Short life and spectacular death of a budget LED lamp

A formal review of these lamps was published on another resource and I did not plan to return to them. However, last night in my room there was a soft cotton and the apartment was plunged into darkness. Knocked out a circuit breaker. After the restoration of lighting, it turned out that this lamp had died so spectacularly.

Therefore, I decided to remove the formal review, and rework, supplement and publish the material here.

Initially, the lamps caught my attention by using LEDs such as 7020SMD (88 pcs.). The lamp has a luminous flux of 700 lm, which corresponds to a 60 watt incandescent lamp. Those. I use them as a replacement for such lamps in the lamps. In particular, the kitchen lamp mentioned in other material.

')

Just now contains 4 such lamps. They still work, first of all, I believe, due to the fact that the lamp in the kitchen almost always turns on for a short (no more than 30 min.) Period of time.

Characteristics of the original Buybay Foxanon 7W 700 WL

The lamp looks like this (photo from the online store).

I ordered lamps with E27 and E14 bases (warm and cold light).

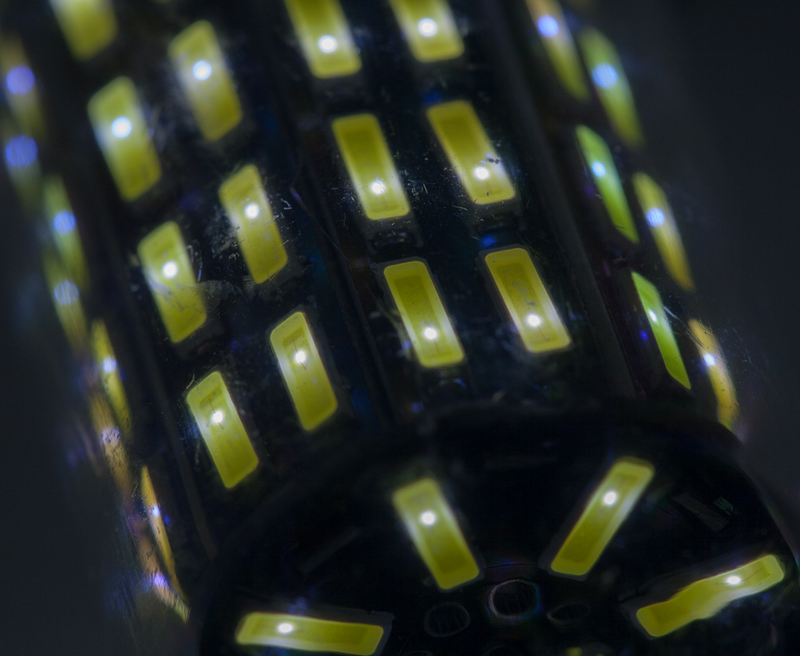

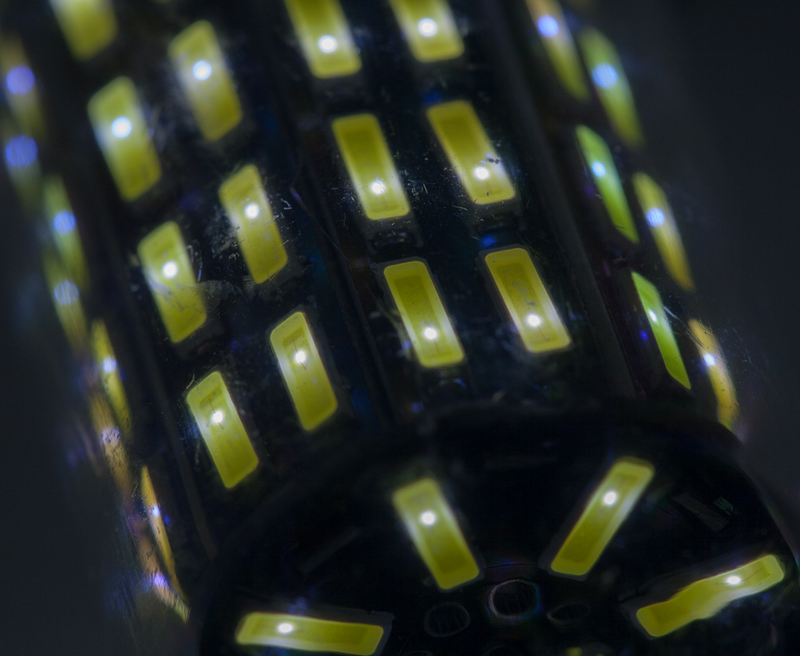

Photos of burning LEDs:

Curious asymmetrical arrangement of the LED under the phosphor film.

