Snapmaker Multifunctional 3D Printer Review

What is it?

Snapmaker is a multifunctional device with replaceable modules. In its simplest configuration, it is a compact desktop 3D printer made of metal, and with additional blocks it acquires the capabilities of a laser engraver and a small milling machine.

Specifications:

Materials: PLA, PVA, ABS, Nylon and other plastics with printing temperatures up to 250 ° C

Nozzle temperature: 180-250 ° C

Platform temperature: 20-100 ° C

Layer thickness: from 50 to 300 microns.

Printing area: 125x125x125 mm.

External dimensions: 289x272x332 mm.

Price: from $ 199 to $ 699, depending on the configuration and without shipping and overhead, subject to early backing at KickStarter.

')

The retail price in the series is still unknown, but you can pre-order and be the first to get the actual price information.

What is interesting?

Strength and stiffness

Snapmaker is made of metal - there are no responsible or supporting plastic parts in it. At the same time, the use of sheet steel for massive parts would significantly weigh down the design and make the printer more expensive, because aluminum alloys are used.

Accuracy

The accuracy of the work is ensured, along with the rigidity of the structure, by the fact that in the linear modules, a screw transmission is used as the drive mechanism.

Modularity

The device consists of replaceable modules, which allows not only quickly switching functionality, but also easy to make repairs and upgrades. Replacing the working head of a 3D printer makes a laser engraving machine or a software-controlled mill.

Simplicity

The modularity of the design is associated with the simplicity of handling the device. The linear modules responsible for the movement of the working heads cannot be confused - they are the same and interchangeable.

Snapmaker also assembles and disassembles in minutes.

Management is done through an easy-to-use Snap3D program and a 3.2-inch removable touch-sensitive terminal.

There is no need for a special lacquer or film to fix the product in the process of printing or processing - the design provides for a reusable, self-adhesive platform with heating.

Due to the design and Snap3D, manual platform calibration is also not needed.

What can?

3D printing

Snapmaker prints PLA, PVA, ABS, Nylon and other materials with printing temperatures of up to 250 degrees Celsius. The maximum size of a possible printout is a cube with an edge of 125 mm.

This vase, for example, 8 cm high and 6.45 cm in diameter, was printed with a standard 1.75 mm PLA, with a layer thickness of 0.2 mm, approximately 1 hour and 20 minutes.

Other printouts:

Laser engraving

One of the modules supplied is a laser for engraving wood, plastic and other surfaces.

The laser power is 0.5 watts, this is enough for applying any images on wood and composites from it, polymers, fabrics, and skin.

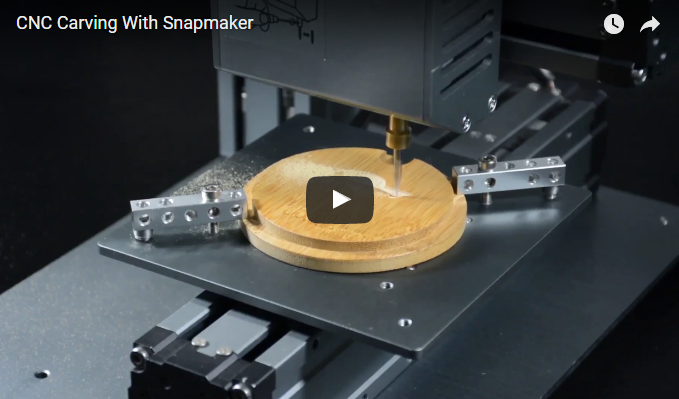

Milling

The milling module, with a spindle speed of 2000–7000 revolutions per minute, is capable of reproducing relief images on any surfaces suitable for rigidity — mainly wood and plastics.

Video from Hong Kong Electronics Fair:

Uncompressed video engraving on a bamboo detail (1 hour 10 minutes):

Yes, not too fast, but accurately and accurately.

Total:

So why are we interested in Snapmaker?

First of all, the fact that this compact and easy-to-use device, which fits easily on any table, can replace the whole workshop. He alone prints, burns, and cuts. An indispensable thing.

Not surprisingly, he raised $ 2,277,182 out of $ 50,000 requested at the start of the campaign on KickStarter.

There are unconditional minuses.

First of all it is, of course, the size of the work area. Seriously, 12.5 centimeters - this may be quite enough for 3D printing, but for laser engraving and milling it is quite modest.

Nevertheless, the device is certainly interesting. We will closely monitor the completion of the crowdfunding campaign and the launch of mass production.

And those who are especially interested can already pre-order now - they will be the first to find out the current prices and get the opportunity to buy the device, bypassing the customs bureaucracy and receiving a local guarantee for service.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/403923/

All Articles