3D printer Raise3D N2 Dual

The market of 3D printers in Russia is already quite settled - there are popular models, there are “exclusives” for fans of a certain brand. There are a lot of manufacturers of such equipment now. Every month there are several new models. But the real attention is attracted only by the novelties from the market leaders. The rest, if they do not have any clear advantage, remain in the shadows. Regardless of the price and appearance.

One of the new products on the Russian market at the end of 2016 was the 3D printer Raise3D N2 Dual. This is a newcomer to our country, and its appearance has created some intrigue. The printer has a memorable appearance that distinguishes it from other similar technology. Appearance is nice, but does it have any advantages over other similar machines to become a popular model?

What does the manufacturer offer us?

First of all, a large print area attracts attention: 305 x 305 x 305 mm. This is more than the standard area 200 x 200 x 200mm, which most other representatives of additive manufacturing possess.

')

Model Raise3D N2 Dual, as can be seen from the designation “Dual”, has two extruders, which allows printing of complex models with support from soluble materials (for example, PVA). Such a combination — a large printing area and two extruders — is not common.

The appearance of a 3D printer leaves the impression that not only engineers, but also designers worked on its appearance ... Unfortunately, this is not often the case. Basically, large companies that are major players in the market are serious about this. We write in the plus.

The abundance of transparent panels leaves a feeling of lightness and openwork design. This is achieved by the fact that transparent areas are located, including in the corners of the case.

Original design and design solution. We have not seen anything like that from any other printer yet.

At the same time, the printer has a hard frame made of aluminum, which has a positive effect on print quality.

Workmanship and assembly at a height. This can be seen in the photo below.

Coils with plastic are installed on the side one above the other and closed with a transparent door. Thanks to this solution, we can monitor the amount of plastic remaining. In this case, the coils do not stick out beyond the case. And the plastic itself is protected from dust and humidity (due to being inside the chamber, where there is no humidity from the heating of the table and the extruder, and the plastic dries out if it was previously stored without a ZIP package).

Let us dwell in more detail on the features of the mechanics of a 3D printer.

