Rocket Fuel Saga - The Other Side

When discussing the article “The Saga of Rocket Fuels” , a rather painful question was raised about the safety of liquid rocket fuels, as well as products of their combustion, and a little about refueling PH.

Definitely I am not an expert in this field, but “for the ecology” is insulting.

The article ends with a clipping from the publication "The fee for access to outer space . "

Legend (not all are used in this article, Greek letters are difficult to write, so the screenshot)

')

Indices and abbreviations (not all are used in this article):

a - active

without - safe

input input

explosion

out - day off

g - fuel

dv - engine

h - delay

g - liquid

k - camera

kip - boil

cr - critical

l - flight

m - model

n - full-scale

max - maximum

min - minimum

o - oxidizer

t - fuel

AK - nitric acid

AT - nitrogen tetroxide

NPP - Nuclear Power Plant

GG - gas generator

DI, ZDI, KVI and KTI - finishing, finishing finishing, control and sampling and control and technological tests;

DU - propulsion system

LRE - liquid rocket engine

IR - test complex

KA - spacecraft

KVRB - oxygen-hydrogen accelerating unit

Spacecraft - spacecraft

Efficiency - coefficient of performance

- rocket fuel components

KS - combustion chamber

LA - aircraft

MTKS - reusable space transportation system

UDMH - asymmetric dimethylhydrazine

OK - the orbital ship

PGSP - pneumohydraulic power system

MPC - maximum permissible concentration

PU - firing device

RKK - rocket and space complex

RN - Booster

SAZ - emergency protection system

LED - pressure alarm

SC - launch complex

SNiP - building codes

LNG - liquefied natural gas

THA - Turbopump

TNT - Trinitrotoluene

TE - fuel cell

HSI and OSI - cold and fire bench tests of remote control

ECG - electrochemical generator.

without - safe

input input

explosion

out - day off

g - fuel

dv - engine

h - delay

g - liquid

k - camera

kip - boil

cr - critical

l - flight

m - model

n - full-scale

max - maximum

min - minimum

o - oxidizer

t - fuel

AK - nitric acid

AT - nitrogen tetroxide

NPP - Nuclear Power Plant

GG - gas generator

DI, ZDI, KVI and KTI - finishing, finishing finishing, control and sampling and control and technological tests;

DU - propulsion system

LRE - liquid rocket engine

IR - test complex

KA - spacecraft

KVRB - oxygen-hydrogen accelerating unit

Spacecraft - spacecraft

Efficiency - coefficient of performance

- rocket fuel components

KS - combustion chamber

LA - aircraft

MTKS - reusable space transportation system

UDMH - asymmetric dimethylhydrazine

OK - the orbital ship

PGSP - pneumohydraulic power system

MPC - maximum permissible concentration

PU - firing device

RKK - rocket and space complex

RN - Booster

SAZ - emergency protection system

LED - pressure alarm

SC - launch complex

SNiP - building codes

LNG - liquefied natural gas

THA - Turbopump

TNT - Trinitrotoluene

TE - fuel cell

HSI and OSI - cold and fire bench tests of remote control

ECG - electrochemical generator.

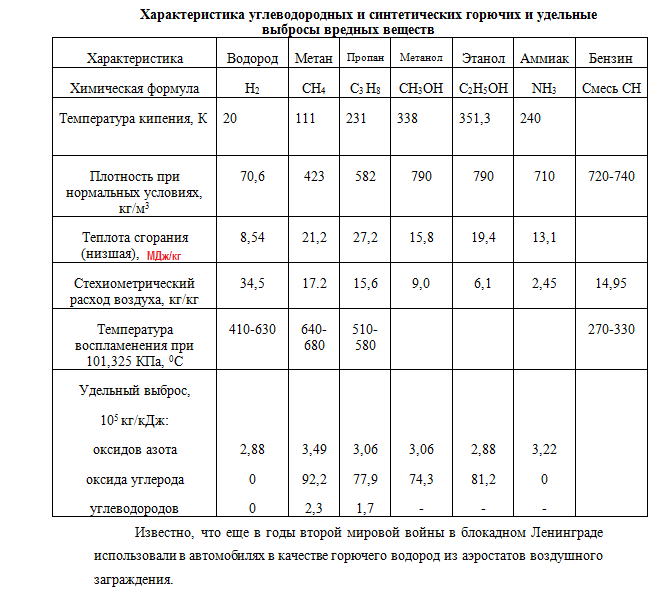

The environmental safety of rocket launches, testing and testing of propulsion systems (DU) of aircraft (LA) is mainly determined by the used components of rocket fuel (). Many are distinguished by high chemical activity, toxicity, explosion and fire hazard.

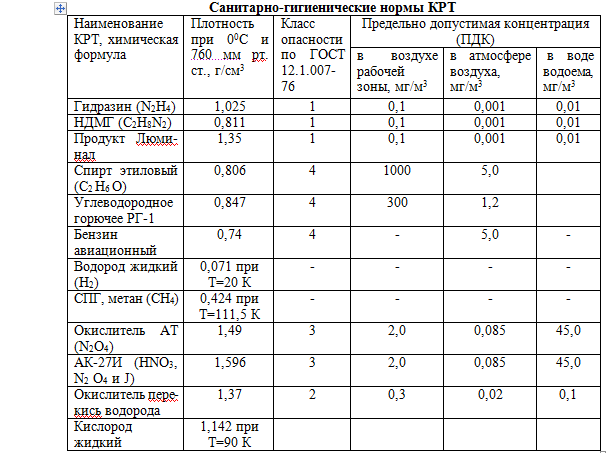

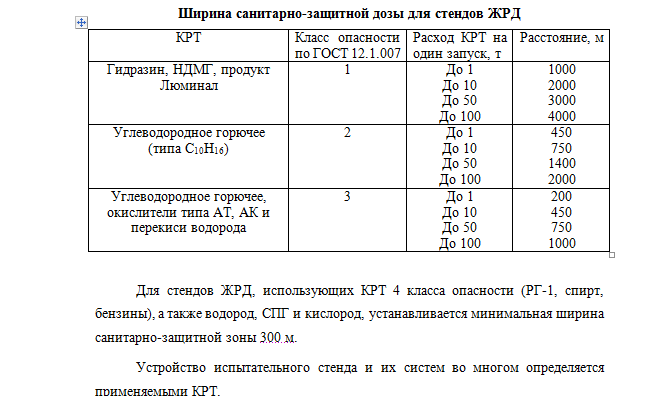

Taking into account the toxicity, are divided into four hazard classes (as the hazard decreases):

- first class: combustible hydrazine series (hydrazine, UDMH and the product Luminale-A);

- the second class: some hydrocarbon combustible (modifications of kerosene and synthetic combustible) and oxidizer hydrogen peroxide;

- the third class: oxidizers nitrogen tetroxide (AT) and AK-27I (a mixture of HNO3 - 69.8%, N2O4 - 28%, J - 0.12 ... 0.16%);

- the fourth class: hydrocarbon fuel RG-1 (kerosene), ethyl alcohol and aviation gasoline.

Liquid hydrogen, LNG (methane CH4) and liquid oxygen are not toxic , but when operating systems with these MCTs, it is necessary to take into account their fire and explosion hazards (especially hydrogen in mixtures with oxygen and air).

The sanitary and hygienic norms of are given in the table:

Most flammable explosive and according to GOST 12.1.011 they are classified as IIA.

