Skyscrapers: how to wash them?

We talked about the tallest buildings in Russia and in the world , discussed the technologies used in the construction. In such projects, an effective approach to building maintenance is important. Just imagine how much time it takes to wash the glass with a total area of 17 football fields? The robots come to the rescue, but even they still cannot climb the spire or remove the dirt from curved surfaces.

Roofers also like to climb spiers. Interestingly, window washers and people working with radio towers, looking at the extreme with a laugh?

The first skyscraper in the modern sense was the building of house insurance in Chicago with a height of 42 meters, built in 1885. The innovation of the approach was in use instead of the traditional concrete or brick walls of the steel bearing framework, which allowed the total mass of the building to be reduced by a third. Chicago and New York began to build up high-rise buildings. The windows of these huge buildings had to be washed somehow. And the work of the people who were responsible for this, was initially at risk.

')

In the 43-story Williamsburg Savings Bank building in the New York Brooklyn area, 1,100 windows have been installed. In 1952 only one person washed them - 34-year-old Ed Kemp. Ed systematically washed the glass from the very beginning of the month, going down from the last floor to the first. He washed all the windows for a month, after which he began his hard work from the beginning. In an interview with Eagle, he talked about the loneliness that he felt while working: he saw hundreds of people who talked, laughed and lived inside the building, but were always separated from them by glass.

How dangerous was the job at that time? From 1928 to November 1929, 84 people died in New York as a result of the fall. On November 3, 1929, the five hundred-person window cleaner union demanded from the New York authorities not only a 10% salary increase, but also sanctions against building owners who did not install special hooks on the windows. On the frame below you can see how washers use such hooks: they insure themselves with a special belt.

In 1944, the city authorities demanded that the owners of the buildings replace old hooks with new ones made of stainless steel. There were problems with materials due to the Second World War, and for about a year many buildings simply did not wash. After 1945, the problem was solved, but the human factor has not been canceled. One of the window cleaners in Brooklyn broke from the fourth floor and crashed when he forgot to fasten his belt.

At first, the windows were washed, holding onto the frame. Then - using belts and safety hooks. And in the 1950s, the oldest elevator manufacturer Otis Elevator Company came to the rescue and offered an electrically powered platform. The cradle on the winch installed on the roof allows you to wash windows with greater safety, while there can be several people at the same time. By the way, this company served as a catalyst for the construction of skyscrapers, because without an elevator, to rise to 20-30 floors is a difficult task.

Initially, the area of the windows on the buildings was much smaller than the current modernist architecture provides. 43,600 windows were installed in the buildings of the World Trade Center in New York, that is, each one is 20 times more than in Williamsburg Savings Bank. Publication of The New Yorker writes that at that time they tried to automate the process and used machines with rotating brushes that could descend from the building in 20 minutes. Such a robot was useless at the corners of the towers. Manually washed and upper floors.

Nu-Star Inc. has been producing car washes since 1969. Developed technology used in the machine for washing skyscrapers. Sky Pro and its smaller version of the Sky Pro Mini work in the same way: using a roller inside the case. The device is raised and lowered with a winch installed on the roof. Sky Pro Mini can wash more than two thousand square meters per day. In order for such washers to work efficiently, the building itself must be a box with a smooth facade.

Serbot offers a more flexible solution in the form of Robot Cleat Ant Profi . This "ant" does not hang on the rope, the winch only insures it. While one side of the robot is chained to the glass with the help of suction cups, the second one rotates around the first one and washes the window. Thanks to several degrees of freedom, the robot can move from one plane to another - that is, to overcome the corners of the building.

Ant is still at the development stage, and Serbot calls its other product "the first commercially available cleaning robot that can move in all directions on inclined, vertical or even steep surfaces." The robot is controlled by the operator remotely. Water is supplied to it with a 250-meter hose.

“Domesticated” versions of the cleaning robots sometimes consist of two modules that are held on both sides of the window with a magnet at the same time. In part, they are able to solve the problem of washing glass at a height, but with reservations: the window should open; From window to window, the robot must be manually transferred.