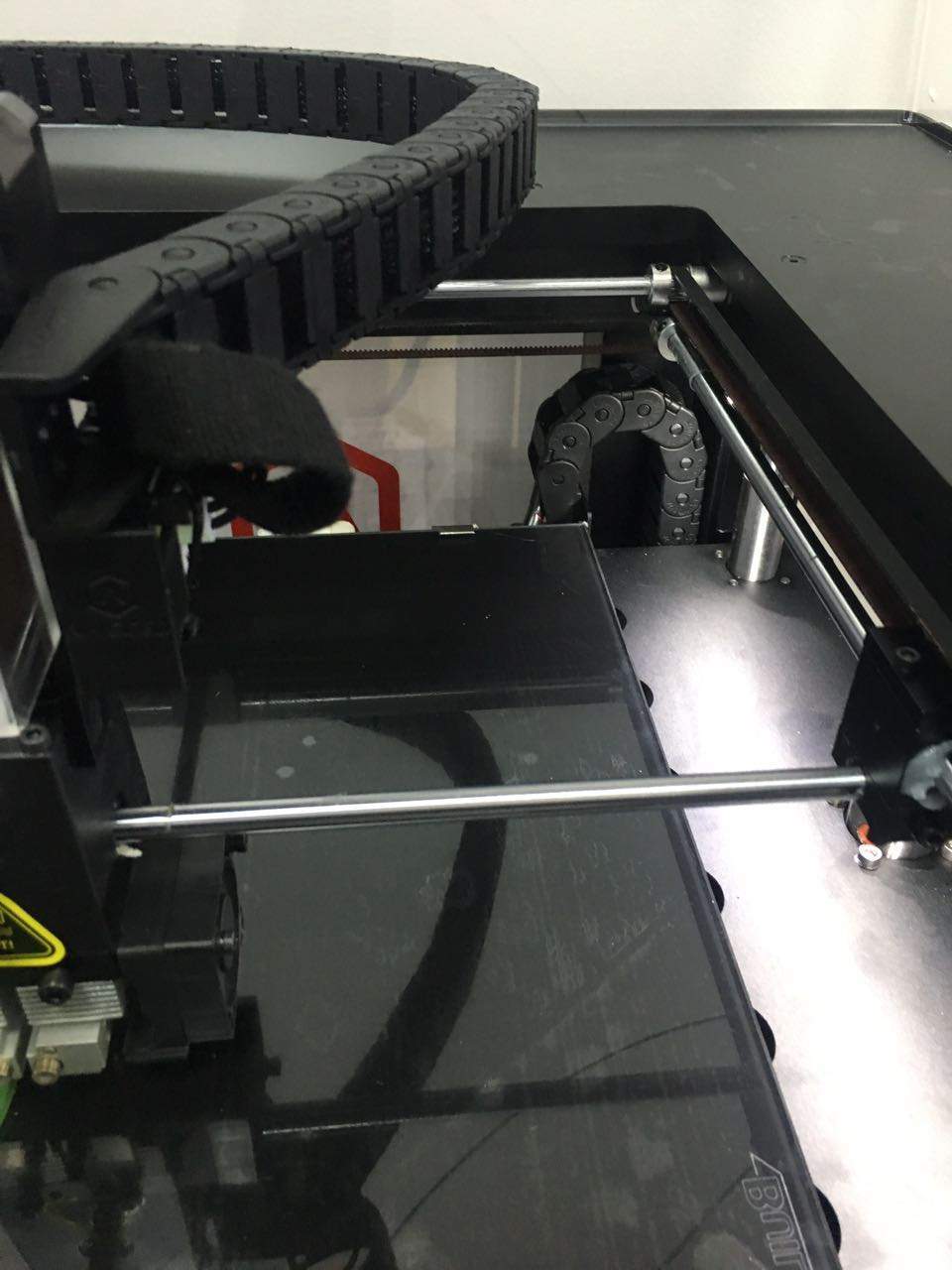

Two guide shafts and ball screws are installed on each side of the table. The desktop moves along four guides, which makes it possible to achieve stability of movement and to avoid such a wobbling phenomenon (literally “wobble” is a stepped side surface).

View of the guide shafts from the coils.

All wires in the 3D printer are hidden in special boxes. No screeds or other signs of handicraft. All this improves the appearance and adds reliability. Again, the feeling of factory assembly and complete construction.

The case has a fully enclosed design. This allows you to create a favorable temperature regime for high-quality printing, plastics with high shrinkage. For example, for high-quality printing, the most popular material is ABS, an enclosed body is one of the most important conditions after the heated table.

Heated table in the printer is also present. Recently, many manufacturers have a tendency to refuse heating. But this removes the popular ABS from the list of available materials and creates problems with printing with some other materials. The creators of Raise 3D decided not to limit their customers, or what framework. And so the printer can use any available print media.

The glass on the working surface is removable, which makes it very comfortable to work. The table itself can heat up to 110 ° C. This is sufficient for all materials used in 3D printers. Heating the table to operating temperature takes very little time.

Literally 5-7 minutes. That, compared with 10-15 minutes in many other printers, looks like a serious advantage.

Table calibration is as automated as possible. It will cope with an absolute newcomer to 3D printing. Additional knowledge is not required. The printer is designed for a wide range of users. It can be seen that the manufacturer proceeded from the principle of “3D printing right out of the box.”