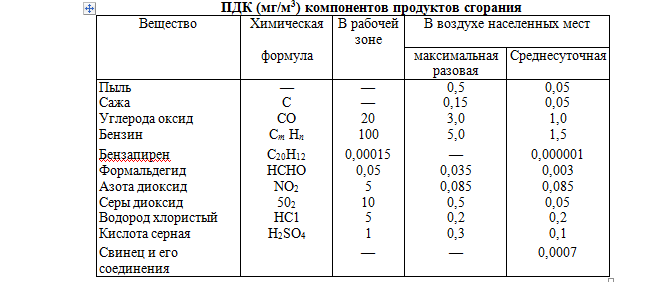

Products of complete and partial oxidation of in engine elements and products of their combustion, as a rule, contain harmful compounds: carbon monoxide, carbon dioxide, nitrogen oxides (NOx), etc.

In the engines and power installations of rockets, most of the heat supplied to the working fluid (60 ... 70%) is released into the environment with a jet stream of a taxiway or a cooler (in cases of operation of a taxiway on test benches water is used). Emission of heated exhaust gases into the atmosphere can affect the local microclimate.

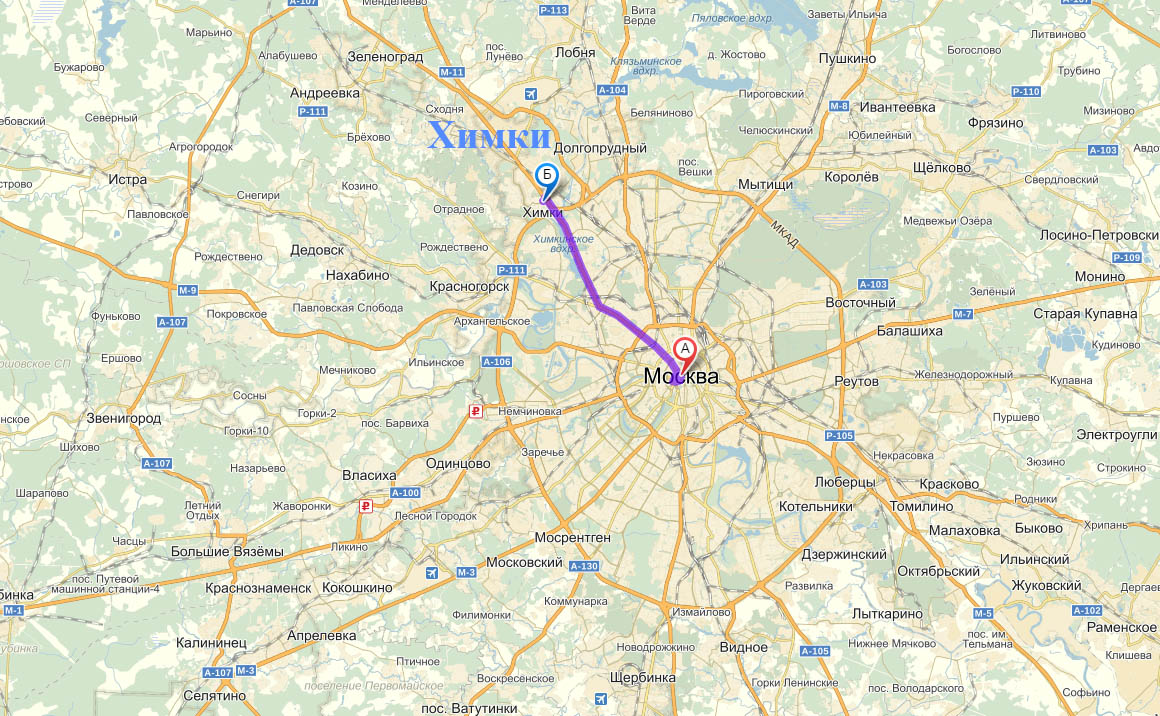

A film about the RD-170, its production and testing . NPO "Energomash" two huge chimneys test benches, associated buildings and the neighborhood of Khimki:

On the other side of the roof: you can see spherical tanks for oxygen, cylindrical - for nitrogen, kerosene tanks just to the right, did not get into the frame. In Soviet times, the engines for the Proton were tested on these stands. Very close to Moscow.

Currently, many "civilian" LRE use hydrocarbon combustible. Their products of complete combustion (water vapor H2O and carbon dioxide CO2) are conventionally not considered to be chemical pollutants of the environment.

All other components are either smoke-generating or toxic substances that have a harmful effect on humans and the environment.

It:

sulfur compounds (S02, S03, etc.); products of incomplete combustion of hydrocarbon fuels - carbon black (C), carbon monoxide (CO), various hydrocarbons, including oxygenated (aldehydes, ketones, etc.), conventionally referred to as CmHn, CmHnOp or simply CH; nitrogen oxides with the general designation Nx; solid (ash) particles formed from mineral impurities in the fuel; compounds of lead, barium and other elements that make up fuel additives.

Compared to other types of heat engines, the toxicity of rocket engines has its own characteristics due to the specific conditions of their operation, the fuels used and the level of their mass flow rates, higher temperatures in the reaction zone, effects of combustion of exhaust gases in the atmosphere, and specific engine designs.

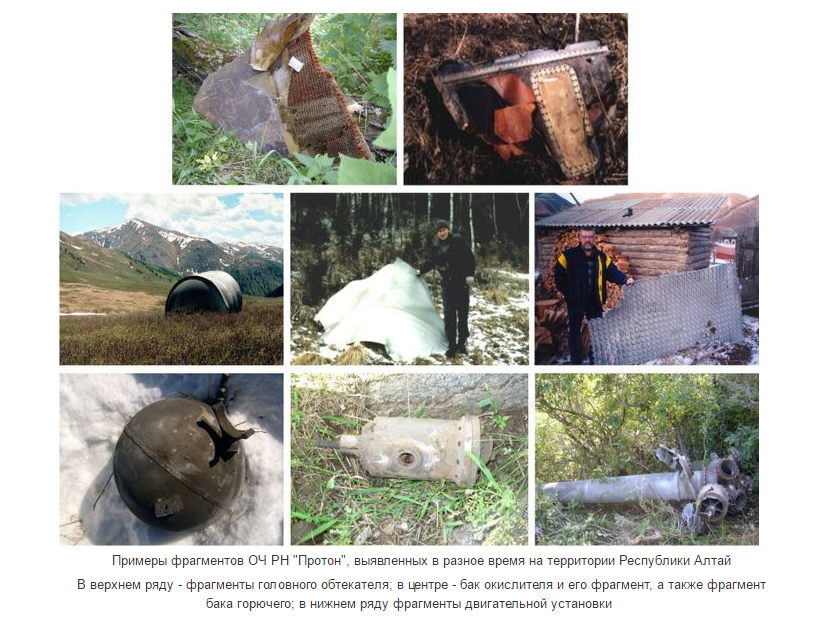

The spent stages of launch vehicles (PH), falling to the ground, are destroyed and the guaranteed reserves of stable components of fuel remaining in the tanks pollute and poison the plot of land or reservoir adjacent to the place of fall.

