3D printing lessons. Printing parts with different layer thickness from 3Dtool

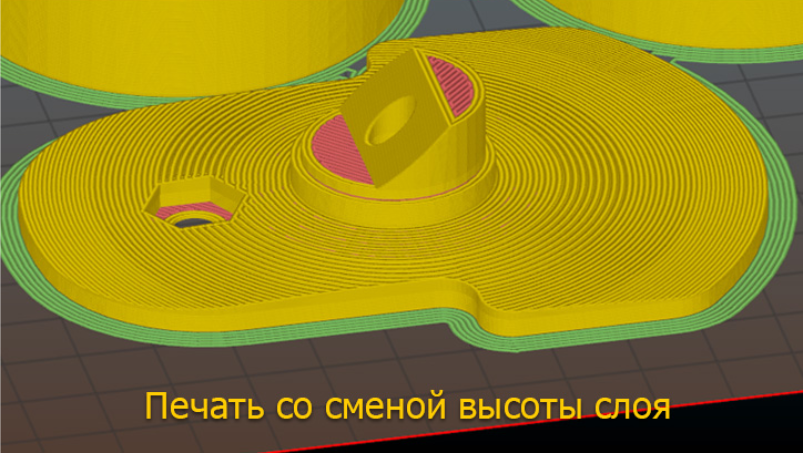

Hello, with you company 3Dtool ! Today we decided to test in practice the possibility of Slic3r, to print individual objects with different layer heights and different properties in one 3D printing session.