This option is not suitable for industrial purposes. There are versions from one module - something like a reduced Ant Profi, but without degrees of freedom - while one part sticks to the glass, the second moves and washes it.

The architecture is complicated. The tallest buildings in the world have complex terrain, they twist, have curvatures and seams, and antennas and spiers are installed on their tops. Robots-cleaners again replaced the living human labor.

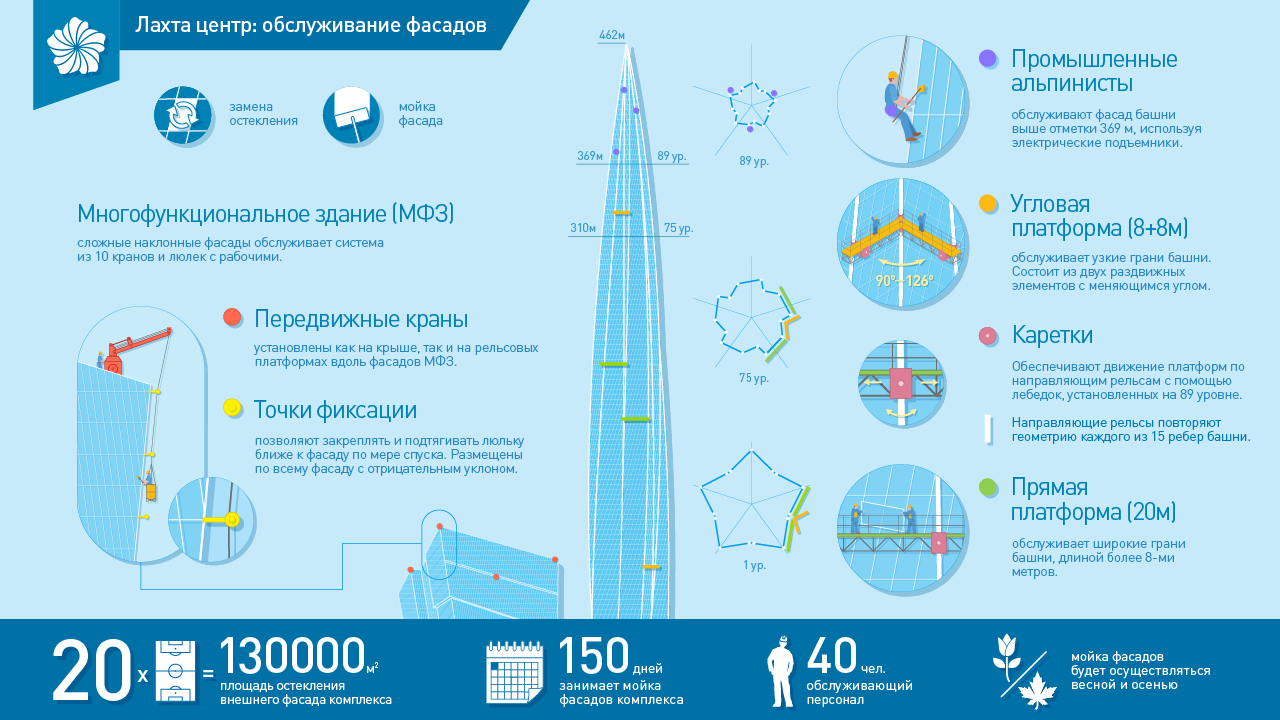

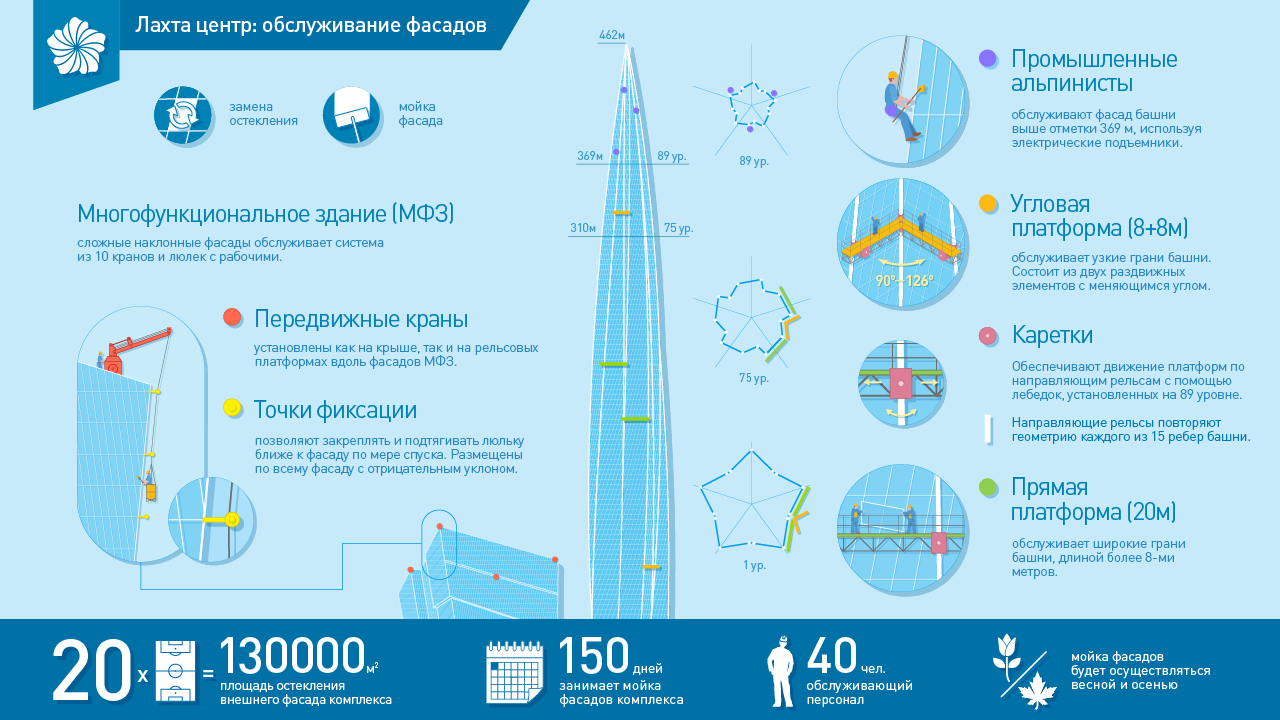

The Lakhta Center tower will be washed by industrial climbers using standard individual equipment, cradles for one person and special prefabricated platforms allowing for simultaneous washing of two faces of a building of complex shape.

Let's estimate the scale of the work. In the 43-meter Williamsburg Savings Bank there were 1,100 windows, with which the washer coped in a month. The 828-meter tower of Burj Khalifa has a whole staff of industrial climbers washing for three months. The percentage of glass in the Dubai Tower is incomparably higher than in the old New York skyscrapers.

The surface area of the Burj Khalifa tower is 17 football fields. One field is 105 by 68 meters, or three nine-story houses in length and two in width. Imagine aspherical nine-story square building in a vacuum in a vacuum . Now - six such houses. And multiply them by 17. This is 121,380 square meters. One Sky Pro Mini robot could wash the entire building in two, rather than three months, as the current team of cleaners. But the machine is not able to wash the building of such a complex shape.

Mentally take water, a brush, a rubber scraper and try to wash this mountain of glass. Now look at how they do it on the tallest building in the world. Without robots.

Roofers also like to climb spiers. Interestingly, window washers and people working with radio towers, looking at the extreme with a laugh?

The first skyscraper in the modern sense was the building of house insurance in Chicago with a height of 42 meters, built in 1885. The innovation of the approach was in use instead of the traditional concrete or brick walls of the steel bearing framework, which allowed the total mass of the building to be reduced by a third. Chicago and New York began to build up high-rise buildings. The windows of these huge buildings had to be washed somehow. And the work of the people who were responsible for this, was initially at risk.

')

In the 43-story Williamsburg Savings Bank building in the New York Brooklyn area, 1,100 windows have been installed. In 1952 only one person washed them - 34-year-old Ed Kemp. Ed systematically washed the glass from the very beginning of the month, going down from the last floor to the first. He washed all the windows for a month, after which he began his hard work from the beginning. In an interview with Eagle, he talked about the loneliness that he felt while working: he saw hundreds of people who talked, laughed and lived inside the building, but were always separated from them by glass.

