Overview of new 3D printing from CES 2017

The Consumer Electronics Show was held in Las Vegas, Nevada, from January 5 to 8. At this exhibition, which is already more than four decades old, manufacturers presented technological innovations - potential bestsellers of the near future.

3D printing did not go overboard - the exhibitors presented a lot of new things.

')

Getting to know about the 3D technology platform at CES is a great way to learn about promising innovations in the field of 3D printing. Unfortunately, the industry leader - 3D Systems - did not participate in the exhibition this year, but there were a lot of other players, old and new, who showed their designs in the printing of three-dimensional objects.

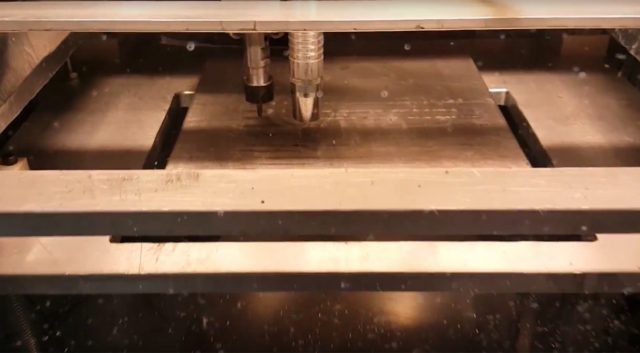

Ability 3D

Ability 3D promises to fans an affordable 3D printer for metal.

This is not an ordinary 3D printer - in an effort to make 3D metal printing more accessible, a welding machine and a CNC router were crossed in their Ability device. Each layer, in the process of printing, is first welded by welding, and then processed by a mill.

In March, a campaign on KickStarter starts, the purpose of which is to raise funds for the launch of the serial production of THE ABILITY3D-888 , and in February Ability is going to present the cylinder of the internal combustion engine printed by their printer to the public without serious postprinting. The price for the printer, in serial already release, guys from Ability see somewhere around $ 3000.

We'll see.

Formlabs

Several years ago Form from Formlabs, with its photopolymerization technology, was a novelty in the consumer electronics market, however, stereolithography is still something exotic enough for use in desktop models. FDM cannot compete with stereolithographic printers in printing accuracy, while stereolithography has long been inferior in the variety of materials used. As time goes on, manufacturers are trying to reduce this gap: this year Formlabs presented Formlabs Form X Ceramic ceramic photopolymer, which, after printing, can be painted and baked like ordinary ceramics.

Rigid plastics that have become more durable than before have been updated, for example, Formlabs Tough Resin , imitating ABS with its mechanical properties.

In general, Formlabs is constantly expanding its line of polymers .

XYZ Printing

In order to print a color object with gradients, now you have to go to a 3D studio, which is quite expensive. Few people can afford a 3D printer capable of this. XYZ Printing is trying to change this situation with its new inexpensive Da Vinci Junior 2.0 Mix 3D color printer, which is suitable for home and home use.

This printer can mix in one extruder two filaments of different colors, in any proportion.

The capabilities of the printer are still limited to using only two colors, but the supplied software allows you to get any shade that is possible when mixing them. Da Vinci Junior 2.0 Mix will find its satisfied user.

Da vinci Nano is another new model from XYZ Printing.

This is a compact modification of the Da Vinci Mini 3D FDM already known to everyone - the Nano workspace is a cube with a 11.9 cm face, against a 14.9 cm Mini model. Its main feature is compactness, but there is another advantage - a closed printing chamber, the door of which protects the printout from drafts and dust.

CoLiDo

Interesting CoLiDo printers are inexpensive and not too complicated 3D printers, including delta bots, which are available in the DIY version - as a set for self-assembly. For example - CoLiDo Delta D1315 .

Due to their size, they can print fairly large objects, while remaining relatively inexpensive while providing more than acceptable quality. This and interesting.

The company plans to launch a model for metal printing soon. It seems somewhat presumptuous, but — everything is possible — we will not run ahead of the locomotive and see what happens.

3doodler

The 3Doodler line of 3D pens, the founder of this market segment, has long been no news for anyone, but you rarely see such neat and voluminous structures created with just a 3D pen. Apparently, for the exhibition stand they hired a very skillful “draftsman”, which is not surprising - the company tries to convince the public that 3D pens can be useful to artists, designers and people of other creative professions, and are not just expensive children's toys. Not so long ago, following the concise all-metal 3Doodler 2.0 , an impressive and sophisticated 3Doodler Pro was released - a handle with a carbon body and convenient speed and temperature control rings designed for work with a large range of materials.