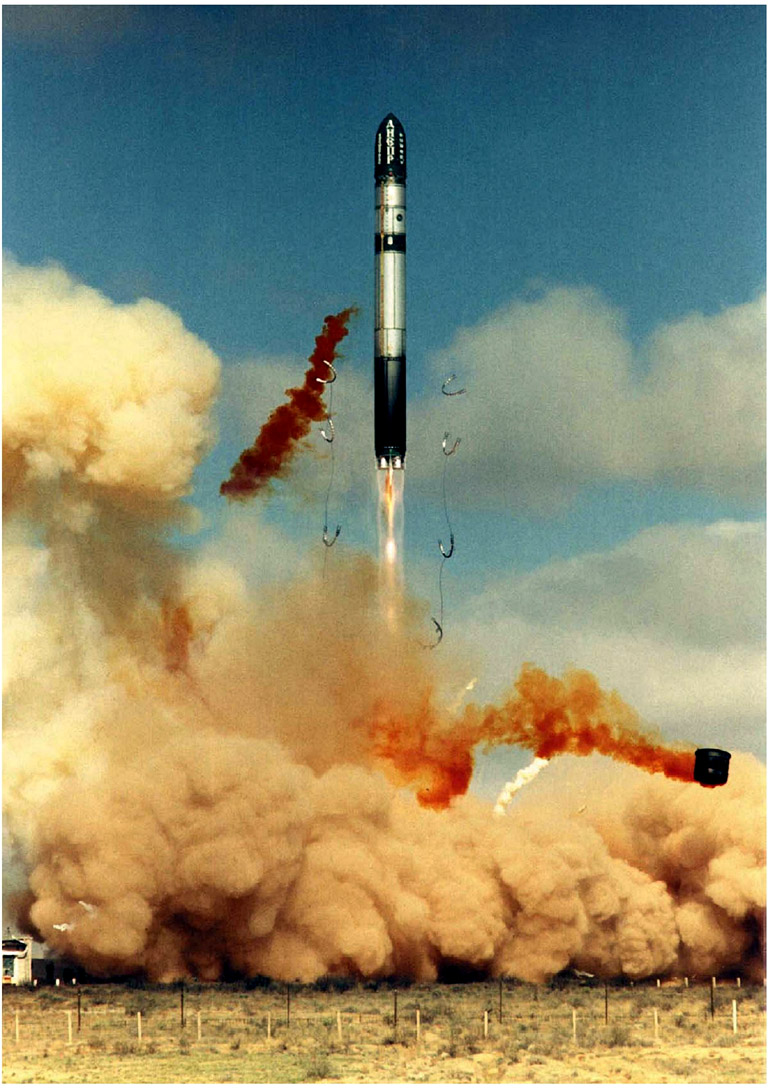

Chinese peasants at the site of the fall of the first stage of the rocket "Great March": a step on the "stinker" (UDMH + AT). The orange cloud in the picture is an amyl vapor, a very sad thing in terms of toxicity and carcinogenicity. In vain there these people crowd, in vain ...

In order to improve the energy characteristics of the LRE, the fuel components are fed into the combustion chamber at a ratio corresponding to the oxidizer excess coefficient α dv <1.

In addition, methods of thermal protection of the combustion chambers include ways to create near the fire wall of the layer of products of combustion with a reduced level of temperature by supplying excess fuel. Many modern designs of combustion chambers have curtain belts through which additional fuel is fed into the wall layer. This first creates a liquid film evenly around the perimeter of the chamber, and then the gas layer of the vaporized fuel. Significantly enriched in fuel, the near-wall layer of the combustion products is maintained until the exit section of the nozzle.

In the photo: single-component peripheral (fuel) RD-107/108 nozzles to create a wall layer (for cooling the walls of the combustion chamber)

Combustion of exhaust combustion products occurs during turbulent mixing with air. The temperature level developed in this case may in some cases be sufficiently high for the intensive formation of nitrogen oxides NOx from nitrogen and oxygen. Calculations show that non-nitrogen fuels O2G + N2G and O2G + kerosene form, when burned out, 1.7 and 1.4 times more nitric oxide NO, respectively, than the fuel nitrogen tetroxide + NDMG .

The formation of nitric oxide during burnout is particularly intense at low altitudes.

When analyzing the formation of nitric oxide in the exhaust plume, it is still necessary to take into account the presence in technical liquid oxygen of up to 0.5 ... 0.8% by mass of liquid nitrogen.

“The law of the transition of quantitative changes into qualitative ones” (Hegel) here again plays a cruel joke with us, namely the second mass expenditure of TC: here and now.

Example: the cost of fuel components at the time of launch of the Proton LV is 3800 kg / s, the Space Shuttle is more than 10,000 kg / s and the Saturn-5 PH is 13000 kg / s. Such costs cause accumulation in the launch area of a large amount of products of combustion, pollution of clouds, acid rain and changes in weather conditions over an area of 100–200 km2.

For a long time, NASA studied the effects of the Space Shuttle launches on the environment, especially since the Kennedy Space Center is located in the reserve .

In the process of launch, three sustainer engines of the orbital ship burn liquid hydrogen, and solid propellant accelerators, ammonium perchlorate with aluminum. According to NASA estimates, the surface cloud in the area of the launch pad contains about 65 tons of water, 72 tons of carbon dioxide, 38 tons of aluminum oxide, 35 tons of hydrogen chloride, 4 tons of other chlorine derivatives, 240 kg of carbon monoxide and 2.3 tons of nitrogen . Tons of brothers! Tens of tons.

Here, of course, it plays a role that the “space shuttle” has not only environmental fuel rocket engines, but also the most powerful in the world “partially toxic” solid propellant rocket motors. In general, even that craving cocktail is obtained at the exit.

Hydrogen chloride in water is converted to hydrochloric acid and causes major environmental disturbances around the starting complex. Near the launch complex there are extensive pools with cooling water, in which fish is found. Increased acidity on the surface after the start leads to the death of the fry. Larger juveniles living deeper survive. Oddly enough, no disease was detected in the birds eating the dead fish. Probably for now. Moreover, the birds adapted to fly for easy prey after each launch. Some types of plants die after the start, but crops of useful plants survive. Under unfavorable wind, the acid falls outside the three-mile zone around the launch complex and destroys the paint on cars. Therefore, NASA issues special covers to owners whose cars are in a dangerous area on launch day. Aluminum oxide is inert, and although it can cause lung disease, it is believed that its concentration at the time of launch is not dangerous.

Okay, the “Space Shuttle” - at least it combines H2O (H2 + O2) with the oxidation products of NH4ClO4 and Al ... And here is an example for the 5UR21A SAMC S-200V:

1. Marching LRE 5D12: AT + NDMG

2. Boosters of solid propellant rocket motors 5S25 (5S28) four pieces of charge of mixed TT 5B28 type RAM-10k

→ Video about C 200 starts

→ Combat operation of the technical division ZRK C200

Invigorating breathing mixture in the area of combat and training launches.

Let's go back to the LPRE. On the specifics of solid propellant solid fuel, their ecology and components for them, in another article.