How dangerous was the job at that time? From 1928 to November 1929, 84 people died in New York as a result of the fall. On November 3, 1929, the five hundred-person window cleaner union demanded from the New York authorities not only a 10% salary increase, but also sanctions against building owners who did not install special hooks on the windows. On the frame below you can see how washers use such hooks: they insure themselves with a special belt.

In 1944, the city authorities demanded that the owners of the buildings replace old hooks with new ones made of stainless steel. There were problems with materials due to the Second World War, and for about a year many buildings simply did not wash. After 1945, the problem was solved, but the human factor has not been canceled. One of the window cleaners in Brooklyn broke from the fourth floor and crashed when he forgot to fasten his belt.

At first, the windows were washed, holding onto the frame. Then - using belts and safety hooks. And in the 1950s, the oldest elevator manufacturer Otis Elevator Company came to the rescue and offered an electrically powered platform. The cradle on the winch installed on the roof allows you to wash windows with greater safety, while there can be several people at the same time. By the way, this company served as a catalyst for the construction of skyscrapers, because without an elevator, to rise to 20-30 floors is a difficult task.

Initially, the area of the windows on the buildings was much smaller than the current modernist architecture provides. 43,600 windows were installed in the buildings of the World Trade Center in New York, that is, each one is 20 times more than in Williamsburg Savings Bank. Publication of The New Yorker writes that at that time they tried to automate the process and used machines with rotating brushes that could descend from the building in 20 minutes. Such a robot was useless at the corners of the towers. Manually washed and upper floors.

Nu-Star Inc. has been producing car washes since 1969. Developed technology used in the machine for washing skyscrapers. Sky Pro and its smaller version of the Sky Pro Mini work in the same way: using a roller inside the case. The device is raised and lowered with a winch installed on the roof. Sky Pro Mini can wash more than two thousand square meters per day. In order for such washers to work efficiently, the building itself must be a box with a smooth facade.

Serbot offers a more flexible solution in the form of Robot Cleat Ant Profi . This "ant" does not hang on the rope, the winch only insures it. While one side of the robot is chained to the glass with the help of suction cups, the second one rotates around the first one and washes the window. Thanks to several degrees of freedom, the robot can move from one plane to another - that is, to overcome the corners of the building.

Ant is still at the development stage, and Serbot calls its other product "the first commercially available cleaning robot that can move in all directions on inclined, vertical or even steep surfaces." The robot is controlled by the operator remotely. Water is supplied to it with a 250-meter hose.

“Domesticated” versions of the cleaning robots sometimes consist of two modules that are held on both sides of the window with a magnet at the same time. In part, they are able to solve the problem of washing glass at a height, but with reservations: the window should open; From window to window, the robot must be manually transferred.

This option is not suitable for industrial purposes. There are versions from one module - something like a reduced Ant Profi, but without degrees of freedom - while one part sticks to the glass, the second moves and washes it.

The architecture is complicated. The tallest buildings in the world have complex terrain, they twist, have curvatures and seams, and antennas and spiers are installed on their tops. Robots-cleaners again replaced the living human labor.

The Lakhta Center tower will be washed by industrial climbers using standard individual equipment, cradles for one person and special prefabricated platforms allowing for simultaneous washing of two faces of a building of complex shape.

Let's estimate the scale of the work. In the 43-meter Williamsburg Savings Bank there were 1,100 windows, with which the washer coped in a month. The 828-meter tower of Burj Khalifa has a whole staff of industrial climbers washing for three months. The percentage of glass in the Dubai Tower is incomparably higher than in the old New York skyscrapers.

The surface area of the Burj Khalifa tower is 17 football fields. One field is 105 by 68 meters, or three nine-story houses in length and two in width. Imagine a

Mentally take water, a brush, a rubber scraper and try to wash this mountain of glass. Now look at how they do it on the tallest building in the world. Without robots.

Source: https://habr.com/ru/post/401461/

All Articles