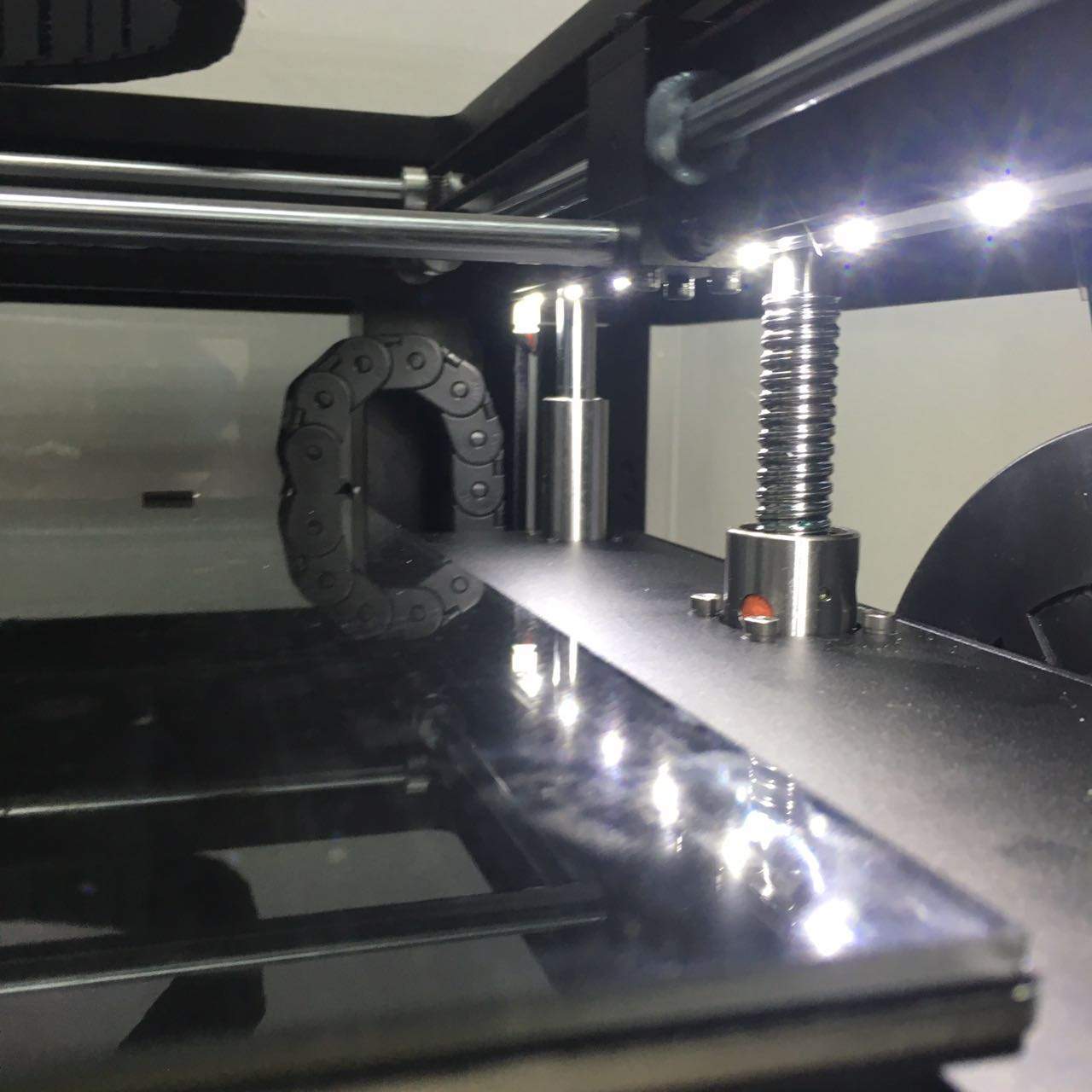

Along the inner edge of the 3D printer, the LED lighting of the working area is installed. This allows you to monitor the printing process and control it without having to open the working chamber.

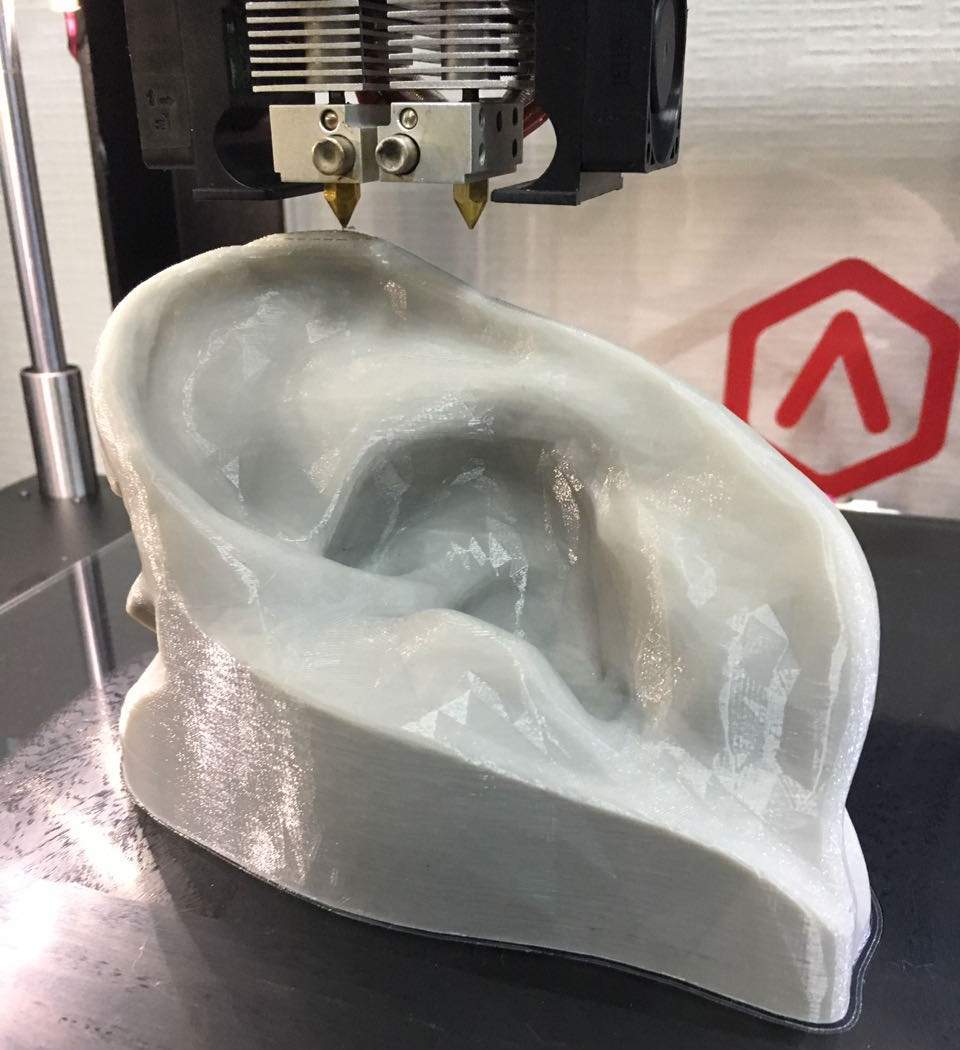

The printer is in the process of printing.

