Signaller "loaf"

It is difficult for operators to do without mobile laboratories for the maintenance and installation of fiber optic links. Cars equipped with everything necessary for the work of mobile teams of communications installers, as a rule, are made to order by integrators based on well-known brands. There are many similar offers on the Russian market and the price tag for such laboratories is simply too heavy for a small operator. What to do if you are an alternative operator with a modest subscriber base and it is simply unrealistic to spend round sums for you. Under the cut is a living example of how to turn an ordinary “loaf” into a communications laboratory.

A shabby life "UAZ" with leaking antifreeze, huge fuel consumption and problematic electricians. And also a few days off and a lot of enthusiasm. Such initial data were available before the solution of the problem: to create, on the basis of the old “loaf,” an equipped vehicle for the work of the visiting brigade of communications workers.

')

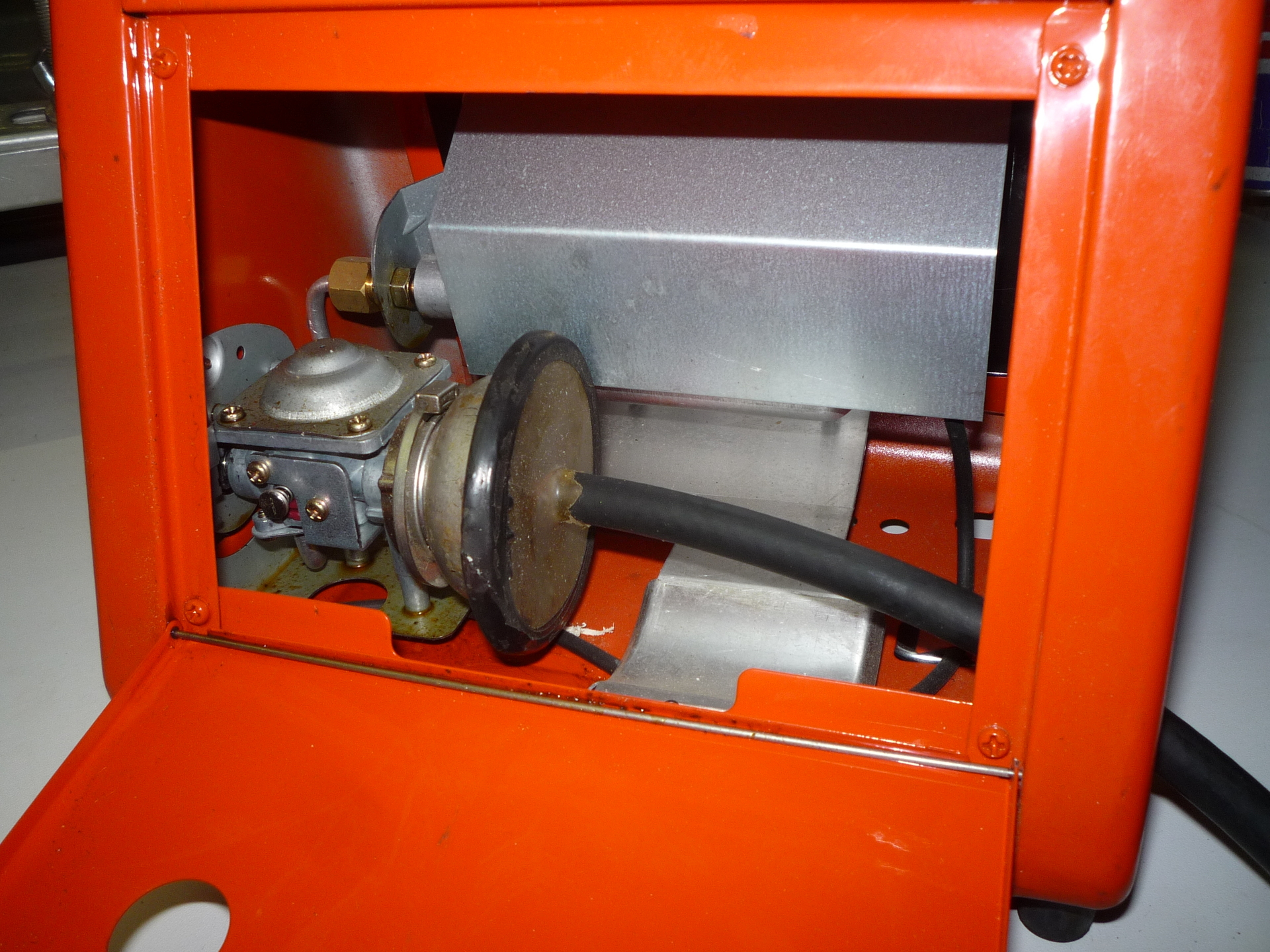

The first step was to pay attention to the motor. Reduce the appetite of the car and improve the dynamics. As a result, the carburetor from the “classics” and filtering system with AZLK 2141 was put on the “UAZ”.

As a result, the car has improved dynamics, and fuel consumption has decreased by 10 liters.