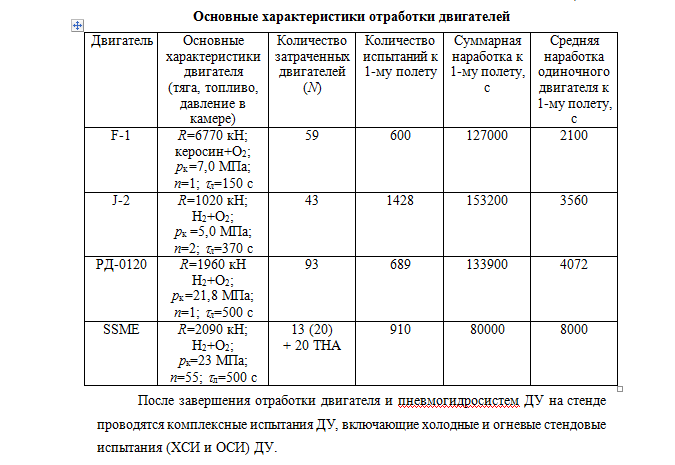

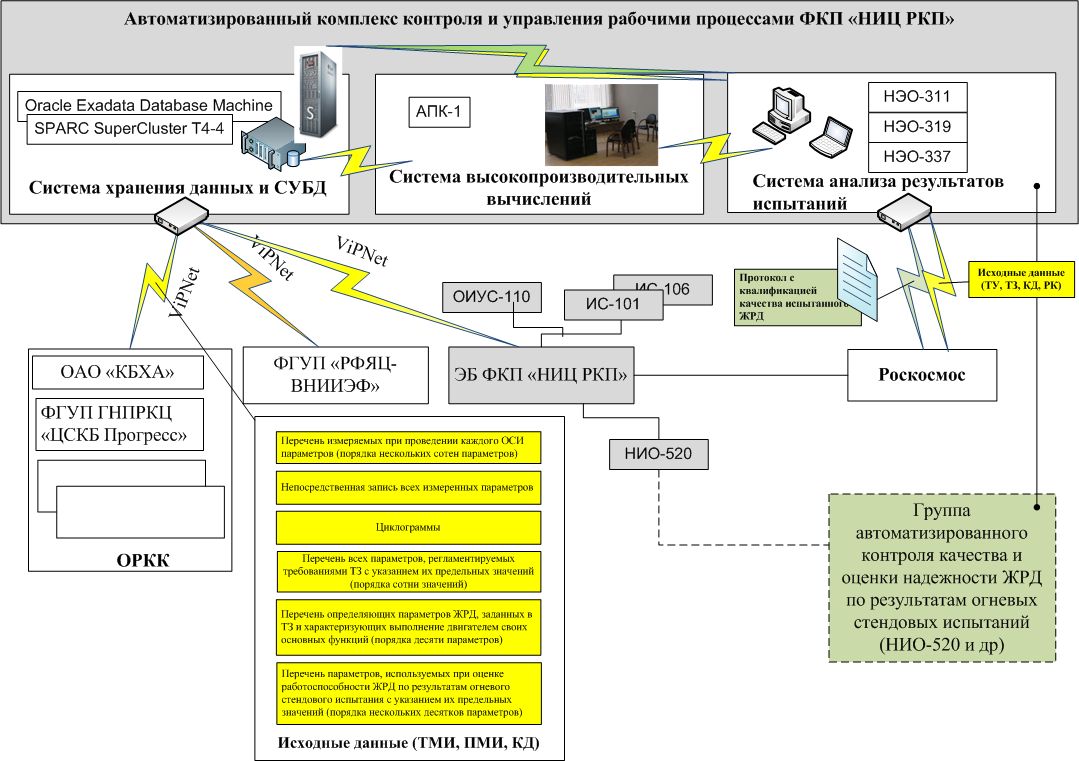

The performance of the propulsion system can be assessed only on the basis of test results. So, to confirm the lower limit of the probability of failure-free operation (FBG) Rn> 0.99, with a confidence level of 0.95, n = 300 fail-safe tests must be carried out, and for Rn> 0.999 - n = 1000 trouble-free tests.

If we consider the LRE, the process of mining is carried out in the following sequence:

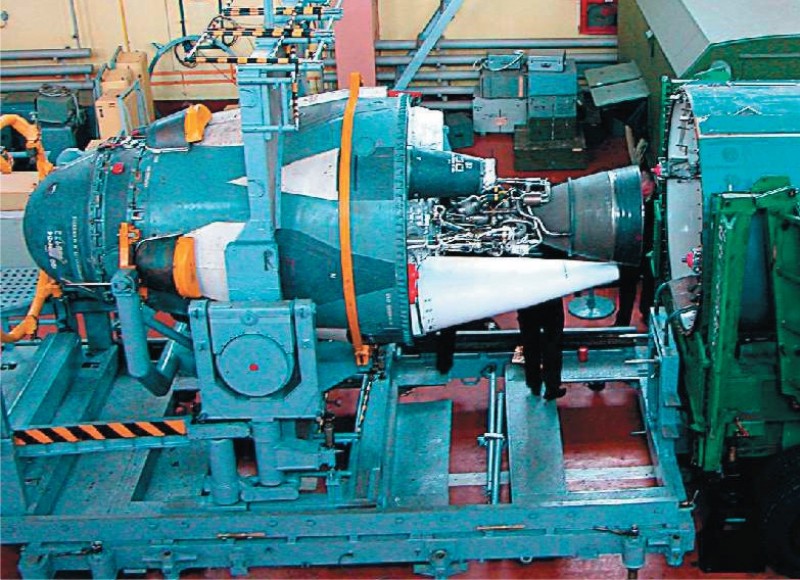

- testing of elements, assemblies (pumping units and pump supports, pump, gas generator, combustion chamber, valve, etc.);

- testing systems (THA, THA with GG, GG with KS, etc.);

- tests of the engine simulator;

- engine tests;

- engine tests as part of a remote control;

- flight tests of the aircraft.

In the practice of creating engines, there are 2 known bench-finishing methods: sequential (conservative) and parallel (accelerated).

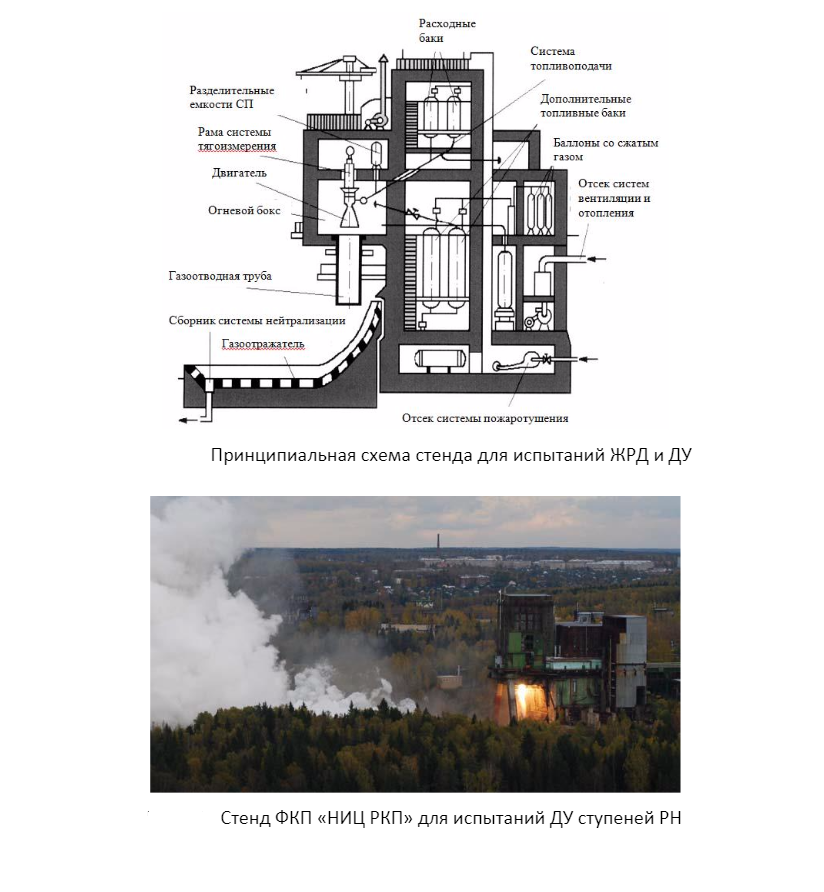

The test bench is a technical device for installing the test object at a predetermined position, creating impacts, retrieving information and managing the test process and test object.