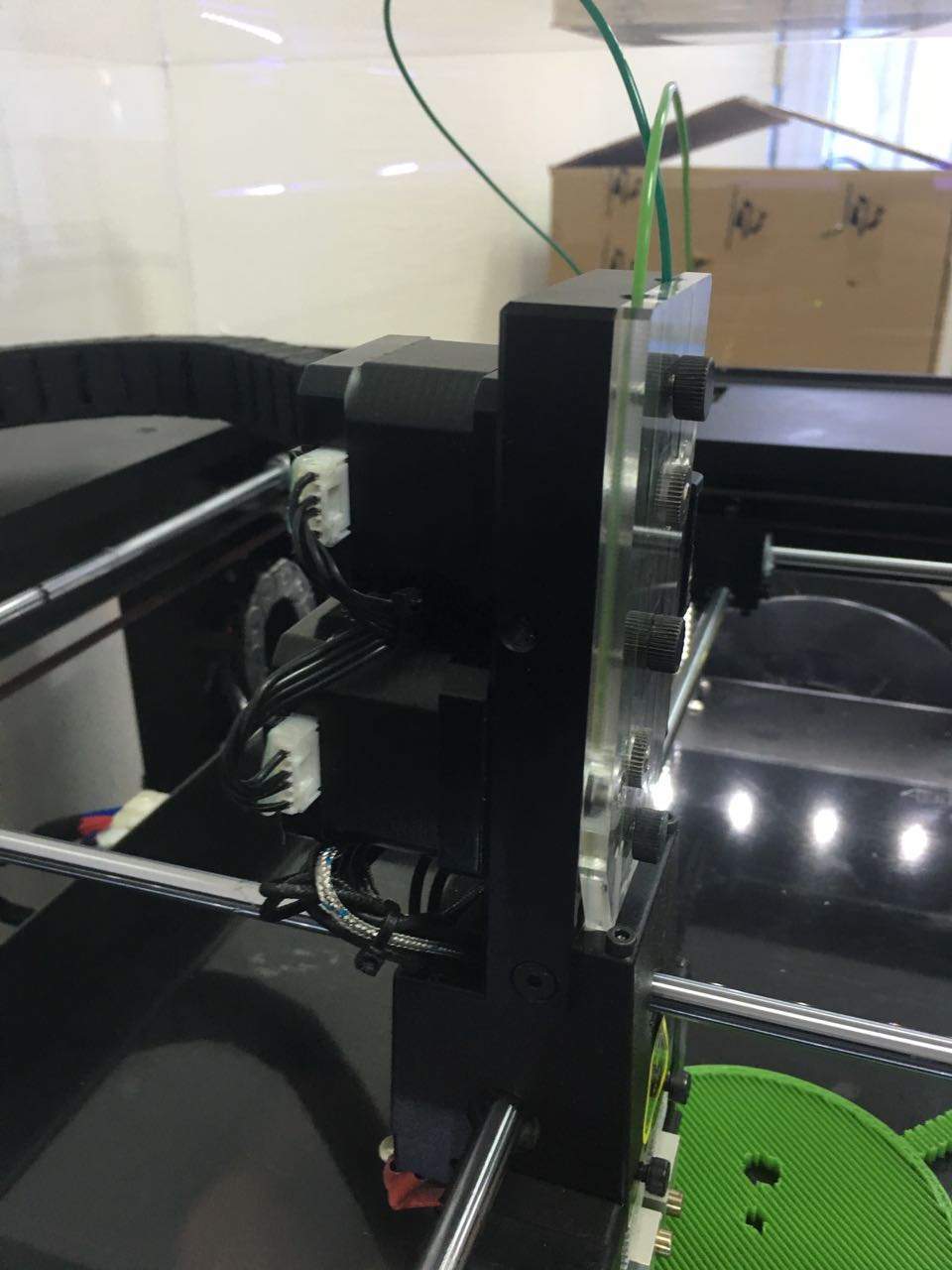

Printer kinematics are based on the circuit used in Ultimaker 3D printers. To do this, just look at this photo below.

The same guides, which simultaneously perform the role of axes, for drives of movement of the extruder. What gives such a solution? The maximum simplification and simplification of a design. This has a positive effect on print quality and printer reliability. Plus, this design is compact enough to maximize the use of the internal space of the printer. Here we see a large print area of 305 x 305 x 305 mm, with a fairly small dimensions of Raise 3D.