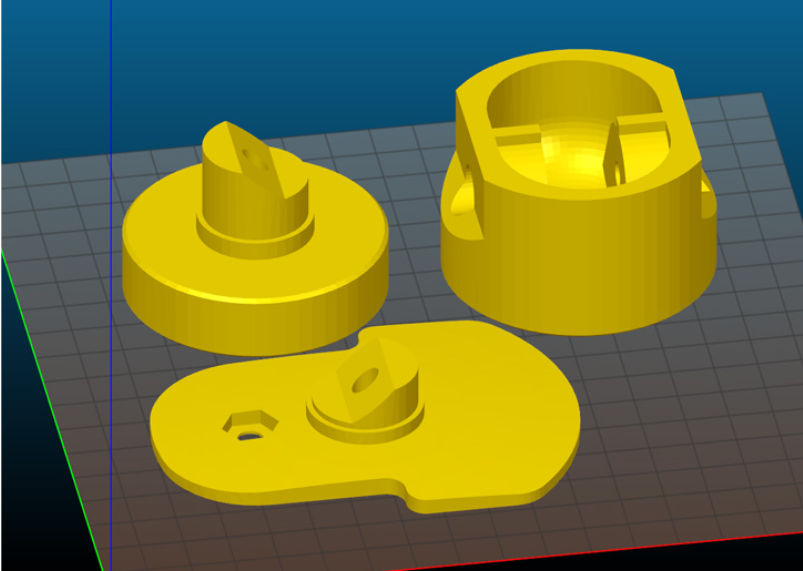

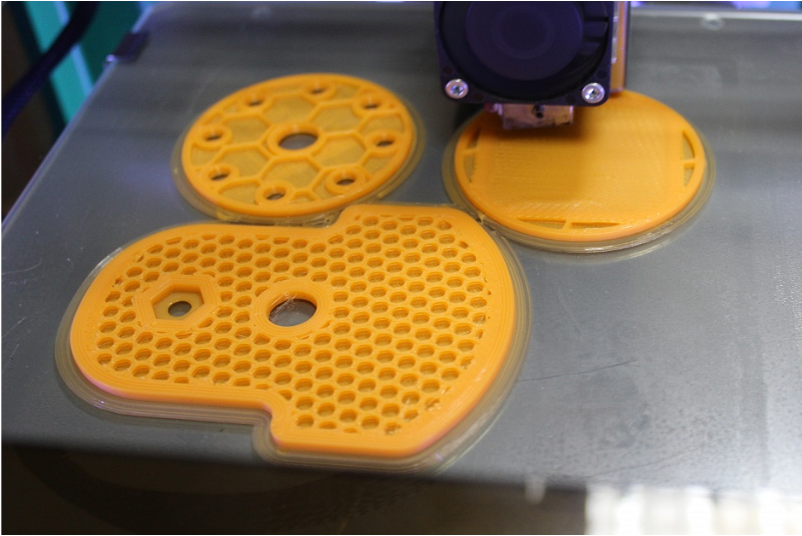

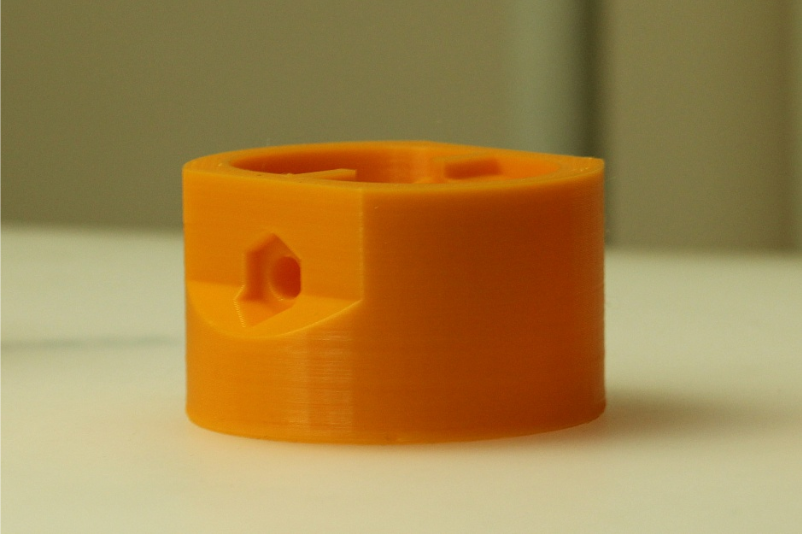

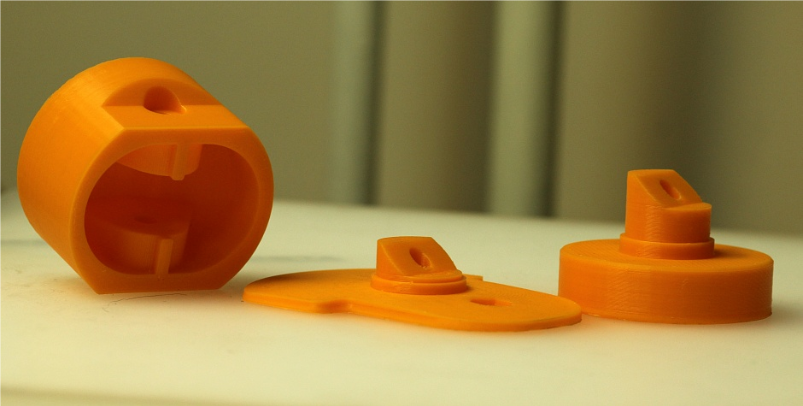

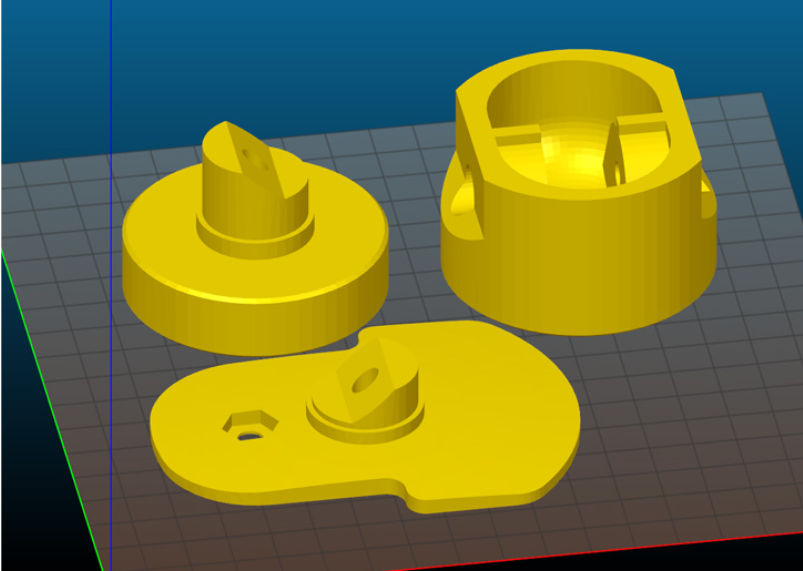

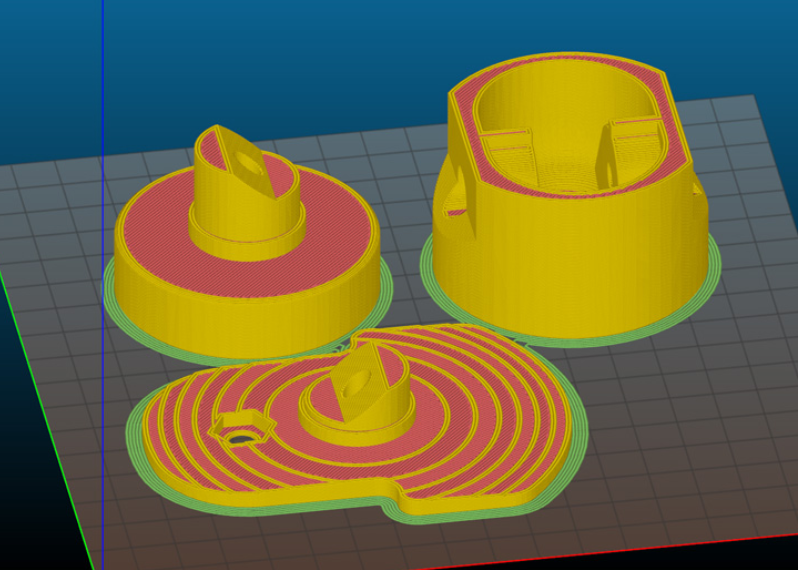

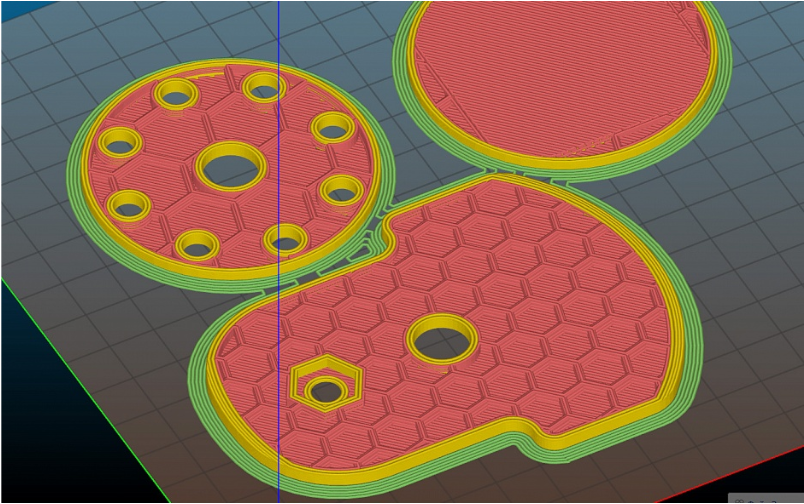

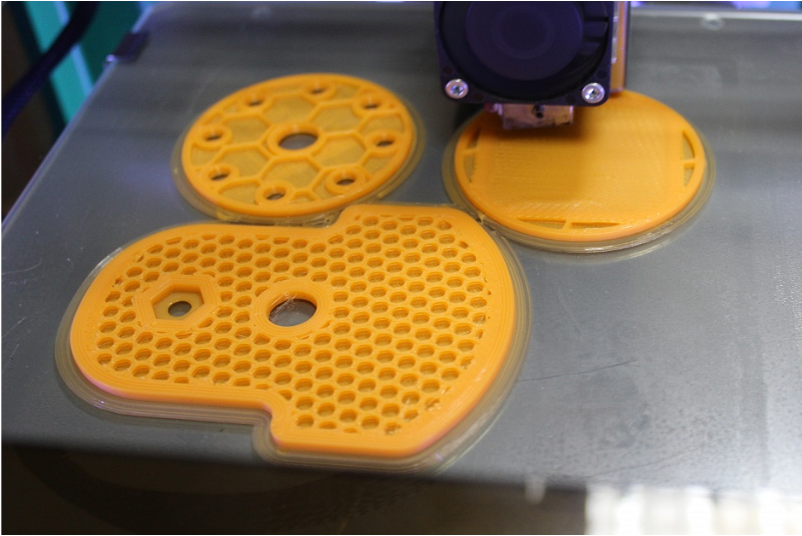

For example, we took three different engine parts.

