SFP module butt cleaning

Clients often come to us with numerous questions regarding pollution of the optical components of the network. Some are interested in how to diagnose pollution, while others want to learn how to effectively clean the ends of optical components. Some even thought that "NAG" sells optical components with dirty ends. It even happened that buyers of SFP-modules returned them to the store due to poor performance. Then it turned out that the cause of the problems with the SFP was the trivial pollution of the ends. The specialists of “NAGA” decided to put everything on the shelves, and to tell what most often causes pollution of the butt of optical components and what tools to use for diagnostics and removal of pollution.

To understand the situation, let us cite some statistical data, according to which more than 85 percent of problems in fiber-optic networks are a consequence of contamination of the end surface of optical components. Contamination of the optical connector is a direct way to the deterioration of fiber optic parameters, which leads to a decrease in the signal level, increases insertion loss and back reflection. In the worst case, there is a failure of the communication line or its individual components of the data transmission network.

The causes of contamination of optical components are many. For example, improper storage and the absence of any prophylaxis of the same patch cords and adapters. A common phenomenon is considered when the pollution of the end of a module occurs due to the use of a patch cord in handling it, which has been gathering dust for a long time. As a result, microscopic dust particles are deposited inside the connector, adversely affecting the operation of the module and the passage of light.

')

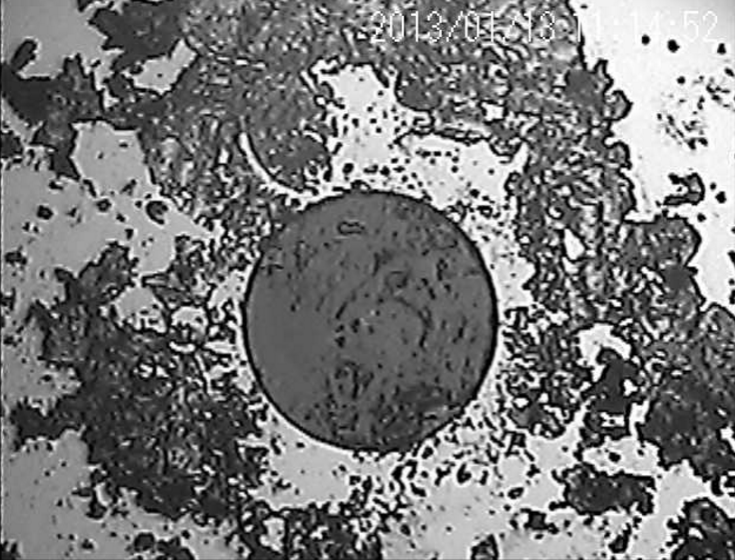

It looks like a contaminated ferule under a microscope

Diagnostics

Let's start with the diagnosis of pollution.