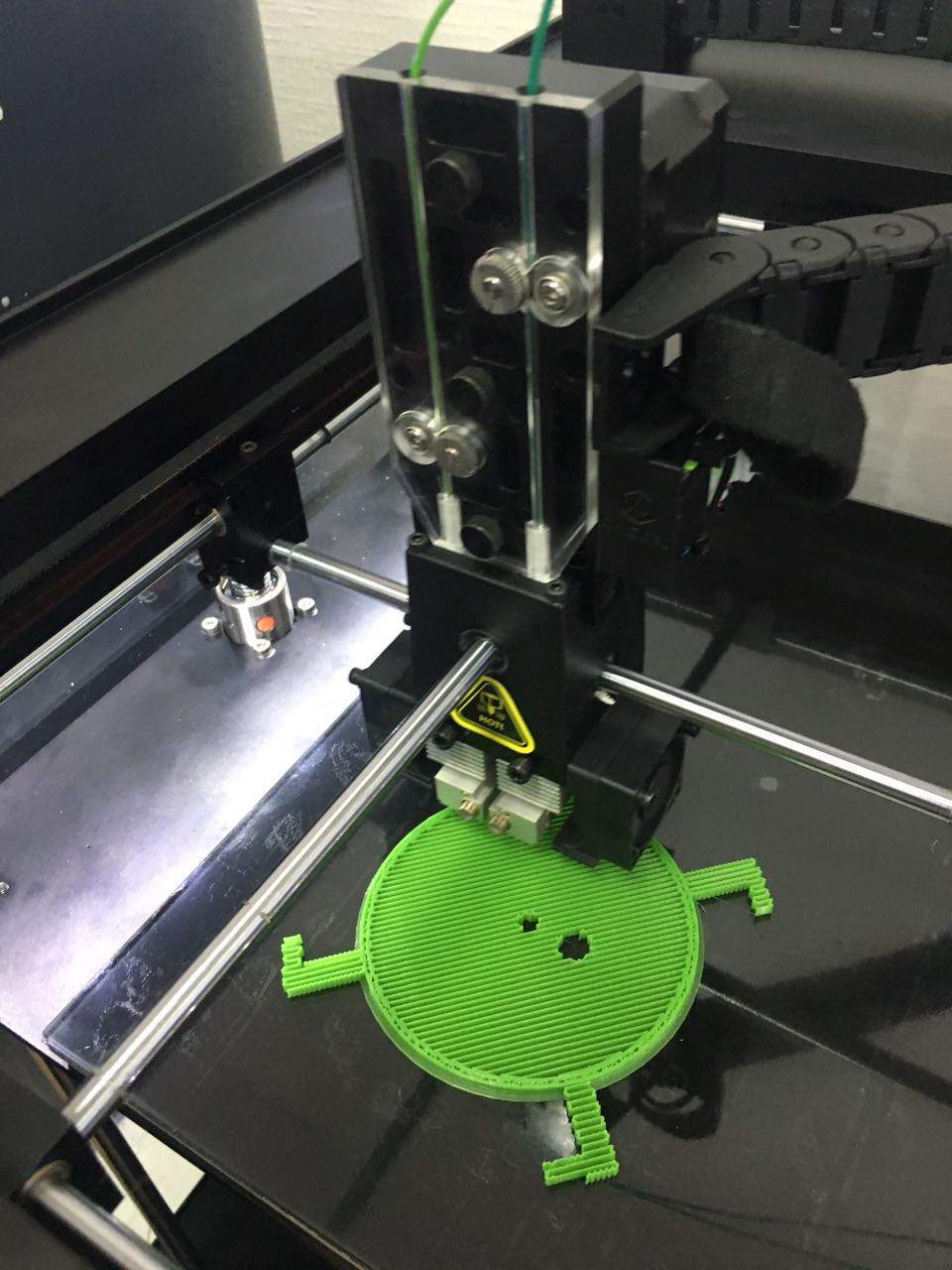

Unlike Ultimaker, a direct-extruder with two nozzles of original design is used in the printer from Raise3D.

In order to keep the dimensions of the print area, the drives of the extruders are not placed next to each other, as is commonly practiced. In this 3D printer engines are placed vertically above each other. This allowed us to create a very compact design. Unlike other 3D printers, the two-extruder and single-extruder versions of 3D Raise3D printers have the same print area. In addition, I would like to note the important advantage of direct extruders - the possibility of trouble-free printing with flexible materials.

The photo below shows how this is implemented.

Maintenance of the extruder, thanks to the transparent panels and simple design, is not difficult.

The Raise3D N2 Dual 3D printer has nozzles with a diameter of 0.4 mm installed by default. It is possible to replace the nozzle with a different diameter. But in the delivery set there are no other diameters. They are offered by the manufacturer separately. Available in sizes from 0.2mm to 0.8mm.

The extruder provides heating to 300C. This allows you to print all available materials for 3D printing (i.e., printing without restrictions on materials).

It is possible to control a 3D printer, both from a computer, and with the help of a stand-alone color touchscreen display.

The menu is intuitive. Printer management will not cause difficulties.

A large list of settings that will satisfy the requests of both novice and advanced users.

In the upper corner of the screen you can see the battery icon. The display (and this is a full-fledged tablet computer) has an autonomous power source. With its help, implemented a function that is not found in other 3D printers, but is very convenient.

When the power is turned off, the printer goes into standby mode and stops printing. However, the current status of 3D printing with all parameters remains in the memory of a stand-alone computer. When restoring electrical power, it is possible to continue 3D printing from the point of stopping.

The implementation of this function will save a lot of nerves for users of a 3D printer, especially when printing large models at 20-30 hours. Moreover, this solution is used only with Raise3D N2 series 3D printers. Other manufacturers can not pamper users with similar functionality.