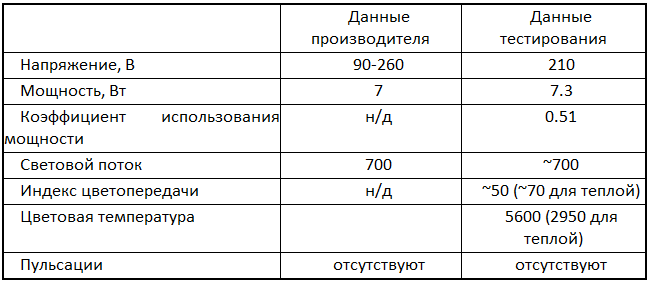

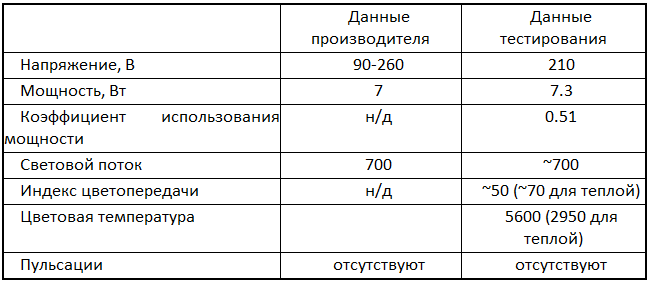

I recall the assessment methods described in the book. The table below provides information for a cold light lamp with an E27 base.