Test benches for various purposes usually consist of two parts connected by communications:

- Executive, consisting of the test object and systems that ensure the impact of various operational factors;

- command in the form of a control panel and information systems (transformation, analysis and display of information about the parameters of the test object).

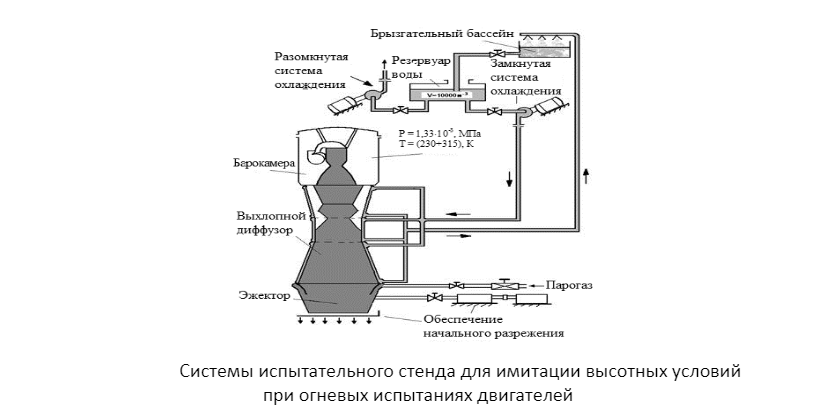

Schemes will give understanding more than my verbal constructions:

Reference:

testers and those who worked with UDMH / heptyl / were granted in the USSR: 6-hour working day, vacation 36 working days, length of service, retirement at 55, subject to working in hazardous conditions for 12.5 years, free food, preferential trips to a sanatorium and d / o. For medical care, they were attached to the 3rd State Administration of the Ministry of Health, as well as the enterprises of Sredmash, with mandatory regular medical examination. Mortality in the departments was much higher than the average for the enterprises of the industry, mainly for oncological diseases, although they were not classified as professional.

At present, the Proton carrier rocket using highly toxic components of the UDMH and AT fuels is used for the withdrawal of heavy loads (orbital stations with a mass of up to 20 tons) in the Russian Federation. To reduce the harmful effects of the LV on the environment, the stages and the rocket engines (“Proton-M”) were modernized to significantly reduce component residues in the tanks and power lines of the remote control.

More for the withdrawal of payloads in Russia are used (or used) relatively cheap conversion missile systems "Dnepr", "Strela", "Rokot", "Cyclone" and "Cosmos-3M", working on toxic fuels.

There was an idea (I will tell you separately about OCD), to transfer these engines from AT + UDMG fuel components to environmentally friendly ones. For example, on oxygen and kerosene. Many dealt with this issue in the KBKHA. The task turned out to be far from simple. Together with the KMZ / Krasnoyarsk / more than 10 years, work continues on the translation of the 3D-37 engine. In fact, it turns out almost a new engine, although there remained an “acidic” scheme and there were no questions about the cooling capacity of the CS. This engine received an index RD-0155 and RKK Makeeva is considering its possible use in the “Air start”.

For launching manned spacecraft with astronauts, they are used only (and in our country and in the world, except for China) the Soyuz carrier rockets on oxygen-kerosene fuel.

The most ecological TCs are H2 + O2, followed by kerosene + O2, or HCG + O2.

“Stinkers” are the most toxic and complete the ecological list (fluorine and other exotic things I don’t consider).

Note: the stoichiometric flow rate is given for air, but essentially it does not change much.

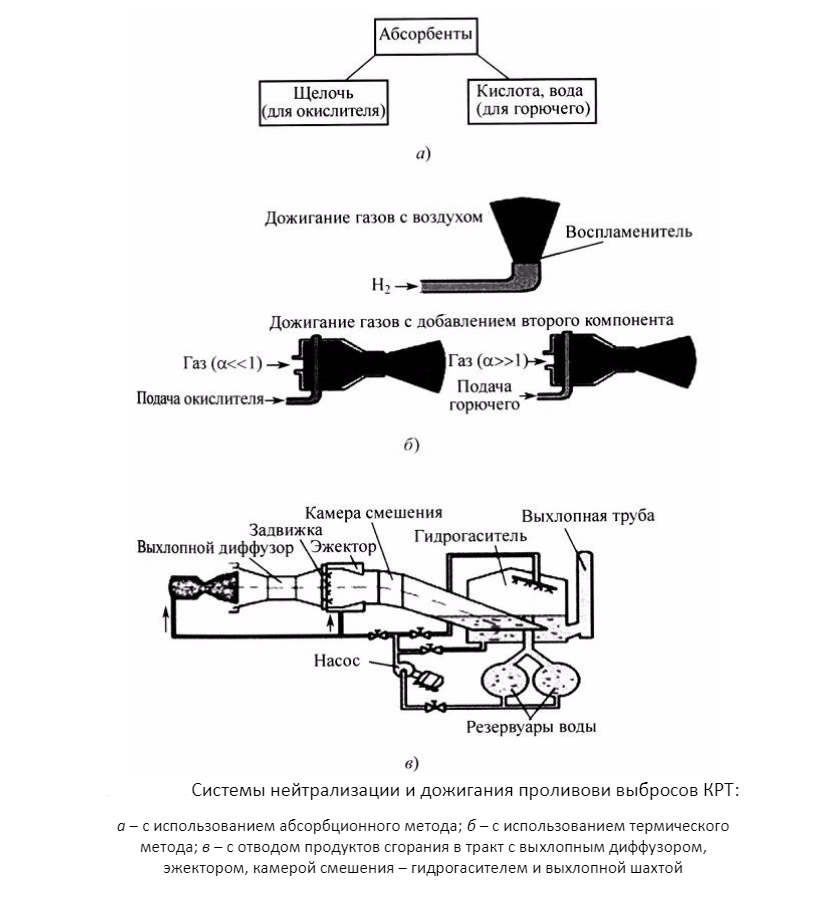

Hydrogen and rocket engine test benches for such fuels have their own “gadgets”. At the initial stage of work with hydrogen, due to its significant explosion and fire hazard in the United States, there was no consensus about the advisability of post-burning all types of hydrogen emissions. Thus, Pratt-Whitney (USA) was of the opinion that burning the entire amount of hydrogen emitted guarantees complete safety tests, therefore, a flame of propane gas is maintained over all the ventilation pipes for hydrogen discharge of test benches.

Douglas-Erkraft (USA) considered it sufficient to release gaseous hydrogen in small quantities through a vertical pipe, located at a considerable distance from the test sites, without afterburning it.

In the Russian stands, in the process of preparing and conducting tests, hydrogen emissions are burned at a cost of more than 0.5 kg / s. At lower costs, hydrogen does not burn out, but is removed from the technological systems of the test bench and is discharged into the atmosphere through drainage outlets with nitrogen blowers.

