Robert Sheckley and I are testing a modular 3D START printer - part 1

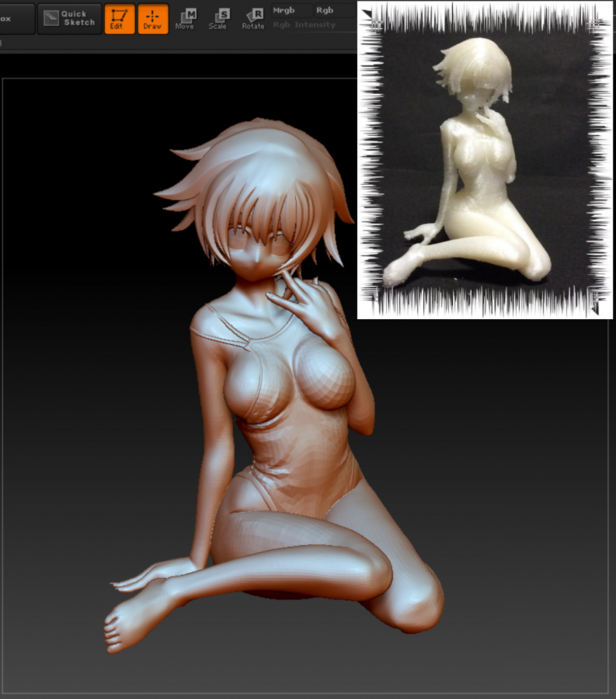

We are engaged in 3D modeling. Well, orders are mainly jewelry, book design. I used to do them under the CNC. There are many HD models, the highest detail. And then the reins came under the tail, so I want BJD dolls. Now it is very fashionable, the whole world collects them. Not only children, but also adults are addicted.

Instead of the preface

Arnold triumphantly opened the hatch.

')

- Here! He exclaimed. - Look! This is a panacea for all possible ills!

Gregor stepped inside. He saw a large, fantastic-looking car with dials, lights and indicators randomly placed on the case.

- What is it?

- Isn't it beautiful? - Arnold gently patted the car.

- I fished her off at interplanetary junkber Joe for almost nothing.

Robert Sheckley "Necessary thing"

Why is actually Robert Sheckley. Yes, because he practically came up with a printer - configurator.

So. With incredible efforts and brutal torture of managers of the company Dadzhet, I managed to get them to get the 3D START printer. My friend has a CNC, expensive, not according to my finances. A friend of his daughter bought Chinese, he is a computer programmer and a lover of toys. His resume on a Chinese printer is not worth the money. Seeing the configuration of our 3D Start, he became enviable, he paid for exactly the same 2 times more expensive. Because of what sulked and did not talk for almost a couple of days. Then the question: "Where did you get it?"

The printer arrived quickly. For a couple of days. It's nice that his parts are printed on the printer too! Therefore, my daughter and Dear Robert Sheckley winked out! Now we have it! Configurator! What does happiness look like!

Here on the photo clips, which put the coil, very favored, and Circuits are also made on a 3D printer! Our printer, domestic. Some items are only imported.

Collected relatively quickly, for an hour and a half. Long sorted out and laid out the contents. A lot of polyethylene packaging. There is nothing complicated. Were delighted with the huge plastic coil. The only negative short USB cable. Laptops do not hold, the last test died, otpahav years 7. And with inpatient problems. We'll have to take an adapter extension.

By configuration

Brief characteristics

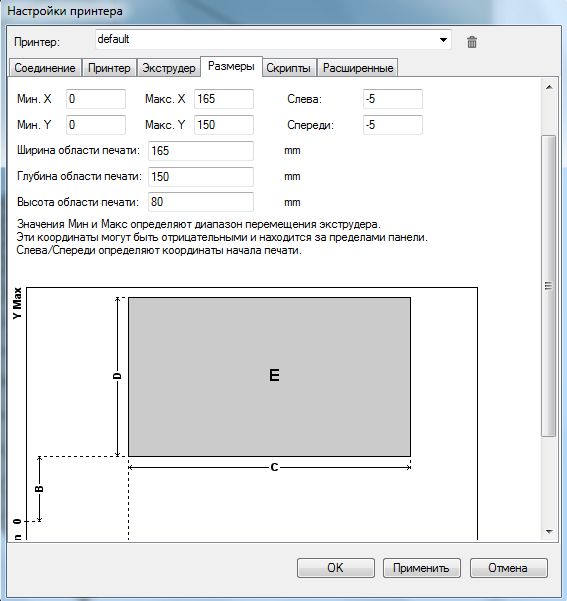

The size of the print area is 155 x 165 x 80 mm (XYZ)

Material for printing PLA, BATCOH (1.75 mm)

