Turn off the light. What to do?

Hello. My name is Sergey and I develop 3D printers. In this article we will talk about what to do if the power supply is periodically disconnected, and I really want to print (I mean 3D printing).

A bit of background

I have a customer from one sunny city, and there are some problems with food there. Sometimes, the light is turned off for a couple of seconds, and sometimes a few hours. No periodicity or schedule, of course, no. The customer addressed me with this problem. I, like everyone, like many advised him to put an uninterruptible power supply. Yes, it helps, but from short-term outages. What else can you do? I asked this question ...

')

And there is a solution; moreover, this option was conceived at the very beginning of development, but the implementation, as usual, was delayed.

So, what we have is:

1. Printer. In this case, it is the RK-1, but there can be any other printer. As FDM (only when printing PLA plastic or equivalent), SLA, and DLP. Important note - the printer should monitor the supply voltage from the power supply (tautology, but not terrible, the essence is clear).

2. Network with unstable voltage (power).

The essence of the method is reduced to the fact that the supply voltage from the power supply does not fall from the nominal value to zero instantly. And there is a transition process. Moreover, the time of the voltage drop depends on the load. The greater the load, the less time and vice versa.

Implementation

We will use the gradual voltage drop from the power supply to realize the idea. Conditionally divide the work into several consecutive steps.

Step one.

We monitor voltage drop. The power supply voltage of the 24V power supply unit, if the supply voltage drops below 20V and is located in this area for more than 10 ms, the process of stopping and saving starts.

Step two

Turning off the display, stopping the stepping motors and removing them from the load.

Step Three

Turn off the laser diode.

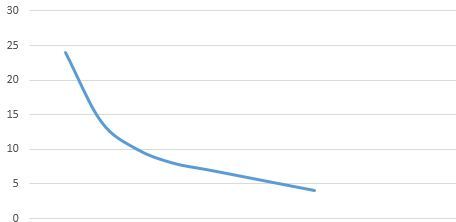

It turns out that we have disconnected all the main consumers and can work autonomously for some time from the power supply. The voltage drop graph looks like this:

Step Four

The following parameters must be stored in non-volatile memory:

It takes less than 10 ms. Everything, now you can safely "die")

After turning on the "printer" looks to see if there is a record of stopping printing. It searches for a file on a flash drive, searches for the line on which printing was stopped. And it starts the printing process.

But, there are nuances:

First: the Z axis does not need to be touched if movement along Z did not occur.

Second: do not reset the axis on the limit switch. The fact is that the limit switches are not as accurate as we would like, even though they are optical. It is necessary to do this: knowing the current position on the axis, shift to the limit switch and start the laser there, then return to the starting position and continue printing. Similarly, you can do in the case of working with FDM printer. Although, perhaps, there it will not affect the model (it will not be seen).

Here is a short video on how this works.

Thanks for attention. What methods do you still know?

A bit of background

I have a customer from one sunny city, and there are some problems with food there. Sometimes, the light is turned off for a couple of seconds, and sometimes a few hours. No periodicity or schedule, of course, no. The customer addressed me with this problem. I, like everyone, like many advised him to put an uninterruptible power supply. Yes, it helps, but from short-term outages. What else can you do? I asked this question ...

')

And there is a solution; moreover, this option was conceived at the very beginning of development, but the implementation, as usual, was delayed.

So, what we have is:

1. Printer. In this case, it is the RK-1, but there can be any other printer. As FDM (only when printing PLA plastic or equivalent), SLA, and DLP. Important note - the printer should monitor the supply voltage from the power supply (tautology, but not terrible, the essence is clear).

2. Network with unstable voltage (power).

The essence of the method is reduced to the fact that the supply voltage from the power supply does not fall from the nominal value to zero instantly. And there is a transition process. Moreover, the time of the voltage drop depends on the load. The greater the load, the less time and vice versa.

Implementation

We will use the gradual voltage drop from the power supply to realize the idea. Conditionally divide the work into several consecutive steps.

Step one.

We monitor voltage drop. The power supply voltage of the 24V power supply unit, if the supply voltage drops below 20V and is located in this area for more than 10 ms, the process of stopping and saving starts.

Step two

Turning off the display, stopping the stepping motors and removing them from the load.

Step Three

Turn off the laser diode.

It turns out that we have disconnected all the main consumers and can work autonomously for some time from the power supply. The voltage drop graph looks like this:

Step Four

The following parameters must be stored in non-volatile memory:

- the current position of the Z axis and the mode (it was raised or lowered);

- the name of the file being printed;

- line number of the file on which the stepping motors were stopped.

It takes less than 10 ms. Everything, now you can safely "die")

After turning on the "printer" looks to see if there is a record of stopping printing. It searches for a file on a flash drive, searches for the line on which printing was stopped. And it starts the printing process.

But, there are nuances:

First: the Z axis does not need to be touched if movement along Z did not occur.

Second: do not reset the axis on the limit switch. The fact is that the limit switches are not as accurate as we would like, even though they are optical. It is necessary to do this: knowing the current position on the axis, shift to the limit switch and start the laser there, then return to the starting position and continue printing. Similarly, you can do in the case of working with FDM printer. Although, perhaps, there it will not affect the model (it will not be seen).

Here is a short video on how this works.

Thanks for attention. What methods do you still know?

Source: https://habr.com/ru/post/403709/

All Articles