New XPRO - focus on detail

In anticipation of the massive sales of the new PICASO 3D Designer X PRO , which is already available for pre-order , the question becomes - how does this 3D printer differ from numerous colleagues, what are the features of working on it and how it will look in practice. With these questions we turned to the representatives of the company PICASO 3D, who kindly shared the information.

The printer is equipped with several new systems, which are designed to both significantly improve print quality and ensure ease of working with it. The number of these innovations included the systems responsible for: control of plastic supply, automatic notifications about the operation of the device, control of the first layer, profiles of work with different materials, network printing and accurate auto-calibration. About each of them we will tell a little more below.

')

The print head of the printer (hereinafter - PG) is equipped with the updated JetSwitch technology, which has proven itself in the previous Designer PRO 250 model. Let us explain for those who are not familiar with this technology: the technology allows using 2 materials for operation simultaneously - which instantly blocks the feed of one of the materials, without the need for cooling, which makes printing two materials at the same time cleaner and much faster.

Updated JetSwitch now has two print modes. In one of them, which is enabled by default, using the built-in nozzle cleaning system, you can confidently print even the most subtle elements, so it is perfect for complex presentation and detailed printing.

The speed of switching between materials is 5 seconds.

The second print mode is accelerated. The speed of switching between materials in this mode is less than one second. Due to this, the speed of printing parts with support and printing in two colors is significantly increased. This mode is more suitable for printing large objects with walls thicker than one millimeter.

The rest is further, in order.

Plastic control system

PICASO 3D Designer X PRO is equipped with sensors (encoders) that control the slippage of the thread in the plastic feeding system. The printer constantly “counts” how much plastic passes through the extruder per unit of time. What does this give? The use of such a solution helps to avoid many cases of print failure, and therefore unnecessary loss of material, time and nerves. Now, if plastic runs out or the nozzle starts to get clogged, Designer X PRO will automatically identify the problem and try to fix it by using the built-in nozzle cleaning algorithm.

If the problem is solved after automatic cleaning, the printer will continue to work and notify the user that there were difficulties in the printing process. This will help to draw attention to this situation and avoid its recurrence.

If the automatic cleaning does not work, the Designer X PRO will pause the print and inform the user, using the built-in alert system, about the situation. The user can manually clean the printhead, replace the material, or replace the nozzle. As soon as the problem is solved, the printer will be able to continue working without loss of print results, material and time.

Continuous feed control helps to avoid situations where plastic is already out of the coil and the printer has not finished building the model. Designer X PRO is not yet able to change plastic itself, but it is already capable of sending a signal to the user when a problem occurs.

Alert system

As we have said, Designer X PRO not only controls its state, but also shares this information with the user. By changing the color of the backlight of the working chamber, the device will tell you: at what stage is printing, are there any difficulties in the process of work and whether user intervention is required. If you have an Internet connection, the device will be able to notify you of its condition, even if you are not near the printer. The controllability and predictability of the process is one of the most important features of the new Designer X PRO.

First layer control system

Anyone who has used a 3D printer at least once knows the importance of the first layer. He is like a foundation. If the foundation is uneven or fragile, then the whole building will collapse sooner or later. Similarly, in 3D printing, a poorly adhered to the platform or an uneven first layer, with a very high probability, will destroy the entire printout. The difficulty lies in the fact that for different types of plastic, a clamp to the printing platform is needed different. Thanks to the feedback system, in each case, the Designer X PRO achieves optimal clamping.

When you start a print job and first touch the table nozzle, the printer measures the speed of the filament and, almost instantly, corrects the position of the table along the Z axis for optimal construction of the first layer.

Profile system

Thanks to the new profile system, Designer X PRO “knows” what material is currently installed in which nozzle of the printer. This immediately solves a whole complex of possible problems that may arise due to improper settings for the type of material - in the process of preparing for printing or during changeover, after changing the material. Now, after loading the filament into the printer, when preparing the print job, there is no need to set the temperature separately, feed speed separately, etc. - having prepared once a profile for each material and saving it in the printer, you can print with any similar material, without losing time to prepare a new job.

Network printing

Networking is not just the ability to remotely receive alerts from the printer. This is a function that allows you to combine several Designer X PROs into a single structure managed from one computer using the updated Polygon X program. Monitor printing, track installed materials, create job queues, assign them to devices, schedule work schedules, track alerts from all devices in single interface - now all this can be done quickly, without getting up from the workplace.

Jet Switch Extruder

The updated Jet Switch extruder is a twin-nozzle extruder that allows you to print with two materials and instantly stop the flow of one of them without reducing the temperature. The modified new version of the extruder, due to changes in the internal structure, has a high print quality, increased productivity and resistance to blockages.

Specifications:

Printing material: PLA, ABS, PLA Flexible, PVA, PC, Hips, Nylon, Laywood, FilaFlex, Filamentarno.

Thread diameter: 1.75 mm.

Printing area: 200 x 200 x 210 mm.

Body Material: Aluminum (composite).

Guides (steel): X and Y - rail, Z - cylindrical.

Layer thickness: from 0.05 to 0.25 mm, adjustable through software.

Positioning accuracy: XY: 11 microns, Z: 1.25 microns.

The presence of a heated platform: Yes.

Printing platform: Aluminum and glass.

Number of printheads: 2.

Automatic table calibration: Yes.

Nozzle diameter: 0.3 mm.

Maximum extruder operating temperature: 380 ° C.

Maximum working temperature of the working platform: 140 ° C.

Noise level: 55 dB.

Management board: based on ARM CORTEX M4 32 bit STM.

Interfaces: USB, Ethernet, USB Flash (drive included).

