The use of Agile in 3D printing. Russian experience

I thought for a long time what could be of interest to a respected community on the subject of 3D printing and digital production. Nobody is interested in writing about the next pseudo-breakthrough. I myself have been engaged in this field for 5 years and know the objective reality, both in the world and in Russia.

Therefore, I decided that I would share our rich experience and tell you how, in practice, you can commercially use technology that smoothly brings us to a robotic future and deprives everyone of work (joke).

As we all know, Russia has its own special way and therefore, even the use of 3D printing is special. Due to the almost complete absence of the automotive and aircraft industry, the demand for rapid prototyping remains only in the military sphere. However, not only rapid prototyping is one 3D printing.

Due to the fact that many things are being done at the last moment, the very essence of fast production (in 24 hours, for example) finds its application in unexpected areas. For example, 3D printing layouts for exhibitions . And from this place I will tell in more detail.

AR and VR technologies are developing at a rapid pace and soon, as promised, we are in for a real revolution. It is worth remembering even the ubiquitous Pokemon. But practice shows that so far and in the foreseeable future, an idea of a construction project, a prototype of equipment or a vehicle model allows mostly “trite” layouts.

A model is a model of an object on a reduced scale or in full size, which, as a rule, is deprived of the functionality of the represented object and intended to represent the object. Working on a variety of tasks in the field of 3D printing, we often encounter the need of customers for the rapid production of models and models for exhibitions, presentations and forums.

As often happens, the decision to participate in the exhibition is made at the last moment, when the production of a presentation model in a mockup workshop is impossible. And here comes the stage of 3D-printing, which is still not the most obvious way to quickly produce, for example, models of buildings, equipment and so on. Besides the fact that 3D printing speeds up the process by 2-3 times, a nice bonus is the cost savings.

