC milling machines

We will help you to make your choice easier by talking about 5 CNC milling machines that you should pay attention to.

3D CNC milling machine AMAN 3040

')

This machine is used in the production of plates, promotional items, art and craft items, souvenirs and much more of wood and plastic. The rigidity and power of this machine will be enough for processing soft metals, such as aluminum, copper.

The working area is 30 by 40 cm along the X, Y axes. Z axis - 80 mm (optional up to 130 mm)

The set comes with a turning device for processing parts around the circumference, the so-called 3D processing.

The machines come with various spindle modifications: the 500W motor is equipped with air cooling. The 800 and 1500 W spindles are water-cooled, ensuring quiet operation and long service life. The spindle is equipped with ER11 collet. Spindle speed up to 24000 rpm

The mechanics of the machine is driven by stepper motors. Cylindrical shafts with a diameter of 20 mm and ball screws are used along the axes.

The work table is made of metal, and the T shaped slots on it make it possible to fix any workpiece without problems.

The main advantages of AMAN milling machines:

• Compact size

• Full 3D processing

• The machine is completely ready to work out of the box.

Desktop CNC milling machine Advercut K6090T

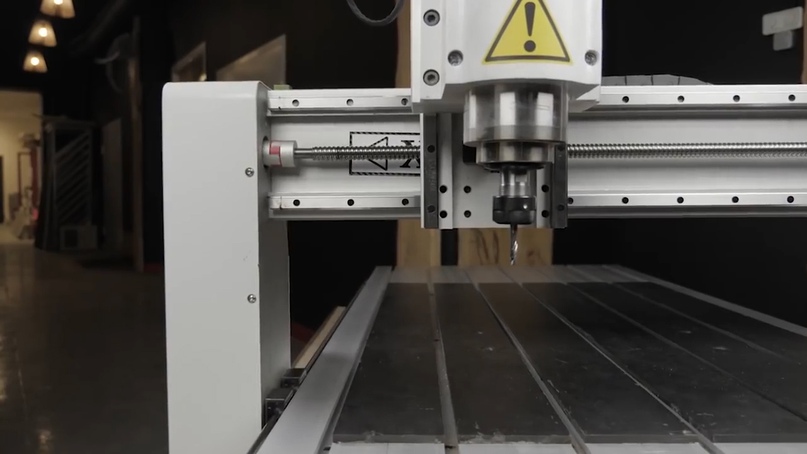

The compact dimensions of the machine make it possible to place it in a limited space. With overall dimensions of the machine 1400 x 1100 x 900 mm, and weight 200 kg, its working area is 600 x 900 x 150 mm.

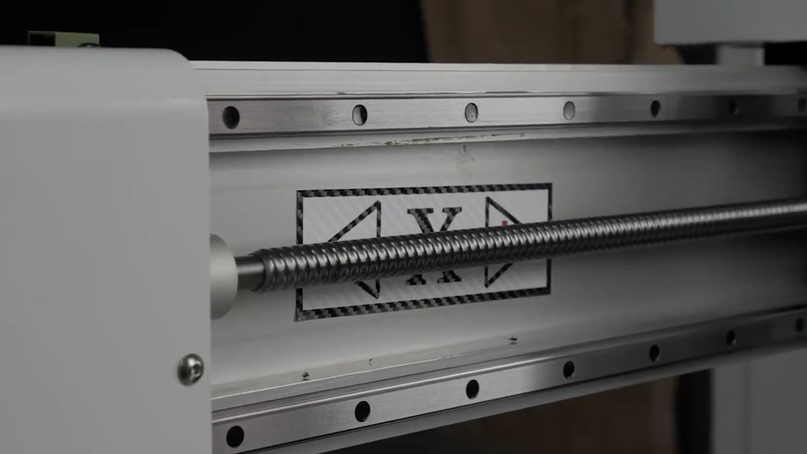

Axis positioning accuracy is 0.05 mm, which is a very good indicator for its size. Along the X, U, Z axes German Ball Screws and square rail guides are used. The limit switches on the axes - induction.

The maximum spindle speed is 24,000 rpm, spindle power is 2.2 kW, the spindle is water cooled, which ensures quiet and stable operation of this machine, and the Delta frequency converter is responsible for controlling the spindle.

The machine can complete the fourth rotary axis, which allows you to perform 3D processing. This is an additional option.

All control takes place with the help of a DSP controller from a reputable manufacturer Richauto, which has proven to be a convenient and reliable system with all the necessary functions for operation.

The table is equipped with T-shaped slots, which allows you to easily secure the material with the help of clamping clamps.

Complete with the machine the nozzle brush on a spindle is delivered. When connecting the nozzle to the dust collector, you can easily remove chips and dust from the treatment area.

Such a set of characteristics allows processing: Wood, plastic, plexiglas, chipboard, fiberboard, MDF, light metals (aluminum, brass, copper).

Universal machine Adverkat K6090T is used in advertising and souvenir industries, furniture production, interior and exterior decoration, molding production.

