Transformers on innovative alloys can save Moscow up to 1 billion rubles a year

The scientific group of the laboratory "Perspective Energy Efficient Materials" of NITU "MISiS" under the guidance of Professor Akihisa Inoue (Hirsch Index = 113) determined the range of amorphous alloys to create innovative transformer cores. When using such an alloy, the loss of electricity can be reduced threefold. Using a 1000 kVA transformer with a new core will save more than 16,000 kWh of electricity per year.

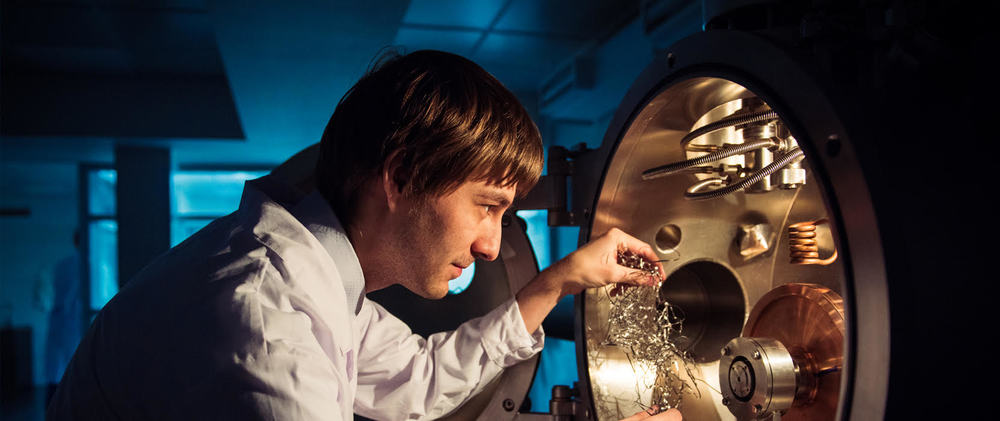

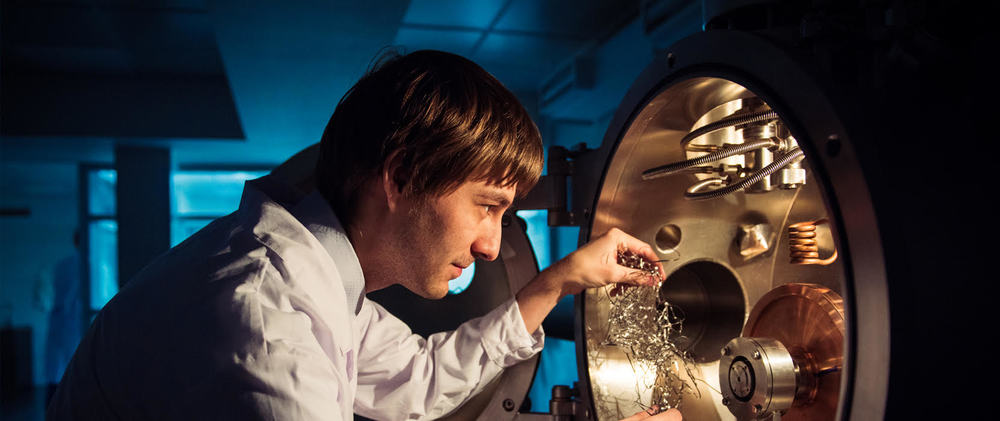

In the laboratory "Promising energy-efficient materials"

The key element of a traditional transformer is a voltage conversion device — a steel core (magnetic core). It is here in the process of conversion that electric energy is lost due to heating. Causes of losses in the formation of Foucault eddy currents and the phenomenon of magnetic hysteresis. Part of the energy is lost, the efficiency of the device is reduced.

')

Innovative amorphous alloy developed by the scientific team of the laboratory "Advanced energy-efficient materials" NITU "MISiS", in fact - metallic glass that does not have a crystal lattice. Due to its amorphous structure, this material has more favorable magnetic properties than traditional electrical steels. Accordingly, the use of this material will reduce energy losses.

“The unique properties of the new alloy are achieved due to the improved composition and the use of the method called melt spinning (casting on a rotating copper disk). Production of a transformer with a core of a new alloy will require changes in technology and will be more expensive than the traditional by about 30%, but reducing losses will recoup the increased financial costs for 3-5 years using a transformer. If we replace transformers with new ones all over Moscow, we can save more than 1 billion rubles a year, according to preliminary estimates, ”the laboratory employees say.

