Tesla Engineer: 40% of parts on a Model 3 conveyor require rework

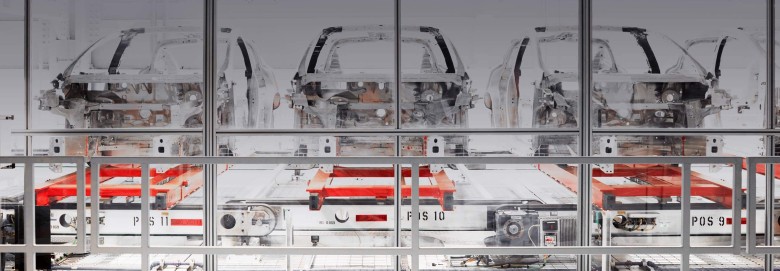

A few weeks ago, the American business news channel CNBC, citing "numerous" anonymous sources "from among current and former Tesla employees," spoke about the problems at Gigafabrika 1 in Nevada. They said that the assembly on the conveyor is partially carried out by old-fashioned methods - manually, practically without using robots. For example, manually assembled battery modules.

Tesla representatives explained in a commentary for CNBC that manual assembly is not some kind of revelation, but is planned from the very beginning: “Until we reach full production, by definition, some elements of the production process will occur using manual assembly. This is what Ilon Musk and Technical Director Jeffrey Strobel told in detail on the teleconference following the results of the third quarter, and this does not affect the quality or safety of the batteries we produce. ”

')

But workers argued that because of manual assembly without proper quality control, unsafe battery modules come off the conveyor, where "the elements are in contact with each other."

Tesla’s shares declined, although the company again refuted: “The assumptions that Tesla will ever release a car with a dangerous battery are completely inaccurate, contradict all the evidence and are cut off from reality. Each battery in the Tesla car has thousands of cells, the vast majority of which have the same voltage potential as the neighboring cells. Hypothetically, even if two cells with the same voltage potential are in contact, it will not lead to anything dangerous - it’s like the contact of two neutral pieces of metal. ”

Tesla representatives said that despite the absence of danger, all the positions of the cells of the Battery Module 3 modules are measured twice in production to check the process control and the quality of the outgoing parts. If at some point in the production process cells with different potentials come into contact, they cannot be interconnected. There are three different tests on the conveyor to verify that the correct number of cells is electrically connected in a Model 3 battery.

Tesla assured the public of the complete security of the assembly process and the absolute impossibility of releasing defective models for sale. But now CNBC has released another report on the same topic, but from a different angle.

Tesla workers again talk about quality control. Only now the main thesis is not in the release of hazardous products for sale, but in a large percentage of the rejection of parts. For example, an anonymous engineer from the Tesla factory in Fremont says that 40% of the parts produced or received at the factory require rework. According to him, the need for additional verification of parts coming off the assembly line is one of the reasons for the delay in the release of Model 3.

Another anonymous worker of the same factory reported that the percentage of rejection is so great that it will be very difficult to meet the planned deadlines and reach the required production volumes. The inability to comply with plans for release, in turn, negatively affects the morale of employees, he said.

CNBC cites two employee recruitment announcements ( 1 , 2 ) for which unusual work duties are indicated: the first one has a duty to “analyze new refusal regimes” for parts that have come off the assembly line, and the head of the refining group hires for daily operations on “large volume” repair and restoration of electric vehicles ".

Tesla responded to these allegations. According to a company representative, CNBC has confused the concepts of factory bulkhead or remanufacturing and rework. "Repeated production is a process that literally every automaker in the world is engaged in," said a Tesla representative. - CNBC snatched a couple of lines from two job descriptions posted on the Internet, and made crude assumptions about the inaccurate work functions of these employees. Our re-production team is very small at only 0.1% (40 people) of almost 40,000 employees. Any “expert” who asserts something unusual in our re-production process or insufficient quality of cars that go off the assembly line, either confuses something very much or is completely mistaken. In fact, like other automakers, Tesla reassembles parts because less material and energy is spent in this way than when creating a new part from scratch. This is a good thing, which ultimately benefits the environment and, if the part is properly made, then it is equally good for the client. ”

Tesla responded to these allegations. According to a company representative, CNBC has confused the concepts of factory bulkhead or remanufacturing and rework. "Repeated production is a process that literally every automaker in the world is engaged in," said a Tesla representative. - CNBC snatched a couple of lines from two job descriptions posted on the Internet, and made crude assumptions about the inaccurate work functions of these employees. Our re-production team is very small at only 0.1% (40 people) of almost 40,000 employees. Any “expert” who asserts something unusual in our re-production process or insufficient quality of cars that go off the assembly line, either confuses something very much or is completely mistaken. In fact, like other automakers, Tesla reassembles parts because less material and energy is spent in this way than when creating a new part from scratch. This is a good thing, which ultimately benefits the environment and, if the part is properly made, then it is equally good for the client. ”According to the original plan, Tesla was going to produce 20,000 Model 3 cars a month since December 2017. Then the dates moved. Now it is said that by the end of this month the conveyor will reach 2,500 cars a week, and by the end of June, 5,000 cars a week.

Source: https://habr.com/ru/post/411041/

All Articles