The internal electronics of the printer (display / tablet) is based on the processor * Freescale imx6, Quad core 1Ghz ARM processor *, RAM - * 1GB *.

The built-in flash disk has a capacity of * 8GB *. Operating system OS: * Embedded Linux *.

Recently, there has been a tendency to use more productive solutions in standard printers to help or replace the standard Arduino. This has a positive effect on both print quality and the comfort of controlling such equipment. The monochrome screen from the Arduino kit is of course hardcore, and in Meiker style. But we live in the 21st century and touch screens and remote control devices have already firmly entered our lives.

To control the 3D printer has the following interfaces:

- 4 USB ports for connecting flash cards and webcams

- 1 Ethernet - to connect to the network for remote control

- 1 port for SD card

- WiFi

Raise3D N2 Dual has the ability to connect a web-camera for remote control printing.

External Interface Panel

WiFi and Ethernet make it possible to place Raise 3D in a convenient office location, regardless of the location of the operator computer of the 3D printer. This enables remote control and control of printing using a webcam. A thing necessary and useful for professional use of such equipment.

We told about the technical advantages of a 3D printer. But in what form will it be delivered to the buyer? We all know about the quality of cargo transportation in Russia ...

The Raise3D N2 Dual 3D printer is well packed. This eliminates shipping damage.

Inside the printer, all moving parts are fixed with special plastic clips. Moving 3D printer nodes inside is excluded. This moment is very important.

Completion of a 3D printer standard: instruction manual in Russian, a set of tools for 3D printing, flash-card, USB cable, fittings, clips.

In addition to the tools included, two coils of proprietary PLA are supplied.

The printer comes with its own slicer called ** ideamaker **. It can be downloaded for free on the manufacturer's website .

Slicer is a universal solution. It has the ability to configure other printers other than Raise 3D.

The software has a large number of settings and wide tuning options. It is possible to prepare for printing a complex model.

For example, in this slicer (the general name of the program for preparing a model for printing) is the ability to manually install supports. This function is present in literally a couple of other programs, despite all their diversity.

The model can even be cut into pieces. Check the correctness of the 3D model and correct any errors or omissions.

Additionally, there are functions for remote control of a 3D printer. You can create a “farm” of 3D printers and manage them with a single computer. The ideamaker software runs under Win, Mac and Linux. A complete set for every taste.

The design and capabilities of the printer, we have considered. And how does he eventually work?

After switching on, you can only hear the faint rustle of cooling fans. We start the seal, and the moment of truth comes.

What is the noise level from a 3D printer when printing? Usually a 3D printer begins to fill the surroundings with various sounds. From quiet rustling and funny melodies, to metallic clank.

Raise 3D on the background of other 3D printers makes little noise. Rustle movement along the guides and a small hum of the fan. Looking at the print area it is clear that printing large models will take a lot of time. And then a comfortable, low noise level adds a big fat plus to the characteristics of the printer.

The noise level is of course an important factor. But the main thing is how the printer prints.

The Raise3D N2 Dual 3D printer prints very well, yet the quality of components, kinematics, and high-performance control electronics all have an effect.

Examples of products printed on the printer:

Height of a layer is 150 microns (0.15 mm), without processing

Height of a layer is 200 microns (0.2 mm), without processing

Print speed at altitude. 80-100 mm / sec. The printer produces no reduction in quality.

According to the manufacturer can print a layer of 10 microns (0.01 mm). This is not surprising, since it uses very high quality components in the mechanics of a 3D printer.

As you know, you can say anything. But only the result is of real importance. And we can see it in the photo. And he is very impressive.

Working on Raise 3D is easy. Intuitive touch screen controls and advanced software give you excellent results when typing.

Maintenance of the printer, thanks to the well-thought-out design, is not difficult for any user.

What can be concluded about the Raise 3D N2 Dual?

Large printer for high-quality, fast printing of large objects. And two extruders make it possible to print with a combination of materials.

Main features of the 3D Raise 3D N2 Dual Printer:

You can buy a Raise3D N2 Dual 3D printer at 3Dtool

One of the new products on the Russian market at the end of 2016 was the 3D printer Raise3D N2 Dual. This is a newcomer to our country, and its appearance has created some intrigue. The printer has a memorable appearance that distinguishes it from other similar technology. Appearance is nice, but does it have any advantages over other similar machines to become a popular model?

What does the manufacturer offer us?

First of all, a large print area attracts attention: 305 x 305 x 305 mm. This is more than the standard area 200 x 200 x 200mm, which most other representatives of additive manufacturing possess.

')

Model Raise3D N2 Dual, as can be seen from the designation “Dual”, has two extruders, which allows printing of complex models with support from soluble materials (for example, PVA). Such a combination — a large printing area and two extruders — is not common.

Specifications:

- Material used for 3D printing: PLA, ABS, Filaflex, PVA, PC, Hips, Nylon, Rubber, Flex (filament diameter 1.75 mm).