Required components to get started

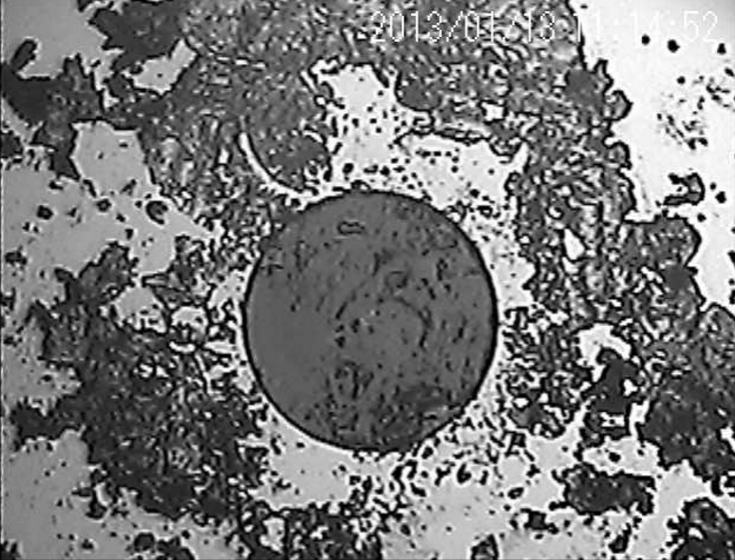

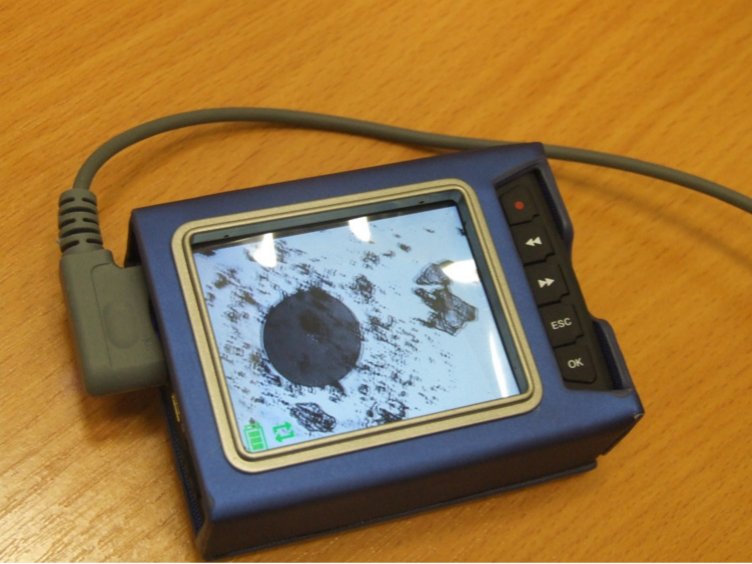

First you need to diagnose and assess the degree of contamination of the optical connector. To do this, we have an excellent device at hand - a high-precision portable microscope Syoptek-FIP-800 .

It consists of a base module with a LCD display and a video probe, the kit also includes optical sockets SC, FC, LC, as well as a nozzle for testing patch cords with a ferule of 2.5 millimeters.

Working with the FIP-800 is easy. The video probe of the microscope must be inserted into the optical connector. Multiple enlarged image is displayed.

Thus, we can most accurately assess the severity of contamination of optical components.

A microscope can not only photograph the state of the butt, but also record video and sound. Diagnostic results are stored on a flash drive. For greater convenience, a special mount for fixing on the wrist is provided in the microscope configuration.

Cleaning

With diagnostics, everything is clear, so we proceed directly to the cleaning. Judging by the reviews of our customers, many are of the opinion that when cleaning it is enough to only blow the ends. However, this does not relieve the end surface of the microparticles of dirt deposited on it, which are visible only under a microscope.

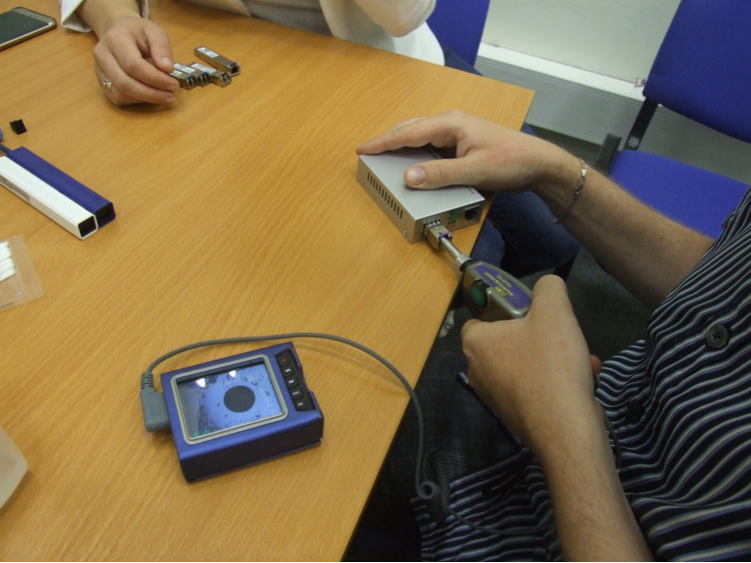

When cleaning optical components resort to the use of cotton swabs and cleaning with the use of special tools. The specialists of “Naga” tried both methods and compared their effectiveness with the help of Syoptek-FIP-800.

First of all, using a microscope, we evaluated the contamination of the end of the optical module.

Next, we cleaned the end of the module with a cotton swab dipped in alcohol.

The result, as you can see in the screenshot below, is not impressive. Dirt simply smeared on the surface of the end of the module, which indicates the inefficiency of this method of cleaning.