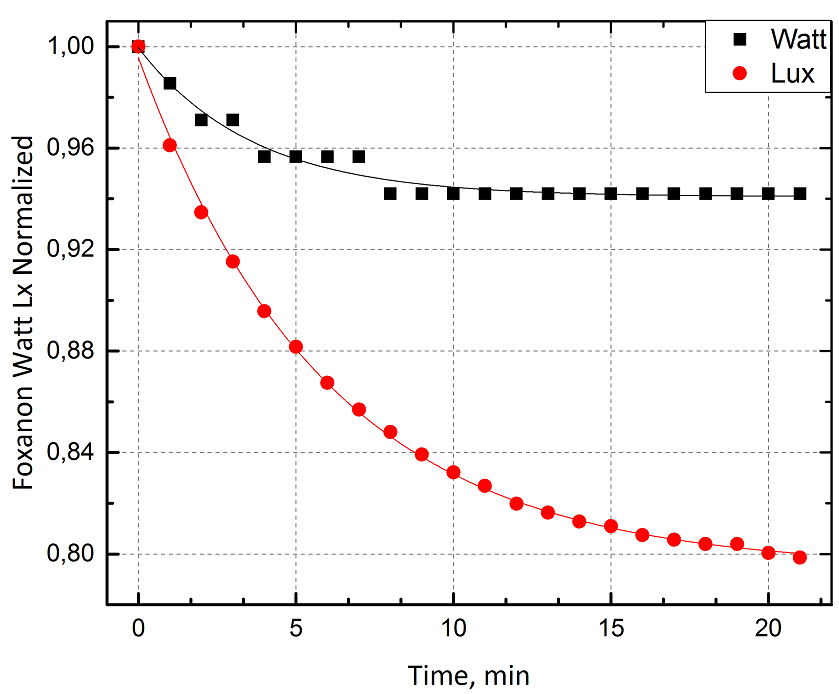

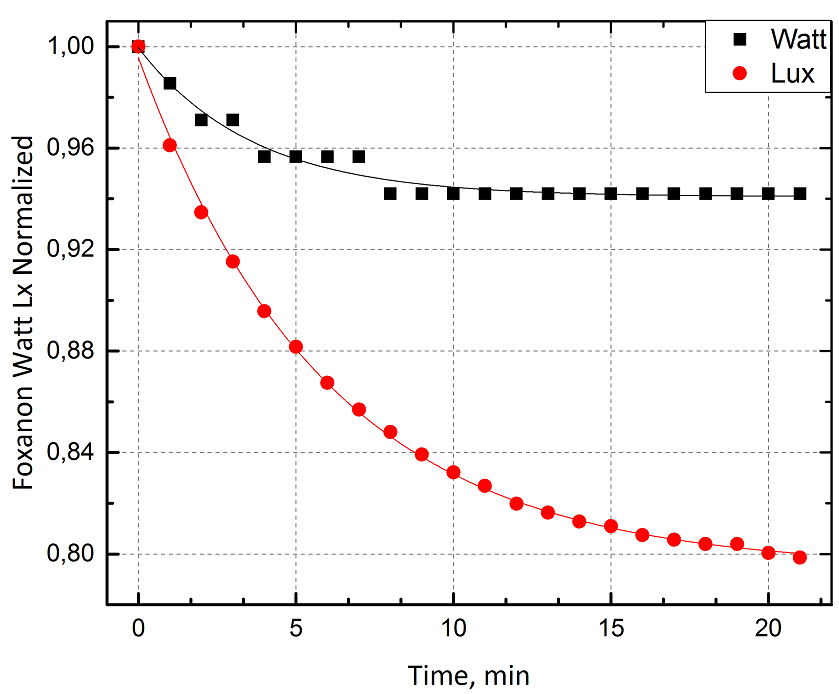

Transitional characteristics.

Reducing electrical power by 8% looks acceptable. But the fall in illumination (i.e., in fact, luminous flux) by 21% is too much. This indirectly indicates too high a temperature of diabetes, i.e. poorly organized cooling. Compared with later developments, this lamp has holes in the upper part of the transparent cap. Newer lamps have long slots for almost the entire length of the cap.

I made two orders. For the first time these were only lamps with an E27 base. Their characteristics (including illumination by lux meter) were almost identical. However, when then I ordered the E27 and E14 lamps - I received lamps of a completely different quality. It was expressed:

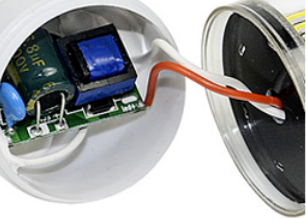

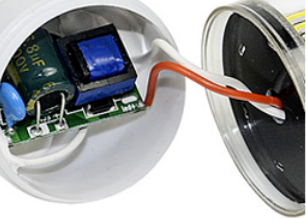

Then, the driver in the E14 lamp differed from those in the E27 base.

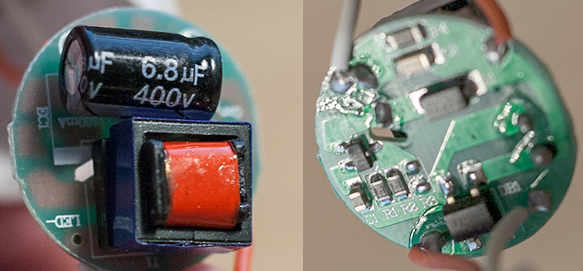

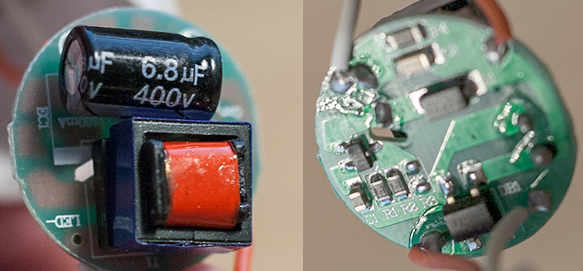

E27 (photo from the seller's website):

E14 (photographed by me):

Tellingly, when disassembling the lamp, the soldered mains wire came off. Those. The build quality of the lamps is low and varies from batch to batch.