- Printing area: 305 x 305 x 305 mm;

- Z-layer height: from 10 to 200 microns (0.01 - 0.2 mm)

- Nozzle diameter: 0.4 mm;

- The presence of a closed camera 3D printing: Yes;

- Heated table: Yes, up to 110 ° C;

- Extruder temperature: up to 300 ° C;

- Number of print heads: 2;

- Availability of touch screen control: Yes

Appearance

The appearance of a 3D printer leaves the impression that not only engineers, but also designers worked on its appearance ... Unfortunately, this is not often the case. Basically, large companies that are major players in the market are serious about this. We write in the plus.

The abundance of transparent panels leaves a feeling of lightness and openwork design. This is achieved by the fact that transparent areas are located, including in the corners of the case.

Original design and design solution. We have not seen anything like that from any other printer yet.

At the same time, the printer has a hard frame made of aluminum, which has a positive effect on print quality.

Workmanship and assembly at a height. This can be seen in the photo below.

Coils with plastic are installed on the side one above the other and closed with a transparent door. Thanks to this solution, we can monitor the amount of plastic remaining. In this case, the coils do not stick out beyond the case. And the plastic itself is protected from dust and humidity (due to being inside the chamber, where there is no humidity from the heating of the table and the extruder, and the plastic dries out if it was previously stored without a ZIP package).

Design features

Let us dwell in more detail on the features of the mechanics of a 3D printer.

Two guide shafts and ball screws are installed on each side of the table. The desktop moves along four guides, which makes it possible to achieve stability of movement and to avoid such a wobbling phenomenon (literally “wobble” is a stepped side surface).

View of the guide shafts from the coils.

All wires in the 3D printer are hidden in special boxes. No screeds or other signs of handicraft. All this improves the appearance and adds reliability. Again, the feeling of factory assembly and complete construction.

The case has a fully enclosed design. This allows you to create a favorable temperature regime for high-quality printing, plastics with high shrinkage. For example, for high-quality printing, the most popular material is ABS, an enclosed body is one of the most important conditions after the heated table.

Heated table in the printer is also present. Recently, many manufacturers have a tendency to refuse heating. But this removes the popular ABS from the list of available materials and creates problems with printing with some other materials. The creators of Raise 3D decided not to limit their customers, or what framework. And so the printer can use any available print media.

The glass on the working surface is removable, which makes it very comfortable to work. The table itself can heat up to 110 ° C. This is sufficient for all materials used in 3D printers. Heating the table to operating temperature takes very little time.

Literally 5-7 minutes. That, compared with 10-15 minutes in many other printers, looks like a serious advantage.

Table calibration is as automated as possible. It will cope with an absolute newcomer to 3D printing. Additional knowledge is not required. The printer is designed for a wide range of users. It can be seen that the manufacturer proceeded from the principle of “3D printing right out of the box.”

Along the inner edge of the 3D printer, the LED lighting of the working area is installed. This allows you to monitor the printing process and control it without having to open the working chamber.

The printer is in the process of printing.

Printer kinematics are based on the circuit used in Ultimaker 3D printers. To do this, just look at this photo below.

The same guides, which simultaneously perform the role of axes, for drives of movement of the extruder. What gives such a solution? The maximum simplification and simplification of a design. This has a positive effect on print quality and printer reliability. Plus, this design is compact enough to maximize the use of the internal space of the printer. Here we see a large print area of 305 x 305 x 305 mm, with a fairly small dimensions of Raise 3D.

Extruder design

Unlike Ultimaker, a direct-extruder with two nozzles of original design is used in the printer from Raise3D.

In order to keep the dimensions of the print area, the drives of the extruders are not placed next to each other, as is commonly practiced. In this 3D printer engines are placed vertically above each other. This allowed us to create a very compact design. Unlike other 3D printers, the two-extruder and single-extruder versions of 3D Raise3D printers have the same print area. In addition, I would like to note the important advantage of direct extruders - the possibility of trouble-free printing with flexible materials.

The photo below shows how this is implemented.

Maintenance of the extruder, thanks to the transparent panels and simple design, is not difficult.

The Raise3D N2 Dual 3D printer has nozzles with a diameter of 0.4 mm installed by default. It is possible to replace the nozzle with a different diameter. But in the delivery set there are no other diameters. They are offered by the manufacturer separately. Available in sizes from 0.2mm to 0.8mm.

The extruder provides heating to 300C. This allows you to print all available materials for 3D printing (i.e., printing without restrictions on materials).

Control

It is possible to control a 3D printer, both from a computer, and with the help of a stand-alone color touchscreen display.

The menu is intuitive. Printer management will not cause difficulties.

A large list of settings that will satisfy the requests of both novice and advanced users.

In the upper corner of the screen you can see the battery icon. The display (and this is a full-fledged tablet computer) has an autonomous power source. With its help, implemented a function that is not found in other 3D printers, but is very convenient.