3D printer for experiments Hercules Strong 17 , PLA material, nozzle with a diameter of 0.8 mm, layer height 0.3 mm.

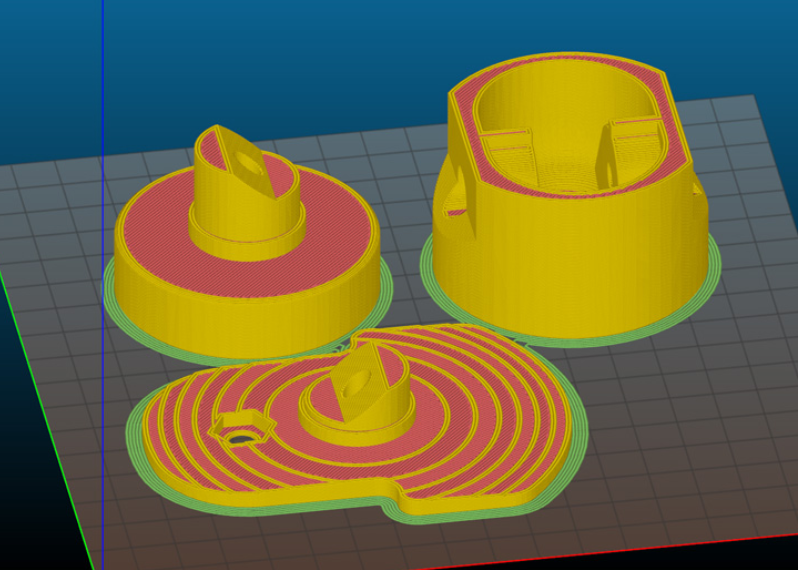

We generate Gcode, print time is 4 hours.

')

But the details on the same platform are not of the same type, with different geometry features. Therefore, for better results, we will again torment Slic3r.