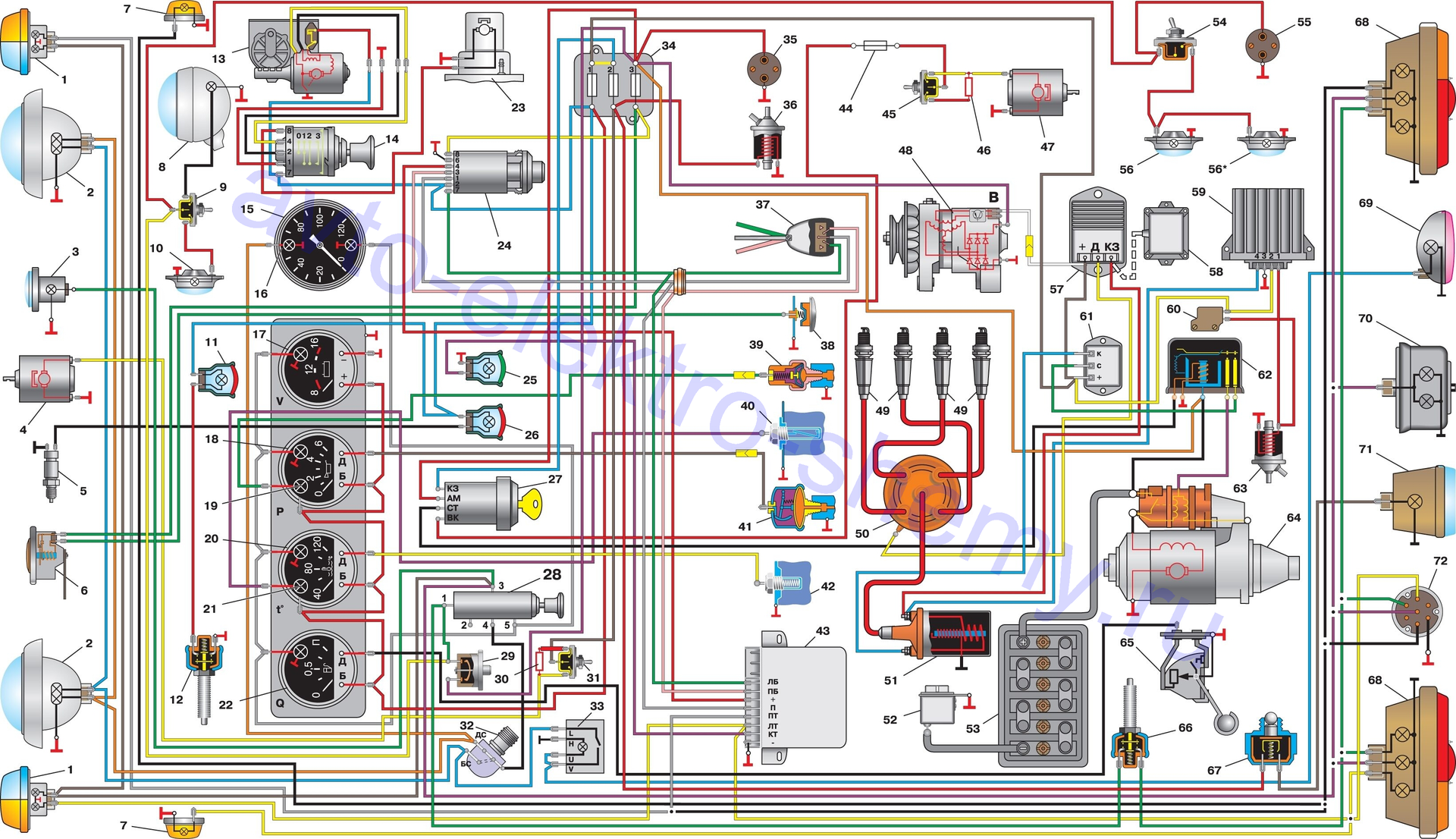

Electrician

With such a scheme, all currents flow through the ignition lock, which is bad for the life of the wiring and the ignition lock. In addition, the thermal relay can turn off headlights while driving. Generally, you will not get problems. Native electrician had to completely eliminate and replace the whole thing with harnesses. All the crimped connections were soldered, and the thermal relay and the old fuse box went to the landfill. In the new scheme, each current consumer has its own fuse.

From the battery to the fuse box, three cables were drawn and three relays installed. One is responsible for connecting current consumers when starting the engine. Another supplies electricity to the headlights, and another feeds the heating devices in the cabin, cigarette lighter and radio. An inverter of 600 watts was also installed.

Lighting switches for the welding table and trunk located on the front panel.

On the roof of the car were installed spotlights.

The interior is insulated with foil insulators and sheathed with plywood. Also inside put infrared heater with a gas cylinder.

The frame of the table was personally welded from a shaped tube.

Installed adjustable seats, the frame for which was also made of shaped tube and angle.

Cigarette lighter and lighting done under the welding table.

We slightly modernize the old clutch holder, making it quick-release.

The salon was equipped with a special holder for a gas burner.

Also in the cabin provides a small heater .

A special adapter was made under the burner.

The air flow from the stove was redirected to the legs.

This is what “svyazmobile” turned out in the end.

Source: https://habr.com/ru/post/401187/

All Articles