The situation with toxic components of RT (“stinky”) is much worse. As with the test LRE:

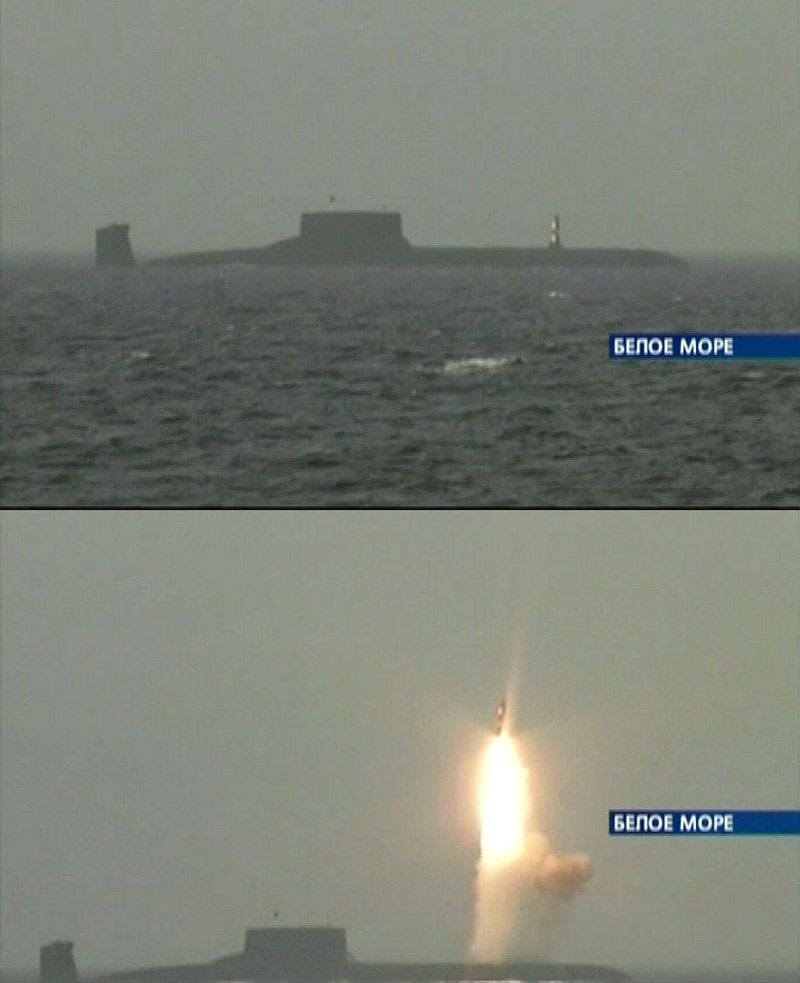

So with the start (and emergency, and successful):

The question of damage to the environment in case of possible accidents at the withdrawal site and in the fall of separated parts of the missiles is very important, since these accidents are practically unpredictable.

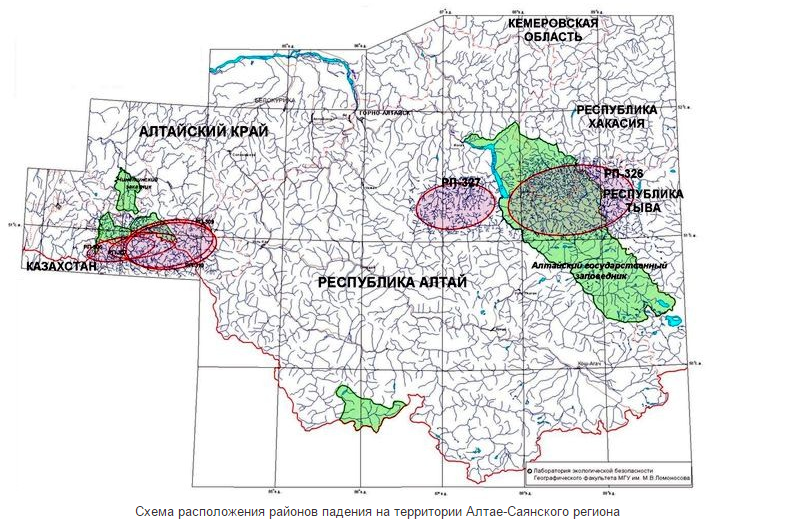

In the western part of the Altai-Sayan region there are six areas (fields) of the fall of the second stages of the launch vehicle launching from the Baikonur cosmodrome. Four of them belonging to the Yu-30 zone (Nos. 306, 307, 309, 310) are located in the extreme western part of the region, on the border of the Altai Territory and the East Kazakhstan Oblast. The falling areas Nos. 326, 327 included in the Yu-32 zone are located in the eastern part of the republic, in close proximity to the lake. Teletskoye.

Fall areas No. 306, 307, 309 have been used since the mid-60s (according to official data) for landing the second stages of the Soyuz launch vehicle and its modifications (on hydrocarbon fuels); the rest of the regions - from the beginning of the 70s for landing the fragments of the second stages of the Proton launch vehicle (hydrazine fuel).

In the case of the use of rockets with environmentally friendly components of fuel, measures to eliminate the consequences in the places of falling of the separating parts are reduced to mechanical methods of collecting the remnants of metal structures.

Special measures should be carried out to eliminate the consequences of falling steps, containing tons of undeveloped UDMH, which penetrates into the soil and, being well dissolved in water, can spread over long distances. Nitrogen tetroxide is rapidly dissipated in the atmosphere and is not a determining factor in the contamination of a locality. According to estimates, it takes at least 40 years for the complete recultivation of land used as a zone of falling steps from UDMH for 10 years. In this case, work should be carried out on the excavation and transportation of a significant amount of soil from the places of fall. Studies in the places of the fall of the first steps of the Proton PH showed that the zone of soil contamination when falling one step covers an area of ~ 50 thousand m2 with a surface concentration in the center of 320-1150 mg / kg, which is thousands of times higher than the maximum allowable concentration.

Currently, there are no effective ways to neutralize the infected zones with combustible UDMH.

World Health Organization UDMH is included in the list of highly hazardous chemical compounds. Heptyl is 6 times more toxic than hydrocyanic acid.

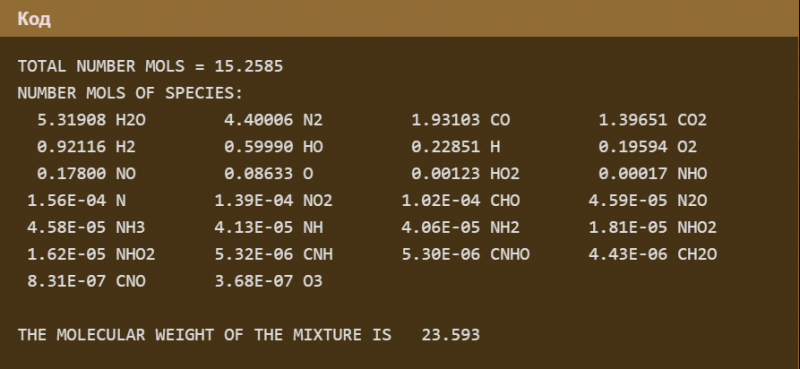

Products of heptyl and amyl combustion (oxidation) when testing rocket engines or launching launch vehicles.