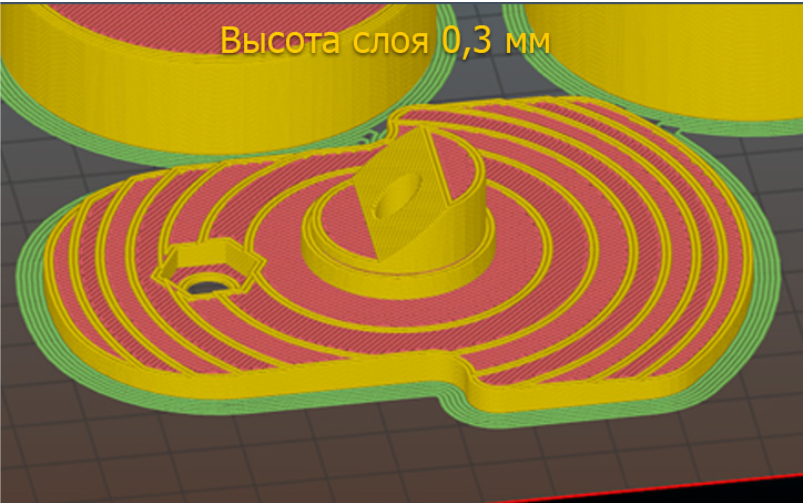

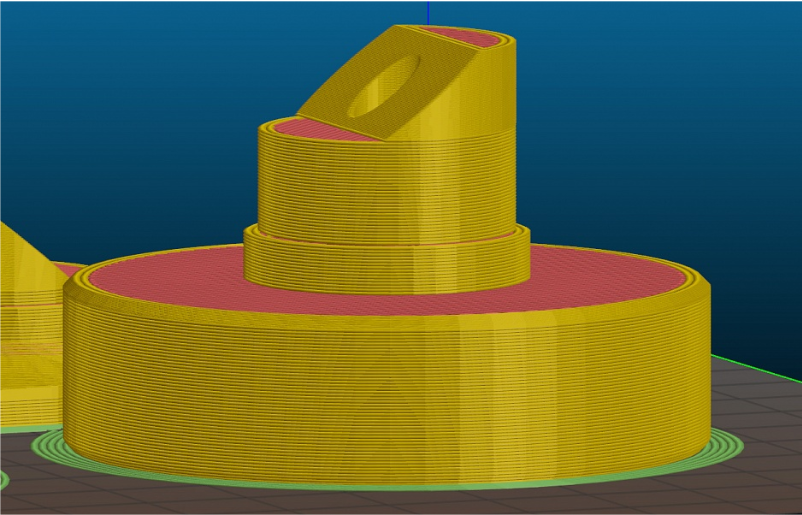

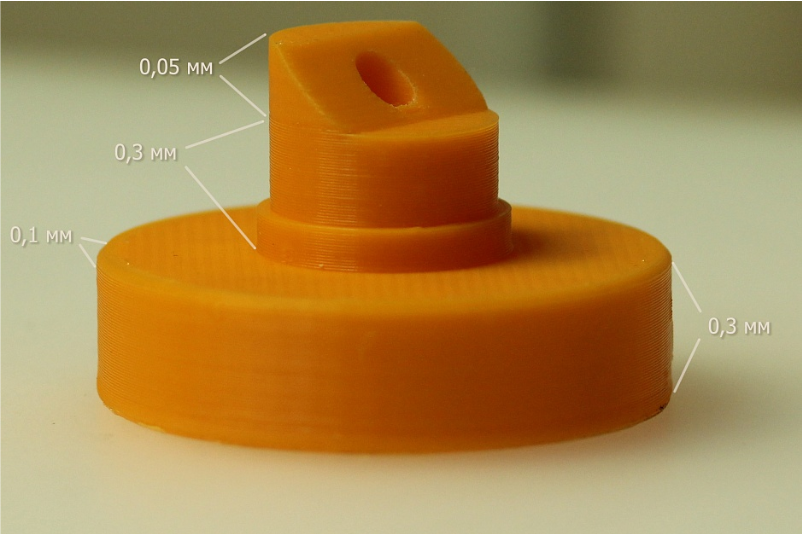

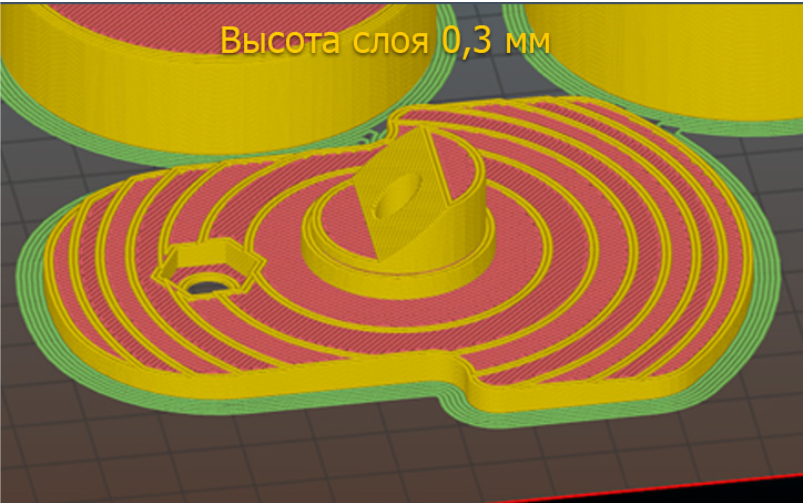

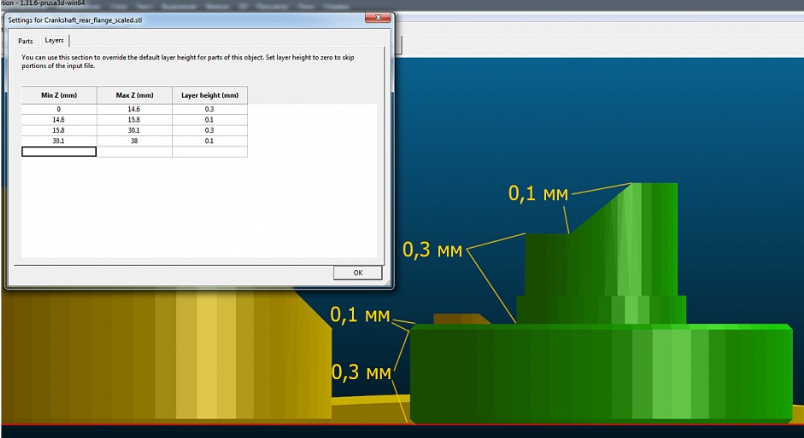