Inspection of the scene

The lamp with E14 base worked in a wall sconce in a horizontal position in a cylindrical diffuser (the ends are open). Used from the beginning of January of this year to March 7, about 5 hours a day. Those. only about 60x5 = 300 hours. Let me remind you that the manufacturer promised 100,000 hours, i.e. the lamp worked 0.3% of the declared resource.

Consider the individual parts of the burnt SDL

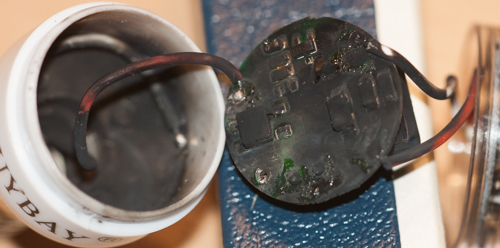

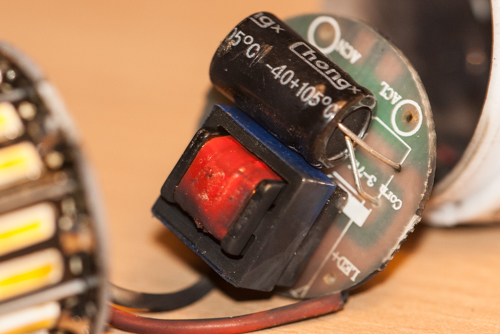

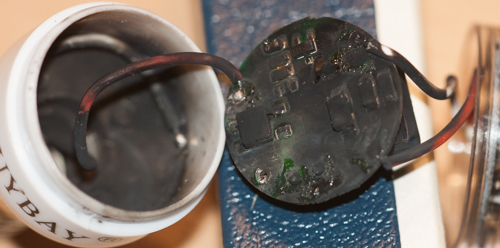

Driver

Downside

I don't know much about electrical engineering, but it looks like the transformer is damaged and the parts on the printed circuit board are burned out. Moreover, they burned very concretely, judging by the amount of soot on the plastic base. In this case, one of the network wires is torn off (in the first picture on the left is white).

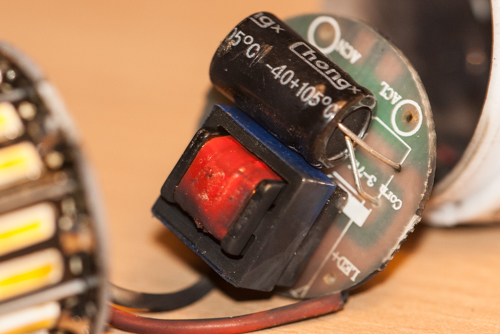

LED array

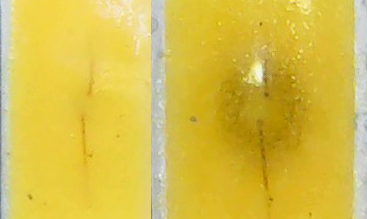

First of all, the changed appearance of SD is striking.

They have become slightly darker, the phosphor is more transparent, and the diamonds themselves are highlighted by dark dots. This indicates exposure to high temperatures.

Here is a comparison of the original and worked 300 hours SD.

(they look brighter compared to the previous picture, because they are illuminated by cold LED microscope USB, and the white balance is not adjusted). Obviously, the SD crystal worked at a very high temperature.

Protective plastic cap

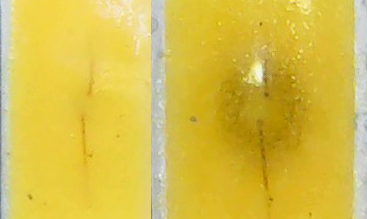

For a start photo of the new (right) cap in comparison with the worked.

Draws attention to the abundance of soot. More interesting is the presence of linear (needle) crystals in the lower and upper parts. Here is the bottom of the larger.