In the "wiki" everything is simple and harmless:

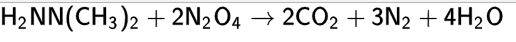

in life Km and alpha: the mass ratio of oxidizer / fuel is 1.6: 1 or 2.6: 1 = completely wild excess of oxidizer (example: N2O4: UDMG = 2.6: 1 (260 g and 100 g respectively)):

When this cocktail is found with another cocktail — our air + organic matter (pollen) + dust + sulfur oxides + methane + propane +, etc., the results of oxidation look like this:

( : N--N-). . . , , , , , . 1- . , . : – 0,01 /3, 10 , — 0,0001 /3 (), -0,01 /.

(4,4,4,4--2-)- . . , . . 3- . : – 0,005 /3, –0,1 /.

NO2 - , . (- ). , , , , , , .: -2 /3, -0,085 /3( ) 0,04 /3 (), –2 .

( ) - product of incomplete combustion of organic (carbon-containing) fuels. Carbon monoxide can last for a long time (up to 2 months) in the air without change. Carbon monoxide poison. Binds blood hemoglobin to carboxyhemoglobin, impairing the ability to transport oxygen to human organs and tissues. MPC: in the atmospheric air of populated areas - 5.0 mg / m3 (maximum one-time) and 3.0 mg / m3 (daily average). In the presence of carbon monoxide and nitrogen compounds in the air at the same time, the toxic effect of carbon monoxide on people is enhanced.

Hydrocyanic acid (hydrogen cyanide) - . . , - : , , , , , , . , , . , , , , , , , , , , , , , .

( ) -toxin. Formaldehyde has a pungent odor, it strongly irritates the mucous membranes of the eyes and nasopharynx, even at low concentrations. It has a general toxic effect (damage to the central nervous system, organs of sight, liver, kidneys). It has an irritating, allergenic, carcinogenic, mutagenic effect. Maximum allowable concentration in atmospheric air: average daily - 0.012 mg / m3, maximum one-time - 0.035 mg / m3.

Intensive rocket and space activity in Russia in recent years has given rise to a huge number of problems: environmental pollution by separating parts of launch vehicles, toxic components of rocket fuel (heptyl and its derivatives, nitrogen tetroxide, etc.)

The whole history of relations between our country and heptyl is a chemical war, only chemical war is not just an undeclared one, but simply unidentified by us.

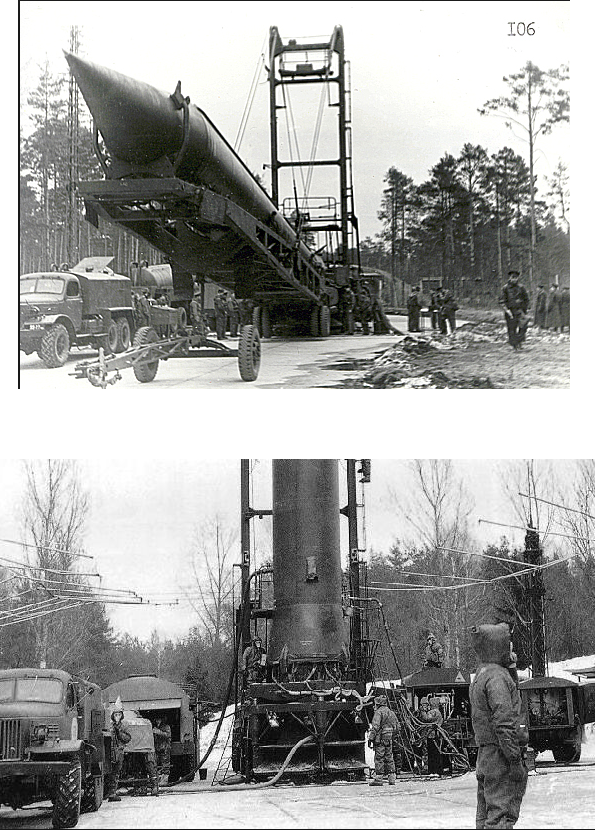

Briefly about the military use of heptyl:

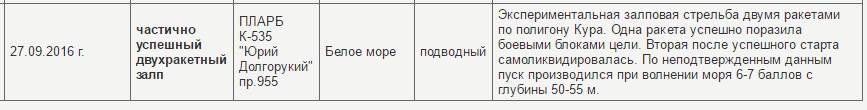

There were missile defense system missile systems, sea submarine ballistic missiles (SLBMs), space missiles, of course, air defense missiles, as well as operational-tactical missiles (medium-range).

In total it turns out at least six directions. The army and Navy left a “heptyl” mark in Vladivostok and the Far East, Severodvinsk, the Kirov region and a number of neighborhoods, Plesetsk, Kapustin Yar, Baikonur, Perm, Bashkiria, etc.

We must not forget that the missiles were transported, repaired, reloaded, etc., and all this on land, near industrial facilities, where this heptyl was produced.

About the accident with these highly toxic components and about informing the civil authorities, civil defense (EMERCOM) and the public - who knows, he will tell more.

It is necessary to remember the places of production and testing of engines are not in the desert: Voronezh, Moscow (Tushino), the Nefteorgsintez plant in Salavat (Bashkiria), etc.

Several dozen ICBMs R-36M, UTTH / R-36M2

and UR-100N UTTH with heptyl dressing are on combat duty in the Russian Federation .

In the photo: “Rokot” (14A05), designed in the Khrunichev Center on the basis of the ICBM RS-18 (UR-100N UTTH)

Unfortunately, the coordinates of the activities of the air defense forces operating with the C-75, C-100, C-200 missiles are more difficult.

Once every few years, heptyl has been drained off and will be drained from missiles, transported in refrigeration units across the country for processing, brought back, re-flooded, and so on. Not to avoid rail and road accidents (it happened and such). The army will work with heptyl, and all will suffer, not only the rocket men themselves.

Another problem is our low average annual temperatures. Americans are easier.

According to experts of the World Health Organization, the period of neutralization of heptyl, which is a toxic substance of hazard class I, at our latitudes is: in soil - more than 20 years, in reservoirs - 2-3 years, in vegetation - 15-20 years.

And if the country's defense capability is sacred and in the 50s to the 90s we just had to put up with it (either heptyl or one of the 10 programs of the US attack on the USSR), then does it make sense and logic using launch vehicles? on UDMH and AT for launching foreign spacecraft, receive money for the service and at the same time persecute their own people or the people of friendly Kazakhstan?

Again "Swan, cancer and pike"?

On the one hand: the lack of costs for the disposal of combat LVs (ICBMs, SLBMs, missiles, and OTR), and even profit and cost savings for the launching of anti-aircraft weapons into orbit;

On the other hand: the harmful effects on the environment, the population in the start and fall zone, the spent steps of the conversion PH;

And on the third hand: right now, it cannot do without a PH on high-boiling components of the Russian Federation.

HLCI R-36M2 / RS-20V Voyevoda (SS-18 mod.5-6 SATAN) in some political aspects (PO Southern Mashinostroitelny Zavod (Dnepropetrovsk)), and simply cannot be extended due to temporary degradation.

Perspective heavy intercontinental ballistic missile RS-28 / OCR Sarmat, missile 15A28 - SS-X-30 (draft) will be on high-boiling toxic components.

We are lagging behind somewhat in the RDTT and especially in the SLBM:

Chronicle of Torment of the Bulava until 2010

Therefore, the SSRB will use the best in the world (in terms of energy perfection, and generally masterpiece) SLBM R-29RMU2.1 / OCR Liner: on AT + UDMG.