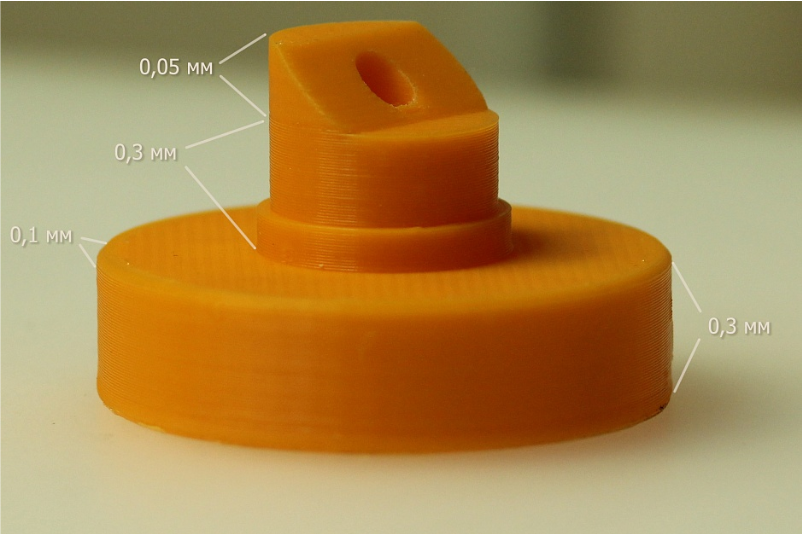

Due to the layer height of 300 μm and the very large angle of inclination of the surface, the layers on the flat part are obtained by steps. To get rid of this, you need to reduce the height of the layer.