Below the dark-colored cylindrical strip is the place where the aluminum horizontal part of the LED block is closest to the plastic. Needle crystals are slightly higher. This is a picture typical of the chemical process of sublimation. So, for example, you can clean naphthalene - put it in a heated bath, its molecules will pass into a gaseous state, and then condense in the cold part of the sublimation apparatus (usually cooled with running water) in the form of crystals. Those. at the place where the hot aluminum part was located at the maximum, the temperature was so high that either the polymer degraded into fragments, or (more likely) individual components were separated from it. Which then condensed in the form of needles nearby, where the temperature is already lower. (I note that it is possible to release substances from PCB or other driver components.).

The block SD contains two similar horizontal round metal parts. Indeed, a similar pattern is observed in the upper part of the cap.

Needle crystals are visible at the bottom of the frame. Curiously, in the upper right corner of the visible liquid droplets. Most likely, this is a plasticizer (quoted from Wiki: “Plasticizers are substances that are incorporated into polymeric materials to impart (or improve) elasticity and (or) plasticity during processing and operation. Plasticizers facilitate the dispersion of ingredients, reduce the processing temperature of the compositions , improve the frost resistance of polymers, but sometimes worsen their heat resistance. Some plasticizers can increase the fire, light and heat resistance of polymers. "). The most widely known (but nameless for the vast majority of people) in everyday life plasticizer is dibutyl phthalate ester. Because it is a mosquito repellent. This I mean that such liquids have a very high boiling point, low volatility and are practically harmless to humans (unless you take them inside).

The appearance of crystals and drops can be due to two reasons (most likely, their combination): the poor quality of the plastic of the protective cap and too high working temperature of the SDL. Drops gathered at the top of the cap because there is the coldest area.

What can be said in conclusion? Of the advantages, we can mention a rather high efficiency of about 100 lm / W and a low price (about 140 rubles per piece).

Cons are much more.

• spread in quality of lamps

• strong variation in the value of the luminous flux from instance to instance

• low color rendering index for cold lamps

• too much decline in light when the lamp warms up to operating temperature

• non-optimal design of the protective cap, which complicates cooling

• the real operating temperature of the SDL is too high, which leads to the degradation of all its parts: the driver, the SD crystals, the phosphor and even the protective cap

• bad driver, which is expressed in:

- low power factor

- in lamps without notification drivers of different types can be used

- failure is accompanied by the release of a large amount of soot, while the driver is not subject to repair.

Buying such lamps for use without modification makes no sense. Completion - at a minimum - should include driver revision and improved ventilation (additional holes or slots in the plastic of the base and protective cap).

Therefore, I decided to remove the formal review, and rework, supplement and publish the material here.

Initially, the lamps caught my attention by using LEDs such as 7020SMD (88 pcs.). The lamp has a luminous flux of 700 lm, which corresponds to a 60 watt incandescent lamp. Those. I use them as a replacement for such lamps in the lamps. In particular, the kitchen lamp mentioned in other material.

')

Just now contains 4 such lamps. They still work, first of all, I believe, due to the fact that the lamp in the kitchen almost always turns on for a short (no more than 30 min.) Period of time.

Characteristics of the original Buybay Foxanon 7W 700 WL

The lamp looks like this (photo from the online store).

I ordered lamps with E27 and E14 bases (warm and cold light).

Photos of burning LEDs:

Curious asymmetrical arrangement of the LED under the phosphor film.

I recall the assessment methods described in the book. The table below provides information for a cold light lamp with an E27 base.

Transitional characteristics.

Reducing electrical power by 8% looks acceptable. But the fall in illumination (i.e., in fact, luminous flux) by 21% is too much. This indirectly indicates too high a temperature of diabetes, i.e. poorly organized cooling. Compared with later developments, this lamp has holes in the upper part of the transparent cap. Newer lamps have long slots for almost the entire length of the cap.

I made two orders. For the first time these were only lamps with an E27 base. Their characteristics (including illumination by lux meter) were almost identical. However, when then I ordered the E27 and E14 lamps - I received lamps of a completely different quality. It was expressed:

- in a wide range of light values

- in the range of electric power values - from 5.6 to 7.3 W

- in the range of Km values: almost all lamps have ~ 0.5, but one lamp showed 0.77.

Then, the driver in the E14 lamp differed from those in the E27 base.