Yes, it can be argued that ampulization has been used in the Strategic Missile Forces and the Navy for a long time and many problems have been solved: storage, operation, personnel security and combat crews.

But using conversion ICBMs for commercial launches is “again the same rake.”

Old (expired guaranteed storage) ICBMs, SLBMs, TRs and OTRs cannot be stored forever, either.

Where is this consensus and how to catch it, I do not know for sure.

Briefly: filling systems for launch complexes of PH using toxic components

At the UK for the Proton launch vehicle, the safety of operations during the preparation and conduct of the launch of the rocket and the support personnel when performing operations with sources of increased danger was achieved by using remote control and maximally automating the processes of preparing and conducting the launch of the launch vehicle, as well as operations carried out on the rocket and technological equipment of the IC in case of cancellation of the launch of the rocket and its evacuation from the SC. A constructive feature of the starting and filling units and systems of the complex, which provide preparation for the launch and launch, is that the docking of the filling, drainage, electric and pneumatic communications is performed remotely, and the undocking of all communications is carried out automatically. At the launch site there are no cable and cable refueling masts,their role is played by the docking mechanisms of the starting device.

The launch complexes of the Kosmos-1 and Kosmos-3M launch vehicles were created on the basis of the R-12 and R-14 systems of ballistic missiles without significant modifications to its connections with the ground equipment.

This led to the presence on the launch complex of many manual operations, including on the fuel-charged PH component. Subsequently, many operations were automated and the level of automation of work on the complex Kosmos-3M is already more than 70%.

However, some operations, including the reconnection of refueling communications to drain the fuel in case of cancellation of the start, are performed manually. The main systems of the IC are systems for refueling with components of the fuel, compressed gases and a remote control system for refueling. In addition, as part of the SC there are units that destroy the consequences of working with toxic components of fuel (drainage fumes of , aqueous solutions formed during various kinds of washes, equipment leaching).

The main equipment of filling-tank systems, pumps, pneumatic hydraulic systems are located in reinforced concrete structures buried in the ground. KRT storage facilities, a facility for compressed gases, and a remote control system for refueling are located at considerable distances from each other and starting devices in order to ensure their safety in emergency cases.

At the launch site of the Cyclone launch vehicle, it has been launched.

PH is 100%.

Heptyl detoxification:

The essence of the method of reducing the toxicity of UDMH is to feed 20% formalin solution into the fuel tanks of rockets:

(CH3) 2NNH2 + CH2O = (CH3) 2NN = CH2 + H2O + Q

This operation in excess of formalin results in the complete (100%) elimination of UDMH by converting it to dimethyl hydrazone formaldehyde in one treatment cycle in 1-5 seconds. This prevents the formation of dimethylnitrosamine (CH3) 2NN = O.

The next phase of the process is the destruction of dimethylhydrazone formaldehyde (DMHF) by adding acetic acid to the tanks, which causes the dimerization of DMHF to glyoxal bis-dimethylhydrazone and the polymer mass. The reaction time is about 1 minute:

(CH3) 2NN = CH2 + H + → (CH3) 2NN = CHHC = NN (CH3) 2 + polymers + Q

The resulting mass is moderately toxic, well soluble in water.

It is time to wrap up, I will not hold back in the afterword and again quote S. Lukyanenko:

" - And the people they call cab drivers.

- Reptiloid pointing to me a short foot. "

- Are you an astronaut, granddaughters? - asked grandma. More approving than questioning. My jacket was too characteristic.

Always we were told about the great future. About the happiness of mankind. After all, I built communism ... then capitalism ... tried ... We all endured for this. For the sake of the future, for the sake of happiness ... Now you are building a stellar future. Boy, do you believe that this is not in vain?

Do these people believe in the stellar future of mankind? Do they need it, shook up transport problems and interruptions in the apartments, planned outages and high prices for products? What gave them space - besides fear of other worlds and forced pride for the planet Earth, for its spaceships - the fastest in the galaxy ...

Primary Sources:

"Ecological safety during testing and testing of rocket engines", A. G. Galeev Study Guide, MAI Publishers, 2006

Methodology of experimental testing of rocket engine and remote control, the basics of testing and device test benches: monograph [Electronic resource] /AG. Galeev, V.N. Ivanov, A.V. Katenin, V.A. Liseikin, V.P. Pikalov, A.D. Polyakhov, G.G. Sidov, A.A. Shibanov

“PROBLEMS OF ECOLOGICAL HAZARDS OF THE APPLICATION OF HEPTIL - SUPERTOXIC ROCKET FUEL. CHRONICLE OF EVENTS ”Perm City Branch of the Union“ For Chemical Safety ”2008

Kolesnikov, S.V. "Oxidation of asymmetric dimethyl hydrazine (heptyl)

and identification of products of its transformation at the straits ”Novosibirsk: Izd. SibAK, 2014

Dilogiya “Stars - cold toys” S.V. Lukyanenko

Rocket fuel as an environmental hazard, from the 1995 State Report, Communication UCS-INFO.97, December 17, 1996

geektimes.ru/post/243763 (Vitaly Egorov @ Zelenyikot)

Methodology of experimental testing of rocket engine and remote control, the basics of testing and device test benches: monograph [Electronic resource] /AG. Galeev, V.N. Ivanov, A.V. Katenin, V.A. Liseikin, V.P. Pikalov, A.D. Polyakhov, G.G. Sidov, A.A. Shibanov

“PROBLEMS OF ECOLOGICAL HAZARDS OF THE APPLICATION OF HEPTIL - SUPERTOXIC ROCKET FUEL. CHRONICLE OF EVENTS ”Perm City Branch of the Union“ For Chemical Safety ”2008

Kolesnikov, S.V. "Oxidation of asymmetric dimethyl hydrazine (heptyl)

and identification of products of its transformation at the straits ”Novosibirsk: Izd. SibAK, 2014

Dilogiya “Stars - cold toys” S.V. Lukyanenko

Rocket fuel as an environmental hazard, from the 1995 State Report, Communication UCS-INFO.97, December 17, 1996

geektimes.ru/post/243763 (Vitaly Egorov @ Zelenyikot)

Used data, photos and videos:

www.leninsk.ru

www.ekologia-ra.ru/osobye-vidy-vozdejstviya-na-okruzhayuschuyu-sredu/raketno-kosmicheskaya-deyatelnost

www.militaryrussia.ru

www.meganorm.ru

www.americaspace.com

www.novosti-kosmonavtiki.ru

www.spaceflightnow.com

www.sl-24.ru

www.npoenergomash.ru/encikloped/media

www.vakhnenko.livejournal.com/182895.html

www.youtu.be

www.epizodsspace.no-ip.org

www.i.ytimg.com

www.mil.ru

www.gamer.ru

www.ekologia-ra.ru/osobye-vidy-vozdejstviya-na-okruzhayuschuyu-sredu/raketno-kosmicheskaya-deyatelnost

www.militaryrussia.ru

www.meganorm.ru

www.americaspace.com

www.novosti-kosmonavtiki.ru

www.spaceflightnow.com

www.sl-24.ru

www.npoenergomash.ru/encikloped/media

www.vakhnenko.livejournal.com/182895.html

www.youtu.be

www.epizodsspace.no-ip.org

www.i.ytimg.com

www.mil.ru

www.gamer.ru

Source: https://habr.com/ru/post/401927/

All Articles