XYZPrinting Polymerization Chamber Overview

Hello! With you Top 3D Shop and today we present to your attention the polymerization chamber from the company XYZPrinting .

What is polymerization

')

It is no secret that the models printed from photopolymers using SLA and DLP technologies must be pre-exposed — expose to ultraviolet radiation immediately after printing, in order to achieve complete polymerization. For example, Formlabs standard resins need to be exposed for at least half an hour.

In industrial machines, the issue is resolved - optionally, a special camera can be purchased for the final processing of models. But manufacturers of personal SLA and DLP printers do not offer the user ready-made solutions in this narrow matter, but only give recommendations on the correct illumination and hint at the purchase of nail lamps.

Formlabs stood out a little against this background - they offer several instructions for manually assembling the camera, with milling of the box, examples of painting and a list of all the necessary electronics, but the cost of such a project and time spent at a certain stage can become uncomfortable.

An example of the most budgetary version of the camera for UV illumination

XYZPrinting has long established itself as a manufacturer of low-cost solutions in 3D scanning and FDM printing, so the announcement of their Nobel 1.0 SLA printer at CES 2015 was a pleasant surprise for the market - the budget target did not change, but the car had quite decent performance, and Already in December 2016, the successor of this model was introduced - 1.0A, in which laser positioning accuracy was adjusted, print speed and some other parameters, while the print area is 128x128x200mm, and the printer is still one of the most affordable similar solutions on the market SLA-equipment.

Exactly with the announcement of this model, a special chamber was introduced for the polymerization of printed models, which we tested in the service department's mode of operation, when printing and processing of polymer models occurs almost daily. This device has proved its necessity to us.

XYZPrinting Polymerization Chamber

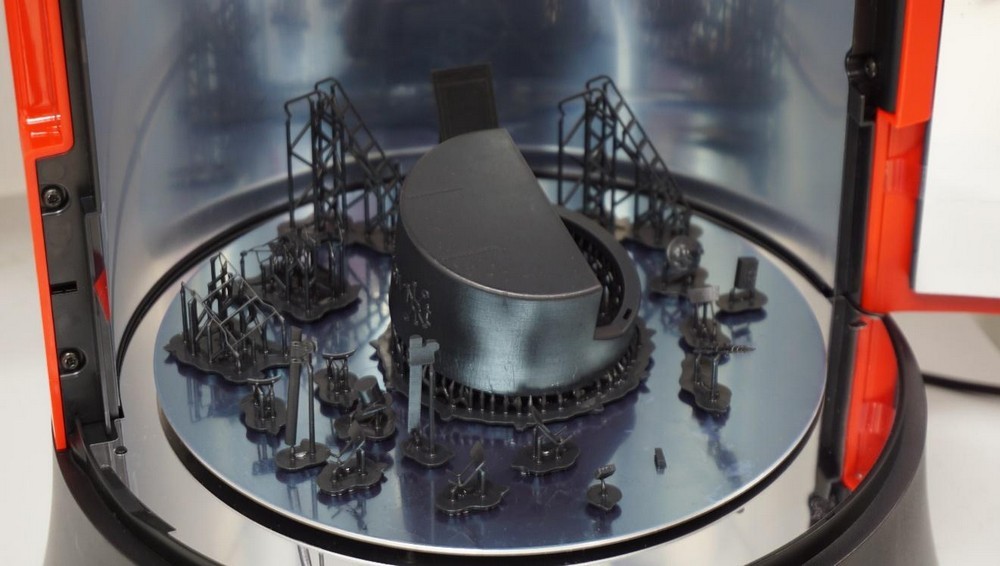

The device has a pleasant design and is made in the corporate colors of the professional line of equipment XYZ - black with red. Comes in a small box, in a tight foam frame. The kit is minimalistic - the device, the manual and the power cable with the unit.

The internal space of the camera is 180 mm in diameter and 200 mm in height, which exceeds the size of the cameras of many SLA and DLP printers, respectively - all printed models fit in one go, even with supports.

Device and control

The ultraviolet diode at 16 watts is installed on top, the radiation wavelength varies from 370 to 405nm, the claimed diode life is 10,000 hours of operation, from the bottom there is a turntable that can withstand weight up to 1.5kg, all surfaces inside are completely mirror and glossy, for all-round UV propagation -radiation.

Control of the illumination parameters is carried out on a small panel with a display and diodes. Use the Mode button to switch between three main features:

Power - power of illumination, from 1 to 3, adjusts the wavelength of illumination - 370, 385 and 405 nm;

Time - flare time in minutes, from 1 to 60;

Power + Time - when both diodes are lit, the work of the rotary table is regulated, the number 1 - the table will rotate during illumination, 0 - respectively, will not.

Having defined the necessary settings, press the Start button and the device begins to count down the specified time, while the diode with the inscription Curing is activated. At the end of the process, a short beep will sound. If you open the door in advance, the process pauses and the diode turns off, so that you will not be able to catch the device directly from the inside.

Modes of operation

It may be a fair question - from what considerations is chosen the power and time of exposure? It depends solely on the recommendations of the manufacturer of photopolymers that you print. For example, XYZPrinting themselves, for polymers of their own production, are recommended to put the power on the figure 3, time - 10 minutes.

Formlabs for polymers Clear, Black, Gray, White, Flexible recommend 60 minutes of exposure at a power of 405nm, for Castable and Durable 120 minutes, for Tough 30 minutes, respectively, this is the third mode in the Power section, but for High Temp you need 60 minutes of exposure to The emission wavelength is 365nm, in this case you need to set the Power mode to 1.

We tested the camera for a week, it proved to be an easy-to-use tool. The advantages over DIY solutions are obvious - this is the final product with a nice design, a turntable and a spacious camera. The device is compact, allowing to process polymers with different requirements for the length of UV radiation. The device will become an indispensable assistant both for companies printing on SLA and DLP technologies per stream, as well as for ordinary users who want a simple and universal solution for exposing polymer models. The cost of the device is 29 900 rubles.

Specifications

Special offer

The polymerizer perfectly complements Formlabs Form2 3D printer - together they make up a ready solution for stereolithographic printing and post-processing of three-dimensional models.

In this regard, we have prepared a special offer:

A set of both positions now costs only 339,000 rubles.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/402561/

All Articles