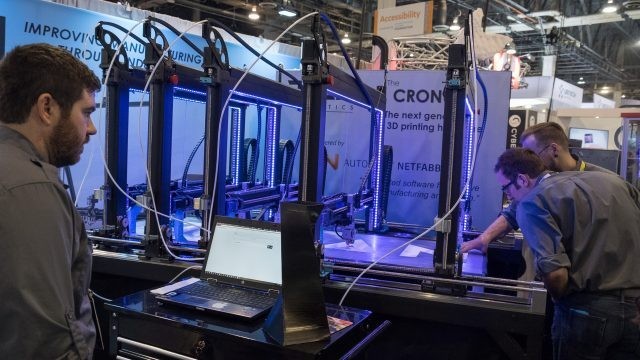

Titan robotics

The most impressive printer on the show, at the same time - one of the most productive, is The Cronus - a five-headed monster of 3D printing from Titan Robotics Ltd. He uses Autodesk's advanced software, the Escher project, to coordinate and neatly work his five robotic manipulators with extruders, which makes it possible to print objects of sufficiently large size.

The printer intends to put on sale this year, with the price "on request", amounting to a six-digit number. The device can be used in manufacturing and online services that allow you to order 3D prints through the network.

Cronus can use any standard 3D materials for printing, without restrictions by manufacturer.

Markforged

Markforged, a leader in carbon fiber printing, presented at CES its new industrial 3D printer - Metal X , which is intended for 3D printing with stainless steel.

It is much smaller and cheaper than metal-printing monsters from 3D Systems, and much easier to use than the optimistic design of Ability.

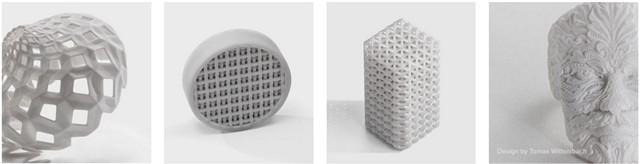

DWS

DWS Lab presents its X-FAB printer as “the first Hi End 3D printer at a consumer price.” It is a stereolithographic printer, a Form 2 direct competitor. According to the manufacturer, the proprietary proprietary technology allows this printer to print in a wide variety of materials, including hard and soft, transparent and opaque, ceramic, waxy and rubber-like polymers.

As the main advantages of its printer, DWS calls a quick replacement of material using smart cartridges, no leaks and the need for manual work with liquids, no cost to replace the polymer tray.

Sprintray

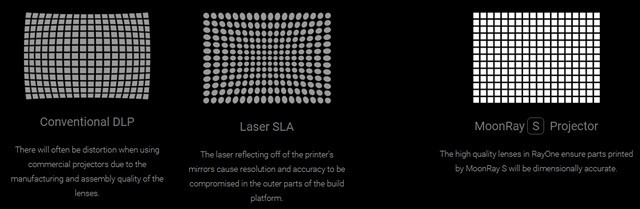

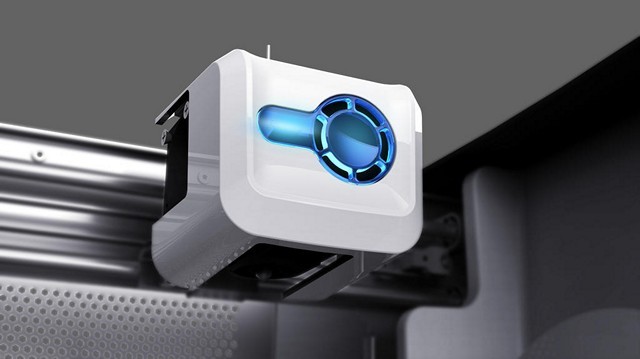

Sprintray has unveiled its new Moonray S.

What is interesting: at the heart of the design is a specially designed RayOne UV DLP ultraviolet projector, which produces radiation with a wavelength of 405 nm.

Due to the design features, this projector provides a more accurate location of each point in the projection than conventional video projectors and laser SLA systems.

Also, the manufacturer emphasizes that the trays for the polymer in this printer do not require such frequent replacement, as in other photopolymer devices.

“Say goodbye to consumables” - the manufacturer tells us and, of course, is cunning. Yes, the estimated life of their trays is more than usual (as stated - 50 liters of polymer), but not endless. With active use of the printer, of course, they will also have to be changed or serviced.

Another feature of Moonray S is the presence of its own software that allows you to control multiple printers simultaneously over a wireless connection, as well as more rational (with material savings of up to 30%) to build support.

In the photo: support generated by the proprietary program RayWare against the supports created by MeshMixer.

Intamsys

Intamsys showed her FUNMAT HT .

FUNMAT HT is a PEEK thermopolymer printer.

PEEK is a polyetheretherketone, it is a light, but very durable and strong thermoplastic. PEEK is increasingly being used in 3D printing, as a number of key patents are now expiring that have limited its use.

The material is so good that Californian company Spinal creates elements from it that are used in spinal surgery .

There are some pitfalls, of course: PEEK requires fairly high temperatures for printing. Therefore, a special printer was needed for him. The printer from Intamsys has a nozzle that can reach temperatures in excess of 400 ° C. In addition to the PEEK, this FDM device can also print with more traditional materials such as ABS.

SHINING 3D

SHINING 3D presented two interesting novelties at its booth.

