Engineers have mastered 3D printing with silicone inside a microgel.

Scientists from the University of Florida have learned how to print silicone inside a microgel . This discovery promises to significantly advance the technology of creating medical implants: they will become more reliable, cheaper and more convenient than all the implants available on the market today. And this is not what you thought, but quite another. For example, heart valves, as well as soft catheters, drainage instruments, implantable nets, and other surgical accessories.

Scientists from the University of Florida have learned how to print silicone inside a microgel . This discovery promises to significantly advance the technology of creating medical implants: they will become more reliable, cheaper and more convenient than all the implants available on the market today. And this is not what you thought, but quite another. For example, heart valves, as well as soft catheters, drainage instruments, implantable nets, and other surgical accessories.At present, such devices have to be molded on presses. If a specific shape and size is required, the procedure for waiting for an operation may take several days or even weeks. Not every patient will live until they make a silicone part of the desired shape. 3D printing reduces production time to several hours, which theoretically could save someone’s life.

Microgel is bloated microparticles formed from interconnected polymers. They have very specific and useful rheological properties, that is, a specific combination of deformation and flow. Therefore, they are manufactured on an industrial scale for use as lubricants, personal care products, for coating materials and even for collecting oil . Under the influence of extreme pressure, the microgel turns into a liquid - this does not occur spontaneously when the substance is heated. It is this property (temporary transformation into a liquid) that is used for 3D printing of liquid objects inside the microgel.

Conventional methods of industrial production - synthesis with swelling - limited the scope of microgels. But a few years ago, scientists mastered 3D printing, and then a completely new hypostasis was found for this material. A crushed microgel is used to print unique structures from hydrogel and silicone, and even constructs to support living cells . With this technique, the printed material is literally physically clamped into the space of the packaged microgel, which temporarily turns into liquid under the influence of the printing (injection) tip, and then quickly returns to its previous gel-like state. Thus, it is possible to print soft and fragile materials inside the container with high accuracy. This technique was used by researchers from the University of Florida. The research team has been working on 3D printing of living organs and tissues for several years, and this project was a by-product of their research.

')

The main scientific discovery in this case is the chemical structure of the container. The former water-based microgels did not allow printing with liquid silicone, which literally dissolved in the container. Therefore, scientists have developed an oil-based material with which the “paint” does not mix.

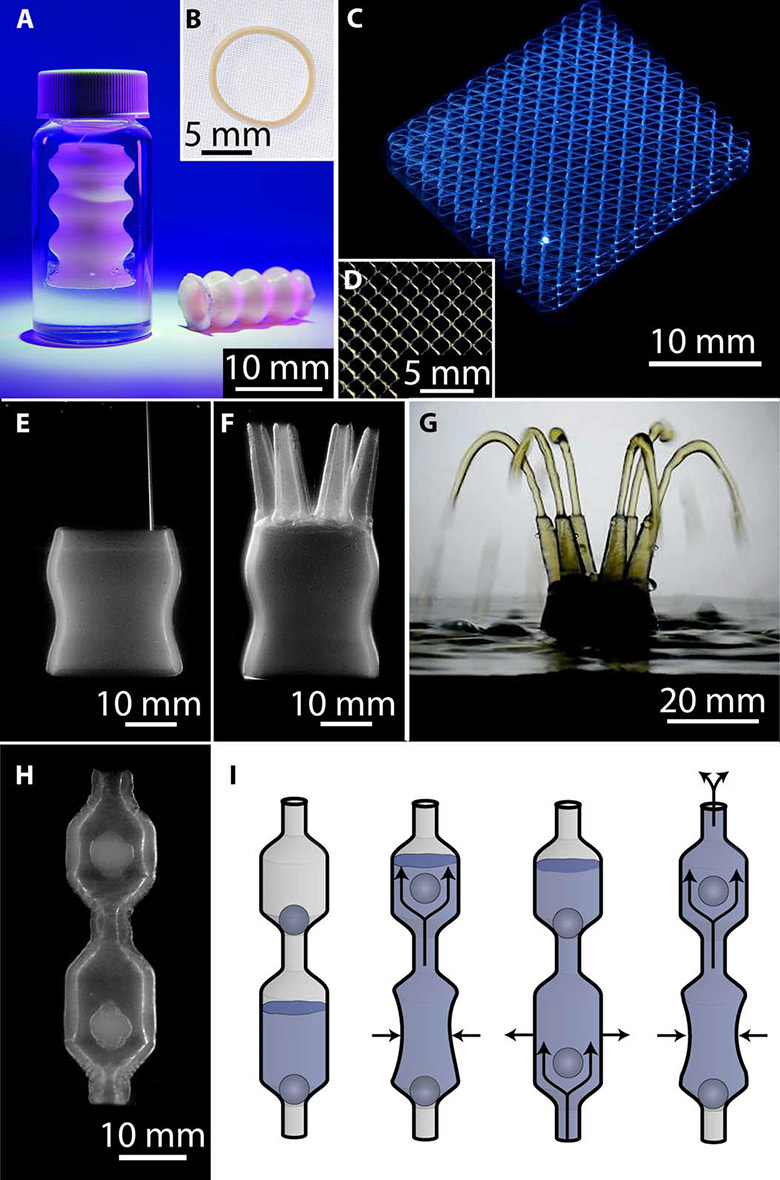

The manufacturing time of surgical accessories and implants is reduced by an order of magnitude, which in itself is a great achievement. But at the same time, it also becomes possible to manufacture parts of more complex shape. Some types of products, such as drainage tubes with pressure-sensitive valves, cannot be made on a press in one stage at all. This is a difficult and painstaking work. Now they can just be printed.

Printed Silicone Objects

"Our new material provides support for liquid silicone and allows 3D printing of very complex structures and even encapsulated parts of silicone elastomer," says lead author Christopher O'Bryan, a doctoral student in mechanical and aerospace engineering.

In this area it is not entirely appropriate to talk about finance, but accessories made in a new way should be much cheaper than the current ones.

Presumably, with the advent of technology, it will be possible to develop even new therapeutic devices that are capable of encapsulating substances - and releasing them in small quantities inside the body. These are drugs or molecules that stimulate tissue growth in the right places. If we dream up, then sometime in the future we will literally build up muscles, blood vessels and nervous tissue over the skeleton - to build a human body from scratch, as in science fiction.

Printing organs and tissues remains the main goal of a group of researchers from the University of Florida, and they continue to experiment with 3D printers and various materials. According to engineers, this will become possible in a few decades. This is quite a distant future, so they were briefly distracted by a side project of printing silicone implants - an invention that can be used today.

The scientific work was published on May 10, 2017 in the journal Science Advances (doi: 10.1126 / sciadv.1602800).

Source: https://habr.com/ru/post/403821/

All Articles