When the power is turned off, the printer goes into standby mode and stops printing. However, the current status of 3D printing with all parameters remains in the memory of a stand-alone computer. When restoring electrical power, it is possible to continue 3D printing from the point of stopping.

The implementation of this function will save a lot of nerves for users of a 3D printer, especially when printing large models at 20-30 hours. Moreover, this solution is used only with Raise3D N2 series 3D printers. Other manufacturers can not pamper users with similar functionality.

The internal electronics of the printer (display / tablet) is based on the processor * Freescale imx6, Quad core 1Ghz ARM processor *, RAM - * 1GB *.

The built-in flash disk has a capacity of * 8GB *. Operating system OS: * Embedded Linux *.

Recently, there has been a tendency to use more productive solutions in standard printers to help or replace the standard Arduino. This has a positive effect on both print quality and the comfort of controlling such equipment. The monochrome screen from the Arduino kit is of course hardcore, and in Meiker style. But we live in the 21st century and touch screens and remote control devices have already firmly entered our lives.

Interfaces

To control the 3D printer has the following interfaces:

- 4 USB ports for connecting flash cards and webcams

- 1 Ethernet - to connect to the network for remote control

- 1 port for SD card

- WiFi

Raise3D N2 Dual has the ability to connect a web-camera for remote control printing.

External Interface Panel

WiFi and Ethernet make it possible to place Raise 3D in a convenient office location, regardless of the location of the operator computer of the 3D printer. This enables remote control and control of printing using a webcam. A thing necessary and useful for professional use of such equipment.

Equipment

We told about the technical advantages of a 3D printer. But in what form will it be delivered to the buyer? We all know about the quality of cargo transportation in Russia ...

The Raise3D N2 Dual 3D printer is well packed. This eliminates shipping damage.

Inside the printer, all moving parts are fixed with special plastic clips. Moving 3D printer nodes inside is excluded. This moment is very important.

Completion of a 3D printer standard: instruction manual in Russian, a set of tools for 3D printing, flash-card, USB cable, fittings, clips.

In addition to the tools included, two coils of proprietary PLA are supplied.

Software

The printer comes with its own slicer called ** ideamaker **. It can be downloaded for free on the manufacturer's website .

Slicer is a universal solution. It has the ability to configure other printers other than Raise 3D.

The software has a large number of settings and wide tuning options. It is possible to prepare for printing a complex model.

For example, in this slicer (the general name of the program for preparing a model for printing) is the ability to manually install supports. This function is present in literally a couple of other programs, despite all their diversity.

The model can even be cut into pieces. Check the correctness of the 3D model and correct any errors or omissions.

Additionally, there are functions for remote control of a 3D printer. You can create a “farm” of 3D printers and manage them with a single computer. The ideamaker software runs under Win, Mac and Linux. A complete set for every taste.

Exploitation

The design and capabilities of the printer, we have considered. And how does he eventually work?

After switching on, you can only hear the faint rustle of cooling fans. We start the seal, and the moment of truth comes.

What is the noise level from a 3D printer when printing? Usually a 3D printer begins to fill the surroundings with various sounds. From quiet rustling and funny melodies, to metallic clank.

Raise 3D on the background of other 3D printers makes little noise. Rustle movement along the guides and a small hum of the fan. Looking at the print area it is clear that printing large models will take a lot of time. And then a comfortable, low noise level adds a big fat plus to the characteristics of the printer.

The noise level is of course an important factor. But the main thing is how the printer prints.

The Raise3D N2 Dual 3D printer prints very well, yet the quality of components, kinematics, and high-performance control electronics all have an effect.

Examples of products printed on the printer:

Height of a layer is 150 microns (0.15 mm), without processing

Height of a layer is 200 microns (0.2 mm), without processing

Print speed at altitude. 80-100 mm / sec. The printer produces no reduction in quality.

According to the manufacturer can print a layer of 10 microns (0.01 mm). This is not surprising, since it uses very high quality components in the mechanics of a 3D printer.

As you know, you can say anything. But only the result is of real importance. And we can see it in the photo. And he is very impressive.

Working on Raise 3D is easy. Intuitive touch screen controls and advanced software give you excellent results when typing.

Maintenance of the printer, thanks to the well-thought-out design, is not difficult for any user.

findings

What can be concluded about the Raise 3D N2 Dual?

Large printer for high-quality, fast printing of large objects. And two extruders make it possible to print with a combination of materials.

Main features of the 3D Raise 3D N2 Dual Printer:

- Large printing area.

- Closed housing.

- Two extruders.

- Convenient operation, using the touch screen.

- Wide range of interfaces: USB, SD card, Ethernet, WiFi.

- Remote control.

- Ability to connect the camera.

- Ability to continue printing after turning off the email. energy.

- Own software included

- Wide range of extruder and table temperatures.

- Ease of maintenance.

- Build quality

You can buy a Raise3D N2 Dual 3D printer at 3Dtool

Source: https://habr.com/ru/post/402913/

All Articles