Recommended RepetierHost software

Number of modules 5

Detailed specifications

Power supply 12 V, 5A

Weight 2500 g

Layer height 0.1 - 0.3 mm

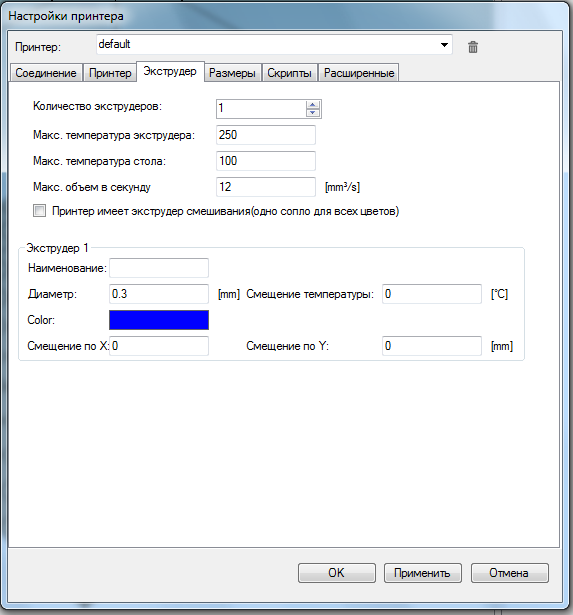

Nozzle diameter 0.3 mm

Build a modular 3D start printer

By the way, there are free slots to buy table heating, for example.

We decided to immediately put all the programs. What you need. What pleases, they are gratis and Russified. One was depressed. The settings are dark and you have to tinker. A little about the models. If your model has nothing to stand on, a jeweler, a figure with height differences, models are added to the model in the form of models of support, which must then be cut off. Approximately, as in the photo, for correct work. The printer then starts to cut from the bottom, and if you have a sharp drop in heights on the bottom right and left, there may be a jamb. Low triangles are added. You can do in 3DS MAX, MOI, for example or RHINO. Conveniently. And you will control a little bit.

By the way, on the assembly and calibration of the table. A small addition to all, which is not specified in the instructions, although it is written in great detail - Setting the table itself.

If the top is not spinning, you need to twist the bottom.

Program settings

While the printer is not connected, set up the program RepetierHost. In the future, the settings will change, depending on the models. The manual is written quite convenient. But everything will be in the process of testing.

Then we plug in USB for now without connecting the battery. Enough for now. Installs plugins. On the C drive, we try not to put anything. We created a daddy on one of the other disks, as stated in the 3D_START instruction. In it, they put the Arduino folder and Marlin. If RepetierHost writes that it did not find it, that's fine. He is looking for them. Point the way.

The main thing to do according to the instructions and consistently. The program is set up. Firmware and slicer decided to do later. If all the way, in the upper left corner the red button will turn green.

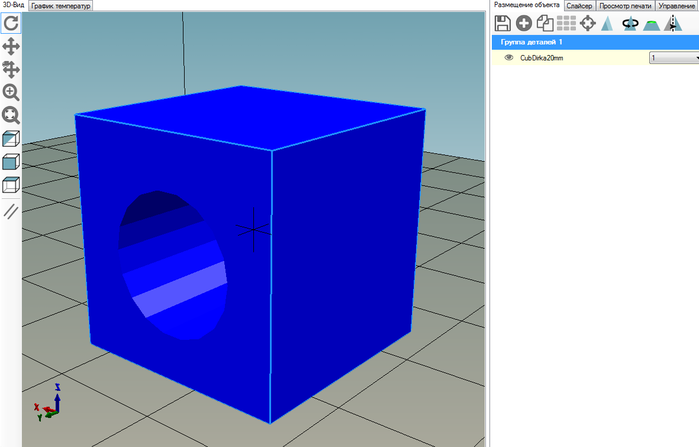

Ship model

And now the video that came out of the test cube. "Snot" virtually none. But this is a cube. Let's see what will happen next. The viewing window is just a thrill.

Modular 3D-printer 3D Start - the first launch.

The table was smeared with glue, because there is no heating yet. And the coupling with the surface almost does not occur on large models. Screwed up first. When they missed with ordinary pencil, it seemed to stick. At first, the ice did not come out because the slicer and parameter settings are needed. I would like a higher detail, but really need to customize.

How to do it - look at the video.

Tyanka after settings. Lowered a bit polygonage. Scratched her a little sandpaper.

The rest is in the second part .

Author Elena Zaitseva, Saratov

3D printer reviews START on GT

Information, bloggers and authors

The company "Dadzhet" is interested in publishing independent objective reviews of dadzhetov in various kinds of media and is happy to provide dadzhetov bloggers and authors who want to test them and write a review. The device after writing a review remains with the author. The company is not trying to tell the author what to write about our product, but asks to show the article before publication. In this case, it is possible to clarify information and prevent errors. Whether to consider company comments or not is always up to the discretion of the author.

Read more ...

Read more ...

Potential buyers

With a 10% discount, you can purchase a 3D START printer and a 3D Smart controller with a monitor by specifying the promotional code GT-3DSTART. The promotional code is valid inclusive until June 6, 2017.

Source: https://habr.com/ru/post/402059/

All Articles