For the machine does not need a separate computer. The task is saved in the G-code format, which allows you to pause production and start from the same place, if suddenly you did not have time to do the work right away.

The main advantages of the machine Advercut K6090T

• Service center in Moscow

• Reliable kinematic scheme

• In the basic configuration DSP remote

• Advercut machines are mass production, not piece production.

CNC milling machine for metal Sicono SIC 330

This milling machine for metal processing, easy to operate, reliable and not least important is of low cost.

A distinctive feature of this machine is very high precision, thanks to the use of high-precision ball screws and linear guides. All moving parts of the machine (relative to the axes and the spindle) - are reliably protected from chips with special casings.

The machine is equipped with a coolant system for cooling the cutter during machining.

Perfect for work on the metal.

On the SICONO (Sicono) SIC 330 DSP machine, you can make: stamping plates, badges, medals, small molds for casting and stamping, seals for sealers, tags and small plates, equipment shields, master models from jewelry wax and other materials, small dashboards, woodwork, etc.

The processing area along the X and Y axes is 290 × 290 mm, along the Z axis - 95 mm;

The weight of the machine is 125 kg, which is enough to ensure rigidity in the processing of metals.

Installed a powerful spindle with water cooling 1.5 kW, with a rotational speed of 6000-24000 rpm; The spindle cooling system is a closed fluid circulation system (i.e., without access to open air).

DSP control system provides high speed data processing and stability of the entire system.

Software resolution of the machine is 0.001 mm; mechanical resolution - 0.02 mm;

Positioning accuracy: 0.05 mm / 300 mm;

Main advantages of the Sicono SIC 330:

• High quality of assembly and components

• In the basic configuration DSP remote, coolant system

• Specialized in metal processing with high accuracy

Roland SRM20 CNC Milling Machine

Roland SRM 20 is the latest generation machine for studio and educational environments. It supports modern software to control the machine at the level of machining centers. What is very important for education. As students when working with this machine, will receive the necessary knowledge to work in modern production.

The overall dimensions of this machine are 451 x 426 x 426 mm and weight is 19 kg, which makes it one of the most compact CNC milling machines on the market.

Despite the small dimensions of this machine, its working area is 203 x 152 x 60 mm; this allows you to solve a wide range of different tasks, be it prototyping, milling, the creation of printed circuit boards, jewelry production or woodworking of varying complexity

The machine mechanics are as follows: railways are used along the XY axes, and gear belts driven by stepper motors are used as drives.

The maximum spindle speed is 7000 rpm, and the movement speed is from 6 to 1800 mm / min. The spindle is equipped with collet ZC-23 -6mm

Accurate and high-quality prototyping is the main task of this machine, and high dimensional accuracy of products allows you to create complex assembled and functional prototypes. A large selection of materials to be processed, not only plastics, but also easily machined metals, opens up tremendous opportunities for you, and the closed compact case and low noise level make it possible to put this machine anywhere, be it a home, school, university or factory.

Main advantages of the Roland SRM-20 machine

• High level of automation and security.

• Mobility

• Advanced software included

CNC milling machine Advercut K30MT / 1212

This machine has very serious technical characteristics and is deservedly popular with manufacturers.

The weight of the machine reaches 900 kg, which guarantees good vibration resistance and rigidity.

The size of the working area is 1200 mm by 1200 mm. Also Advercut machines can be equipped with a working field up to 4 meters .

The machining height along the Z axis is 200 mm. Optionally, you can order a machine with a height of processing up to 300 mm. The machine is primarily focused on the processing of sheet materials, composite materials and light metals.

The machine in the base configuration - is completed with a vacuum work table with T-slots. This is a universal solution for any tasks. Whether it is cutting sheet material, or work with blanks that need to be further strengthened by mechanical fastening to the table with T-slots.

The mechanics of the machine is made on the basis of rails. This allows you to achieve a higher accuracy of positioning of the cutter and the quality of processing. Currently, the declared accuracy is 0.05 mm.

The machine is equipped with a centralized lubrication system.

Also in the database, the machine is controlled via a DSP console.

As the drives along the axes X and Y, Z, Stepper motors are used with transmission by means of a rack. End sensors - inductive. Also included is an auto level to determine the "zero" point along the Z axis, relative to the workpiece.

The Advercut K30MT / 1212 is equipped with a 3000 W spindle, which can output up to 24,000 revolutions per minute. It is enough for high-quality processing of wood and plastics, lightweight materials. The spindle has water cooling, which allows to avoid overheating, provides round-the-clock operation with service interruptions.

The spindle is equipped with an ER20 collet chuck. Depending on the collet used, this allows you to install a cutting tool (cutter) with a shank diameter of up to 13 mm.

Main advantages of Advercut machines:

• Focuses on high load production.

• Reliable kinematics

• Service center in Moscow.

• Advercut machines is a batch production, not a piece publication.

Our company is the official supplier of machines Advercut, Roland, Sicono, Aman. In Moscow there is a showroom, and a service center.

Catalog of CNC milling machines

Source: https://habr.com/ru/post/417577/

All Articles