Compatible with OS: Windows XP, Windows 7, Windows 8-10.

Print speed: up to 30 cm3 / hour.

Supported formats: STL, PLG.

Software: PICASO 3D Polygon X

Operating ambient temperature: 15 ° - 32 ° C.

Dimensions: 492x390x430mm;

Weight: 16kg.

Dimensions and weight in the package: 690 x 500 x 470, 22 kg.

Power Consumption: 220V + - 15% 50Hz (110V + -15% 60Hz option is available) 400W.

Warranty: 2 years.

As we see, the new PICASO 3D Designer X PRO is significantly different not only from 3D printers from other manufacturers, but also from its predecessor - PICASO 3D Designer 250 PRO. In the near future we will be able to see this in practice and will certainly share our impressions.

Look closer

And now the fun part! The new Designer X PRO contains much more: an easily removable magnetic table, directional material feeding, new construction materials and other interesting solutions.

XPRO supports printing with a variety of different materials, including PLA, PVA, flex, rubber, relax, and even carbon.

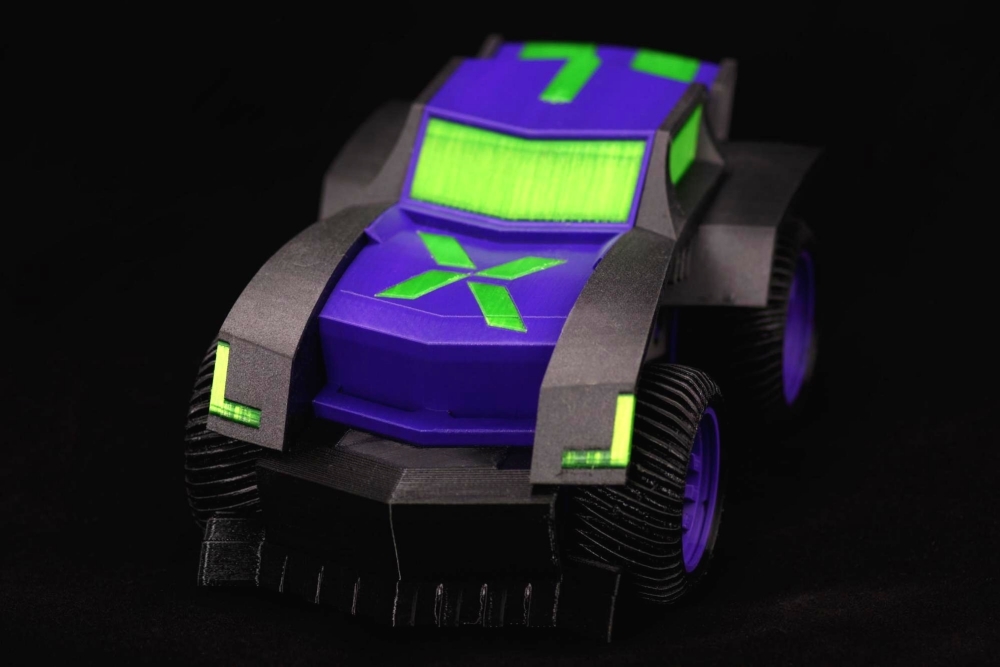

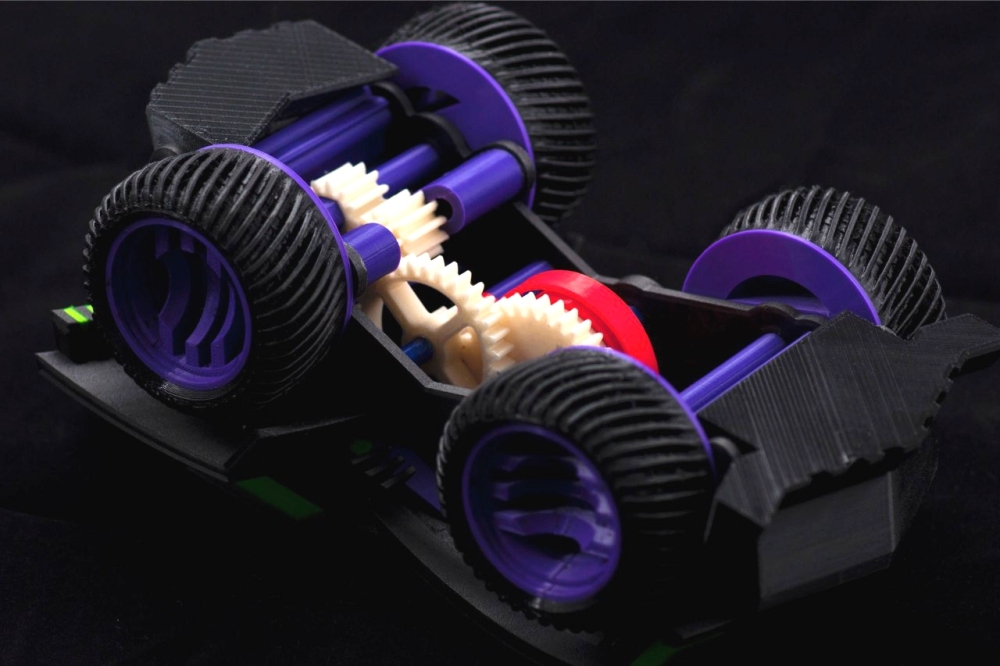

This sample is printed on PICASO DESIGNER XPRO with different materials:

You can take a closer look at this typewriter and other samples, and also see the new printer at work at the upcoming Top 3D Expo 2017 exhibition and conference, which will be held on April 14 in Moscow.

Source: https://habr.com/ru/post/402849/

All Articles