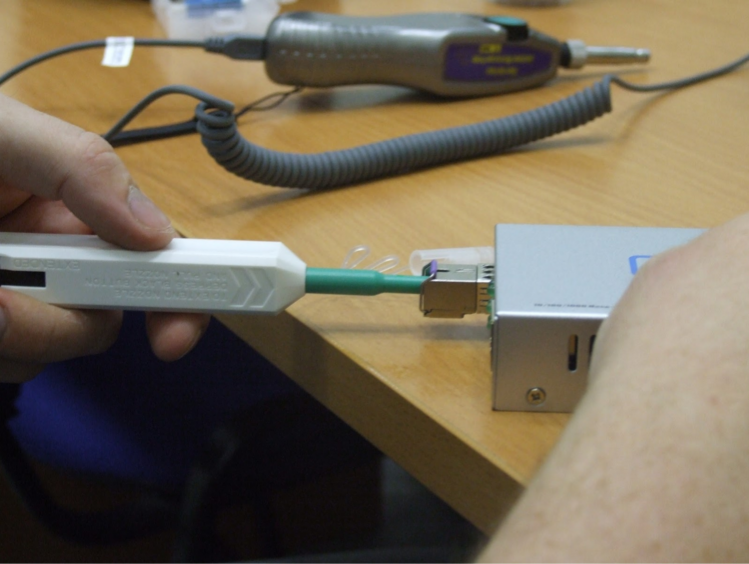

To demonstrate the work of a special tool for cleaning the ends, we used the One-Click-Cleaner SNR . It is easy to use, and cleaning takes place with a tape without the use of alcohol. The device is designed for 800 cleaning cycles. Suitable for cleaning connectors built into FC, SC, ST adapters, patch cords with 2.5 mm ferrule and connectors with PC and APC polishing types. The cleaner is suitable for cleaning embedded optical modules in media converters . In addition, the tool will be extremely useful when using DWDM and CWDM SFP / SFP + modules, as well as for SFP modules with SC connector

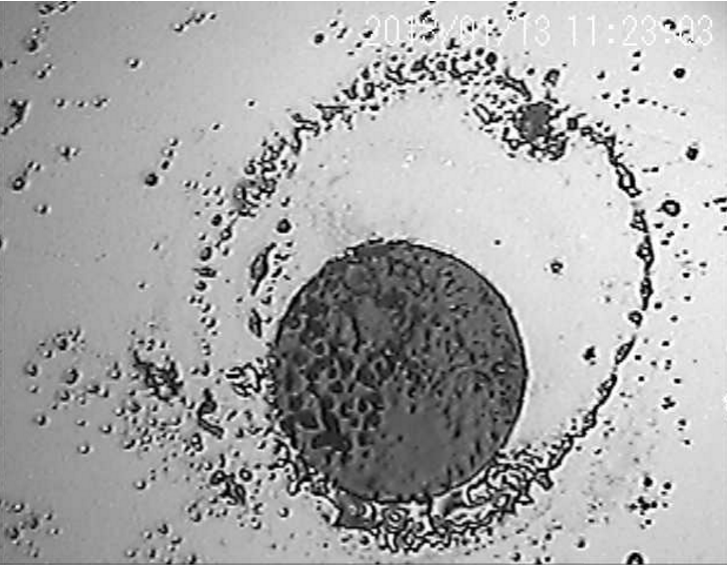

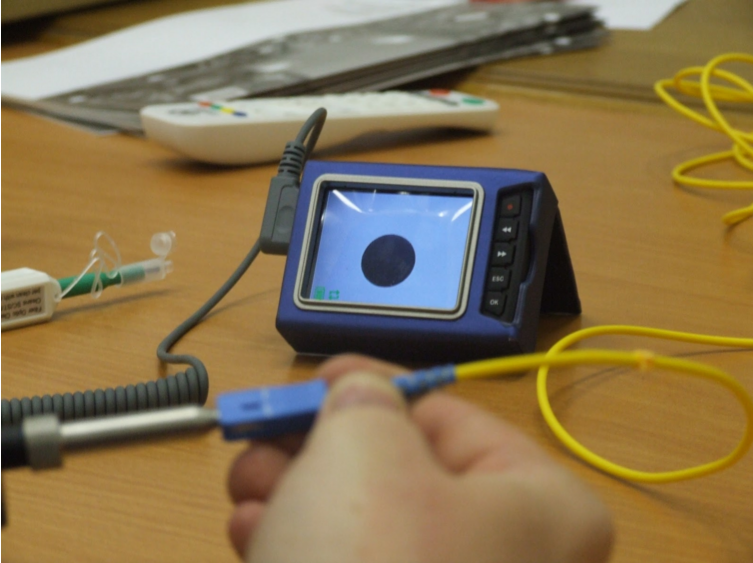

Again, we take a microscope and diagnose the degree of surface contamination.

SNR One-Click Cleaner is inserted into the module slot. Then with a few taps on the handle, the surface is cleared of dirt. Cleaning takes place thanks to a special thread inside the tool. When pressed, it cleans the surface of the butt.

After using SNR One-Click Cleaner, the surface was cleaned of microscopic dust particles. The process did not require any special skills or effort. Everything is extremely simple, clear and effective.

So. Timely cleaning of optical components is vital for networks in order to maintain normal network equipment operability and good fiber throughput. Therefore, in no case can one neglect preventive measures, let alone save, by using ineffective means for cleaning.

Source: https://habr.com/ru/post/400919/

All Articles