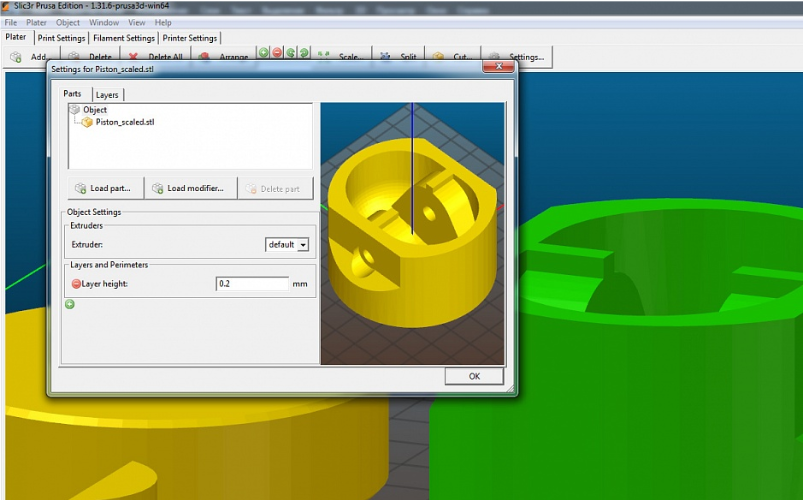

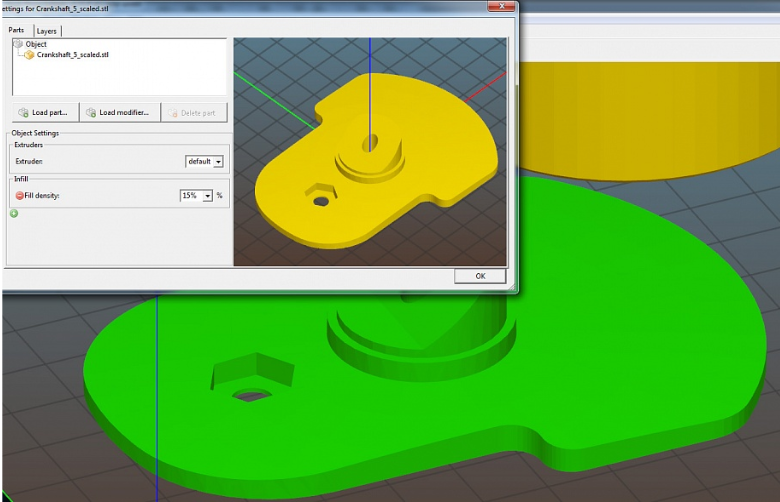

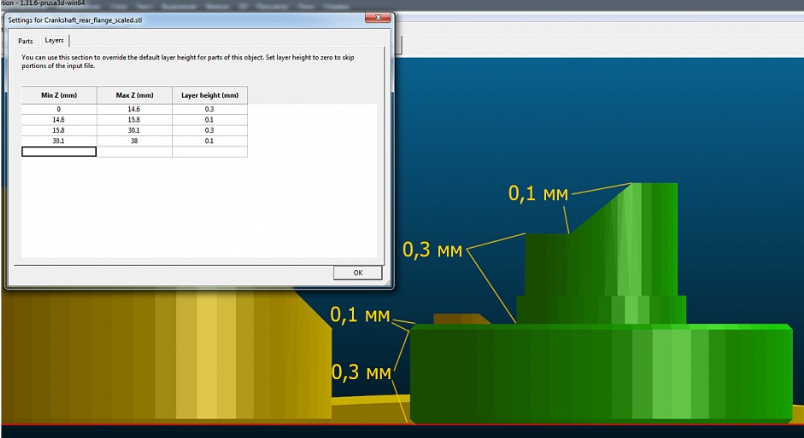

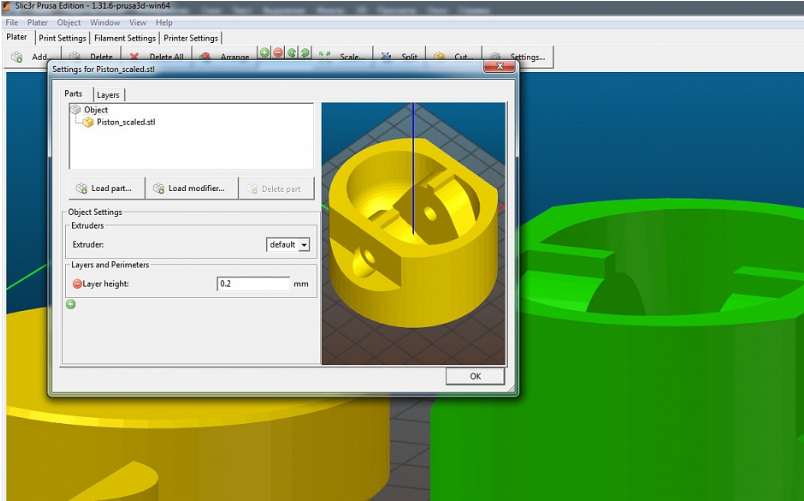

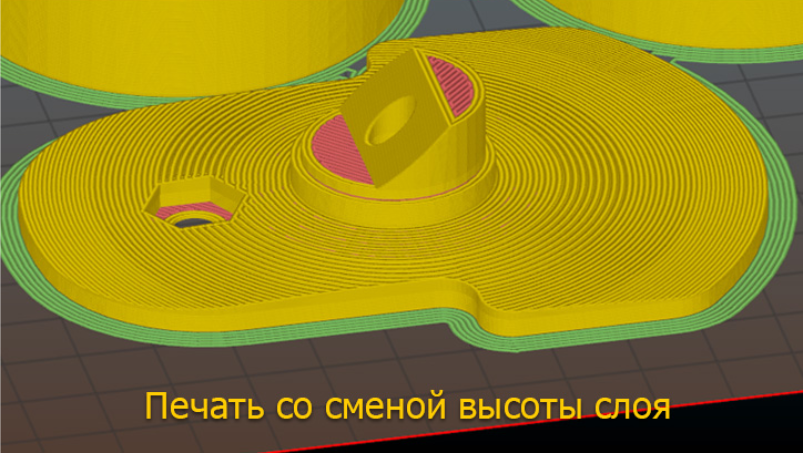

To set different print properties for individual parts, double click on the required part or select the part, click on the Settings button. In the Layers tab, reduce the height of the layer on an inclined surface to 0.05 mm. At the same time we reduce the height of the layer in the upper part to 0.1 mm.