E27 (photo from the seller's website):

E14 (photographed by me):

Tellingly, when disassembling the lamp, the soldered mains wire came off. Those. The build quality of the lamps is low and varies from batch to batch.

Inspection of the scene

The lamp with E14 base worked in a wall sconce in a horizontal position in a cylindrical diffuser (the ends are open). Used from the beginning of January of this year to March 7, about 5 hours a day. Those. only about 60x5 = 300 hours. Let me remind you that the manufacturer promised 100,000 hours, i.e. the lamp worked 0.3% of the declared resource.

Consider the individual parts of the burnt SDL

Driver

Downside

I don't know much about electrical engineering, but it looks like the transformer is damaged and the parts on the printed circuit board are burned out. Moreover, they burned very concretely, judging by the amount of soot on the plastic base. In this case, one of the network wires is torn off (in the first picture on the left is white).

LED array

First of all, the changed appearance of SD is striking.

They have become slightly darker, the phosphor is more transparent, and the diamonds themselves are highlighted by dark dots. This indicates exposure to high temperatures.

Here is a comparison of the original and worked 300 hours SD.

(they look brighter compared to the previous picture, because they are illuminated by cold LED microscope USB, and the white balance is not adjusted). Obviously, the SD crystal worked at a very high temperature.

Protective plastic cap

For a start photo of the new (right) cap in comparison with the worked.

Draws attention to the abundance of soot. More interesting is the presence of linear (needle) crystals in the lower and upper parts. Here is the bottom of the larger.

Below the dark-colored cylindrical strip is the place where the aluminum horizontal part of the LED block is closest to the plastic. Needle crystals are slightly higher. This is a picture typical of the chemical process of sublimation. So, for example, you can clean naphthalene - put it in a heated bath, its molecules will pass into a gaseous state, and then condense in the cold part of the sublimation apparatus (usually cooled with running water) in the form of crystals. Those. at the place where the hot aluminum part was located at the maximum, the temperature was so high that either the polymer degraded into fragments, or (more likely) individual components were separated from it. Which then condensed in the form of needles nearby, where the temperature is already lower. (I note that it is possible to release substances from PCB or other driver components.).

The block SD contains two similar horizontal round metal parts. Indeed, a similar pattern is observed in the upper part of the cap.

Needle crystals are visible at the bottom of the frame. Curiously, in the upper right corner of the visible liquid droplets. Most likely, this is a plasticizer (quoted from Wiki: “Plasticizers are substances that are incorporated into polymeric materials to impart (or improve) elasticity and (or) plasticity during processing and operation. Plasticizers facilitate the dispersion of ingredients, reduce the processing temperature of the compositions , improve the frost resistance of polymers, but sometimes worsen their heat resistance. Some plasticizers can increase the fire, light and heat resistance of polymers. "). The most widely known (but nameless for the vast majority of people) in everyday life plasticizer is dibutyl phthalate ester. Because it is a mosquito repellent. This I mean that such liquids have a very high boiling point, low volatility and are practically harmless to humans (unless you take them inside).

The appearance of crystals and drops can be due to two reasons (most likely, their combination): the poor quality of the plastic of the protective cap and too high working temperature of the SDL. Drops gathered at the top of the cap because there is the coldest area.

What can be said in conclusion? Of the advantages, we can mention a rather high efficiency of about 100 lm / W and a low price (about 140 rubles per piece).

Cons are much more.

• spread in quality of lamps

• strong variation in the value of the luminous flux from instance to instance

• low color rendering index for cold lamps

• too much decline in light when the lamp warms up to operating temperature

• non-optimal design of the protective cap, which complicates cooling

• the real operating temperature of the SDL is too high, which leads to the degradation of all its parts: the driver, the SD crystals, the phosphor and even the protective cap

• bad driver, which is expressed in:

- low power factor

- in lamps without notification drivers of different types can be used

- failure is accompanied by the release of a large amount of soot, while the driver is not subject to repair.

Buying such lamps for use without modification makes no sense. Completion - at a minimum - should include driver revision and improved ventilation (additional holes or slots in the plastic of the base and protective cap).

Source: https://habr.com/ru/post/402131/

All Articles