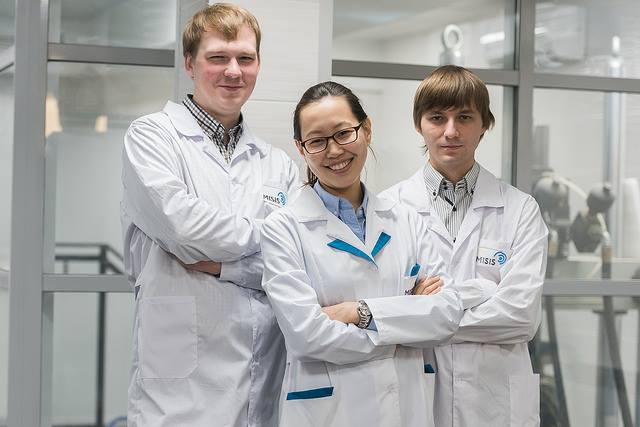

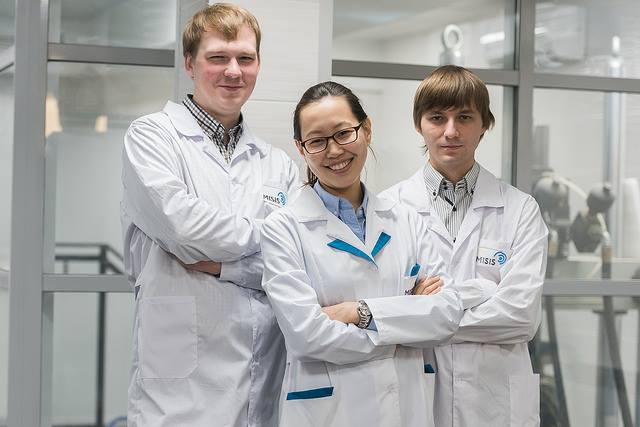

Employees of the laboratory "Advanced Energy Efficient Materials"

Metallic glasses or amorphous metals are metallic alloys in the glassy state, which are formed during the rapid cooling of the metallic melt. Due to the homogeneous amorphous structure, a significantly higher level of material properties is provided in comparison with traditional ones. The special structure of metallic glass provides high elastic deformation, strength, good corrosion resistance, which significantly exceed the properties of crystalline alloys of similar composition.

In addition to the described application, metal glasses are very promising materials for creating high-quality precision mechanisms, parts of micromotors, manometers, surgical instruments, sports equipment, cases for electronics and the watch industry.

The laboratory "Promising energy-efficient materials" under the leadership of the world's leading expert in this field - Professor Akihisa Inoue from the Japanese University Josai was established at NITU "MISiS" in 2015. The research team of the laboratory has already published 10 scientific articles in high-ranking journals included in Web Of Science and also filed 3 applications for patenting. "

The head of the laboratory, Professor Akihisa Inoue.

In the laboratory "Promising energy-efficient materials"

The key element of a traditional transformer is a voltage conversion device — a steel core (magnetic core). It is here in the process of conversion that electric energy is lost due to heating. Causes of losses in the formation of Foucault eddy currents and the phenomenon of magnetic hysteresis. Part of the energy is lost, the efficiency of the device is reduced.

')

Innovative amorphous alloy developed by the scientific team of the laboratory "Advanced energy-efficient materials" NITU "MISiS", in fact - metallic glass that does not have a crystal lattice. Due to its amorphous structure, this material has more favorable magnetic properties than traditional electrical steels. Accordingly, the use of this material will reduce energy losses.

“The unique properties of the new alloy are achieved due to the improved composition and the use of the method called melt spinning (casting on a rotating copper disk). Production of a transformer with a core of a new alloy will require changes in technology and will be more expensive than the traditional by about 30%, but reducing losses will recoup the increased financial costs for 3-5 years using a transformer. If we replace transformers with new ones all over Moscow, we can save more than 1 billion rubles a year, according to preliminary estimates, ”the laboratory employees say.

Employees of the laboratory "Advanced Energy Efficient Materials"

Metallic glasses or amorphous metals are metallic alloys in the glassy state, which are formed during the rapid cooling of the metallic melt. Due to the homogeneous amorphous structure, a significantly higher level of material properties is provided in comparison with traditional ones. The special structure of metallic glass provides high elastic deformation, strength, good corrosion resistance, which significantly exceed the properties of crystalline alloys of similar composition.

In addition to the described application, metal glasses are very promising materials for creating high-quality precision mechanisms, parts of micromotors, manometers, surgical instruments, sports equipment, cases for electronics and the watch industry.

The laboratory "Promising energy-efficient materials" under the leadership of the world's leading expert in this field - Professor Akihisa Inoue from the Japanese University Josai was established at NITU "MISiS" in 2015. The research team of the laboratory has already published 10 scientific articles in high-ranking journals included in Web Of Science and also filed 3 applications for patenting. "

The head of the laboratory, Professor Akihisa Inoue.

Source: https://habr.com/ru/post/401783/

All Articles