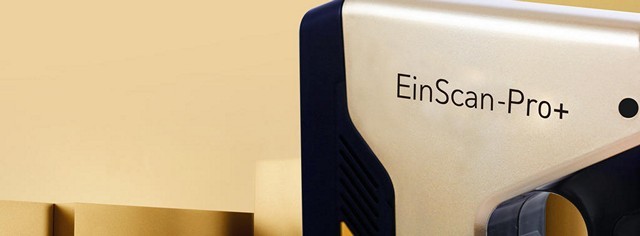

The new model of 3D-scanner EinScan-Pro + - an improved version of the well-known EinScan-Pro , and a completely new personal 3D-printer Einstart-C .

It used to seem a little strange that the Chinese comrades were so restrained and concise in the design of their technology - the Einscan scanners could be considered a model of industrial design. Well, the strangeness is over, the Eastern approach showed itself and everything fell into place: the new EinScan-Pro + is presented in the glamorous color of “champagne gold”.

Technically, this, of course, did not harm him at all. As expected, EinScan-Pro + is superior to its predecessor.

As can be understood from the promotional pictures, the scanning speed has increased by 7.6 times, and the capture area of each frame is 1.6 times.

In addition, with the new scanner comes new software - the latest version of EinScan 2.0 Software.

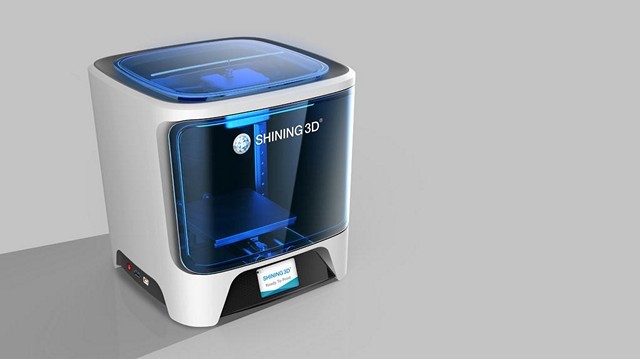

Einstart-C is a new compact printer.

This is a small closed printer with one extruder, printing PLA.

The size of the printed models is up to 15.24 cm on each axis. The printer has a safety mechanism that makes printing impossible when the door is open, but it can be turned off.

An interesting feature of the printer is a self-adjusting platform with a three-point level sensor - the printer automatically aligns the platform before each print session.

Using the example of Einstart-C, we observe a tendency to create more user-friendly and inexpensive, albeit often less functional, consumer-grade 3D printers — not requiring even the most elementary engineering skills from the user.

Well, a small offtop: a couple of new 3D printings that do not directly relate to which few people will remain indifferent:

Qualcomm & ODG

Qualcomm, a well-known manufacturer of mobile processors Snapdragon, presented at the exhibition a new mobile processor Snapdragon 835 and the first wearable devices based on it - made by ODG (Osterhout Design Group) in the format of augmented reality glasses R-8 SMARTGLASSES and R-9 SMARTGLASSES .

R-8:

While the processor has just gone into production and the devices with it are not yet sold, it is difficult to accurately speak about their technical characteristics, but - according to the manufacturer, they are roughly like this:

The Android-based system, the eight-core processor mentioned above (four productive cores and four economical ones), stereo image resolution is 720p (per eye), with a viewing angle of more than 40 degrees, in the R-8 and 1080p models, with 50 degrees of vision, in R-9. It weighs R-8 127.5 grams, this is against the 567-gram Microsoft HoloLens, for example. Too much, but much closer to a really usable wearable device.

Smart glasses work with Vuforia - the most supported, to date, platform for application developers of augmented reality (about 300,000 registered developers have already created more than 35,000 compatible applications .) Agreements have been concluded with 21-st Century Fox and other companies to release content.

On energy supply, there is no reliable information from the manufacturer yet, but the model R-7 , which has been sold since 2015, has two 650 milliamp / hour batteries on board. It seems obvious that in the new models this will not be worse.

R-7:

What about the prices? R-9 plans to sell at a price of about $ 1,800, somewhere from mid-2017, and the R-8 will be available earlier and for less than $ 1,000.

For comparison, the R-7, with a picture like the R-8, with a less productive processor and without 4G (which is in the new models), is now being sent for $ 2,750. Apart from the price of delivery from the US, a separately sold bluetooth keyboard for $ 93 and a bluetooth manipulator.

In general, the prospects are not bad, and how it will turn around - time will tell.

Lego

LEGO Boost is a new line of LEGO designers that allows children (and not only) to assemble a robot, an electronic pet and much more, to program the created device using a tablet and to control it through a wireless module.

It is difficult to imagine a toy that would better introduce the child to the world of robotics.

Production is already deployed, it remains to wait for the start of sales in August 2017.

Want more interesting news from the world of 3D technology?

Subscribe to us in the social. networks:

Source: https://habr.com/ru/post/400985/

All Articles