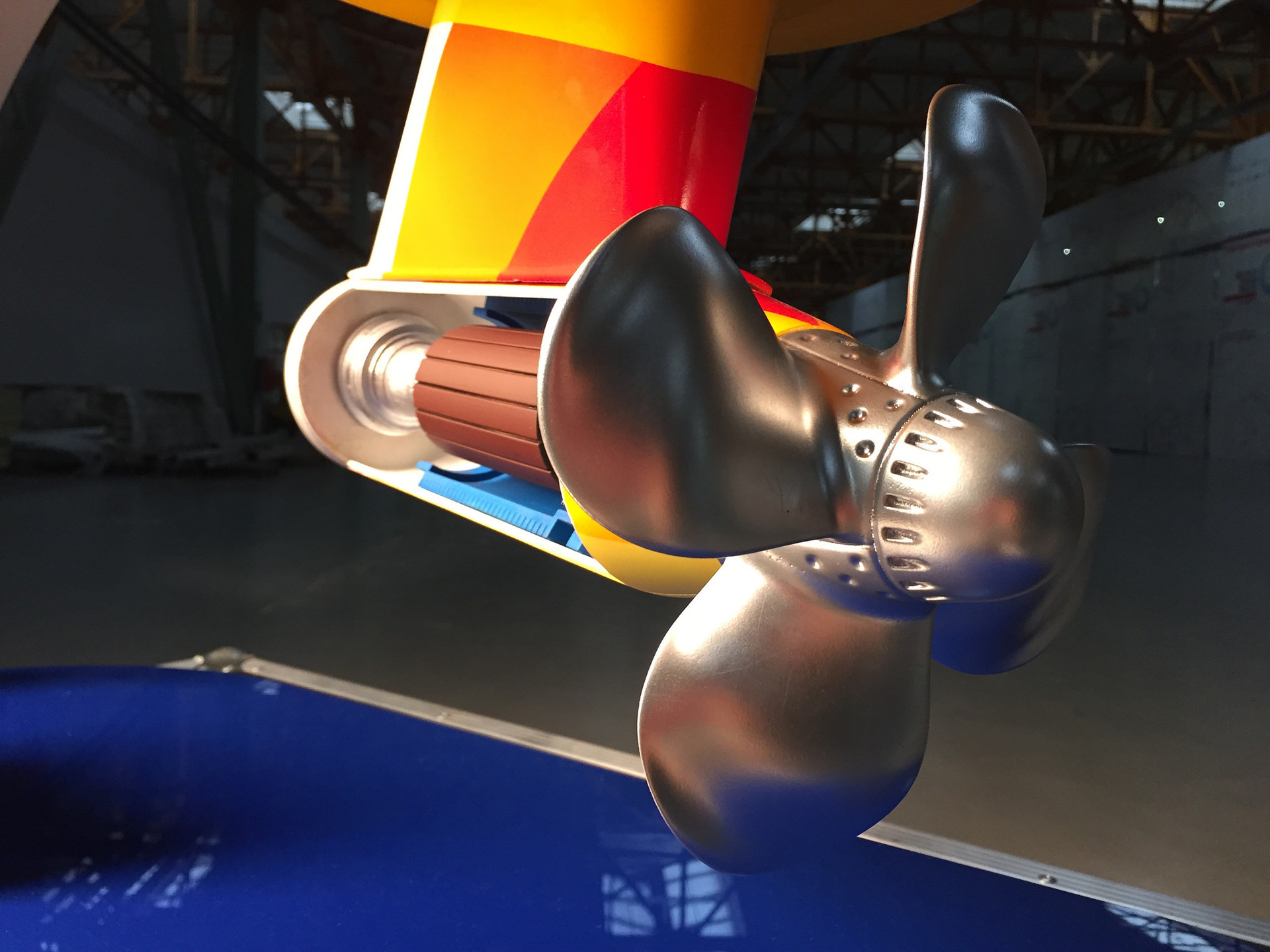

In September, the Eastern Economic Forum was held in Vladivostok with the participation of top officials of the APEC member states and top managers of big business. Just 2 months before the event, we began agreeing on 3D modeling and printing of three layouts: the factory’s production facilities, the ship’s diesel engine layout and the propeller steering column. We could not miss the opportunity to work with one of the largest companies in the world General Electric .

Modeling, printing, post-processing with coloring of all three layouts took only less than a month . During the project, we used 3D printing from all materials available to us: ABS and PLA plastic, polyamide, polymethacrylate, photopolymer resins, as well as milling of acrylic and polystyrene. In addition, each layout has its own unique features. The plant has a size of 1.5 by 1.5 meters, all the workshops are filled with production equipment, machine tools and finished products at different stages of assembly. The layout of the engine is fully printed on the printer from large assemblies, after which it is assembled and painted, and is 75 cm in length.

But the most difficult and fascinating at the same time was the task of designing and printing the WRC - a promising propeller-steering column for ice-class vessels. The uniqueness of the project is that the layout is automated by electric motors that ensure the rotation of the screw and keel, with the management of these functions in the application on the tablet via a wi-fi connection. In addition, a complex scheme of coloring in the corporate colors of one of the customers was applied.

And here Agile-approach, you ask?

Considering the requirements of the technical specifications in the design, we had the opportunity to quickly make changes to the model and thereby ensured the flexibility and speed of implementation of the changes. In fact, many additions were made right during the work. The speed of the production itself also helps to quickly perform tasks. For example, printing large parts up to 50 cm in length after approval and verification of a 3D model takes only 1-2 days. In addition, for the manufacture of each part, we used the most suitable material of all available.

Moreover, for the implementation of such large-scale projects in a short time, you need to be smart. And here, at an opportune moment, the experience of combining 3D printing technology with others, such as, for example, plastic milling, was useful to us.

In other words, the advantages of 3D printing, from the point of view of Agile, can be obtained only when production really takes place in overnight format and fast iterations. This is what allows additive technologies to find, and perhaps even replace, the traditional approaches of mock workshops.

What can be said in the end?

It’s stupid to look at 3D printing through the prism of the media, as a life-saving technology that replaces real production. This is already understood by many. Rapid prototyping technologies are only now actively finding their place in the production process and combining them with other technologies (milling, casting, laser cutting) helps to achieve truly qualitative results in a short time.

Immersion in this area by the software and production, gives an extensive picture of what really is to be expected after the end of the HYIP. I will talk about this in further publications on Giktatimes.

')

Source: https://habr.com/ru/post/400809/

All Articles