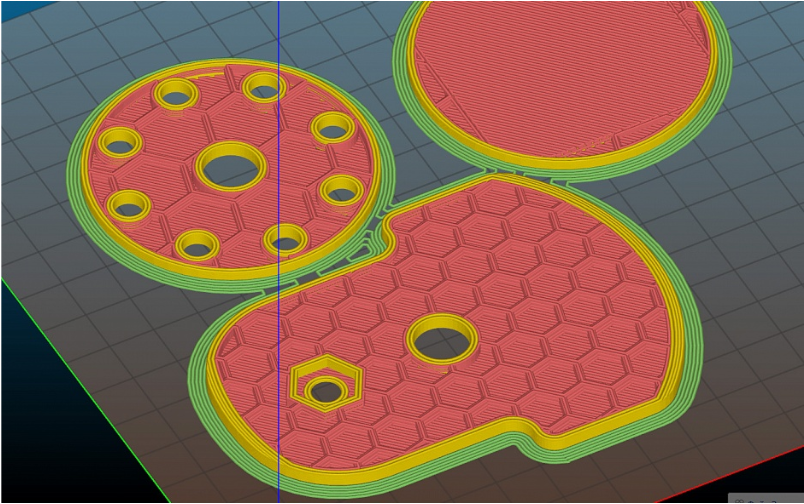

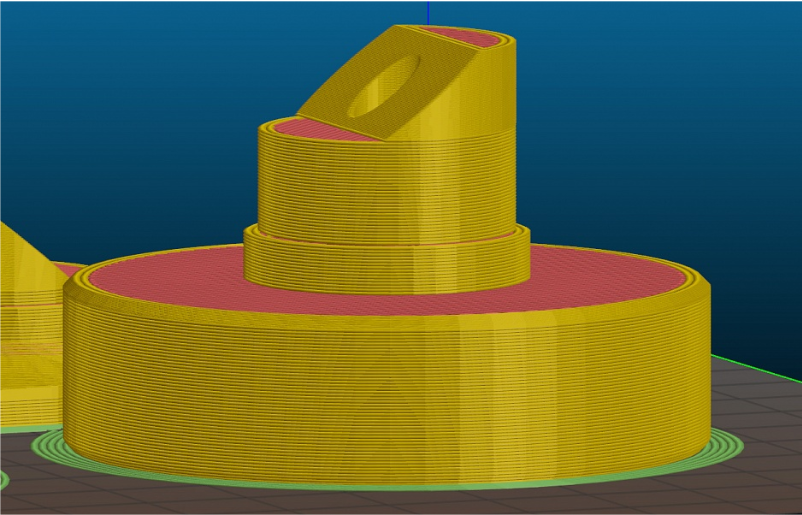

Now the steps are not visible, the surface is smooth. Since the surface is almost inclined, we will increase the percentage of internal filling and the number of perimeters in order to eliminate the formation of holes.

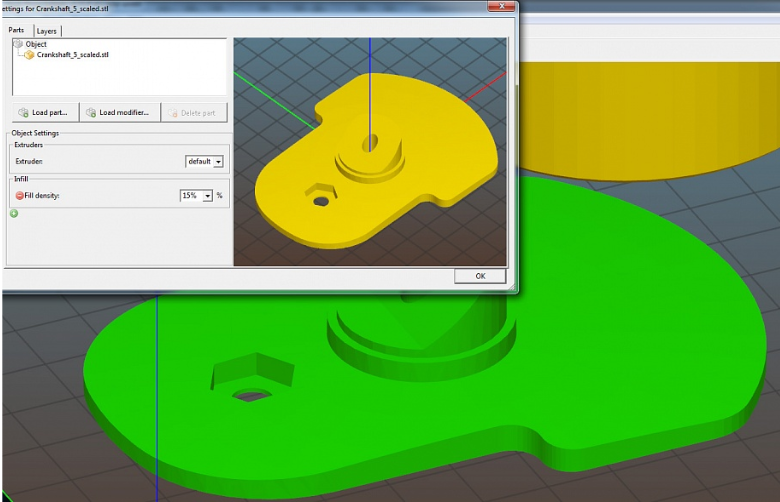

Also in the Settings menu, go to the Parts tab and click on the "+", a list of printing properties that we can change for this part appears. Choose Infill → Fill density, Layers and Perimeters → Perimeters → 4.

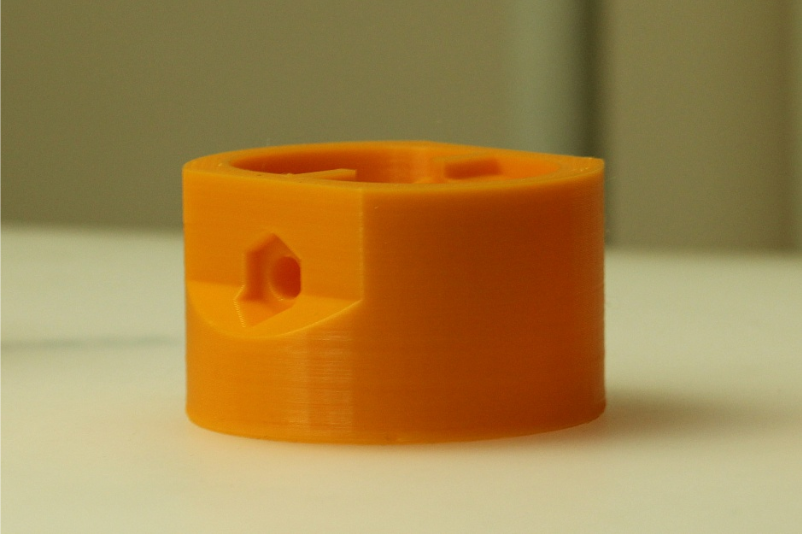

For the next part in the same way we reduce the height of the layer on inclined surfaces.

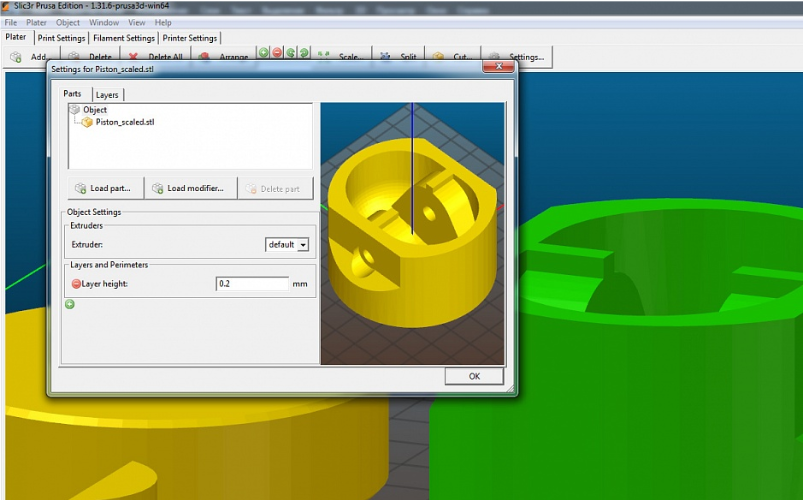

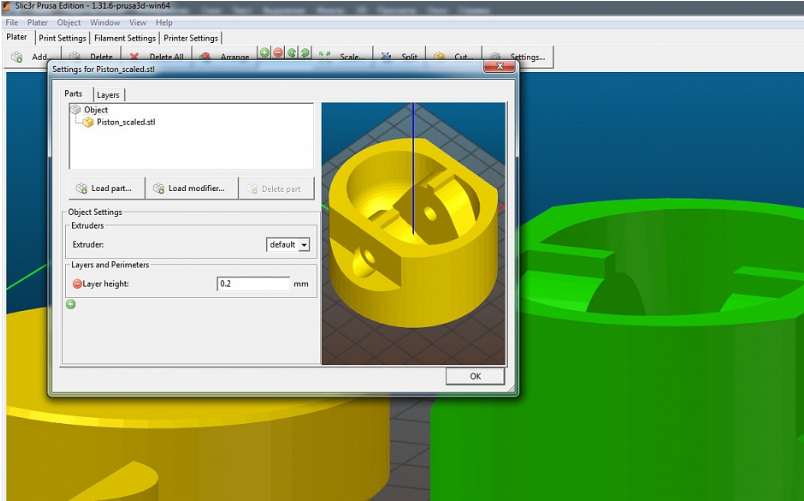

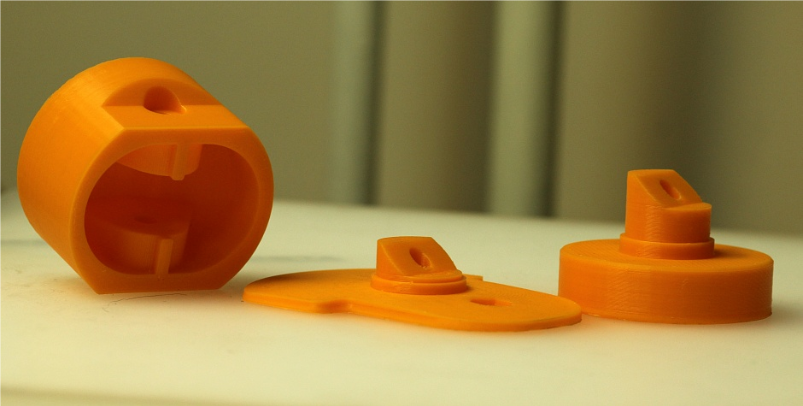

For the experiment, in the last detail we will make the layer height non-multiple - 0.2 mm. Just curious how Slic3r will calculate non-multiple layer height.

Double click on the part, in the Part tab select Layers and Perimeters → Layer height 0.2 mm.

We generate the code. Printing time is 8 hours. We are printing.

The printing time in the first case, where all printing properties and layer height are the same, is 4 hours, and in the second case, the printing time is doubled to 8 hours. However, in our case, an increase in printing time is not critical, and the advantage of this method is the ability to print parts that differ in their properties and geometry features in one session.

We hope you find this useful.

Catalog of 3D printers

3D-printer Hercules Strong 17 (the hero of our experiments)

Do not forget to subscribe to our social networks:

Our Youtube channel

INSTAGRAM

In contact with

Facebook

For example, we took three different engine parts.

3D printer for experiments Hercules Strong 17 , PLA material, nozzle with a diameter of 0.8 mm, layer height 0.3 mm.

We generate Gcode, print time is 4 hours.

')

But the details on the same platform are not of the same type, with different geometry features. Therefore, for better results, we will again torment Slic3r.

Due to the layer height of 300 μm and the very large angle of inclination of the surface, the layers on the flat part are obtained by steps. To get rid of this, you need to reduce the height of the layer.

To set different print properties for individual parts, double click on the required part or select the part, click on the Settings button. In the Layers tab, reduce the height of the layer on an inclined surface to 0.05 mm. At the same time we reduce the height of the layer in the upper part to 0.1 mm.

Now the steps are not visible, the surface is smooth. Since the surface is almost inclined, we will increase the percentage of internal filling and the number of perimeters in order to eliminate the formation of holes.

Also in the Settings menu, go to the Parts tab and click on the "+", a list of printing properties that we can change for this part appears. Choose Infill → Fill density, Layers and Perimeters → Perimeters → 4.

For the next part in the same way we reduce the height of the layer on inclined surfaces.

For the experiment, in the last detail we will make the layer height non-multiple - 0.2 mm. Just curious how Slic3r will calculate non-multiple layer height.

Double click on the part, in the Part tab select Layers and Perimeters → Layer height 0.2 mm.

We generate the code. Printing time is 8 hours. We are printing.

The printing time in the first case, where all printing properties and layer height are the same, is 4 hours, and in the second case, the printing time is doubled to 8 hours. However, in our case, an increase in printing time is not critical, and the advantage of this method is the ability to print parts that differ in their properties and geometry features in one session.

We hope you find this useful.

Catalog of 3D printers

3D-printer Hercules Strong 17 (the hero of our experiments)

Do not forget to subscribe to our social networks:

Our Youtube channel

In contact with

Source: https://habr.com/ru/post/417415/

All Articles